12 - Mechanical Design, Machine Design

This week, we'll work in teams to create a CNC. The team members are:

INTRODUCTION

A CNC (Computer Numerical Control) is a technology used in manufacturing that allows machine tools to be controlled by a computer. These machines can

perform tasks such as cutting, milling, drilling, and turning with high precision and repeatability.

The CNC uses software to convert designs into instructions that the machine follows to create exact parts.

G-codes are a set of instructions used in the programming of CNC (Computer Numerical Control) machines. These codes control the movement and operations

of the cutting tool, allowing the machine to perform machining tasks with precision.

In the context of CNC machines, G-codes are essential for defining how the tool moves and positions itself. For example:

- G00: Rapid movement.

- G01: Linear interpolation.

- G02/G03: Circular interpolation.

INDIVIDUAL CONTRIBUTION

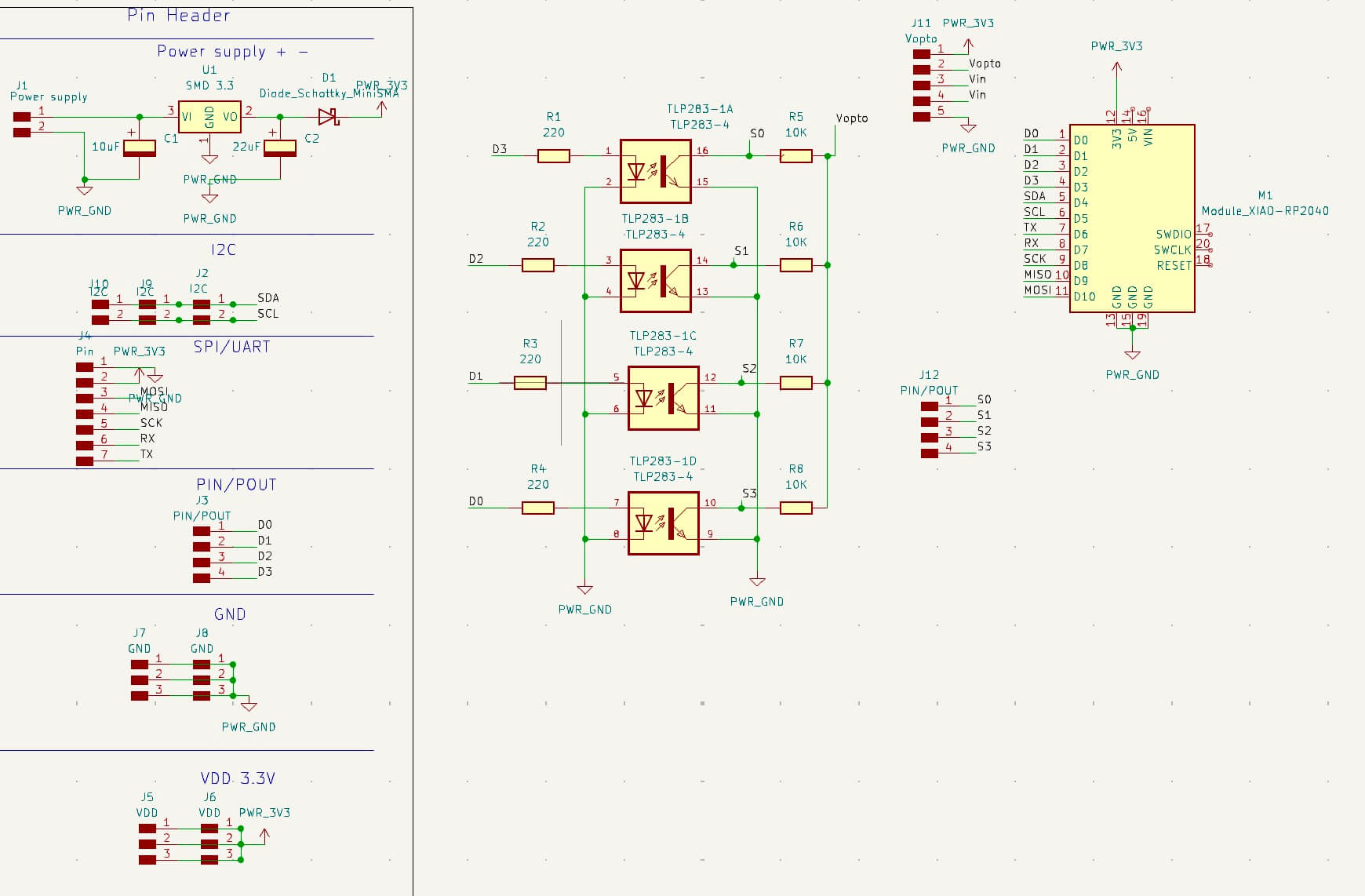

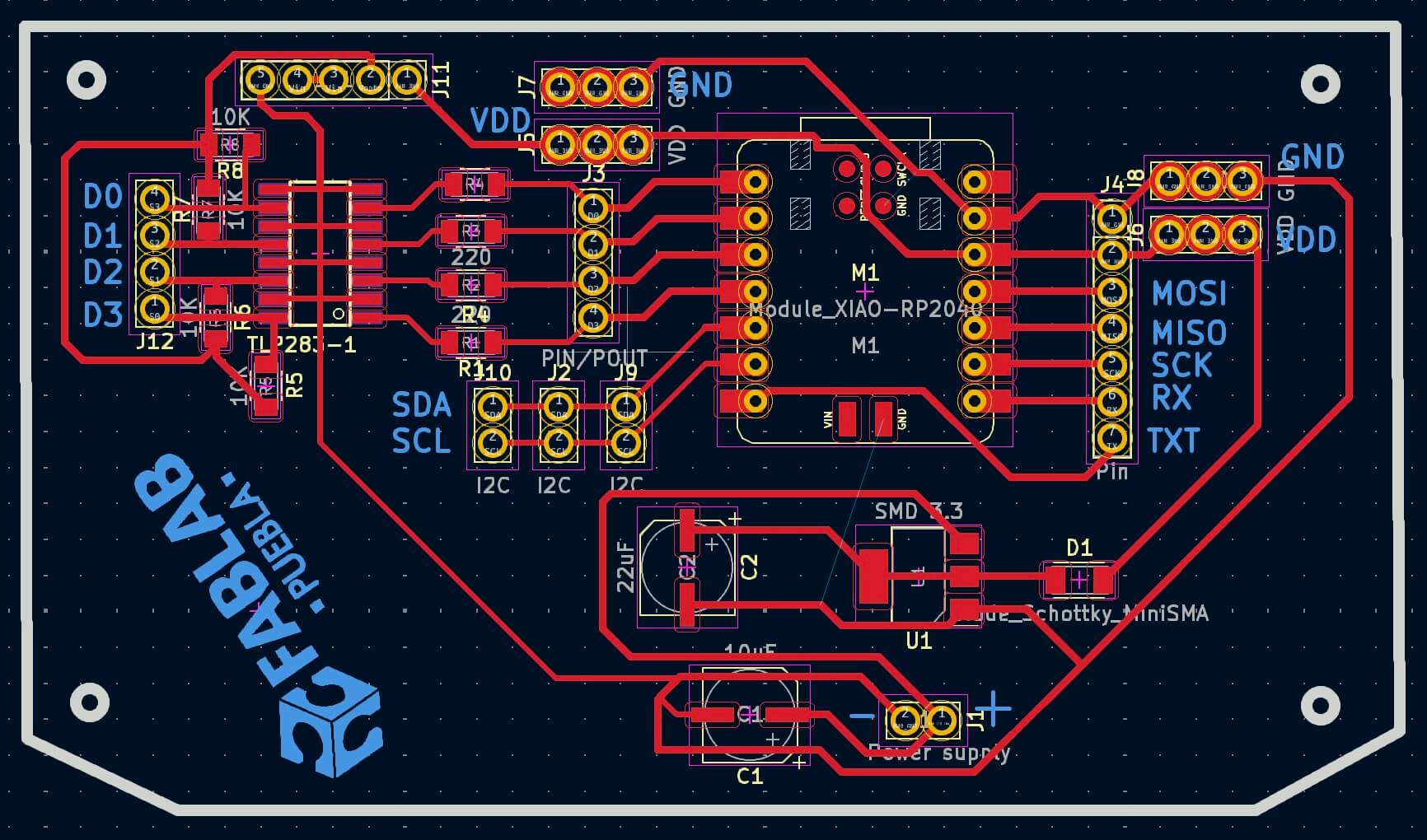

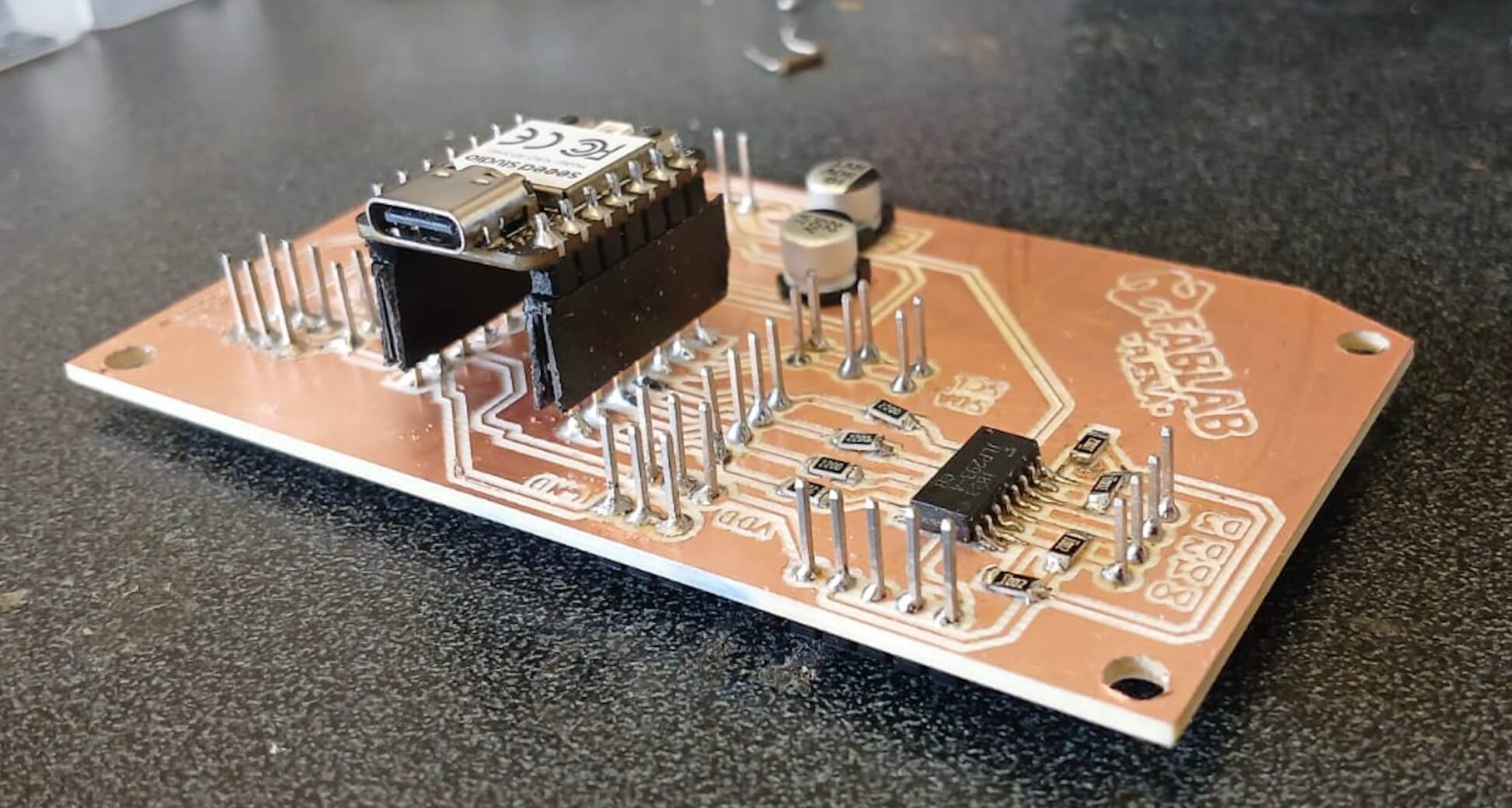

To carry out the CNC, the work was divided among all the members. I oversaw the electrical and power aspects.

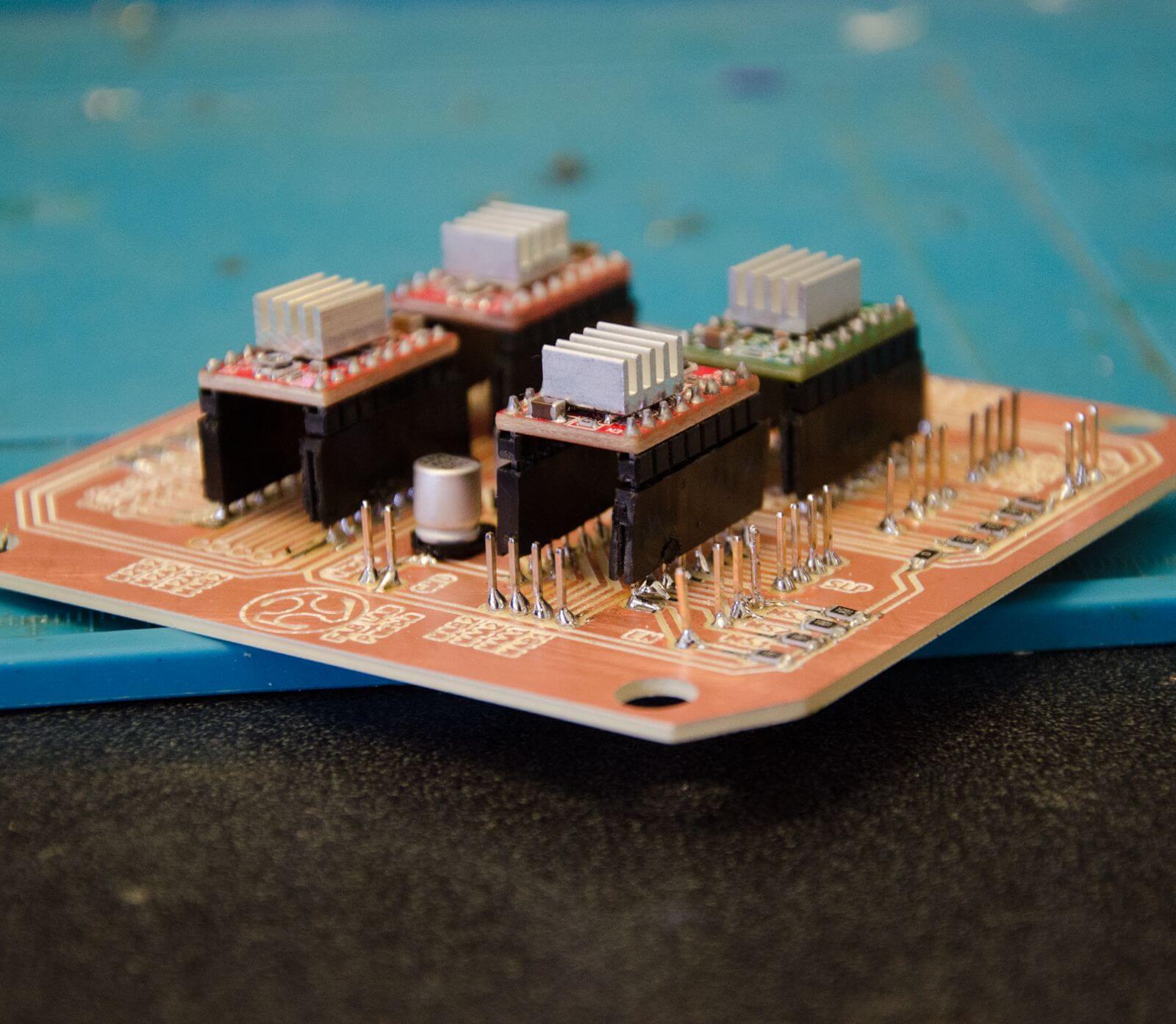

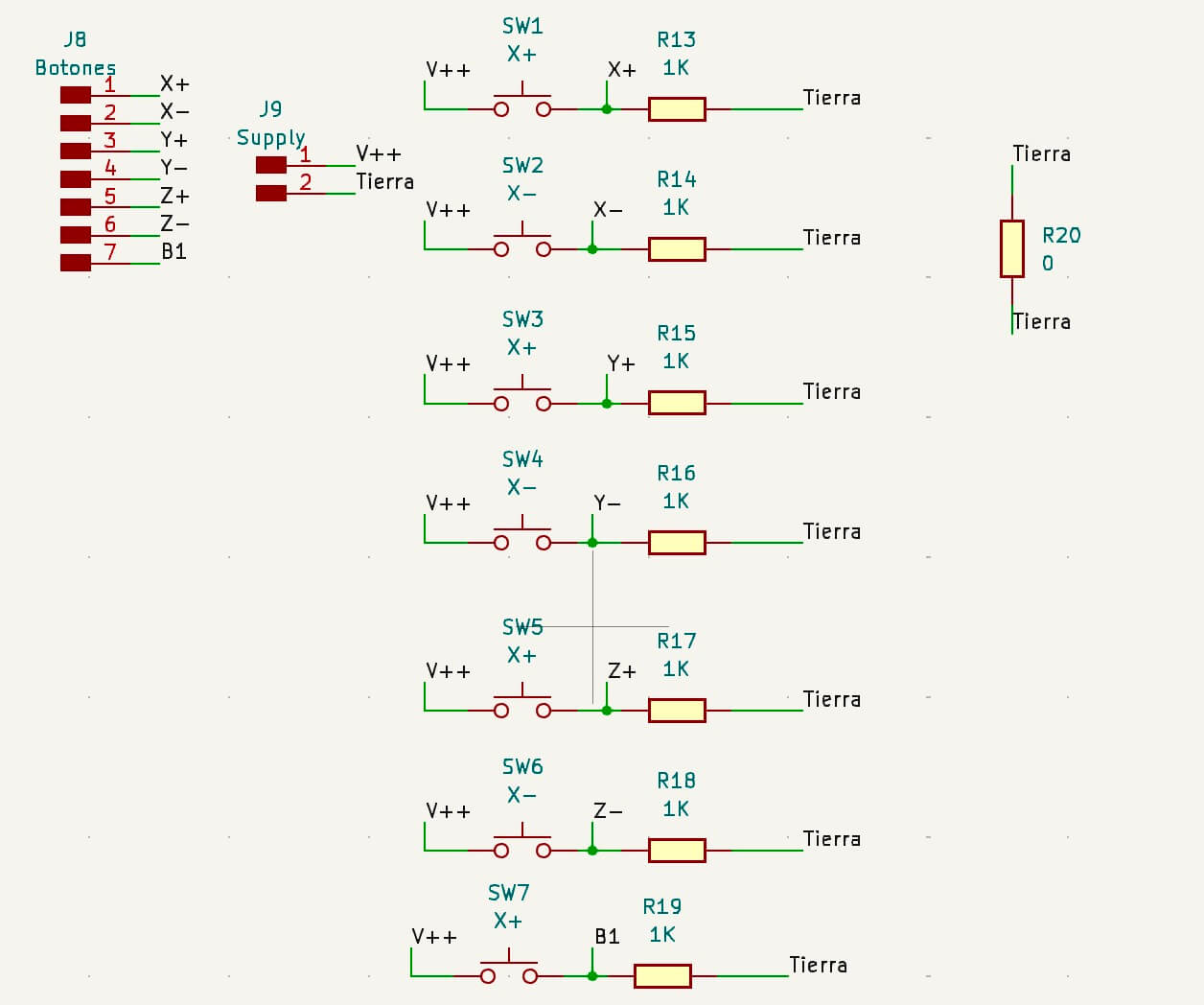

The first thing designed was the board containing all the drivers. It's worth mentioning that this board was designed during

Output Devices Week. Below is an image of the board and a video of its operation.

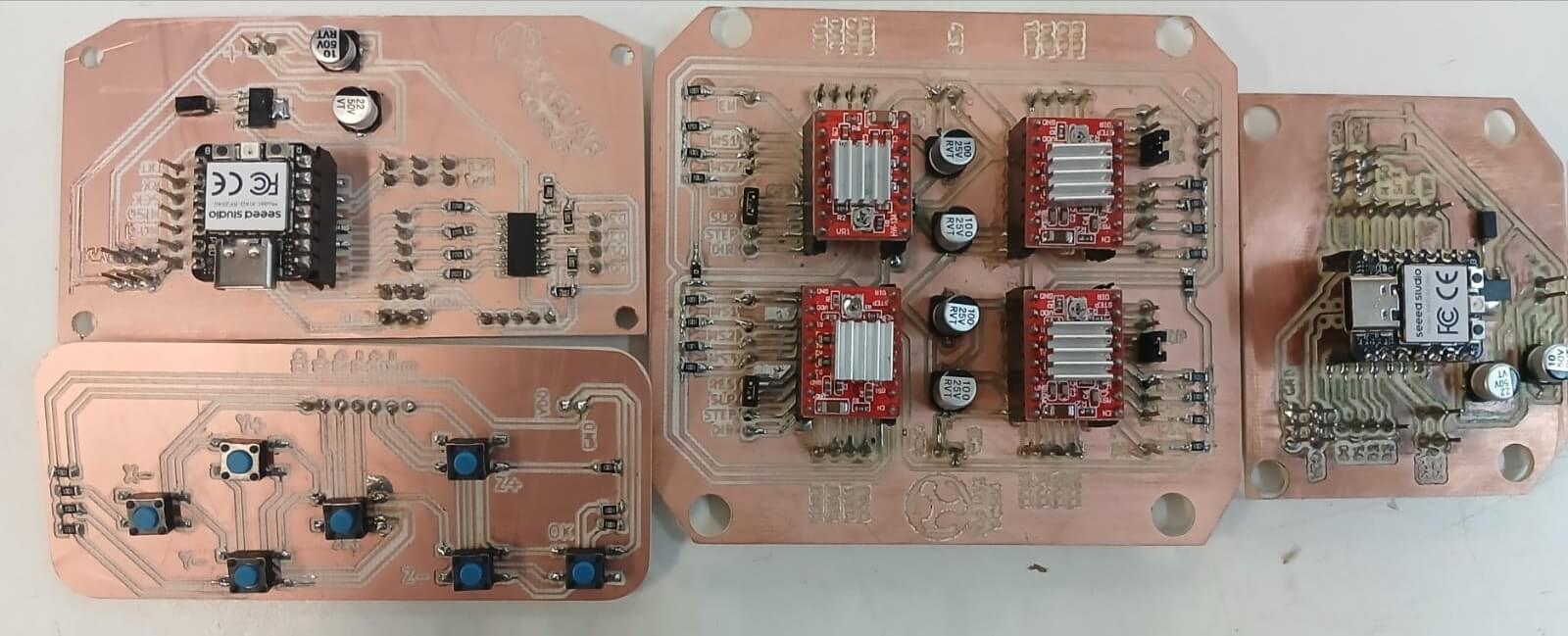

BOTTOM LINE

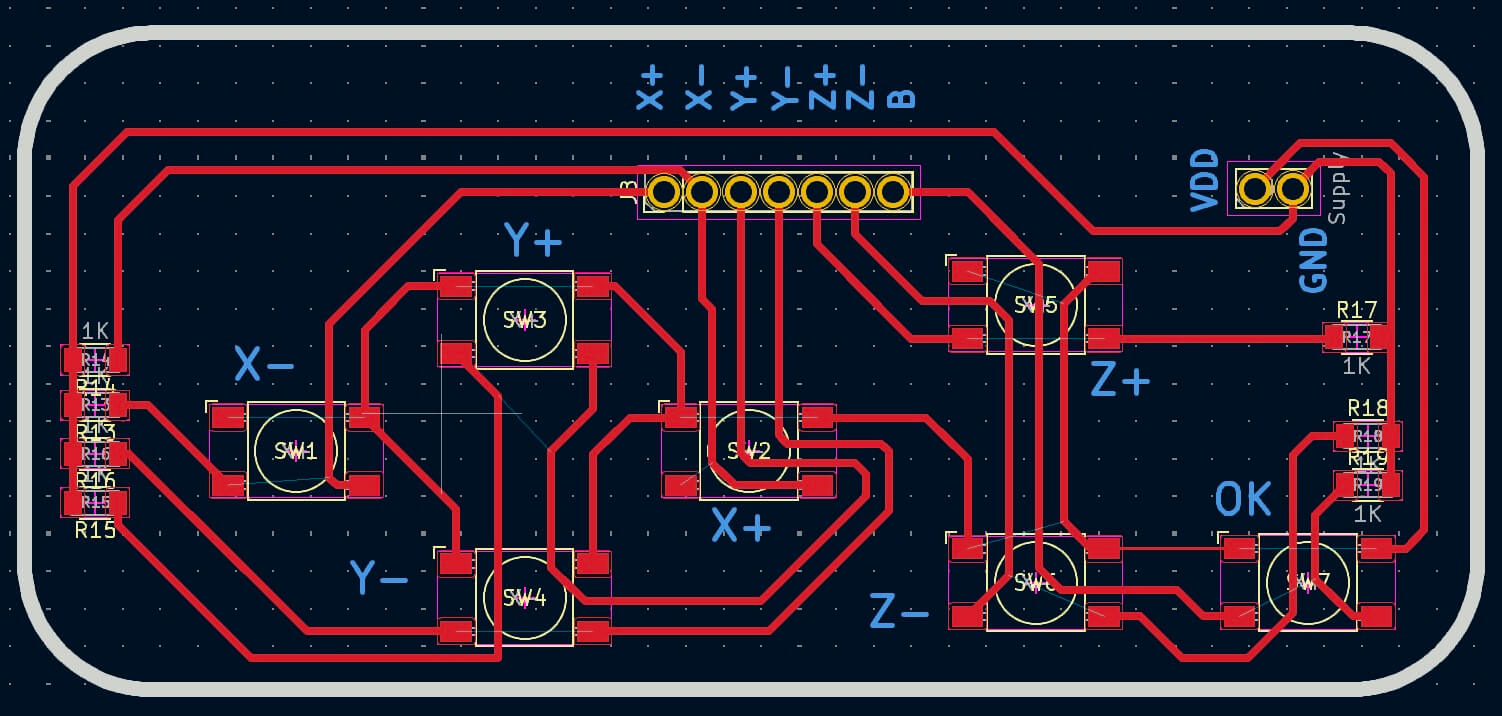

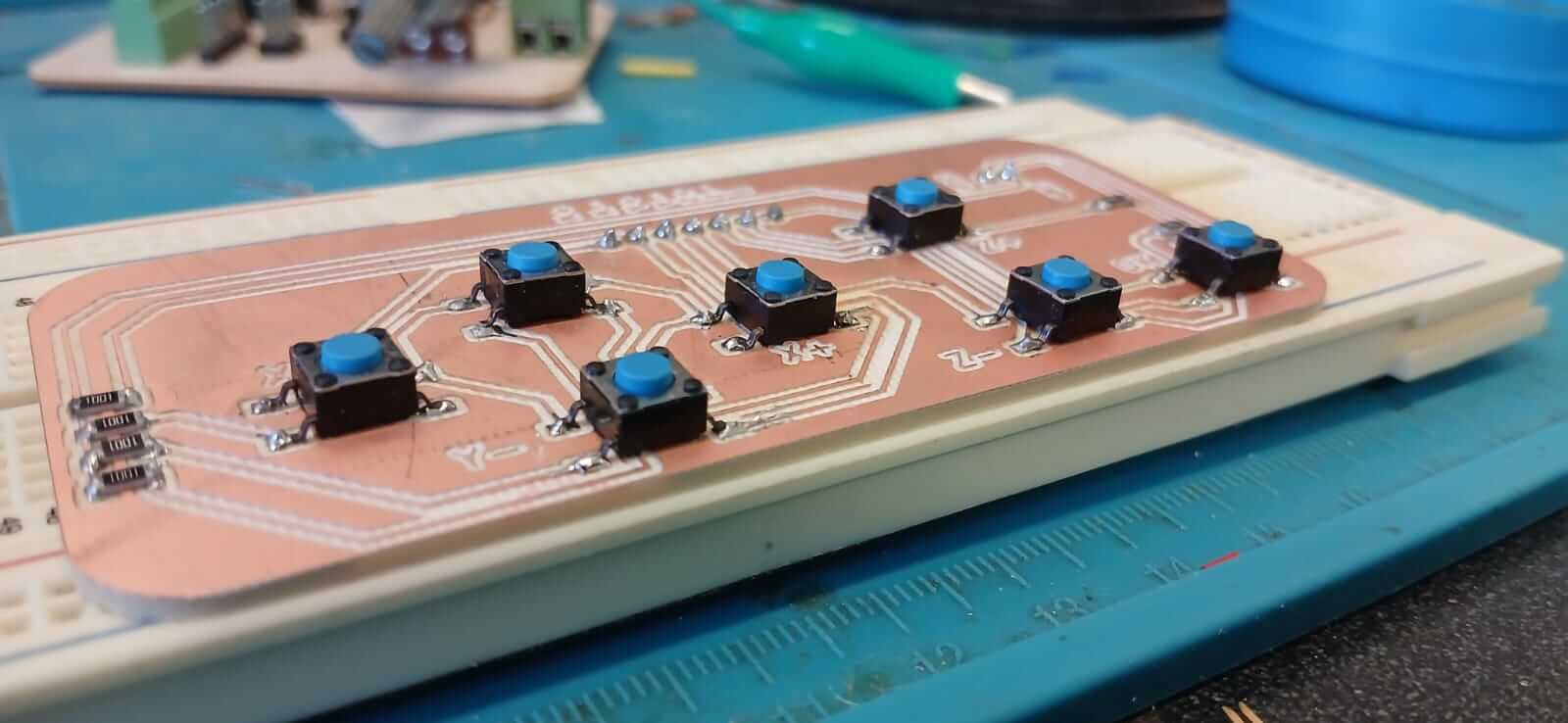

All manufactured PCBs are shown below.

Learning outcome

This week I learned the importance of communication when working as a team, as it allows for the exchange of ideas and improves problem-solving

by combining skills and sharing knowledge, which facilitates learning for all members. Teamwork also allowed for the distribution of work

and streamlined project implementation.

Additionally, we were able to observe that the correct functioning of each stage is crucial as it allows for better integration and,

therefore, better performance of the CNC.

Group Task

-

The group page is shown below.

- Group Task