Molding and Casting

In this week for designing 3D mold here I used Blender 3d design software ; printed its on Machineble wax using Modella MDX-20 and Fabmodule software.Using rubber solution and Hydrostone made casting object.

3D Mold design :

Software tools: Inkscape,Blender 2.69 and Netfab

Mold Object: Indian rupee symbol

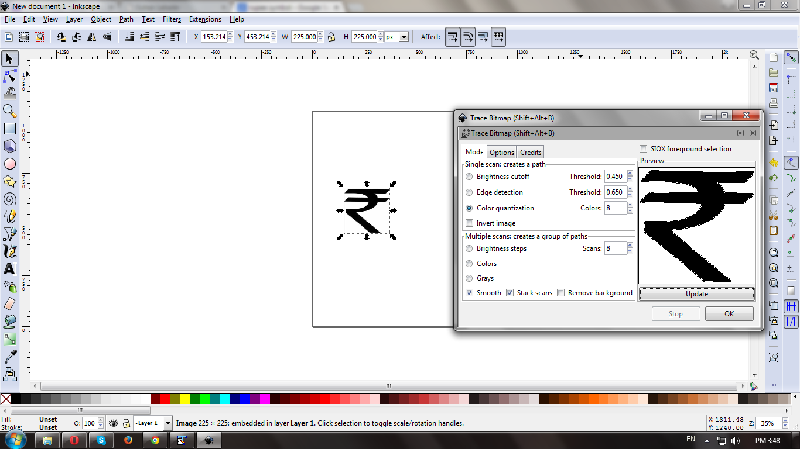

Step 1: Download And import .png file of Indian Rupee symbol inside Inkscape. Set dimensions ;as for 3D printing its needs to trace all nodes of an object. For this go inside'path' window; select 'Trace bitmap'; following window will pop-up set colour quantisation and export as .svg file .

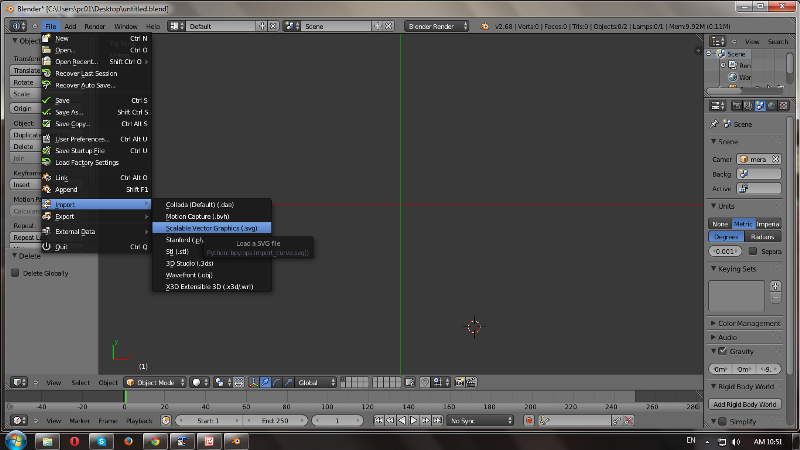

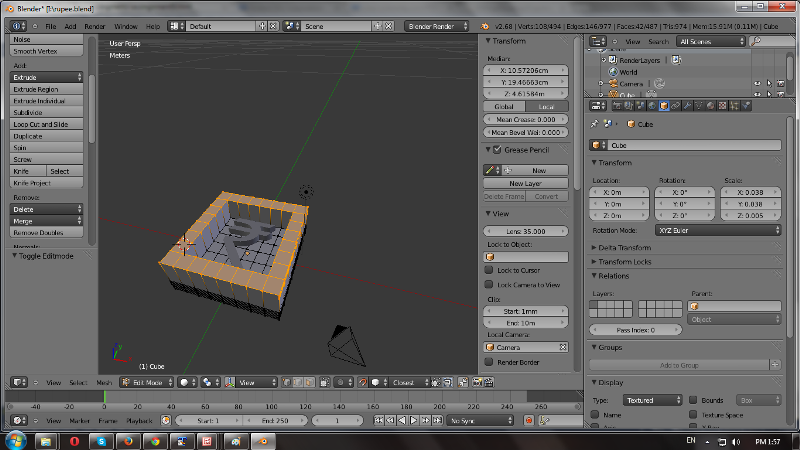

Step 2: To make this Rupee symbol 3d printable; imported this .svg file inside Blender 3D design software. Blender is rich with toolset and open source. Followed video tutorial of blender for this Mold design.

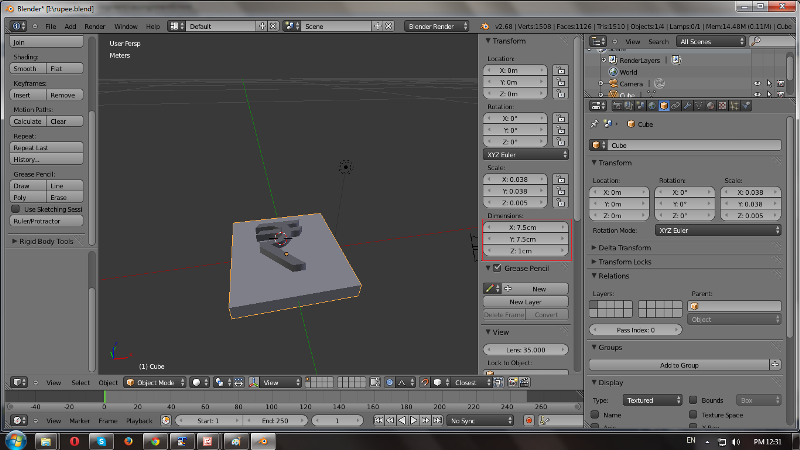

Step 3: Inside blender Import-->Scalable vector graphics(.svg)file from destination as shown below.

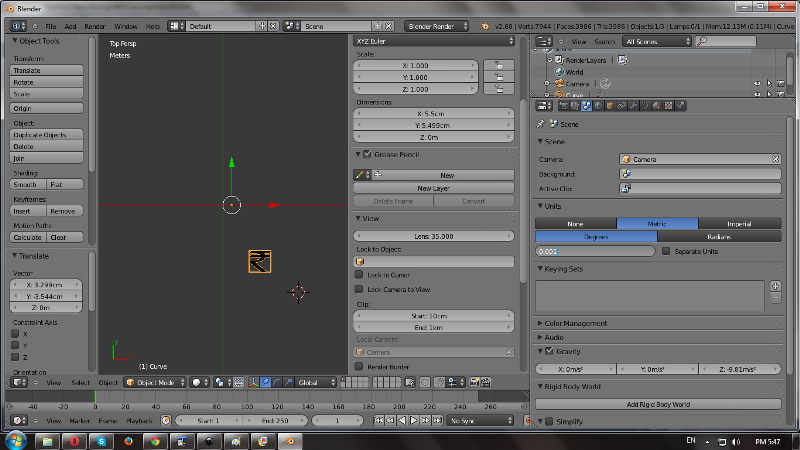

Step 4: Now go inside View--> select top view ; Here select first scale for design to make it 3D printable( selection of scale is more important as I get stucked here ;Amitraj took me up!! During export; design dimensions gets multiplied with scale and design becomes unexpected) To select scale; at right hand side of window go inside Scene-->Metric-->Scale-->here scale is 0.001m (by default its in meter).

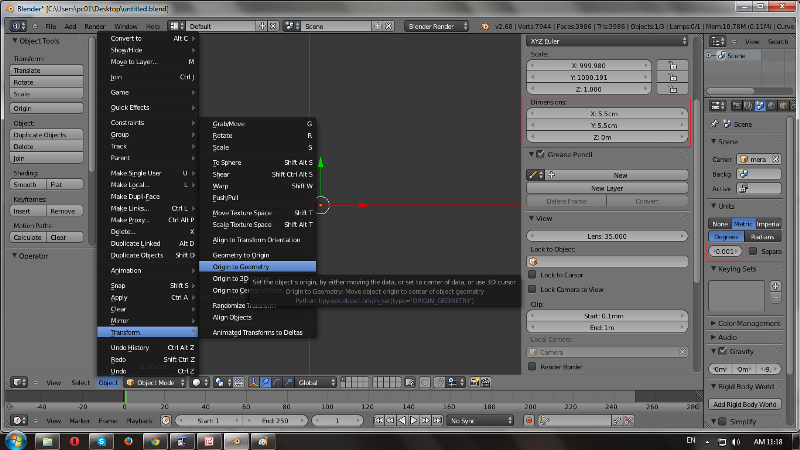

Step 5: Check dimensions of an object;set it as per scale. For rupee sybmbol I set it 55mm X 55mm .Take object at center with Object --> Transform--> origin to geometry; and keeping location co-ordinates all '0'.

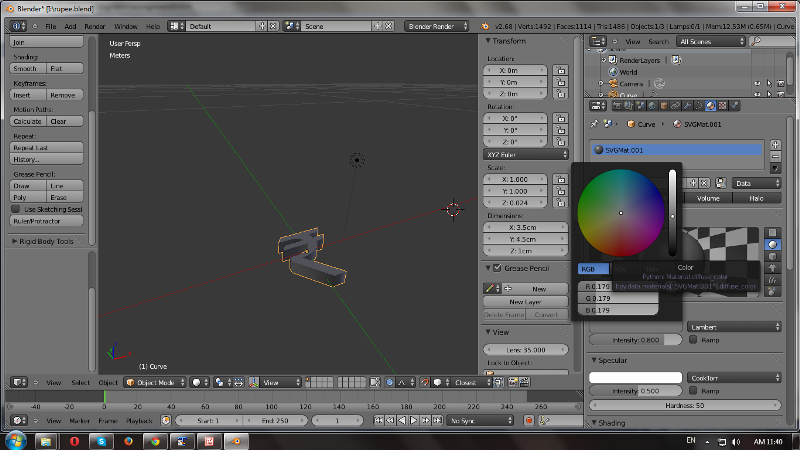

Step 6: 2D rupee symbol extruded 10mm with Z axis ; for extrude select object and go inside Curve-->Geometry--> Extrude(here object extruded with 10mm).Change object color under SVGMat --> Diffuse and slide cursor.

Step 7: To convert this symbol in Mold its need to cover with box outside. Go inside Add--> select Cube -->Set dimensions as 75mm x 75mm x 10mm. Now make origin to geometry for this object and set location axes at '0'.

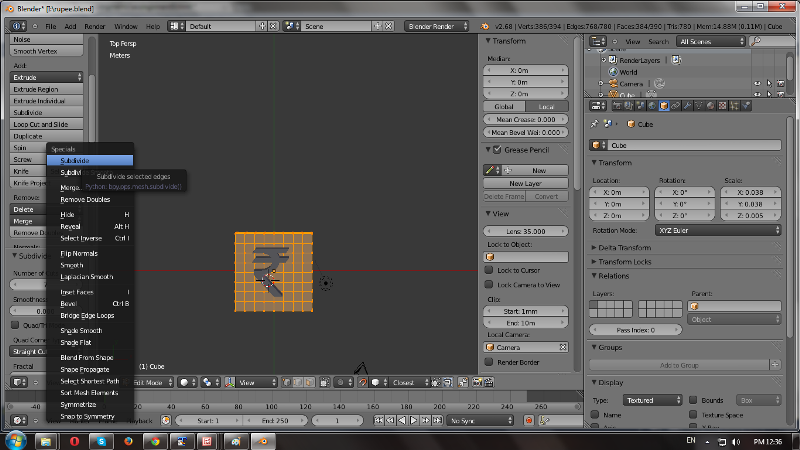

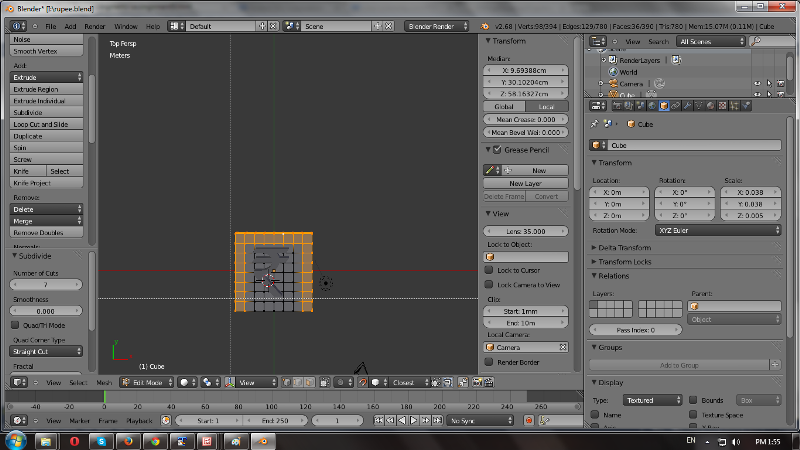

Step 8: To keep borders for an mold object;have to extrude cube sides with width 10mm and hight 10mm distance. For this Go inside Top view--> select Edit mode--> Press 'W' for subdivide a base--> Make number of cuts '7'(as total width is 75mm).

Step 9:Select edges with pressing 'B' for border; select and extrude these under extrude region tag placed at left side of window along z axis 20mm.

Step 10: Now select Object mode ;here we require whole object in group so select both with shift key and apply ctrl+J for joining meshesh to each other. Select scale with ctrl +A--> scale as '1'and export image in .stl file format and save it.

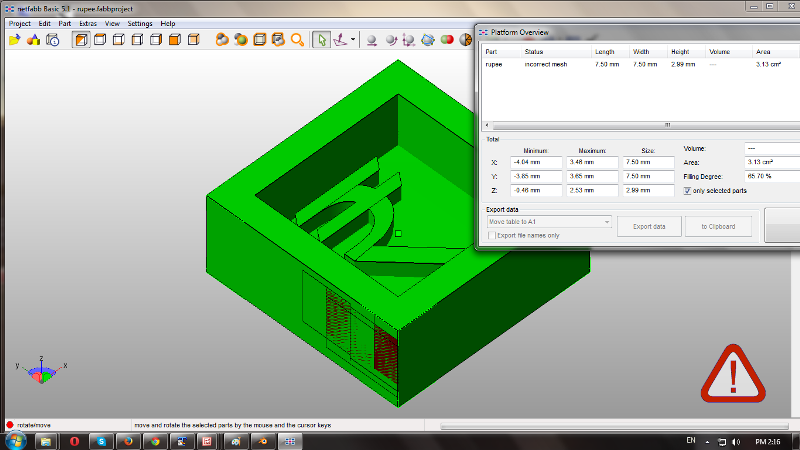

Step 11: Now to check design is 3D printaeble or not ; open it with Netfab. For this design it gives error message 'incorrect mesh'as there are Nonmanifold edges are present in design.

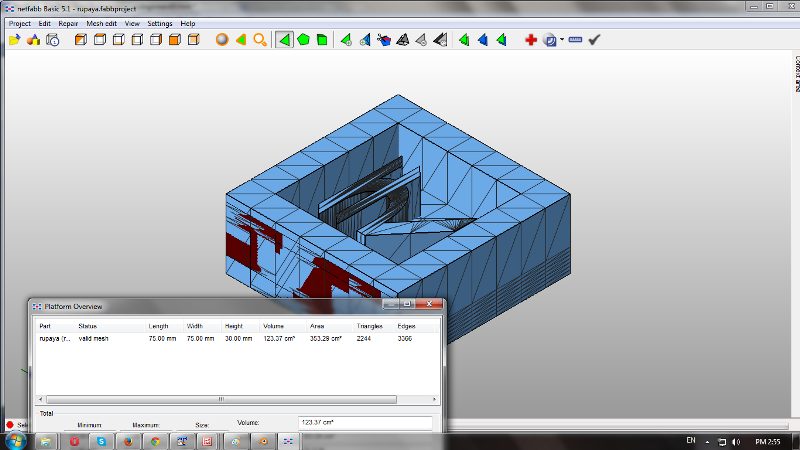

Step 12 : To correct and make design printable ;need to repair it. For this click on '+' sign-->select Autorepair -->Execute--> apply repair--> Remove old part.After this error massage goes and mesh becomes valid.

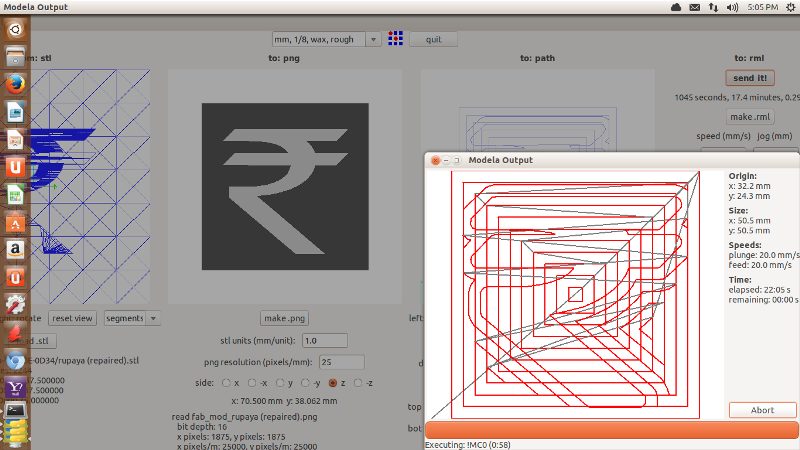

Step 13: Right click on design; select save as STL .Now open this file in Fabmodule ; select bit size 1/8mm, wax-rough make .stl to .png and then .rml and start milling.

Step 14: Final milled mold design..

Mold Making:

For mold making I used here rubber solution;following pictures showing steps for mold making.

|

|

|

|

|

|

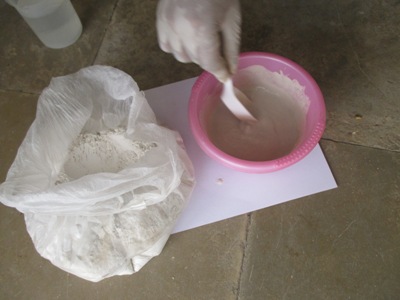

Casting:

Here I've used Hydrostone as a casting Material; go through following steps I did .

|

|

|

|

|

|

Download all files from here:

Mold design file

Completed mold design and casting.