Appearance

Week 14 - Molding and casting

Group Assignment

- Rreview the safety data sheets for each of your molding and casting materials,then make and compare test casts with each of them compare mold making processes

Group Work

Silicone Material Selected

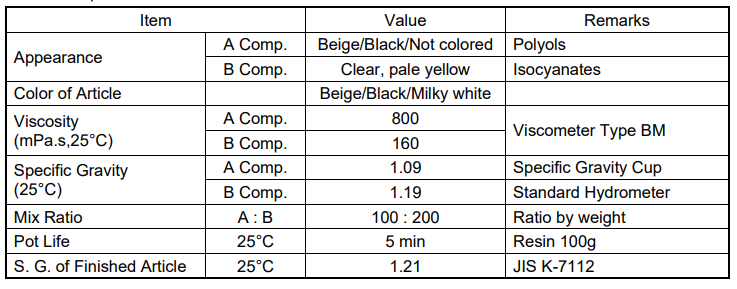

Hei-Cast 8150:Datasheet. It an ABS-grade urethane resin developed by H&K Ltd. for vacuum casting applications. This material offers a balance of physical properties, including high tensile strength (73 MPa), flexural strength (78 MPa), and a Shore D hardness of 84. Its superior dimensional stability and excellent curing characteristics make it suitable for producing prototypes and small-lot production parts that require mechanical properties akin to injection-molded ABS components. With a heat deflection temperature of 100 °C and a low shrinkage rate of 0.3%, Hei-Cast 8150 ensures precision and durability in cast parts. The resin is available in beige, black, and milky white, and is supplied as a two-component system with a mixing ratio of 100:200 (A:B by weight). Its pot life is approximately 5 minutes at 25 °C, and it can be demolded after 45–60 minutes when cured at a mold temperature above 60 °C. These properties make Hei-Cast 8150 an ideal choice for applications requiring high-quality, durable prototypes and functional parts. .

Epoxy Material Selected

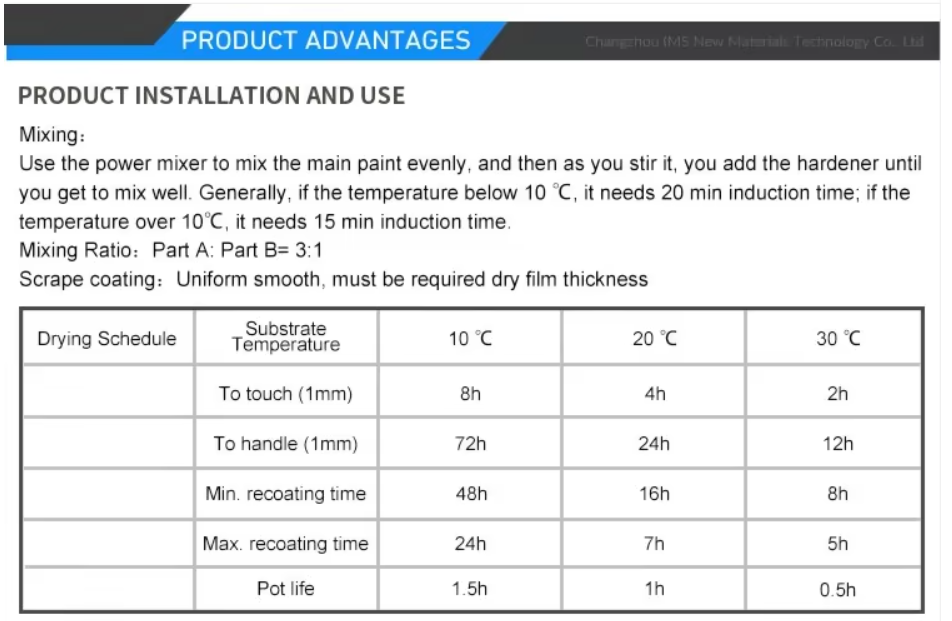

JIANBANG H80-5:Datasheet.From data sheet it can be seen that : the Mixing Ratio is 3:1 / the Pot Life(Set Time) is 20 mins/ the Curing Time is 24-48 hours.

Hazards & safety precautions with Epoxy

Epoxy Resin Hazards

- Skin and Eye Irritation: Direct contact with uncured epoxy resin can cause irritation to the skin and eyes.

- Respiratory Issues: Inhalation of fumes from uncured epoxy resin can lead to respiratory problems, including irritation of the nose, throat, and lungs.

- Chemical Burns: Uncured epoxy resin can cause chemical burns if it comes into contact with the skin.

- Long-term Health Effects: Prolonged exposure to epoxy resin can lead to liver and kidney damage, as well as respiratory issues.

- Fire Hazard: Epoxy resin can be flammable, especially in its liquid form.

Safety Measures

- Proper Ventilation: Always work in a well-ventilated area to disperse harmful fumes. Use an exhaust fan or open windows to ensure good airflow.

- Personal Protective Equipment (PPE): Wear gloves, safety goggles, and a respirator mask to protect your skin, eyes, and lungs from exposure.

- Avoid Direct Contact: Handle epoxy resin with care to avoid spills and splashes. If contact occurs, wash the affected area immediately with soap and water.

- Safe Storage: Store epoxy resin in a cool, dry place away from direct sunlight and heat sources. Keep it out of reach of children and pets.

- Proper Disposal: Dispose of epoxy resin waste responsibly. Follow local regulations for disposal of hazardous materials.

Mold making processes comparison

Comparison of Brick Wax Mold vs. AB Silicone Mold

🧱 Brick Wax Mold

Best Use: Ideal for master molds made with CNC milling or engraving

✅ Advantages:

- High Precision

- Excellent for CNC processing—surface finish is smooth enough to eliminate post-polishing.

- Time-Efficient

- Much faster than manual sculpting—ideal for rapid prototyping or one-off masters.

- Recyclable

- Waste wax can be melted and reused (3–5 times), minimizing material waste.

- Easy to Machine

- Low tool wear; suitable for both roughing and fine-detail carving.

- Self-Releasing

- No release agent required when casting from wax molds.

❌ Disadvantages:

- Heat Sensitivity

- Low melting point (~52–58 °C); not suitable for high-temperature casting.

- Fragile

- Brittle under mechanical stress; not durable for repeated use.

- Limited Lifespan

- Best for creating single-use or short-term molds.

🧪 AB Silicone Mold

Best Use: Ideal for replicating parts, batch casting, or working with complex shapes

✅ Advantages:

- Flexible and Durable

- Excellent for complex, undercut, or flexible designs—can be reused many times.

- High-Temperature Resistance

- Can withstand temperatures up to 200–250 °C, suitable for resin or low-melt metal casting.

- Captures Fine Detail

- Great surface fidelity, even for tiny textures and patterns.

- Versatile

- Compatible with a wide range of casting materials: resins, waxes, plasters, low-melt alloys, etc.

❌ Disadvantages:

- Longer Process Time

- Requires mixing (Part A + Part B), degassing (if needed), and curing time (can take hours).

- Not CNC Machinable

- Must be poured into a mold—not suitable for subtractive processes like milling.

- Higher Material Cost

- Generally more expensive than wax per unit volume and not recyclable.

🔄 Summary Table

| Feature | Brick Wax Mold | AB Silicone Mold |

|---|---|---|

| CNC Machinable | ✅ Yes | ❌ No |

| Precision | ✅ High | ✅ High |

| Reusability | ⚠️ 3–5 times | ✅ 10–50+ times |

| Heat Resistance | ❌ Low (~58 °C) | ✅ High (up to 250 °C) |

| Material Cost | ✅ Low | ❌ Higher |

| Detail Reproduction | ✅ Good (via CNC) | ✅ Excellent (via casting) |

| Time Efficiency | ✅ Fast (if CNC available) | ❌ Slower (due to curing) |

| Eco-Friendliness | ✅ Recyclable | ❌ Single-use waste |

Mold & Cast 2025

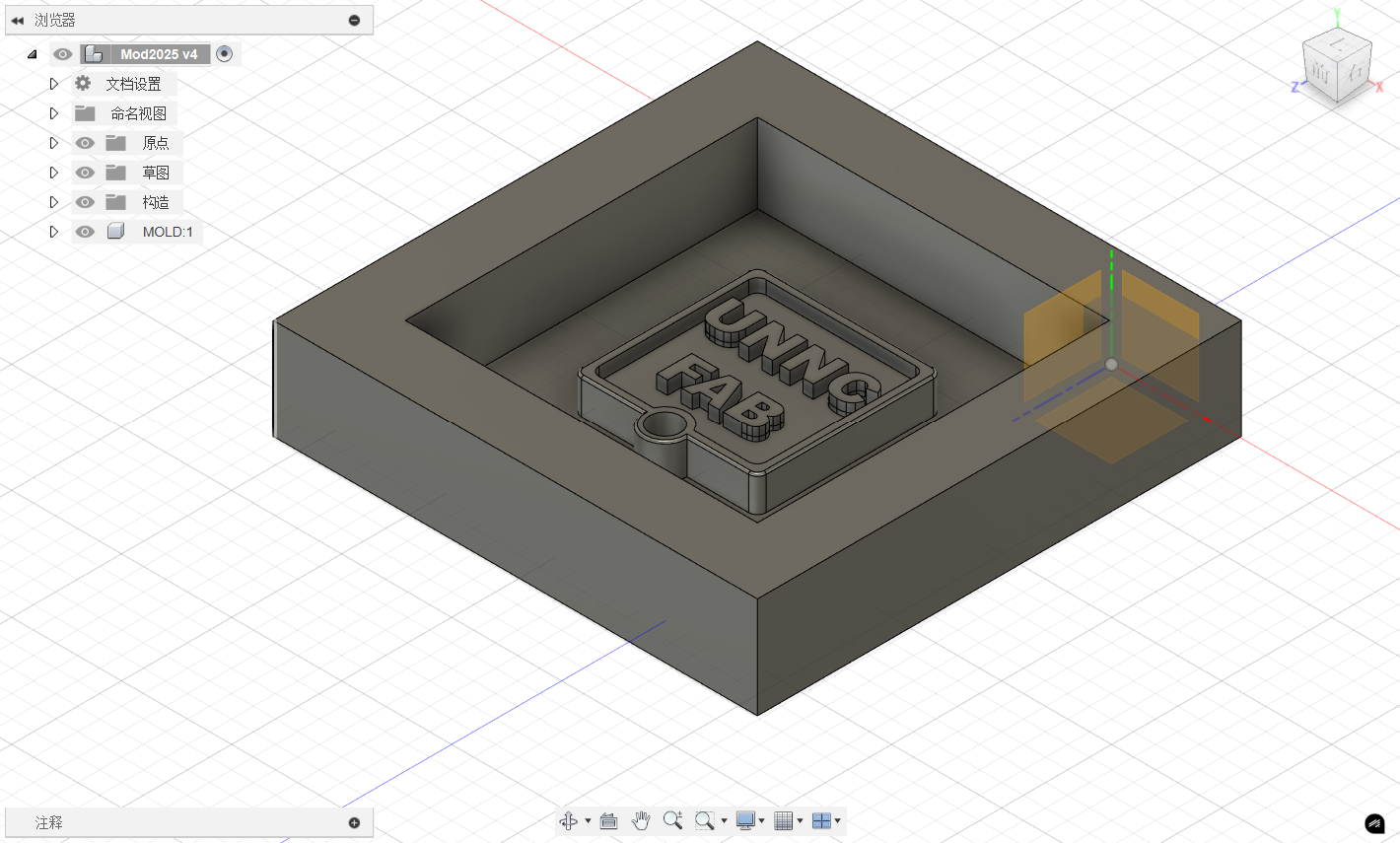

Design a mold with Fusion

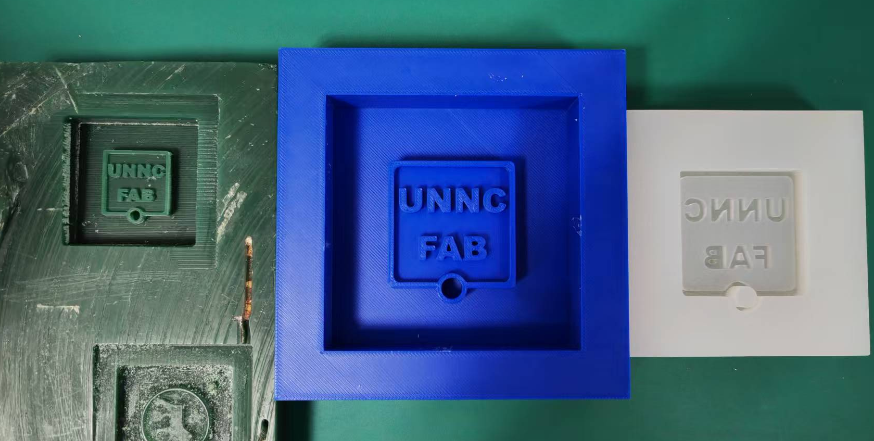

Design a key tag mold for our UNNC-FAB lab. The mold can be download at my repo with file name Mold 2025.

Manufacture the mold

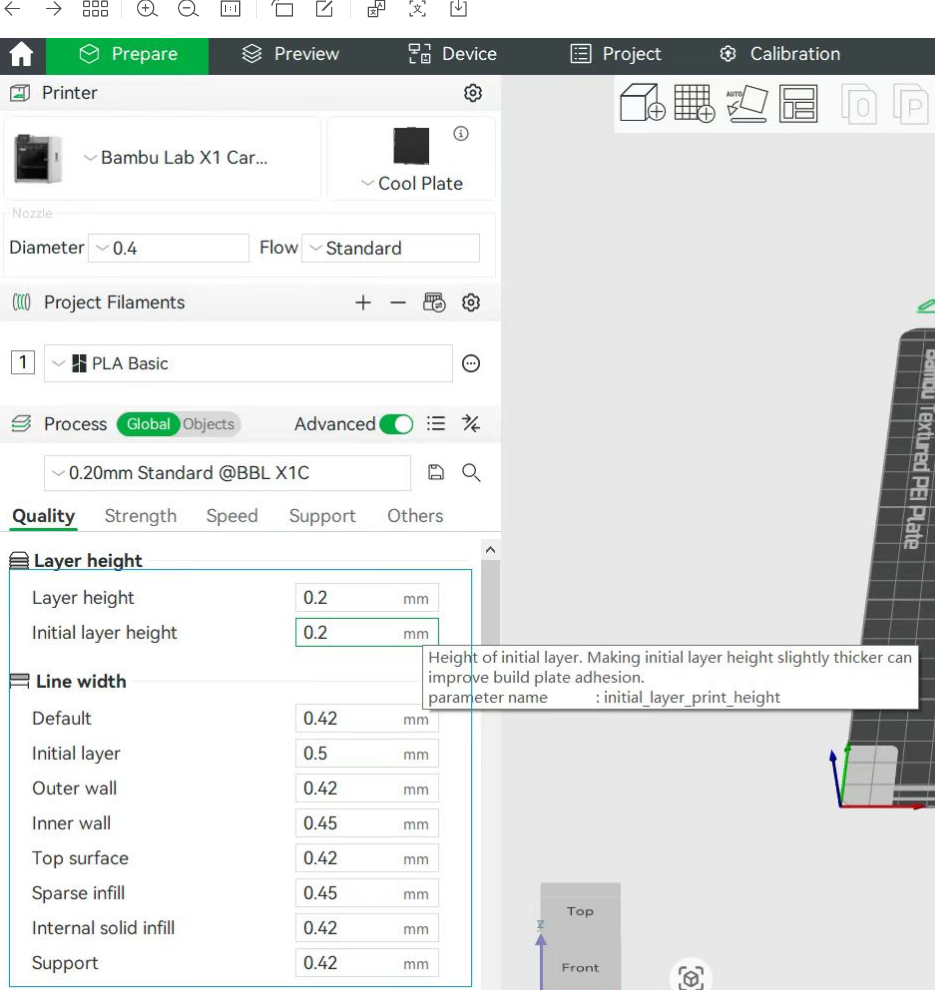

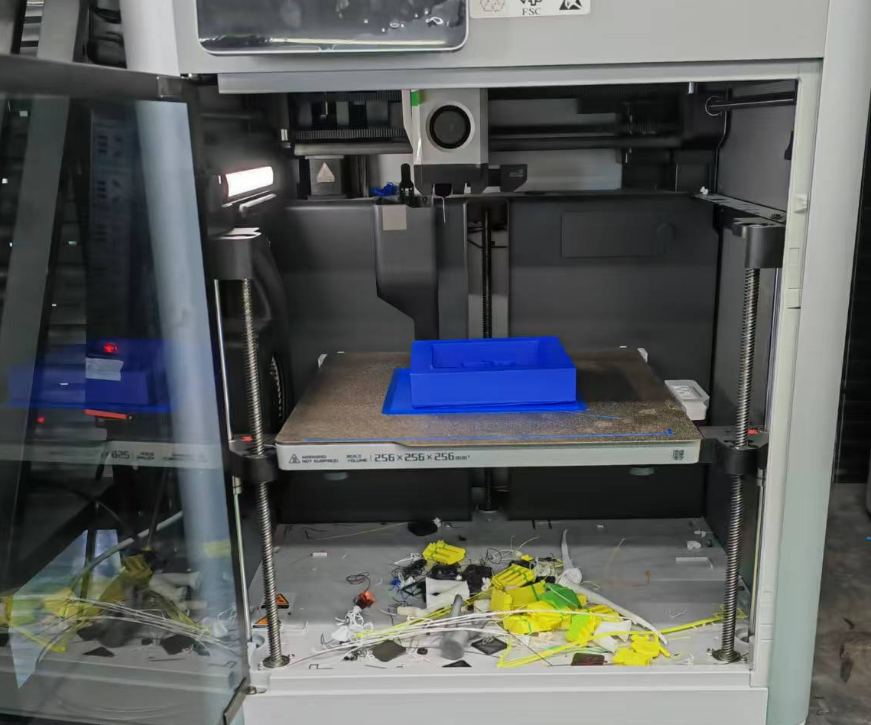

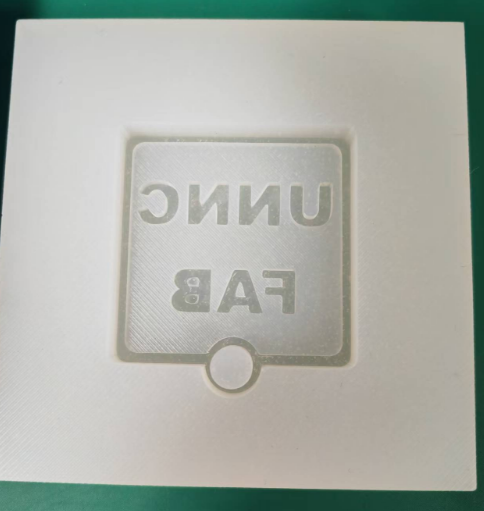

3D Printing PLA

Using the default settings for the printing process. The printer layer height is 0.2mm and default line width is 0.42mm.

Send to our new printer to print the mold.

The result is seen as below.

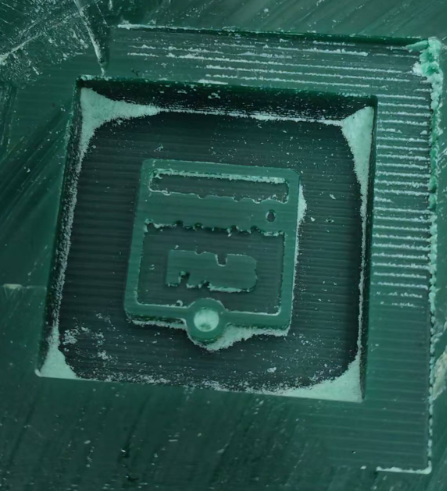

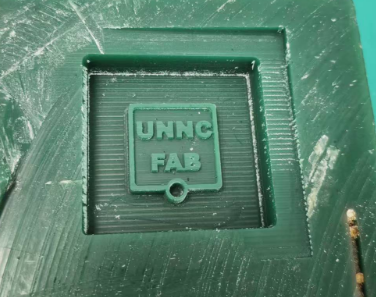

Roland CNC WAX

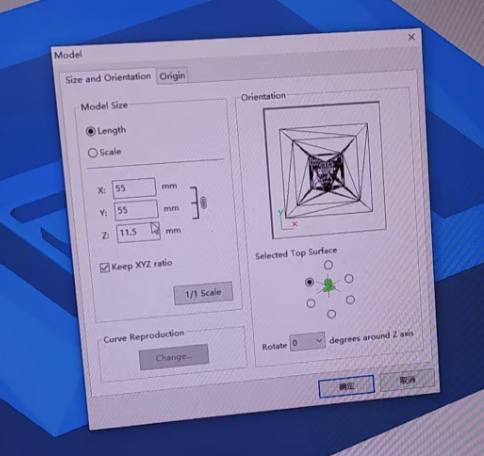

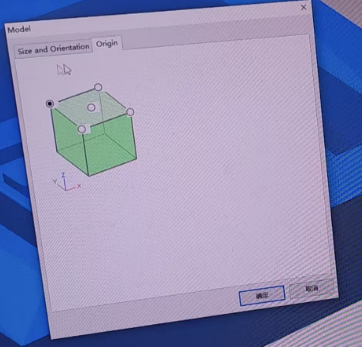

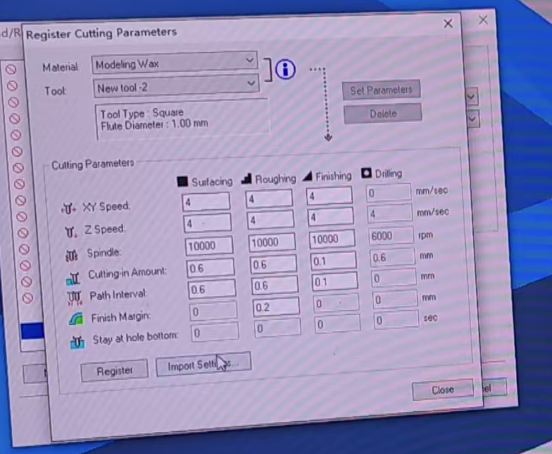

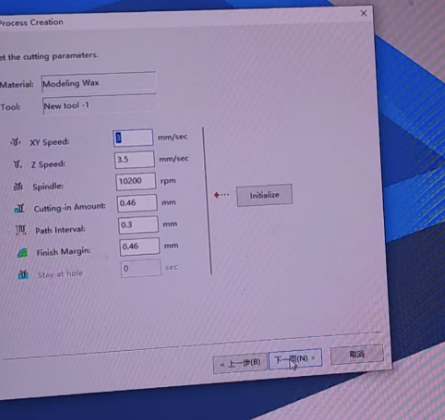

The basic CAM design setting process is documented as pictures below.

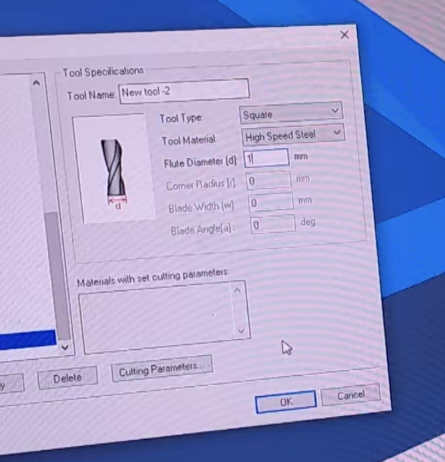

Add new tools.

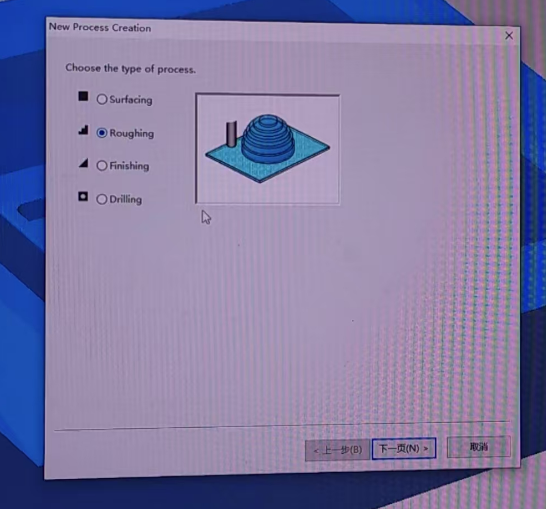

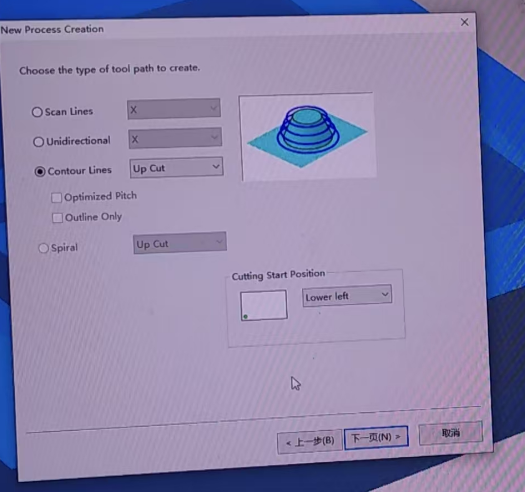

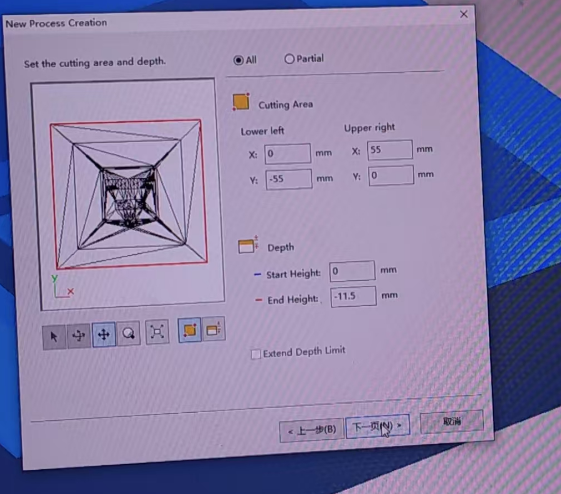

Edit new CAM process.

Using a 1mm cutter for a rough cutting first.

Using a 1mm cutter for a rough cutting first.

Then change to a 0.5mm cutter for fine finishing cutting for better surface quality.

Then change to a 0.5mm cutter for fine finishing cutting for better surface quality.

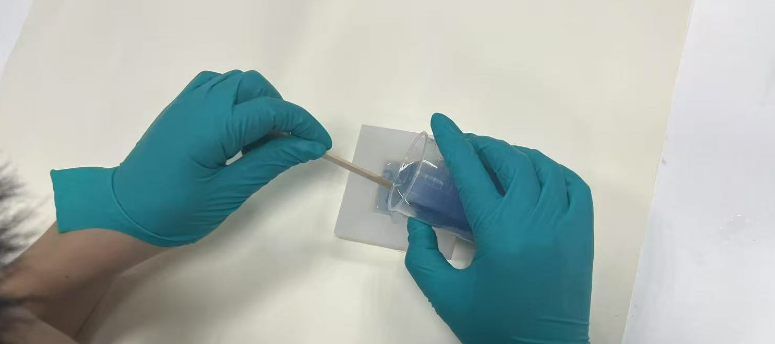

Cast with Silicone & Epoxy

Use the 3D printed mold to cast a silica mold. The proportion of the silicone gel and curing agent need to be accurate 100:3.

Silicone mold.

Silicone mold.

Then using epoxy resin for the casting. Stirring the mixed resin till there is no floccule, pour it into the silica mold then wait 48 hours for solidification.

Then using epoxy resin for the casting. Stirring the mixed resin till there is no floccule, pour it into the silica mold then wait 48 hours for solidification.

Blue dye is added to the clear resin to achieve the blue effect.

Blue dye is added to the clear resin to achieve the blue effect.

Mold result comparison

| Mold Type | Surface Finish Description |

|---|---|

| 🧱 Brick Wax Mold | ✅ Very smooth surface (CNC-machined) |

| 🧪 AB Silicone Mold | ✅ Excellent detail reproduction |

| 🖨️ 3D Printed PLA Mold | ⚠️ Visible layer lines due to FDM printing / Post-processing (sanding/polishing) recommended |