How do you keep plants alive outside their natural habitat?

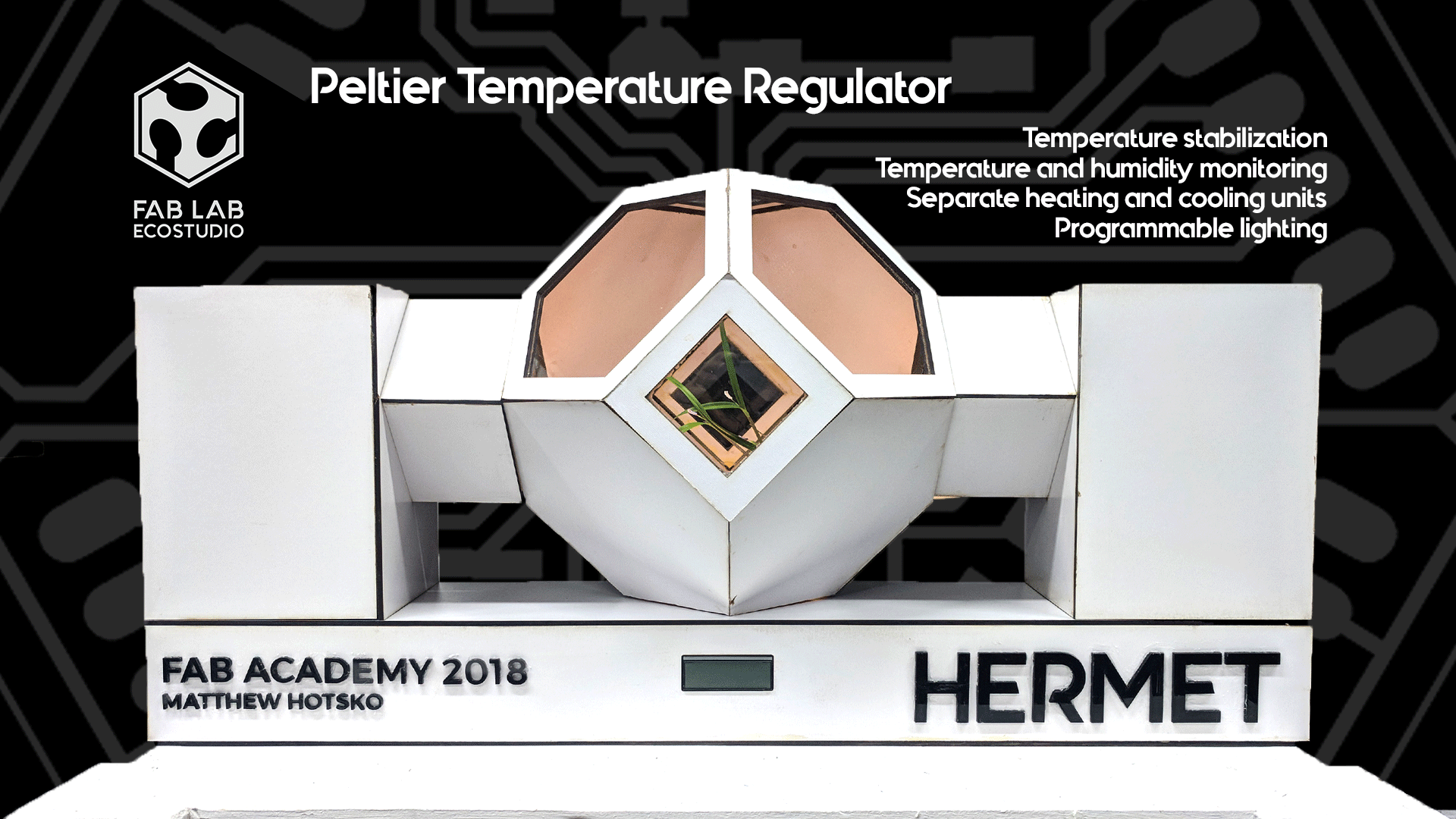

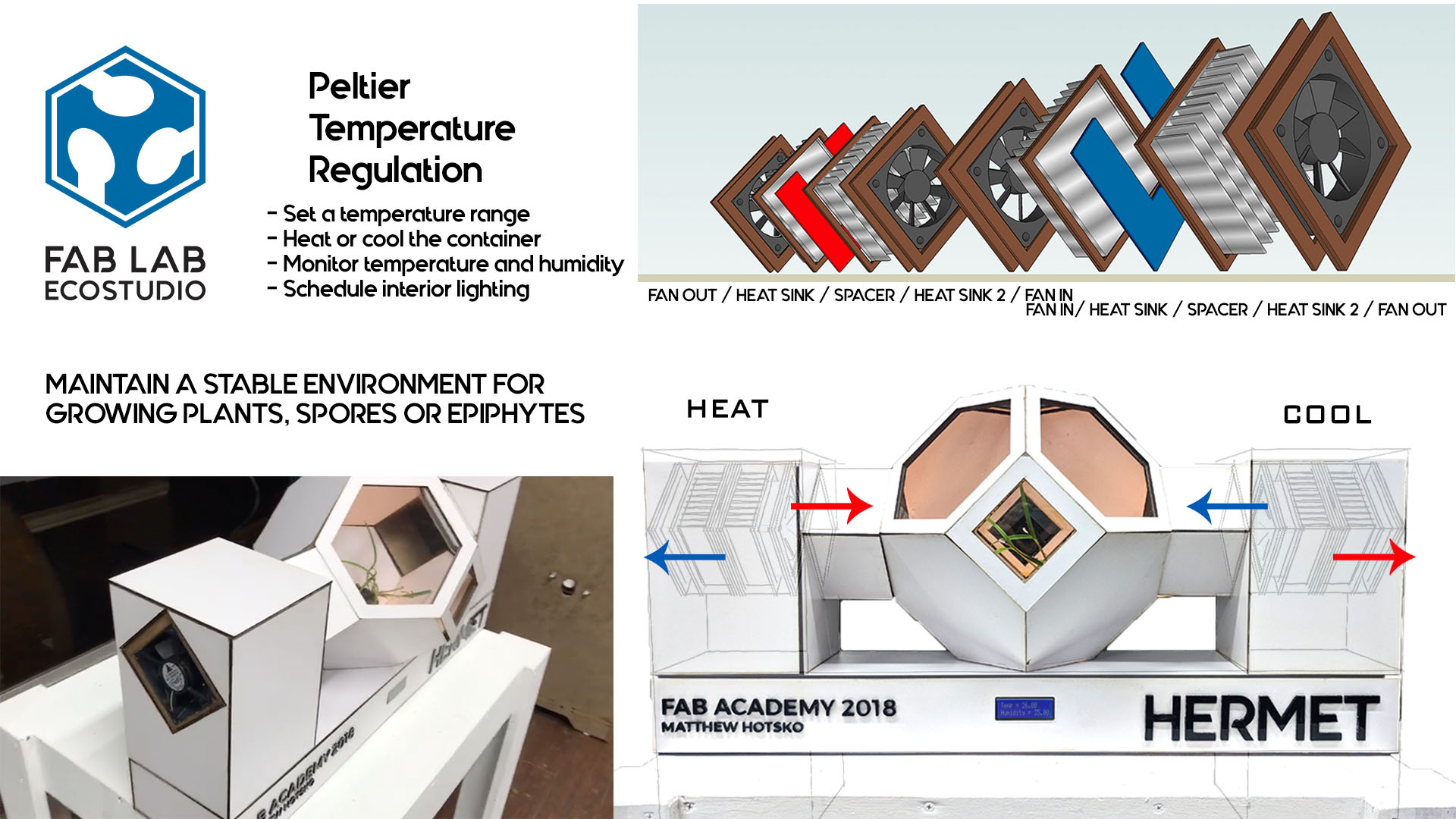

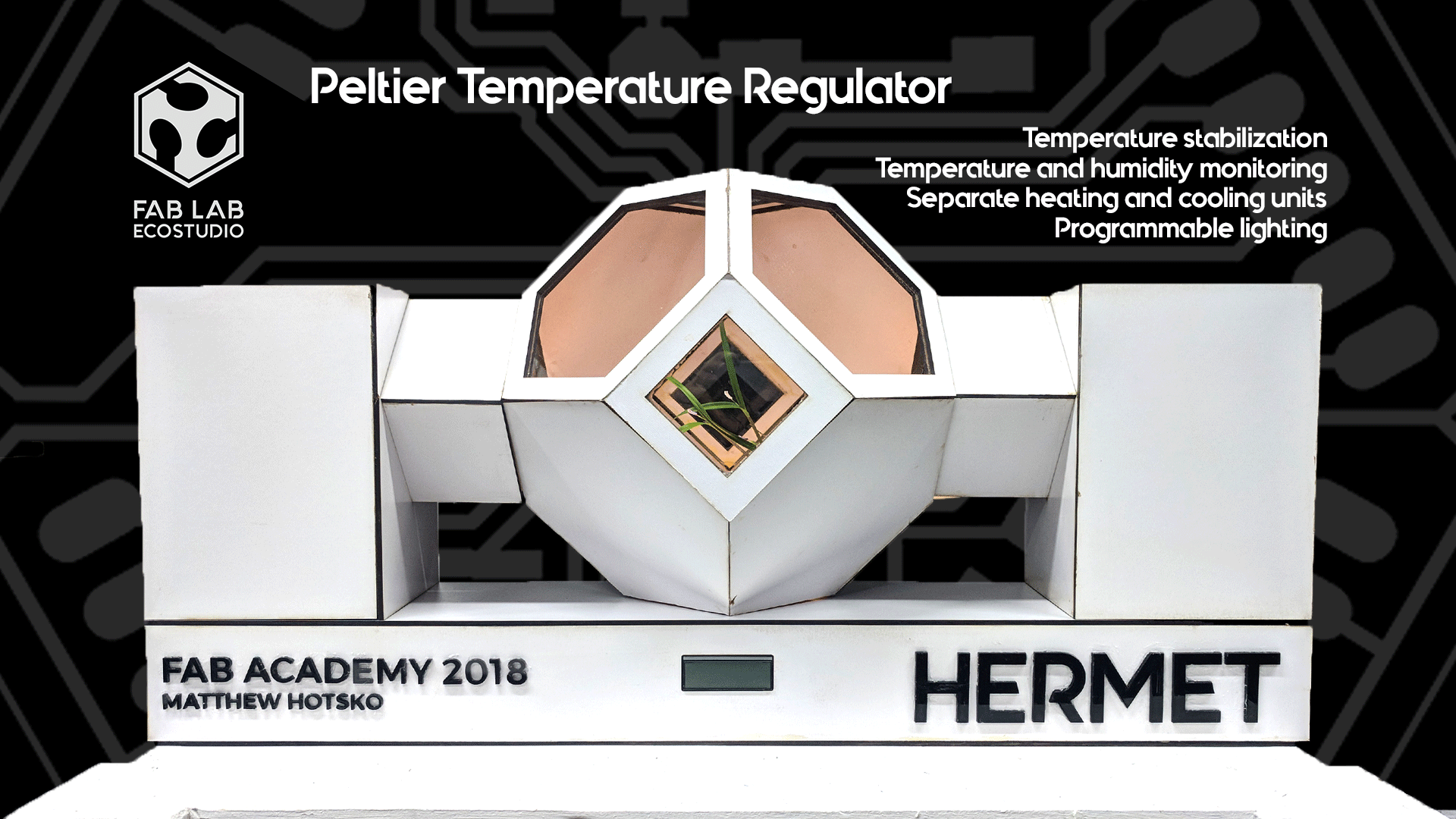

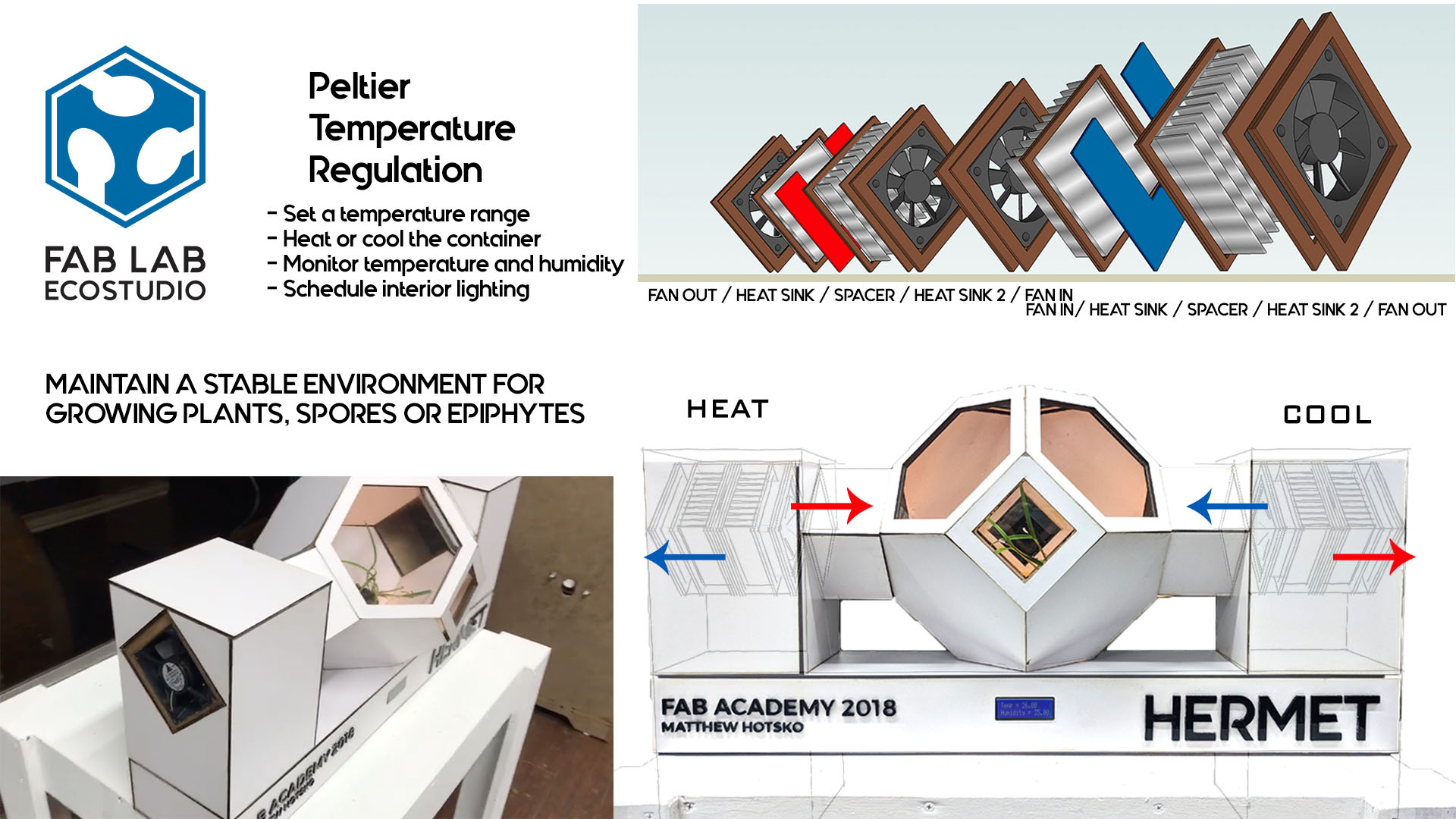

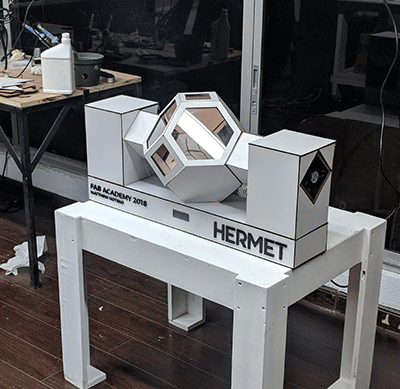

The HERMET works by creating a climate controlled chamber for something to be incubated. The towers on both sides connected to the chamber have identical units which perform the function of heating (left) or cooling (right).

The temperature units are activated via a microcontroller board in the base compartment, underneath the chamber. It receives an input from the DHT11 sensor from within the central chamber. If the temperature is too high, the board sends a message to switch a relay that powers on the temperature unit in the right tower.

The temperature unit remains on until the DHT11 sensor inside the chamber reaches the 5 degree stable temperature range). Likewise if the tower gets too cold, the temperature unit in the heating tower turns on until the temperature range is reached.

One of the reasons for building this is because I couldn't find a consistent solution for reproducing epiphytes (orchids, bromeliads, ferns). I needed a growing environment for germinating seeds at specific temperatures.

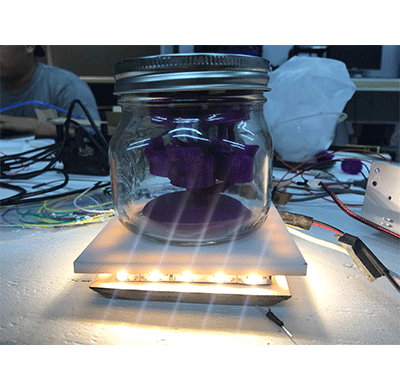

Using glass jars I could create a sterile environment, but I had no control over its temperature.

During the Fab Academy I also tested a prototype for increasing the surface area of growing medium. The waiting process takes almost a year for spores to turn to protocorms and I wanted to see if I could double yield. I designed a prototype for a flask insert that can be used with many common glass jars. It increases the surface area of liquid inside a jar by creating steps with flat basins that allow the liquid to pool at additional heights. Almost like a skyscraper it is an internal structure that uses the otherwise empty vertical space.

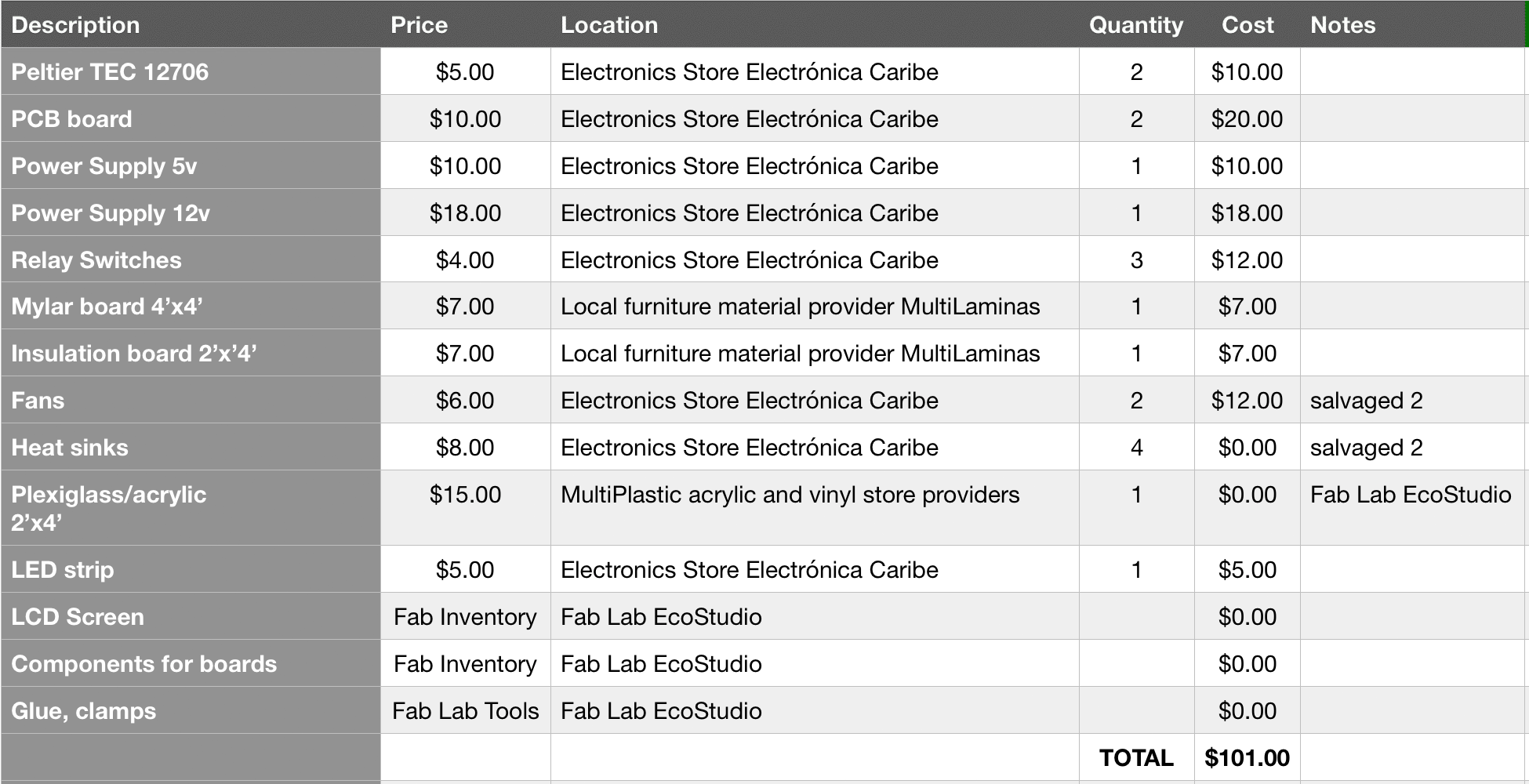

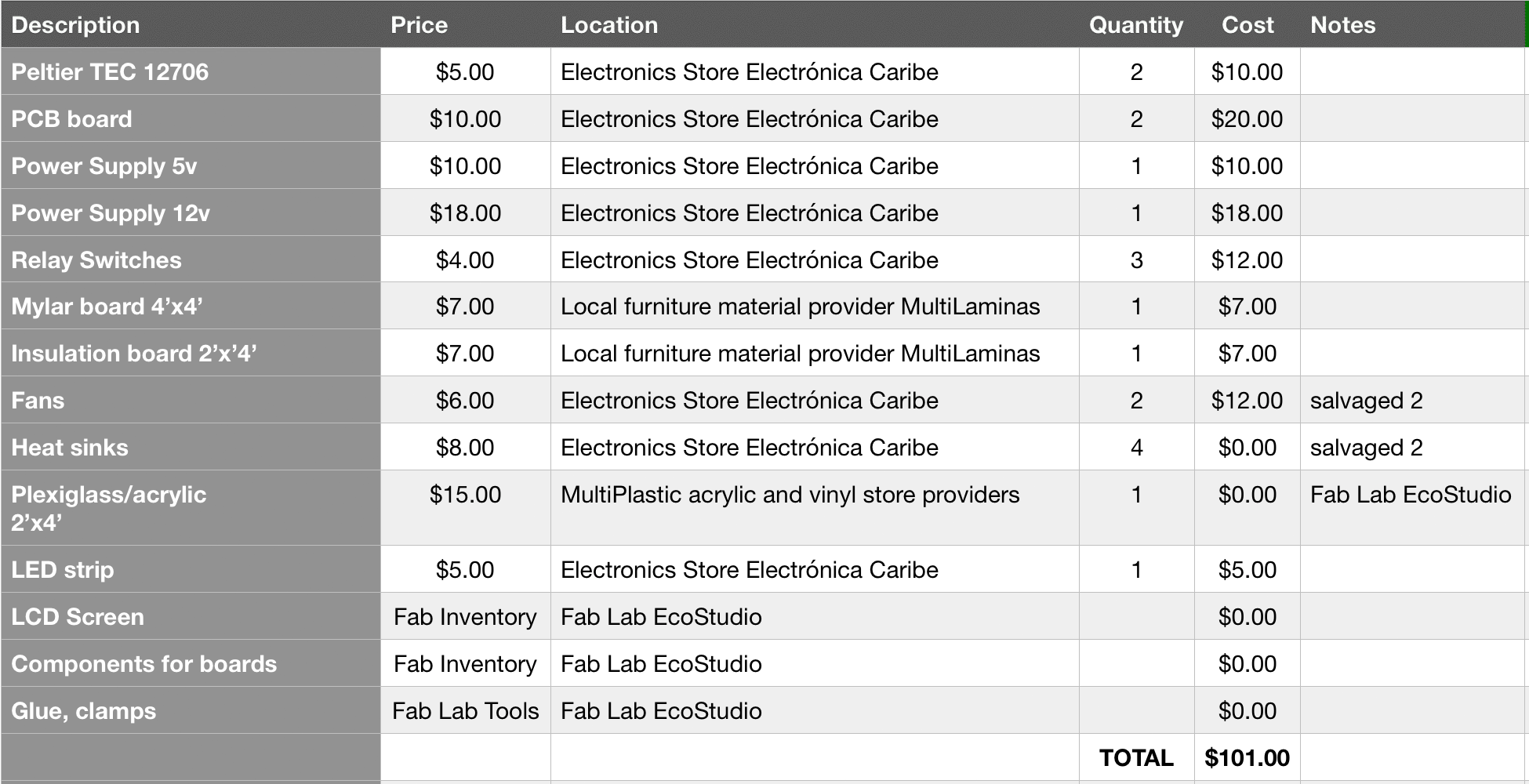

BILL OF MATERIALS

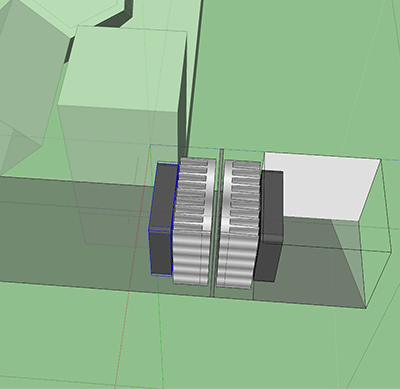

The HERMET works by creating a climate controlled chamber for something to be incubated. The towers on both sides connected to the chamber have identical units which perform the function of heating (left) or cooling (right).

The temperature units are activated via a microcontroller board in the base compartment, underneath the chamber. It receives an input from the DHT11 sensor from within the central chamber. If the temperature is too high, the board sends a message to switch a relay that powers on the temperature unit in the right tower.

The temperature unit remains on until the DHT11 sensor inside the chamber reaches the 5 degree stable temperature range). Likewise if the tower gets too cold, the temperature unit in the heating tower turns on until the temperature range is reached.

One of the reasons for building this is because I couldn't find a consistent solution for reproducing epiphytes (orchids, bromeliads, ferns). I needed a growing environment for germinating seeds at specific temperatures.

Using glass jars I could create a sterile environment, but I had no control over its temperature.

During the Fab Academy I also tested a prototype for increasing the surface area of growing medium. The waiting process takes almost a year for spores to turn to protocorms and I wanted to see if I could double yield. I designed a prototype for a flask insert that can be used with many common glass jars. It increases the surface area of liquid inside a jar by creating steps with flat basins that allow the liquid to pool at additional heights. Almost like a skyscraper it is an internal structure that uses the otherwise empty vertical space.

|

|

|

Slide // Video Click to download. |

PROCESSES:

CAD (Computer Aided Design) Case design

Computer-Controlled Cutting Case manufacturing

Electronics Production PCB manufacturing

3d Printing Flask Insert

Electronics Design Modified Fabduino

Computer-Controlled Cutting Case manufacturing

Electronics Production PCB manufacturing

3d Printing Flask Insert

Electronics Design Modified Fabduino

Embedded Programming Microcontroller programming

Input Devices DHT Temp & Humidity sensor

Output Devices Relay controlled switches

Interface Programming Realtime monitoring

Input Devices DHT Temp & Humidity sensor

Output Devices Relay controlled switches

Interface Programming Realtime monitoring

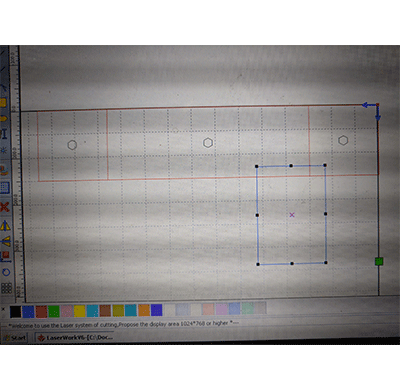

Laying out design of chamber and temperature unit housing. |

Preparing files to laser cut base. |

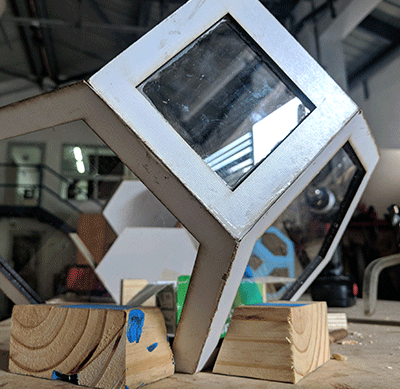

Fabrication of chamber using laser cutter. |

Sealing chamber. |

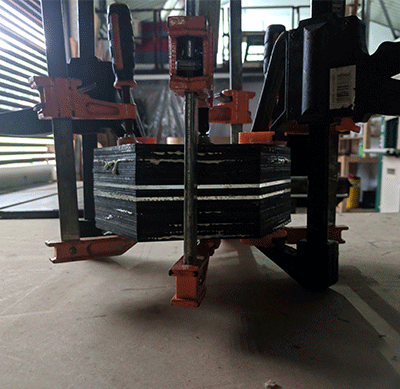

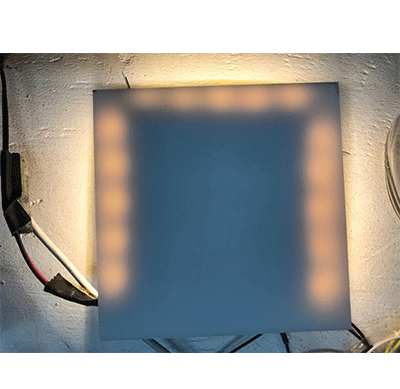

Preparing tiles for chamber. |

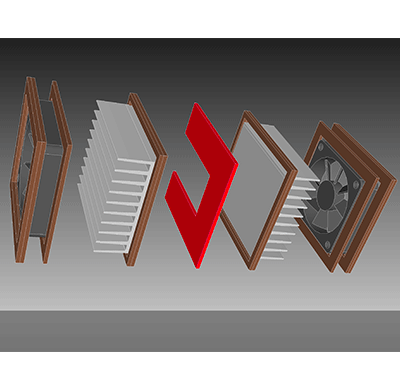

Sandwich of materials for insulation and visibility. |

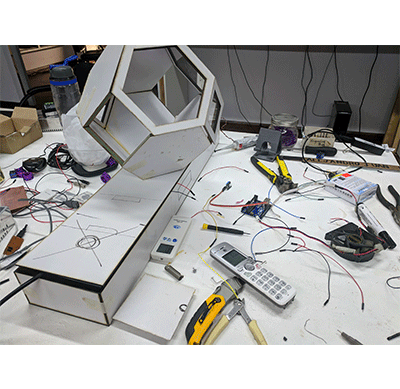

Case modification for inserting "guts". |

Temperature unit digital design. |

Temperature unit heating tower digital render. |

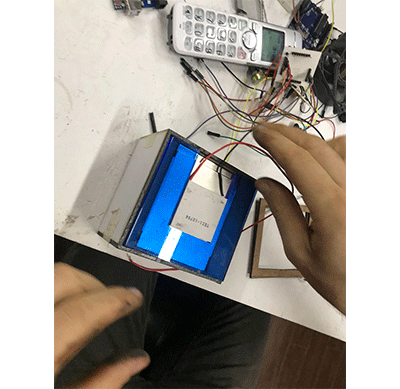

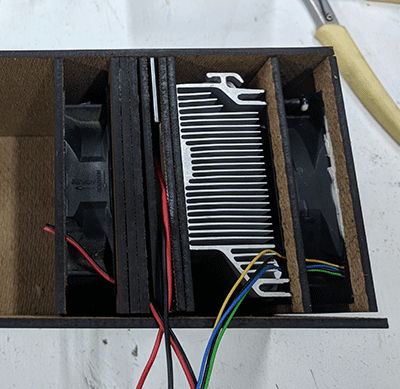

Temperature unit cooling tower peltier assembly. |

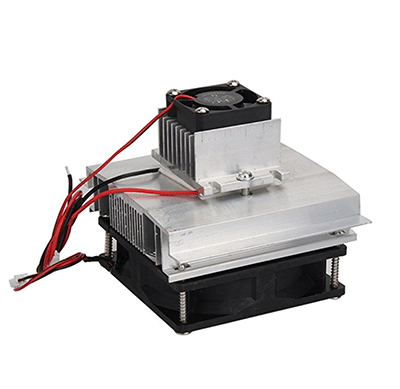

Research/example of a peltier cooler. |

Actual peltier temperature unit inside tower. |

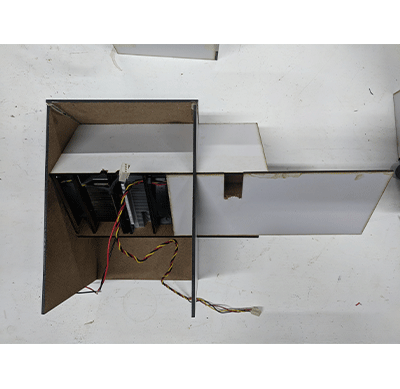

Cooling tower assembled and ready to connect. |

Cooling tower installed on base. |

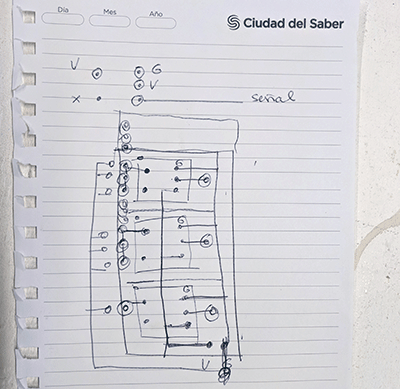

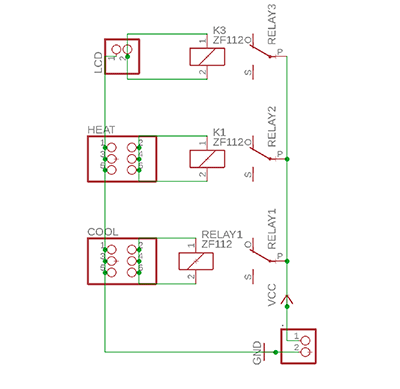

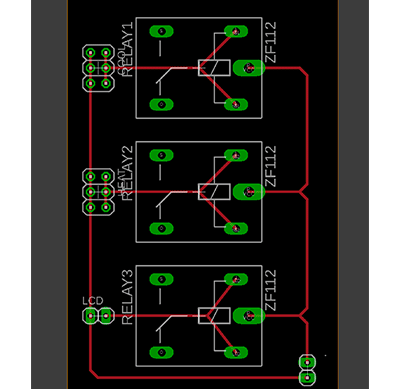

Relay design layout. |

Relay Schematic design. |

Relay board design. |

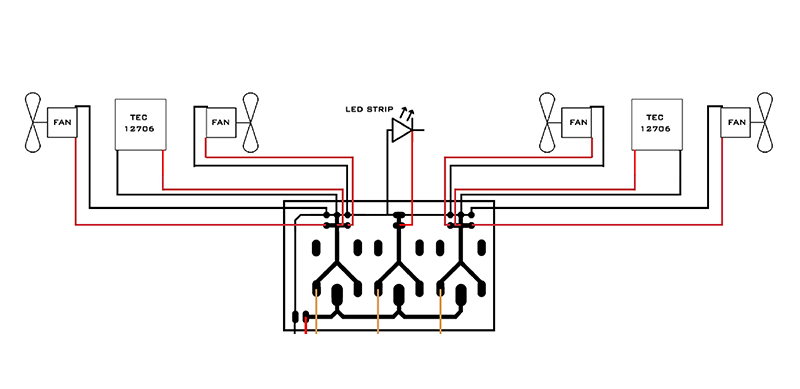

Relay board and peltier temperature unit board layout. |

Project Board

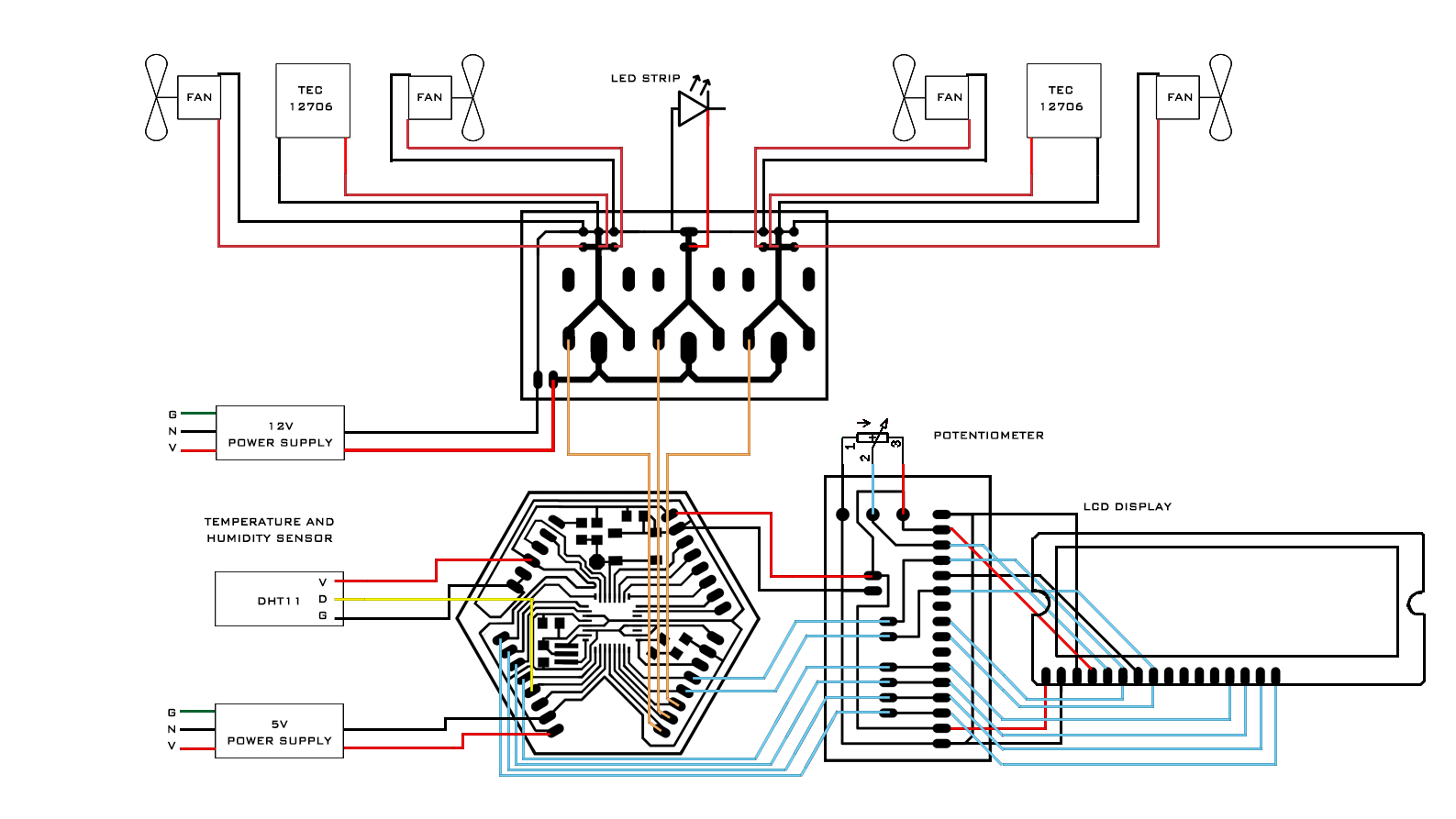

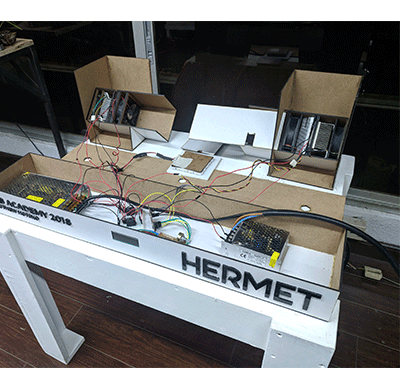

Full board layout for final project: fabduino connected to

- LCD display

- LED strip

- DHT11 temperature & humidity sensor

- relay board controlling heating and cooling towers

Flask insert sitting on base of chamber. |

Base chamber and inset LED strip. |

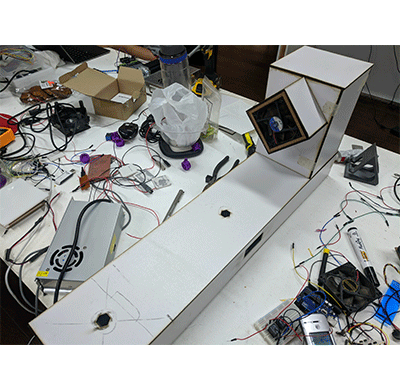

Base assembled with chamber. |

Final project assembled view with power supply and circuits connected. |

Final project assembled and seen as designed. |

PACKAGING AND LICENSING

Invention, Intellectual Property and Income HERMET is a project that was designed to help anyone grow almost anything. This version is open source and licensed under the MIT License (MIT) for anyone who wants to build it. This means it is free to use, copy, modify, merge, publish, distribute, sublicense and/or sell provided copyright notice and this licence shall be included in all copies or subsequent distributions.I would like to see the project replicated by other Fab Labs and perhaps even Bio Labs to grow plants, epiphytes and bromeliads that can be investigated for medical or culinary applications.

Files used:

SPECIAL THANKS

The project exceeded my expectations because the technology was completely new to me. I would not have been able to stumble upon it by myself so a huge thank you to Neil Gershenfeld for telling me about peltier devices.Thank you to my instructor Isaac Robles all the way in Peru and global evaluator Yadu from India, for your thank you for your guidance and input on my project and your help steering me in the right direction.

Also a heartfelt thank you to our Local Instructor on the ground here at the Lab, who went out of her way to help us on weekends with any assignments that we had trouble with. Thank you Montserrat Ciges for your commitment to the program and for sticking with us through the frustrations!

Last and certainly not least, I want to commend the Fab Foundation staff who organize the Academy and coordinate the work done not only during the program but throughout the year.

And thank you to the members and mentors of EcoStudio who were around to give input during the Academy.