Computer-Controlled Machining

The assigment page

The goal of this week was to model and cut with a big CNC milling machine something big!.

⇝ 3D modelling in Fusion ⇝ CAM ⇝ Milling

I wanted to make a desk/shelf for storing this mess:

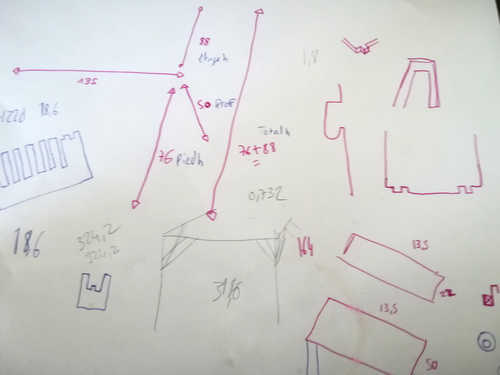

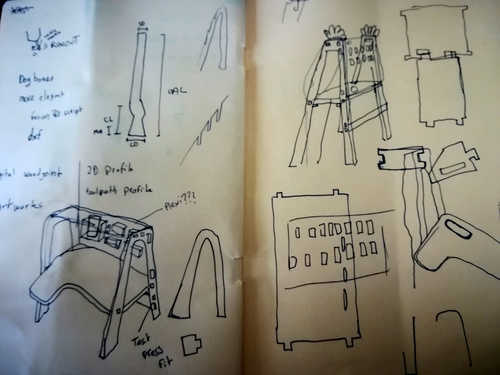

I started to make some measurements and sketches:

In order to have a clear representation, I've made a lasercutted model of my first Fusion sketch:

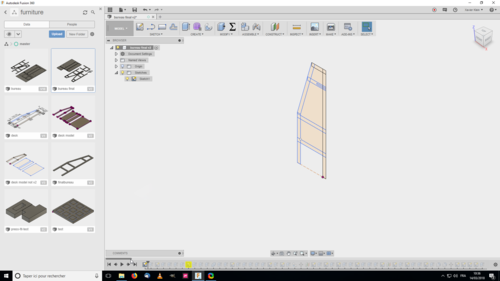

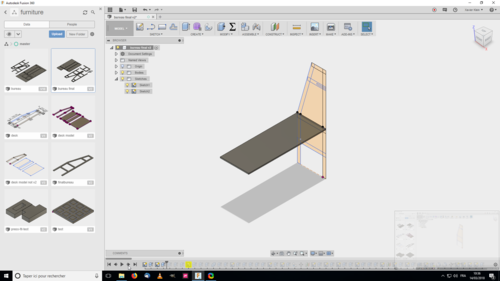

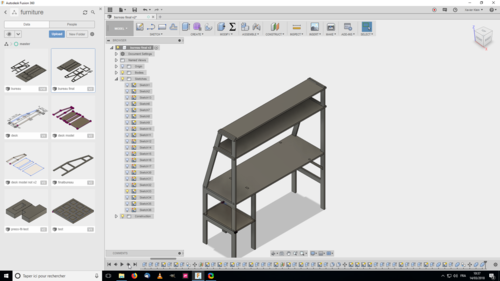

Serious bizness in Fusion360

I followed this Instructables tutorial to help me modelling my desk.

I start to be comfortable with Fusion but I struggle with constraints and parametric, there's always some problems when I change settings.

Here's how I made it on Fusion. I didn't have so much problems, the big one was I thought MDF thickness was 18mm but in real life it was 18.6mm. When I change settings, everything was wrong.

I spent a lot of time to clean the file and I think it still not fully well parametric.

Modeling

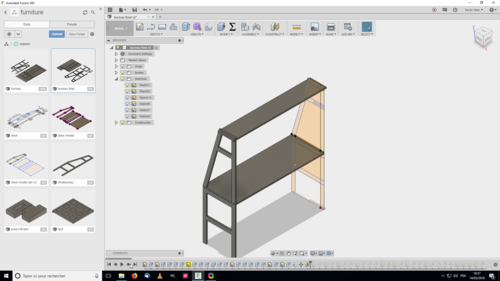

1. I started to design one of 2 faces. I use 2 sides extrud to make the 2 faces.

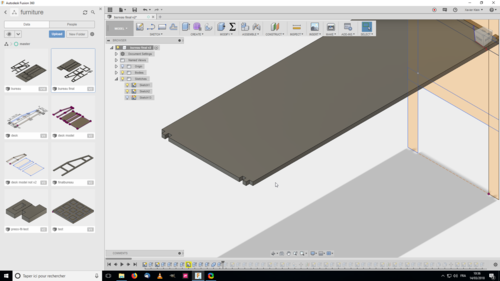

2. I designed the desk and the slots.

3. I designed the first shelf.

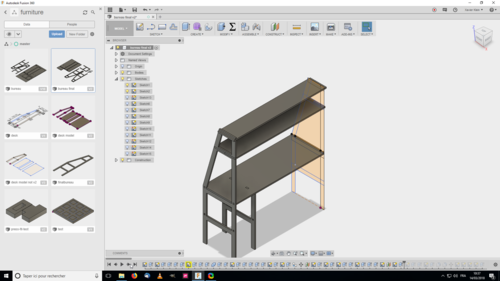

4. I designed the second shelf and the first part of the shelf under the desk.

5. I finished with the second part of the shelf under the desk.

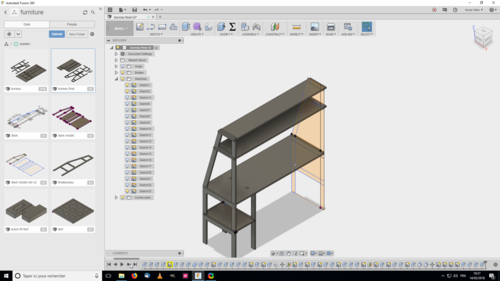

6. I realized that the desk will be not strong enough, so I put some reinforcements.

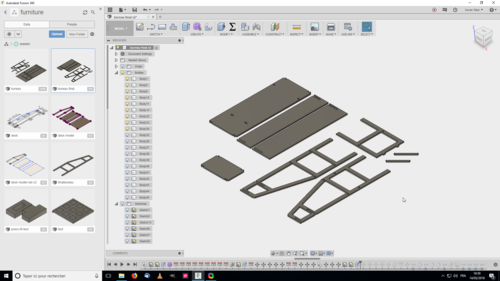

I used the dogbone addin to make dogbones. You have to set the diameter and select the edges.

After modelling in the "model" part of Fusion, I went to the CAM part to prepare my file. See you in the CAM page.