Molding and Casting Group Project: LEGO, Silicone, AB Resin & Low-Temperature Alloy

Project Overview

For this group assignment based on the "Molding and Casting" course content, we completed two practical projects:

- Creating a dog-shaped pen holder using LEGO bricks, clay, and polyurethane resin (PU)

- Casting a small tin soldier using indium-tin-bismuth low-temperature alloy, hot water, and a syringe

These two projects applied the core skills learned in the course, including mold making, soft mold casting, demolding techniques, and low-temperature metal casting, demonstrating the application of different materials and techniques in molding and casting.

Materials and Tools

Materials for Dog Pen Holder:

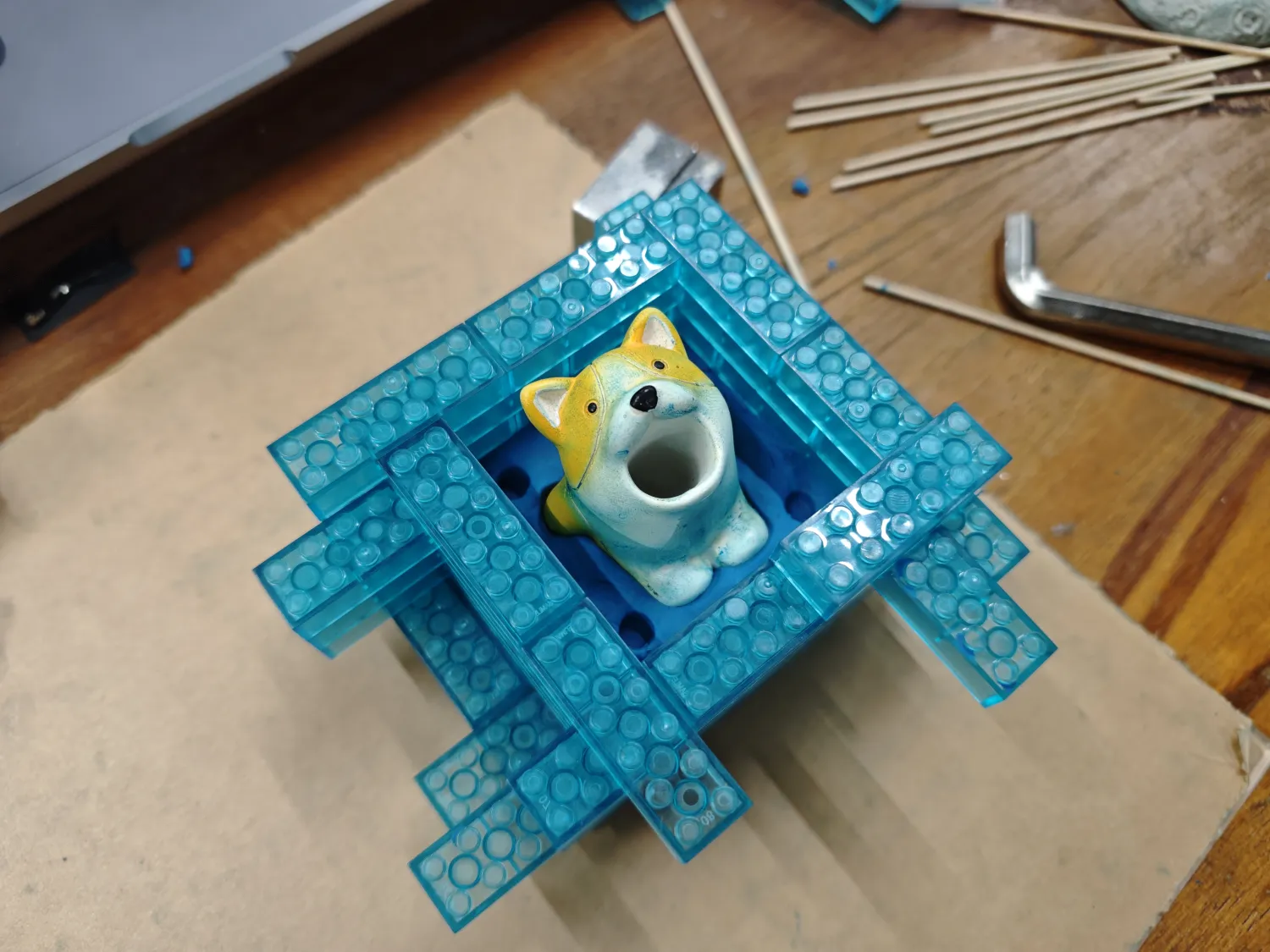

- Original ceramic dog pen holder (for making the mold)

Original ceramic dog pen holder

- Transparent blue LEGO bricks (for making the mold frame)

- Modeling clay

The blue bar-shaped items in the plastic bag are modeling clay, and the blue LEGO bricks are for making the model frame

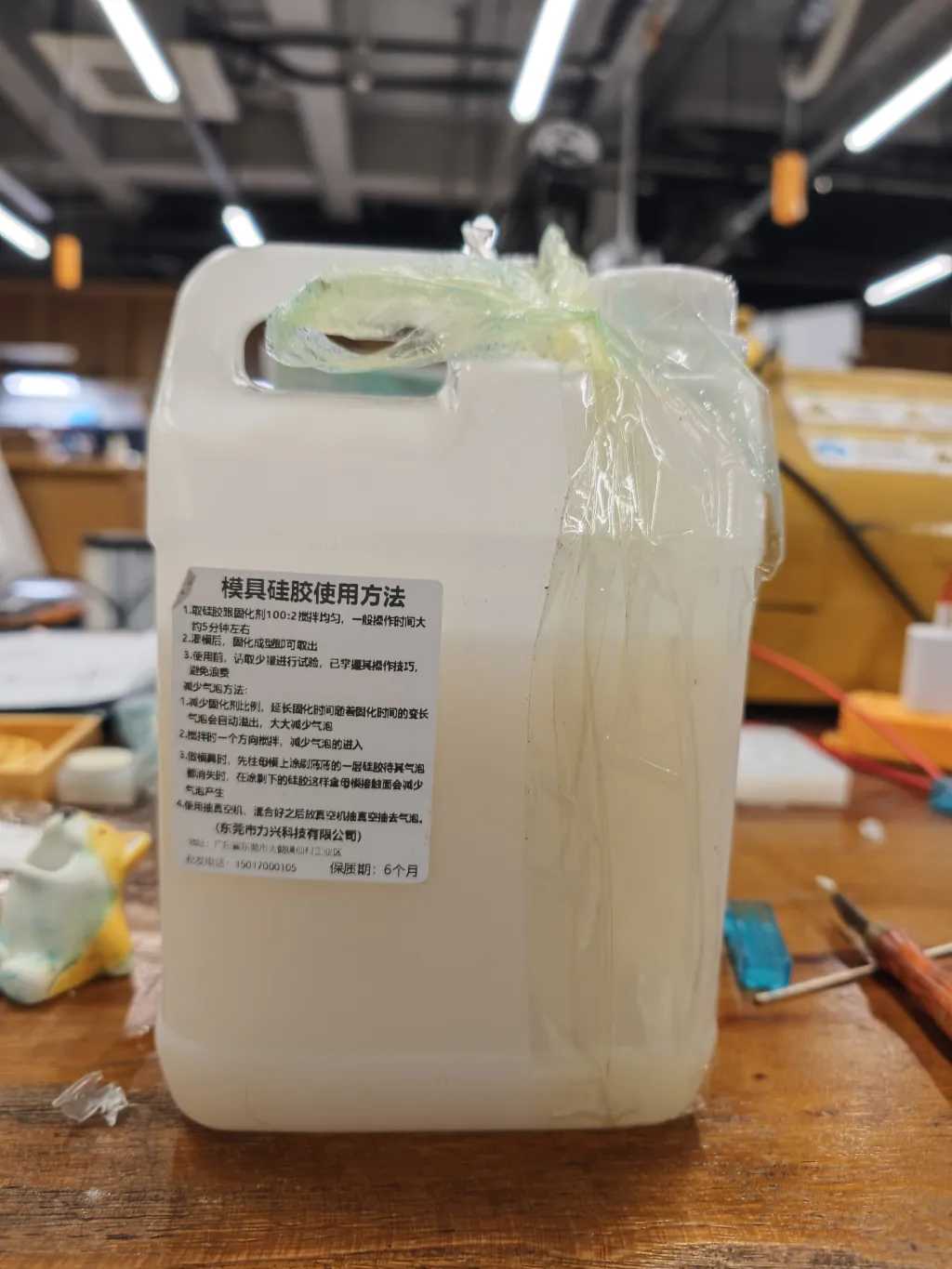

- Silicone rubber (for making the flexible mold)

Silicone rubber in plastic bottle

Silicone Rubber Usage Instructions

1. Mix the silicone with the curing agent at a 100:2 ratio and stir thoroughly. Operation time is about 5 minutes.

2. After pouring into the mold, remove once fully cured.

3. Before use, test with a small amount to understand its characteristics and avoid waste.

Bubble Reduction Methods:

1. Reduce the curing agent ratio to extend curing time. As curing time increases, bubbles will naturally escape, greatly reducing their presence.

2. Stir in one direction to reduce bubble formation.

3. When making molds, first brush a thin layer of silicone on the master mold and wait for bubbles to disappear before applying the remaining silicone. This reduces bubble formation at the contact surface.

4. Use a vacuum machine to extract bubbles after mixing.

(Dongguan Lixing Technology Co., Ltd.)

Address: Xiancun Industrial Zone, Dalang Town, Dongguan City, Guangdong Province

Shelf life: 6 months

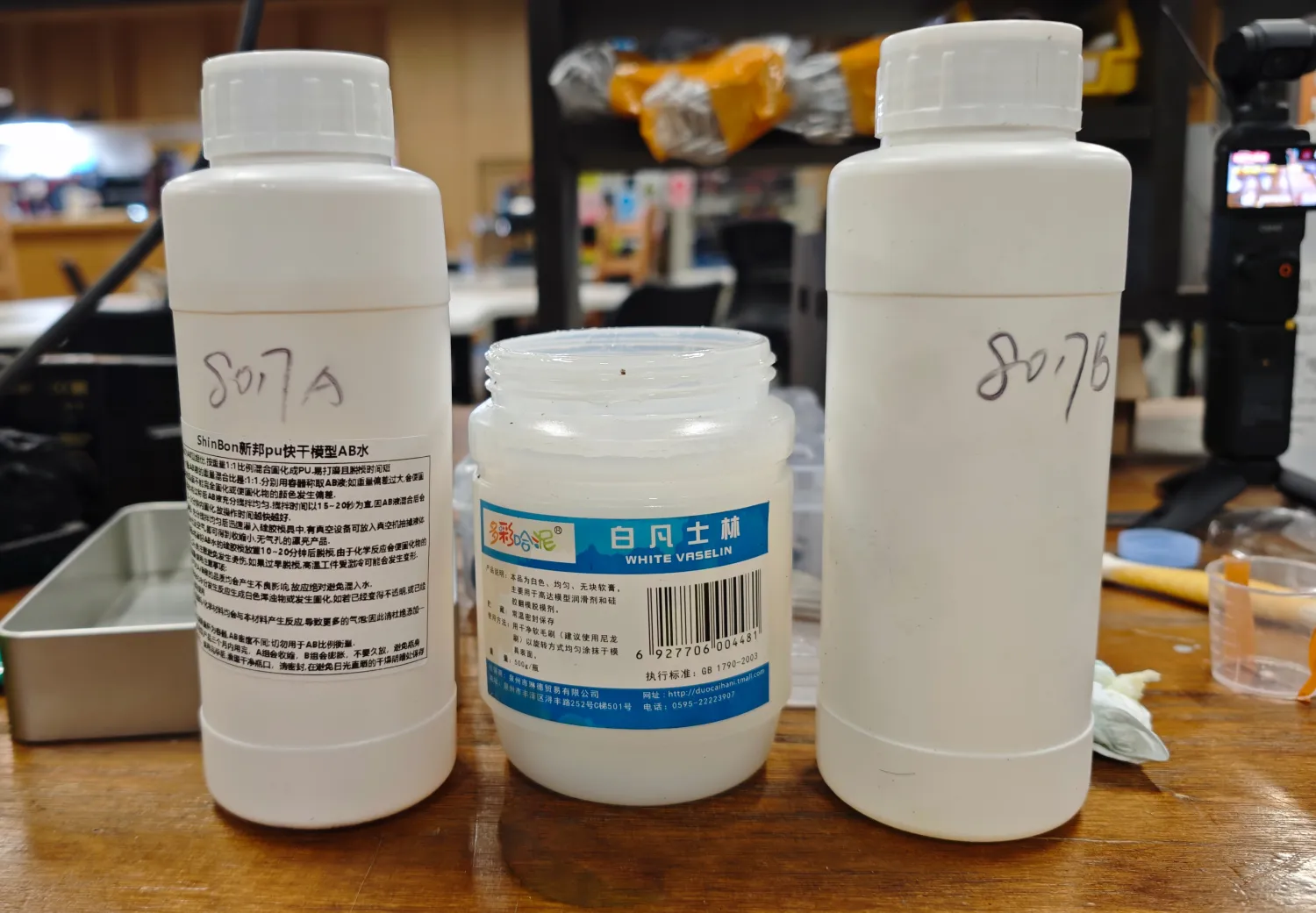

- ShinBon PU Quick-drying Model AB Resin (for final product casting)

ShinBon PU Quick-drying Model AB Resin

This product consists of two components, A and B, mixed at a 1:1 weight ratio to form PU. It is easy to sand and has a short demolding time.

- Measurement: The weight mixing ratio of AB liquids is 1:1. Measure components A and B separately in containers. If the weight difference is too large, the cured surface may not fully solidify or the color of the cured material may deviate.

- Mixing: Thoroughly mix the pre-weighed AB liquids, stirring for 15-20 seconds. Since the AB liquid will solidify within 1.5-2 minutes after mixing, operation should be as quick as possible.

- Pouring: After thoroughly mixing, quickly pour into the silicone mold. If a vacuum machine is available, place it in the vacuum machine to remove moisture and air from the liquid, resulting in a beautiful product with minimal shrinkage and no air holes.

- Demolding: After vacuuming, place the silicone mold filled with AB resin on a flat work table. After 10-20 minutes, you can demold. Due to the heat of the curing reaction, the temperature of the cured material will rise - be careful to avoid burns. If demolded too early, the high-temperature cured material may deform due to sudden cooling.

Usage Precautions:

- Moisture adversely affects the quality of both A and B liquids, so avoid contact with water.

- B liquid will react with moisture to produce white cloudy substance or solidify. If it has become opaque or solidified, do not use it.

- Any pigments/chemical materials will react with this material, causing more bubbles, so avoid adding any pigments.

- The provided dropper and measuring cup are containers only. As the densities of A and B are different, do not use them for balancing AB ratios.

- It is recommended to use the product within 3 months of receipt. Component A will shrink, and component B will expand, so don't store for extended periods to avoid bottle cracking and leakage. After use, clean the bottle opening thoroughly, seal it, and store in a dry, dark place away from direct sunlight.

- White Vaseline mold release agent

- Product name: White Vaseline (WHITE VASSLIN)

- Purpose: Mainly used as a model lubricant and silicone mold release agent

- Usage method: Apply evenly to the mold surface with a clean soft brush

- Weight: 500g/bottle

- Manufacturer: Quanzhou Linde Trading Co., Ltd.

White Vaseline (middle) and AB resin (left and right bottles)

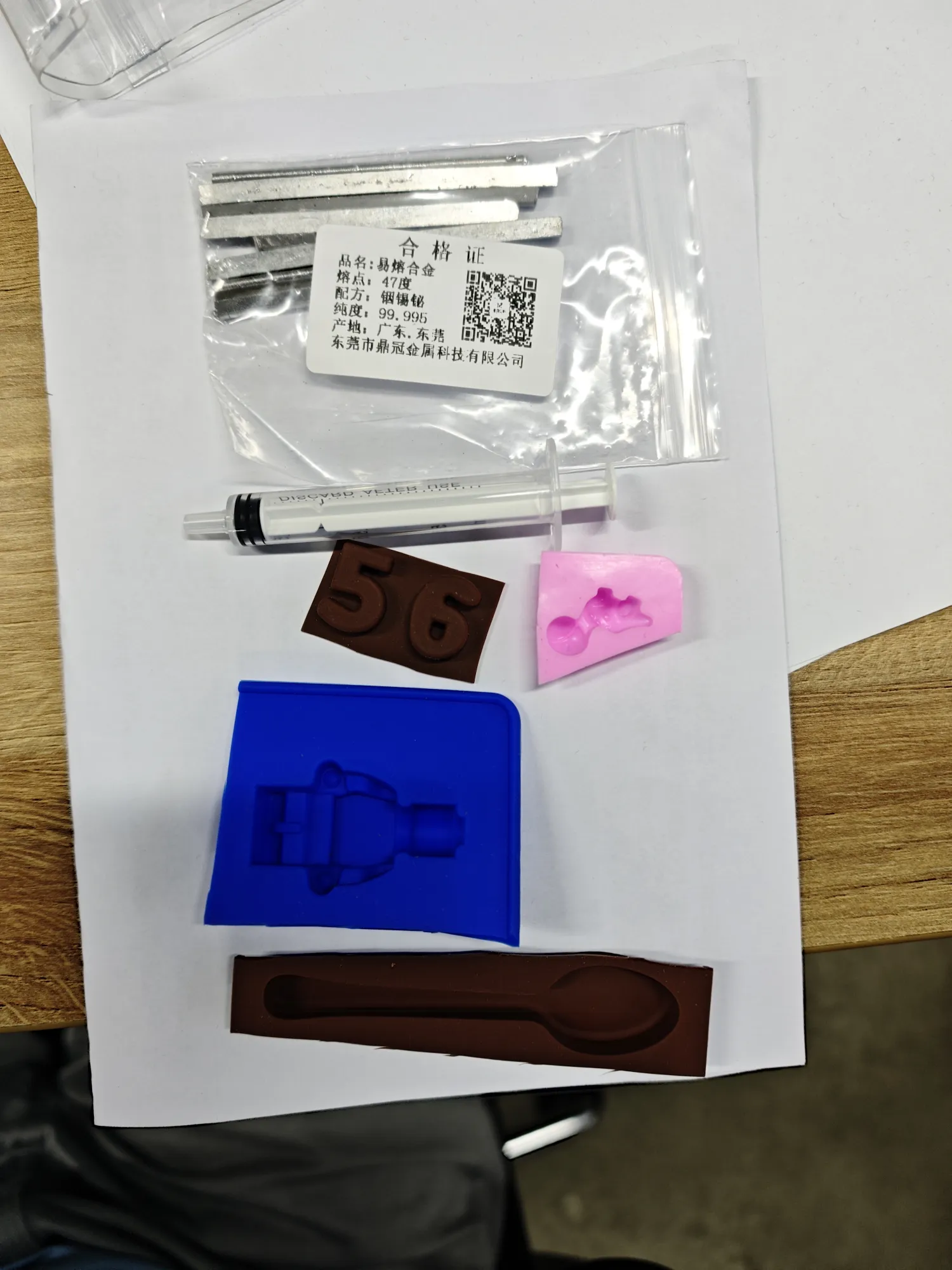

Materials for Indium-Tin-Bismuth Tin Soldier:

- Indium-Tin-Bismuth low-temperature alloy

- Melting point: 47°C

- Purity: 99.995%

- Origin: Dongguan, Guangdong

- Manufacturer: Dongguan Dingguan Metal Technology Co., Ltd.

- Blue silicone mold (LEGO minifigure shape)

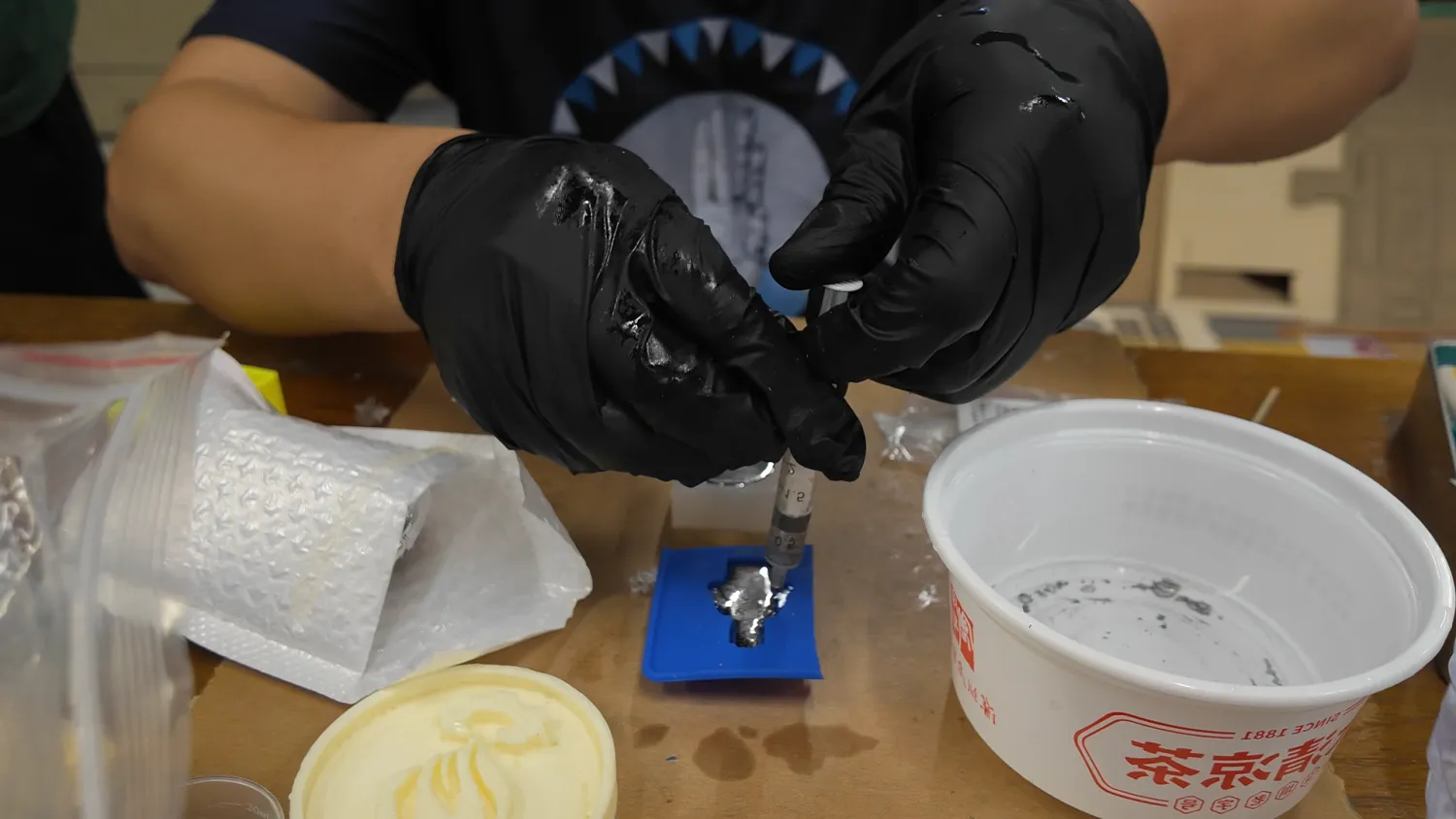

Indium-Tin-Bismuth low-temperature alloy, syringe, and flexible mold

Tools:

- Syringe (for injecting low-temperature alloy)

- Metal files/tools (for post-processing)

- Hot water (for melting low-temperature alloy)

- Glass measuring cup (for material mixing)

- Disposable plastic bowls

- Plastic syringe

- Wooden stick (for stirring)

- Soft brush (for applying release agent)

- Paper (to protect work area)

- Gloves (for protection)

- Mask

- Eye protection

Dog Pen Holder Production Process

Preparation

- Clean the work table (recommended to cover with paper for protection)

- Prepare the original model (ceramic dog pen holder)

- Check all materials and tools

- Ensure the work environment is dry to avoid moisture affecting material quality

We planned to create the mold in 2 parts that could be joined together, making it easier to remove both the original statue and the cast piece after pouring.

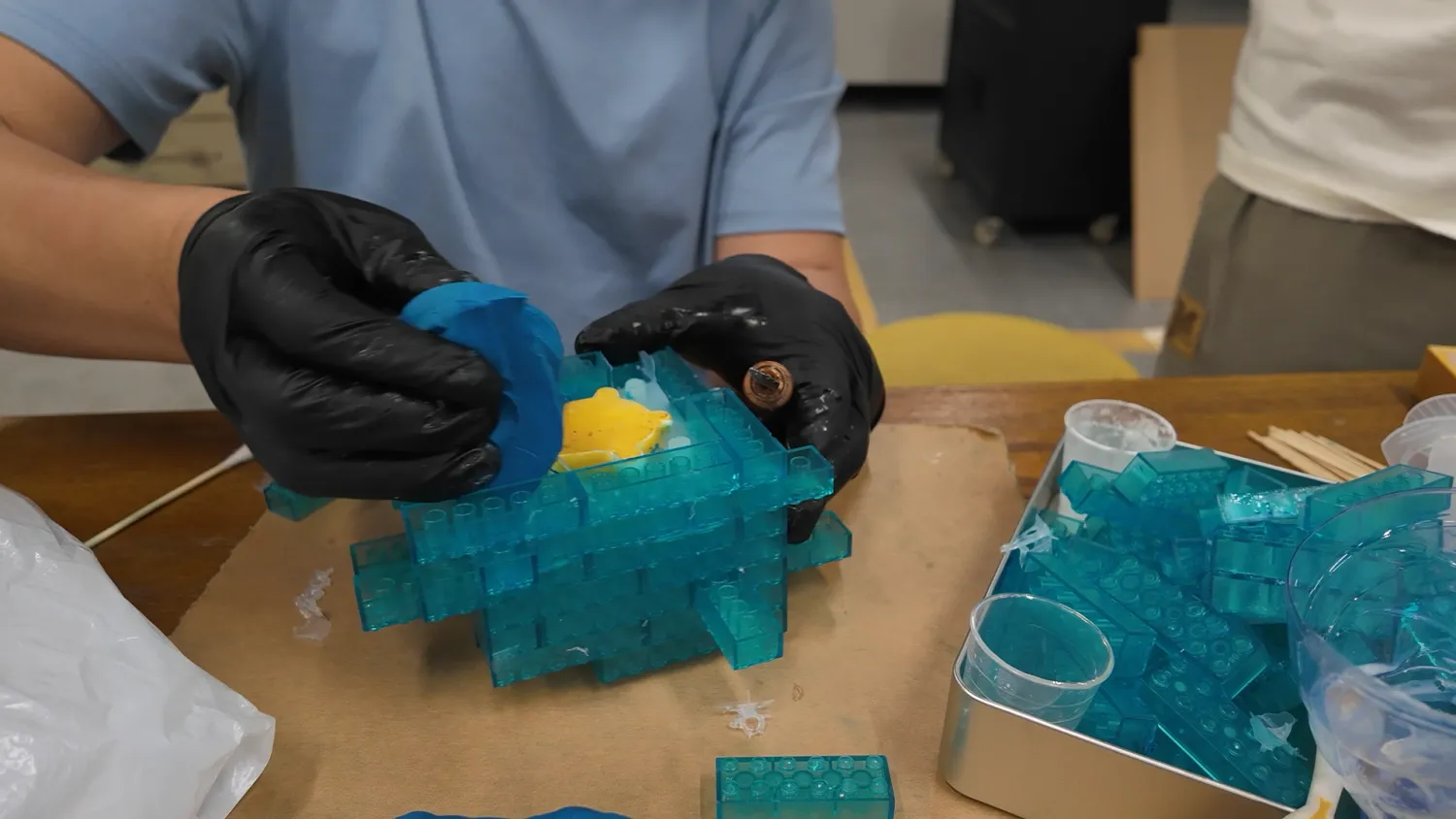

Upper Body Mold Frame Construction

- Build the mold frame using transparent blue LEGO bricks

- Adjust the frame to completely surround the prototype, leaving enough space for pouring in the silicone

- Seal the bottom of the frame with clay to prevent silicone leakage. We pressed the dog statue into the clay until it barely covered the bottom, and used a wooden stick to make 4 holes in the clay to create alignment features for the two mold halves.

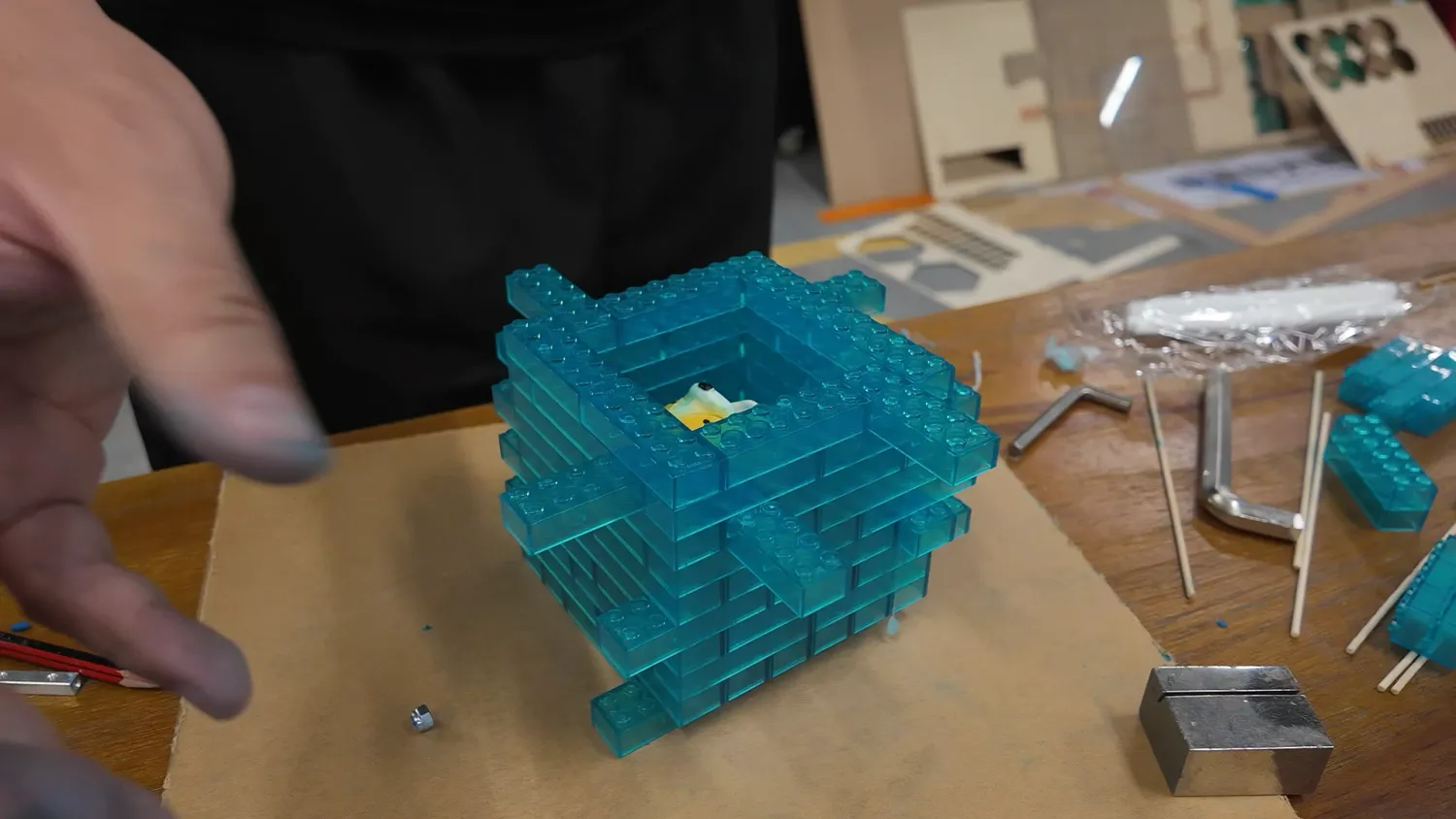

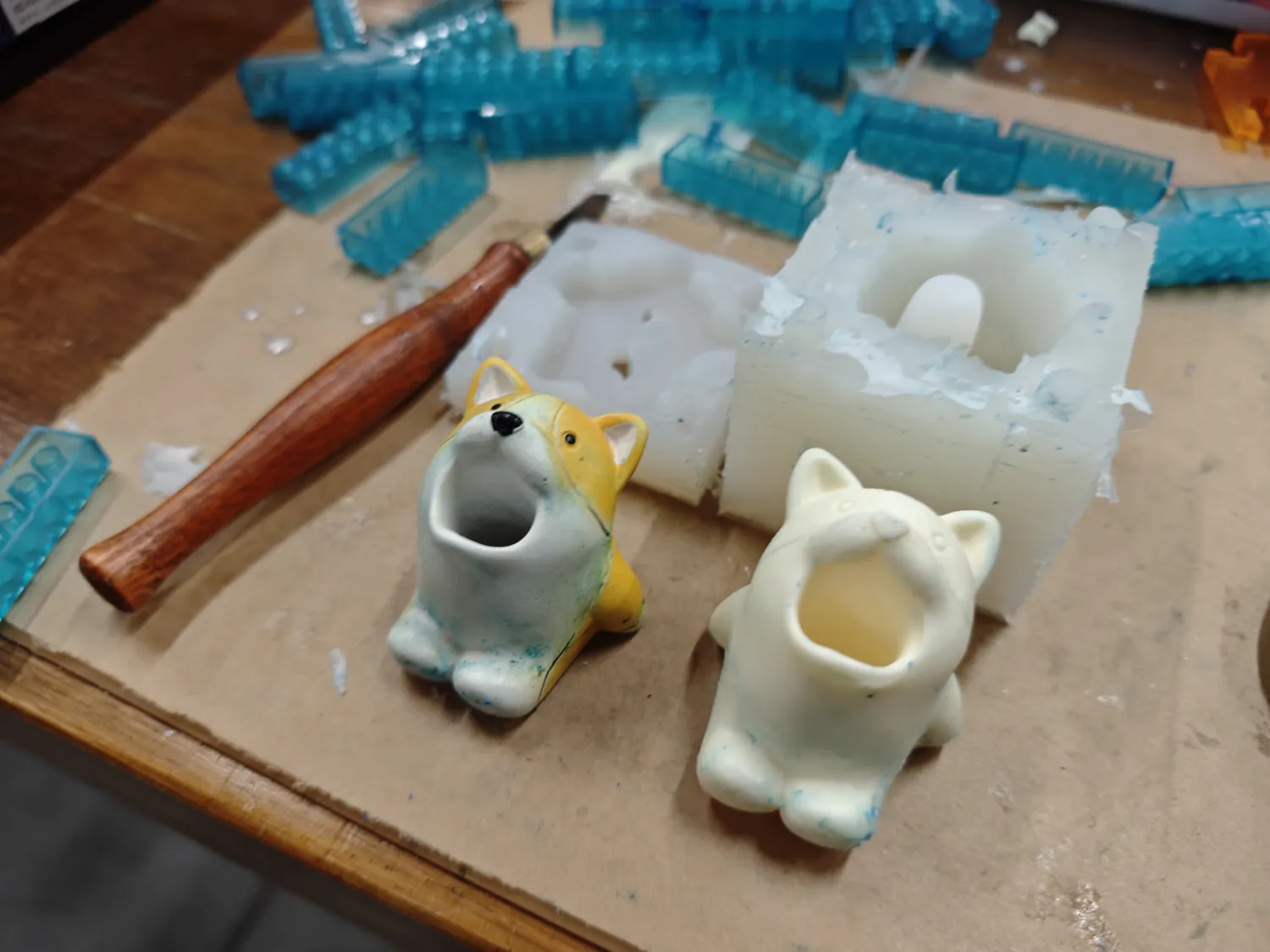

Mold frame constructed with LEGO bricks, clay at the bottom with the dog prototype placed in it. Four alignment holes were pressed into the clay. The poor yellow and white dog has been stained into a spotted dog by the blue clay.

- Then we stacked the bricks about 1 brick height above the statue as shown below.

LEGO bricks should be built at least 1 brick height above the statue

Upper Body Silicone Mold Production

- Prepare silicone rubber and curing agent at a 100:2 ratio

- Evenly apply white vaseline release agent to the dog prototype surface

- First brush a thin layer of silicone on the master mold, wait for bubbles to disappear

- Thoroughly mix the silicone and curing agent, stirring in one direction to reduce bubble formation

- Carefully pour the silicone in a thin stream, allowing it to gradually cover the prototype

- Gently shake the mold frame to help release any trapped bubbles

- Leave at room temperature for the silicone to fully cure (about 5 hours)

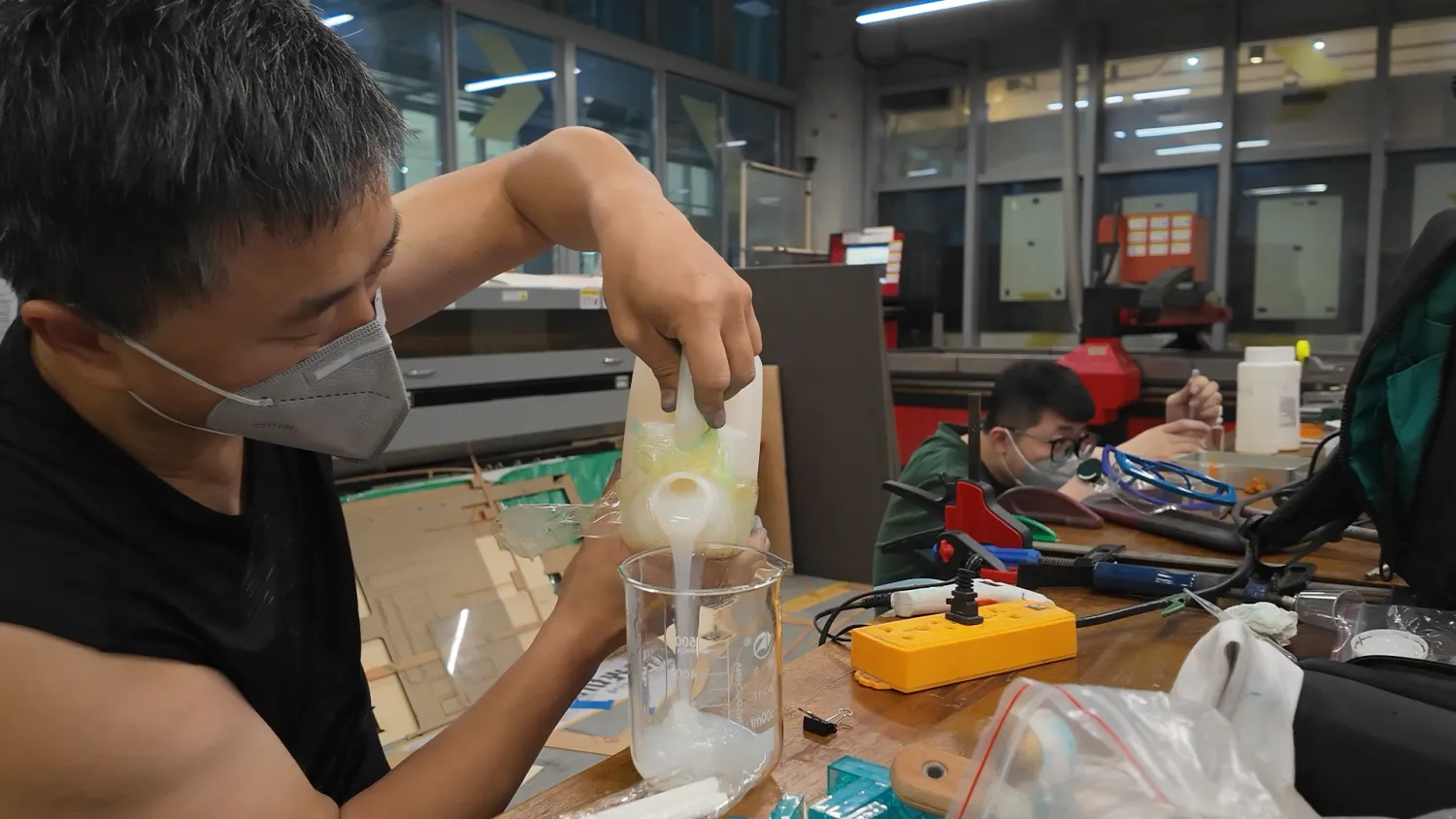

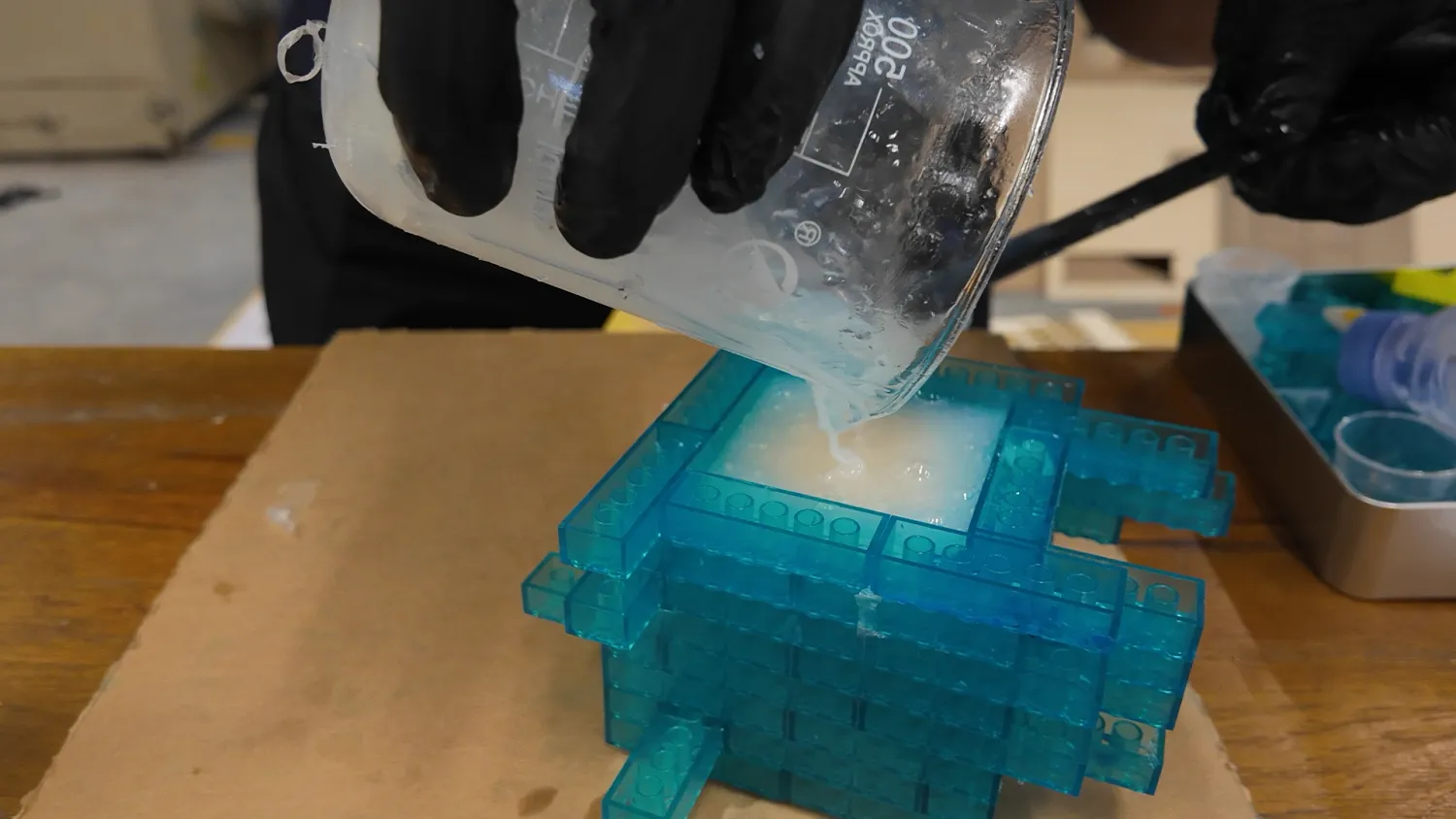

Preparing the silicone rubber, adding curing agent at a 100:2 ratio, then mixing and pouring into the LEGO frame. All this should be completed within 5 minutes, so 2 people worked simultaneously - one person pouring the silicone, the other preparing and measuring the curing agent.

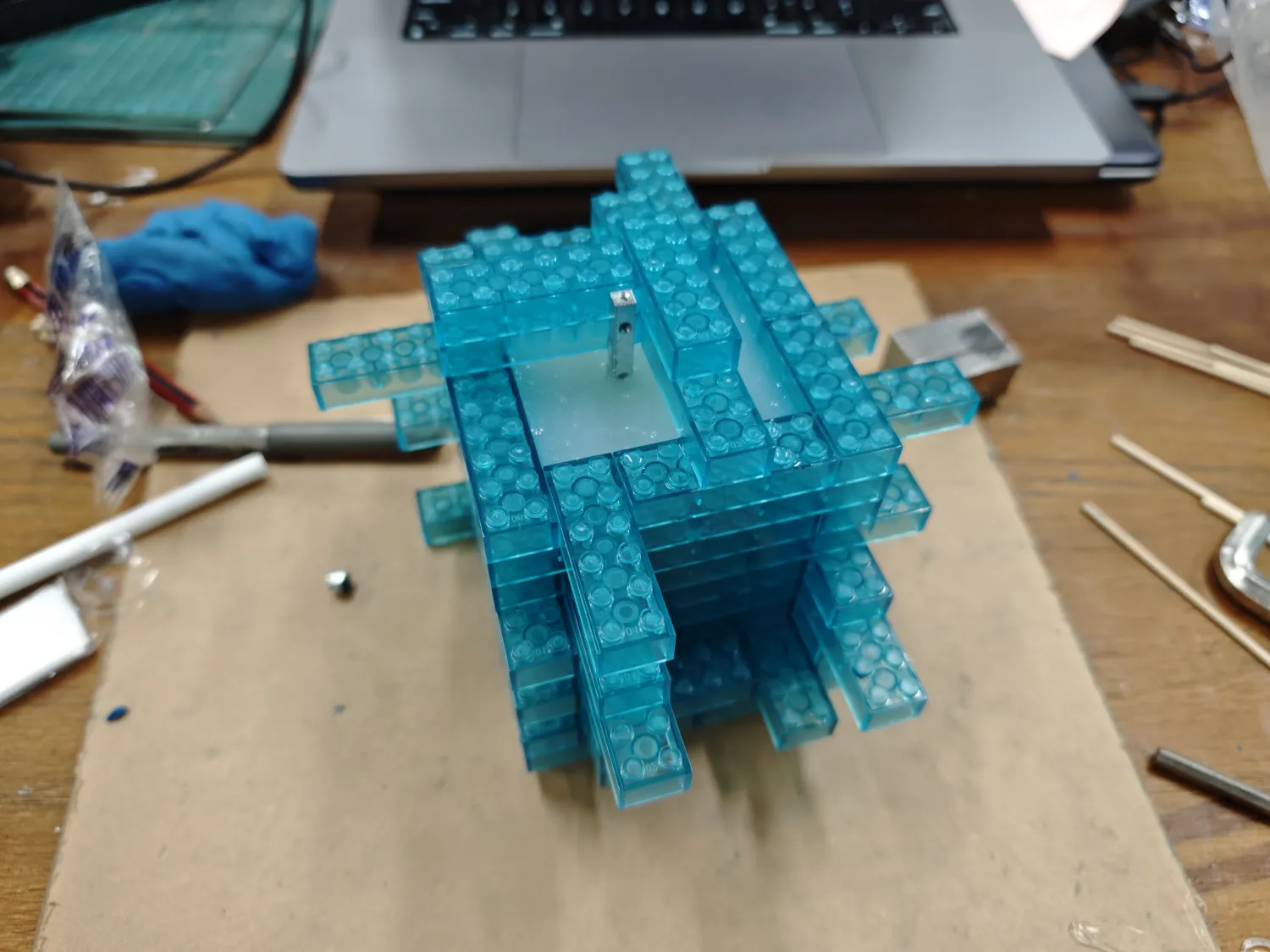

We considered that we would need a pouring hole for the AB resin later, so we inserted a metal rod and built a support structure.

Lower Body Silicone Mold Production

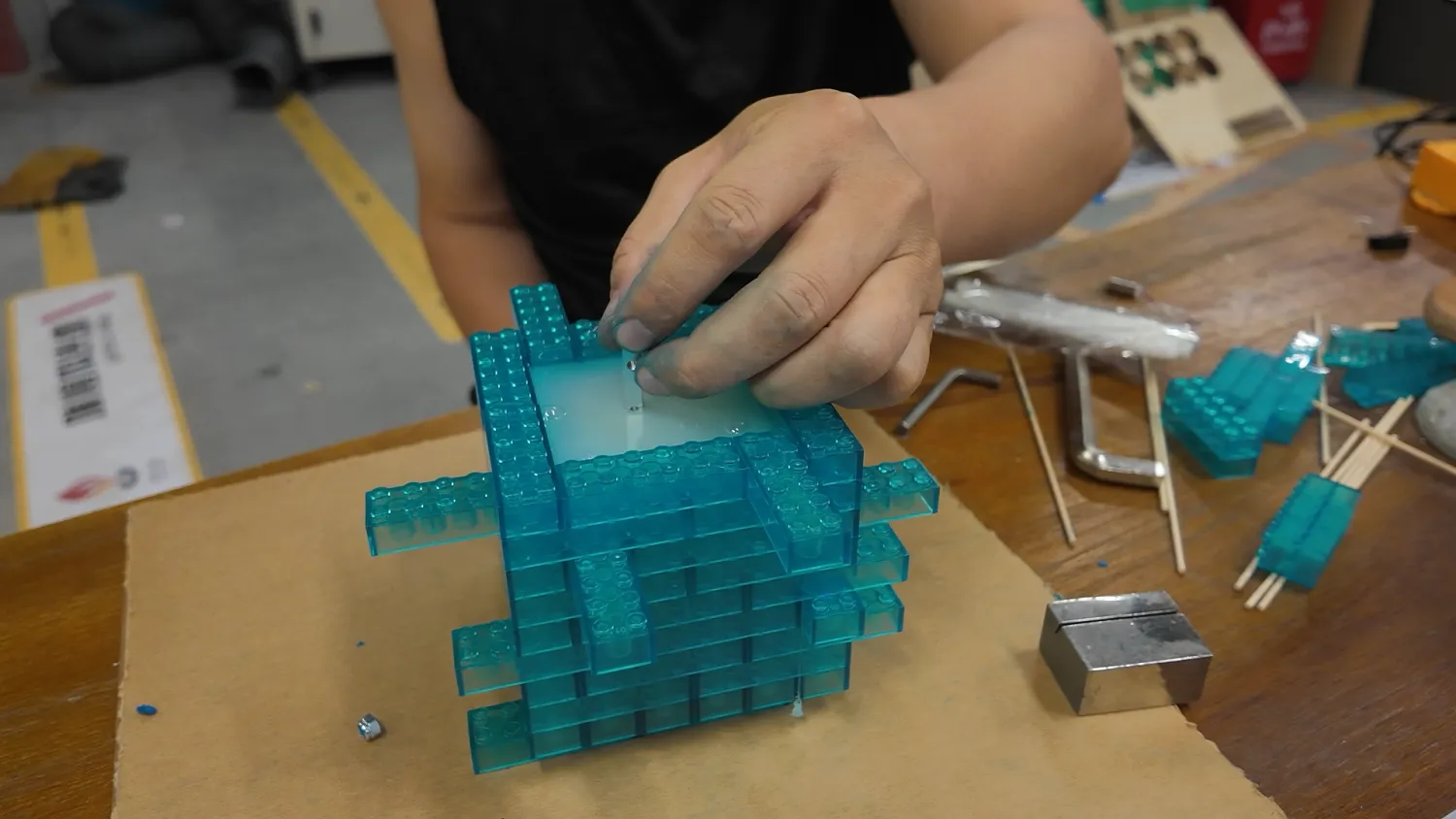

- To ensure the silicone was fully cured, we waited 24 hours before starting this part. We flipped the LEGO frame over and removed the bottom LEGO bricks and clay, as shown below.

After 24 hours, when the upper body silicone mold was fully cured, we flipped the frame over and removed the bottom bricks and clay.

- We continued building the LEGO brick frame, ensuring it extended at least 1 brick height above the model. Now we could prepare to cast the lower half, as shown below.

Using LEGO bricks to create a pouring space for the model's lower half

- We prepared the silicone and curing agent mixture and poured the lower half of the mold, as shown below.

Pouring silicone for the lower half of the mold

- Since we didn't have a vacuum machine, I repeatedly tapped the mold with poured silicone forcefully against the table (ensuring the LEGO frame was secure), using impact force to remove bubbles, which seemed quite effective.

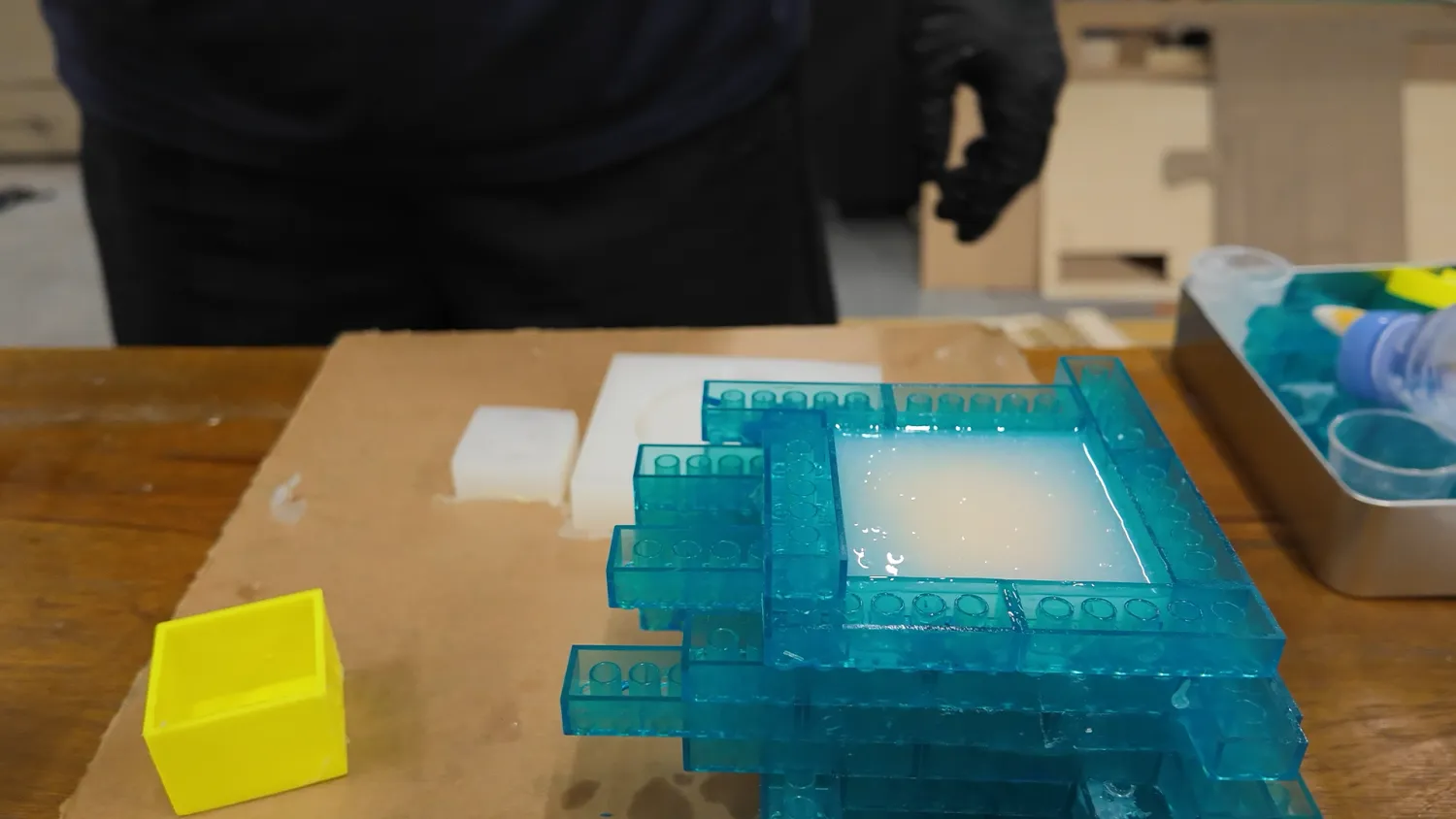

- The bubbles quickly rose to the surface, and then we began another 24-hour curing period.

Beginning the 24-hour curing process

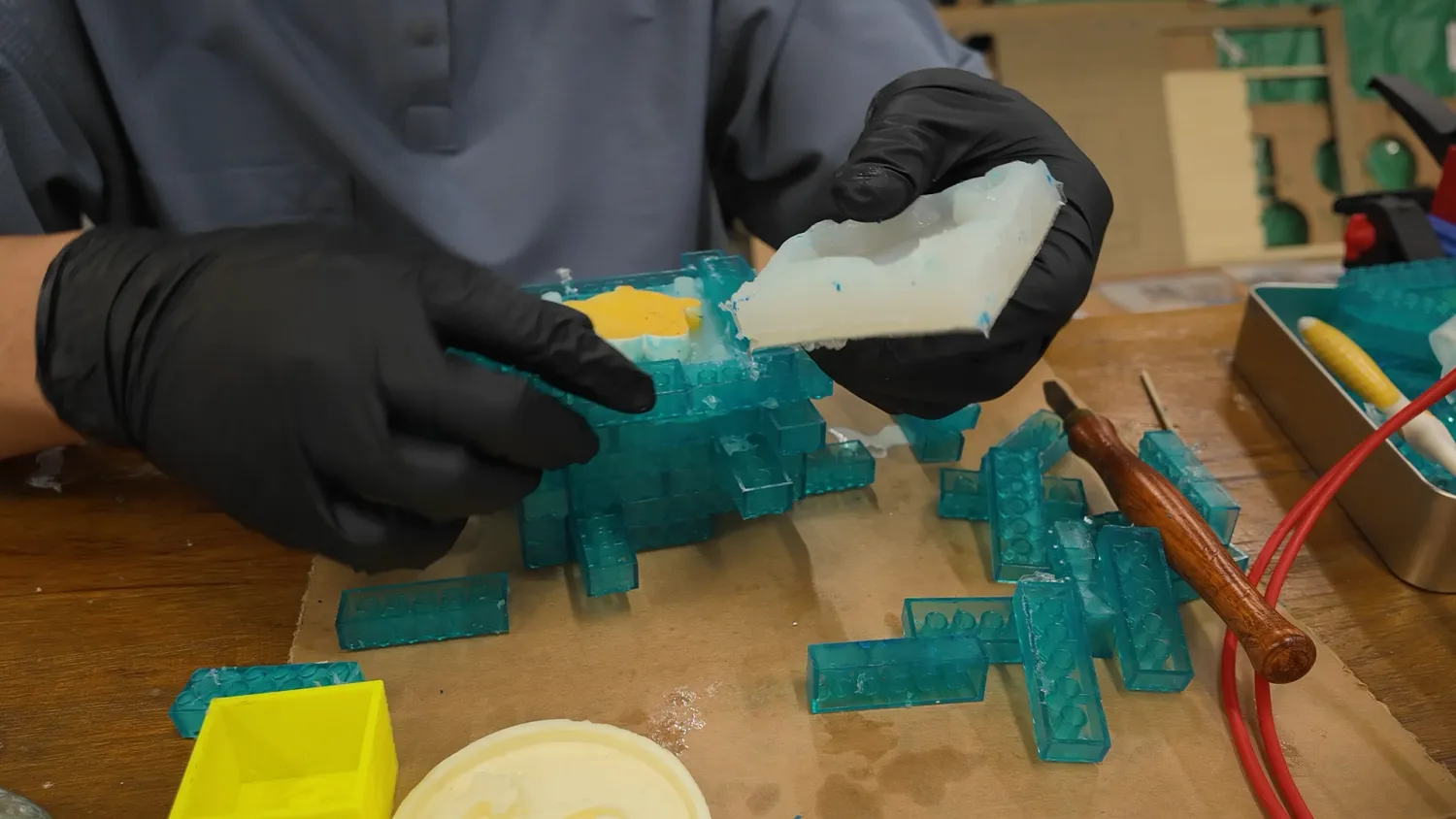

Demolding and Preparation

- Confirm the silicone has fully cured

- Disassemble the LEGO brick frame

- Carefully remove the silicone mold, ensuring no damage to detailed parts

- Check if the silicone mold has completely replicated all details of the prototype

First removing the lower half of the mold

Then carefully removing the upper half of the mold and the dog statue. Now we have 2 complete molds that can be joined together, ready for casting.

Before preparing for casting, we suddenly realized a problem: the pouring hole formed by the metal rod I had inserted at the top (at the dog's nose tip) was too small. The AB resin liquid becomes viscous after mixing, making it difficult to pour through this small hole. Additionally, without a vent hole, air in the mold would be difficult to evacuate, potentially creating cavities or bubble areas.

The pouring hole at the top is barely visible, which would make it difficult to complete the casting in a short time.

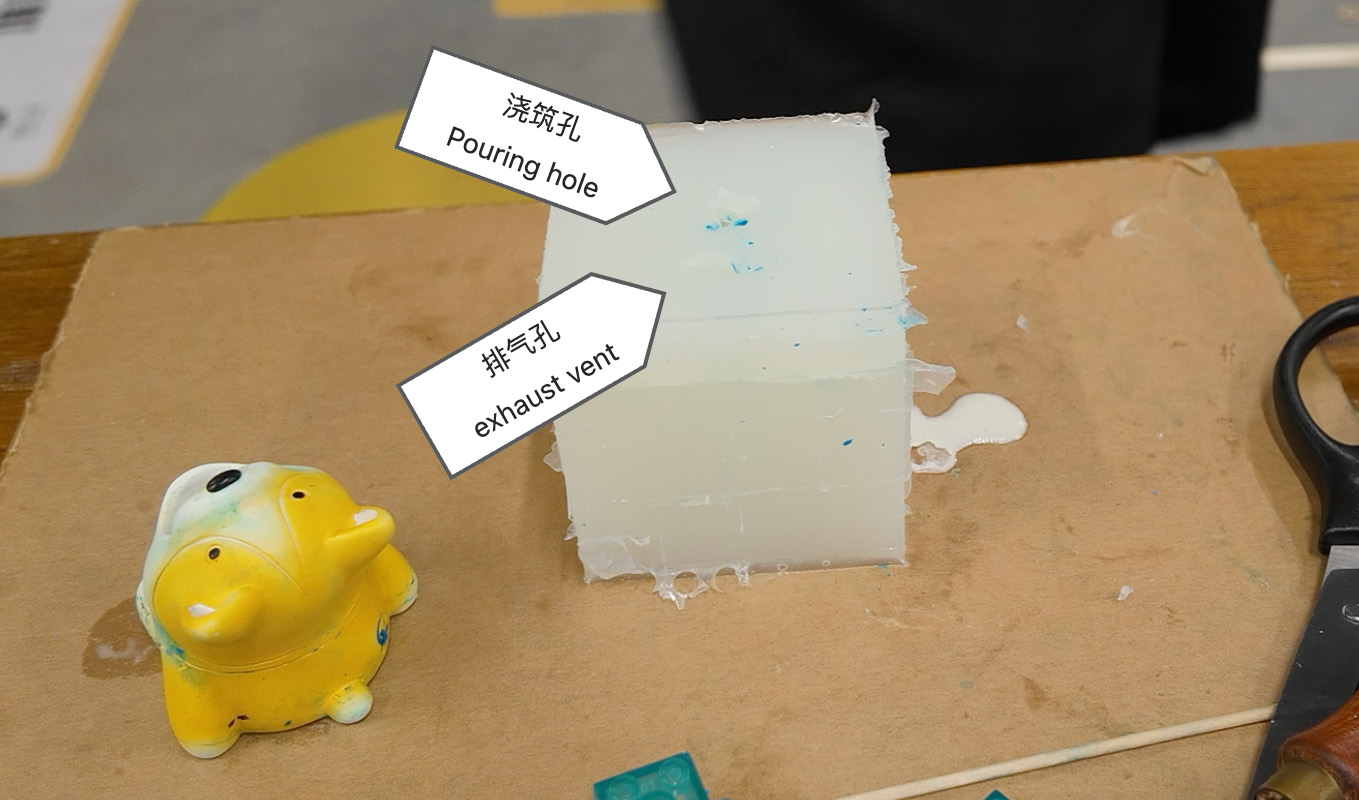

To solve this problem, we came up with a solution: seal the top pouring hole with clay, then flip the mold upside down and cut two holes at the relatively flat and thin bottom area using scissors - a large one for pouring and a small one for air release, as shown below.

We flipped the mold upside down and cut two holes in the relatively flat and thin bottom area using scissors - a large one for pouring and a small one for air release.

Final Product Casting (Using AB Resin)

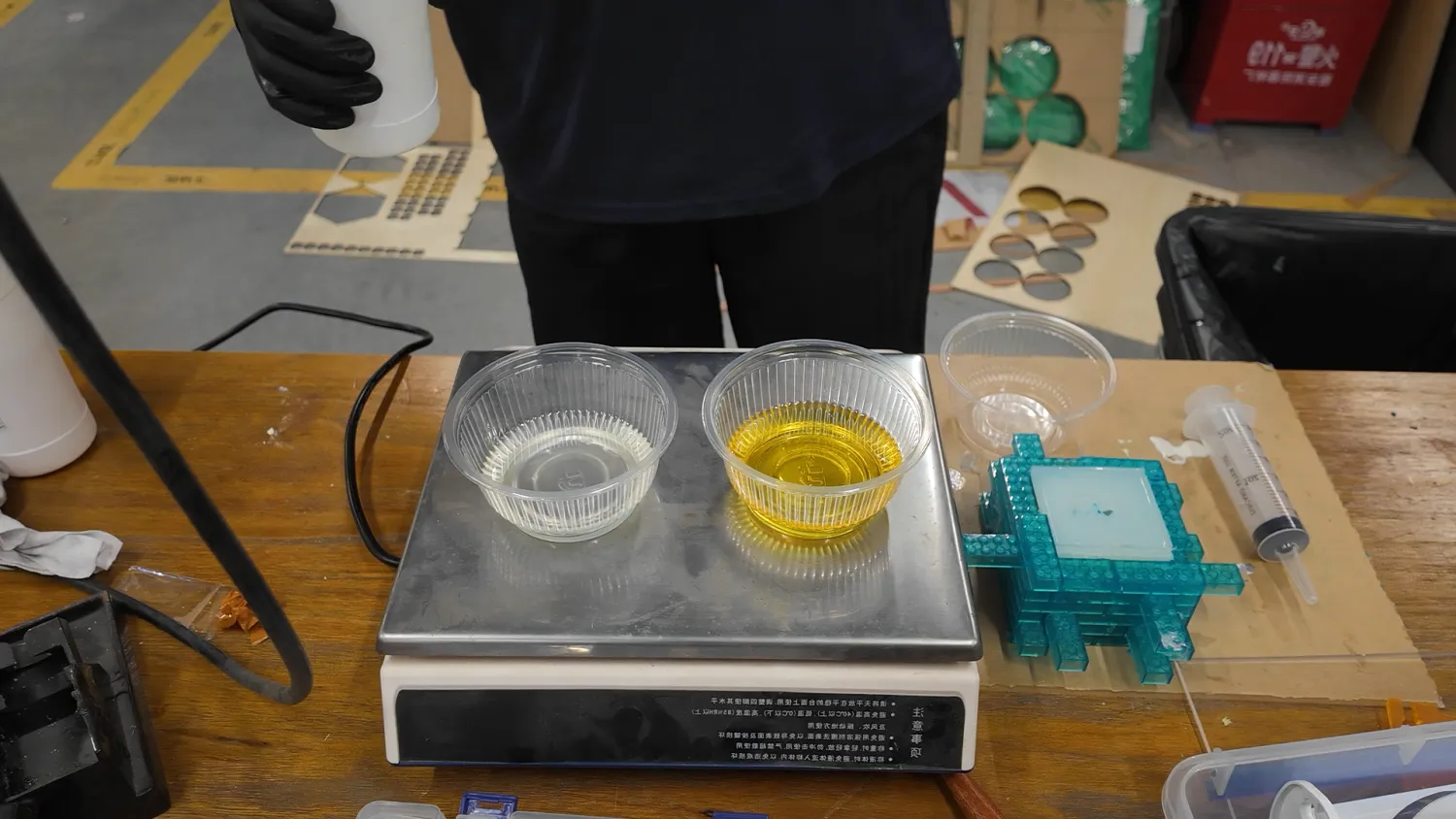

- Prepare AB resin components A and B at a 1:1 weight ratio

- Evenly apply release agent (vaseline) to the inside surface of the silicone mold

- Secure the mold with LEGO bricks

- Quickly mix components A and B in a clean container, controlling stirring time to 15-20 seconds

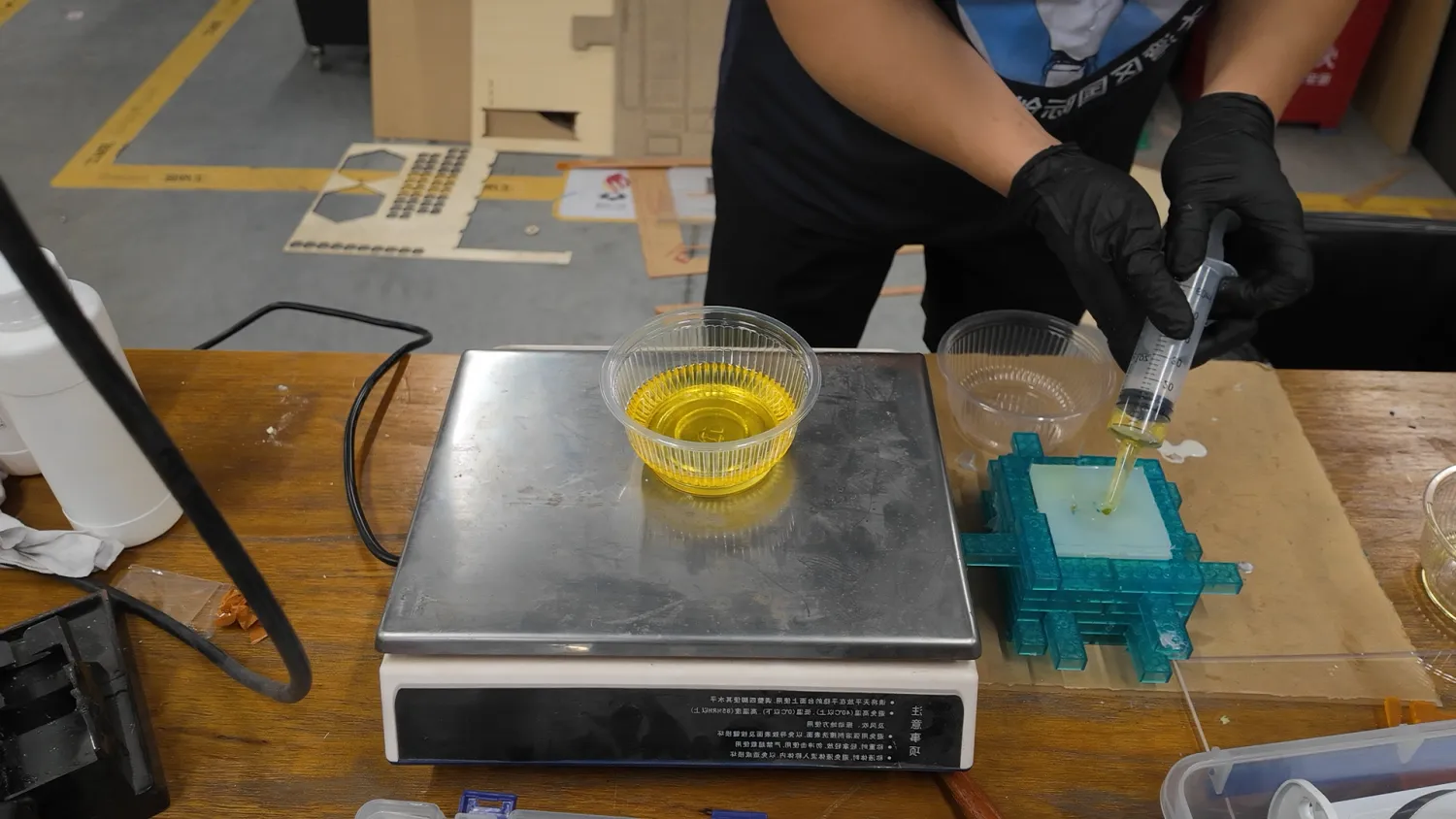

- Within the 1.5-2 minute working time, quickly use a plastic syringe to draw the mixed AB resin and inject it into the mold

For larger castings, we recommend using an electronic scale with tare function. To maintain a 1:1 weight ratio, first pour liquid A, note the weight, then add the same weight of liquid B.

Then pour one bowl directly into the other for mixing, quickly stir, then use a plastic syringe to inject into the mold until liquid flows out from both the injection hole and the air vent.

- Gently shake the mold to ensure the AB resin fills all details and expels air bubbles

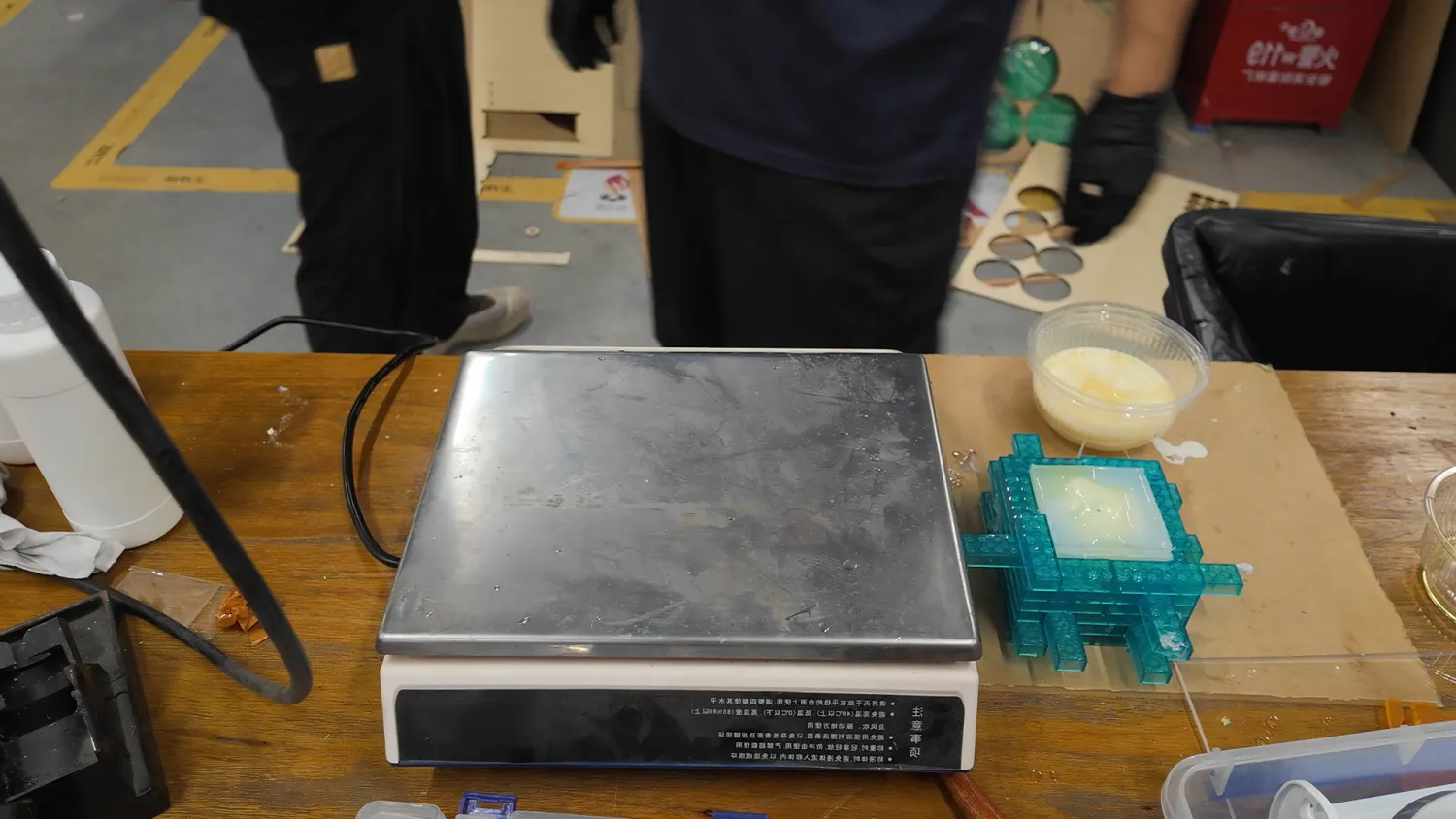

- Leave at room temperature for about 10-20 minutes, waiting for the AB resin to fully cure

Curing time is about 10-20 minutes. Since we didn't accurately estimate the amount of AB resin needed, there was still some leftover in the plastic bowl.

- Carefully remove the finished product from the silicone mold

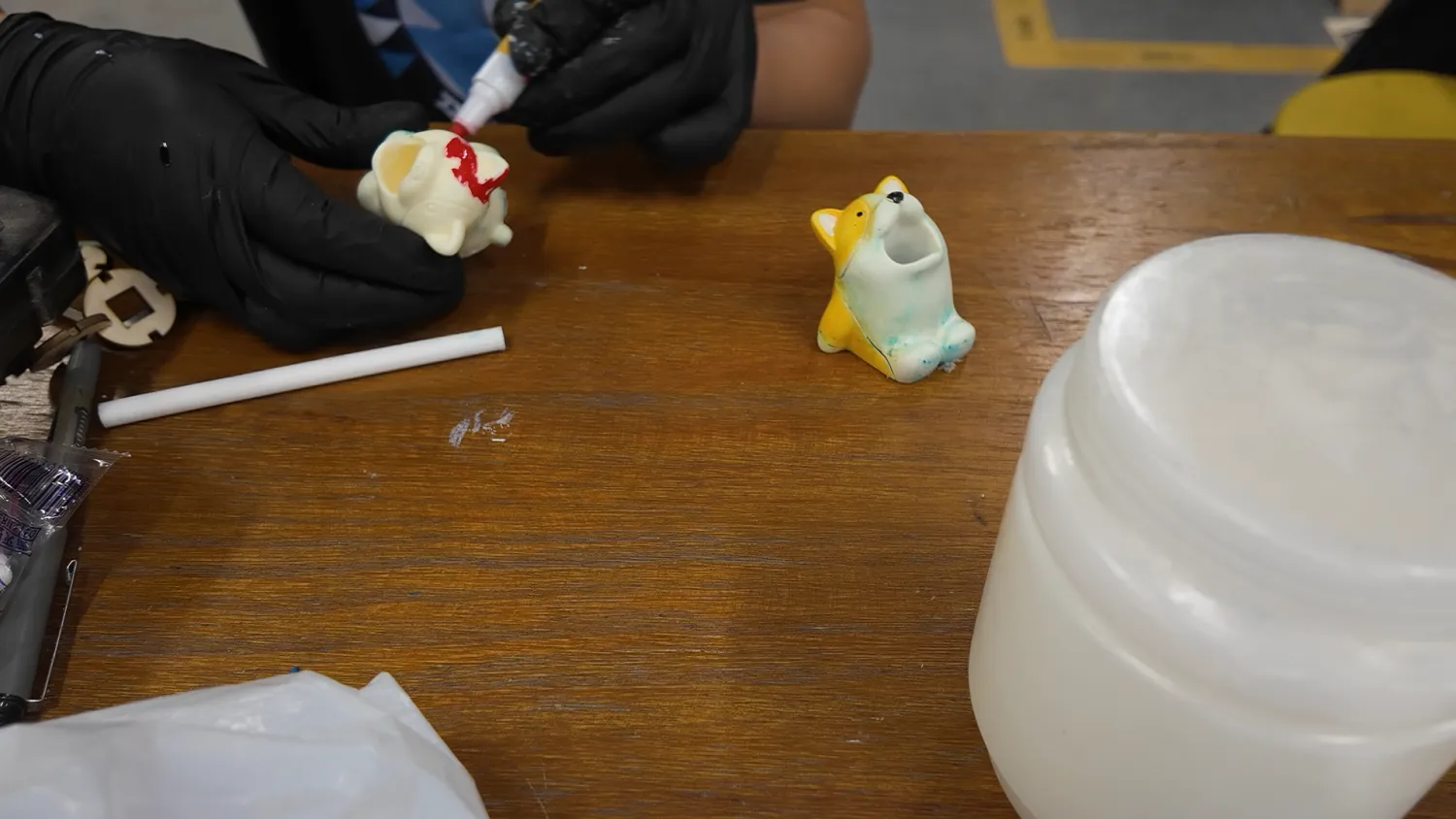

The removed mold looks very good, with a smooth and delicate surface.

We were very satisfied with the final product.

- Coloring

The colored replica (red) compared with the original (yellow)

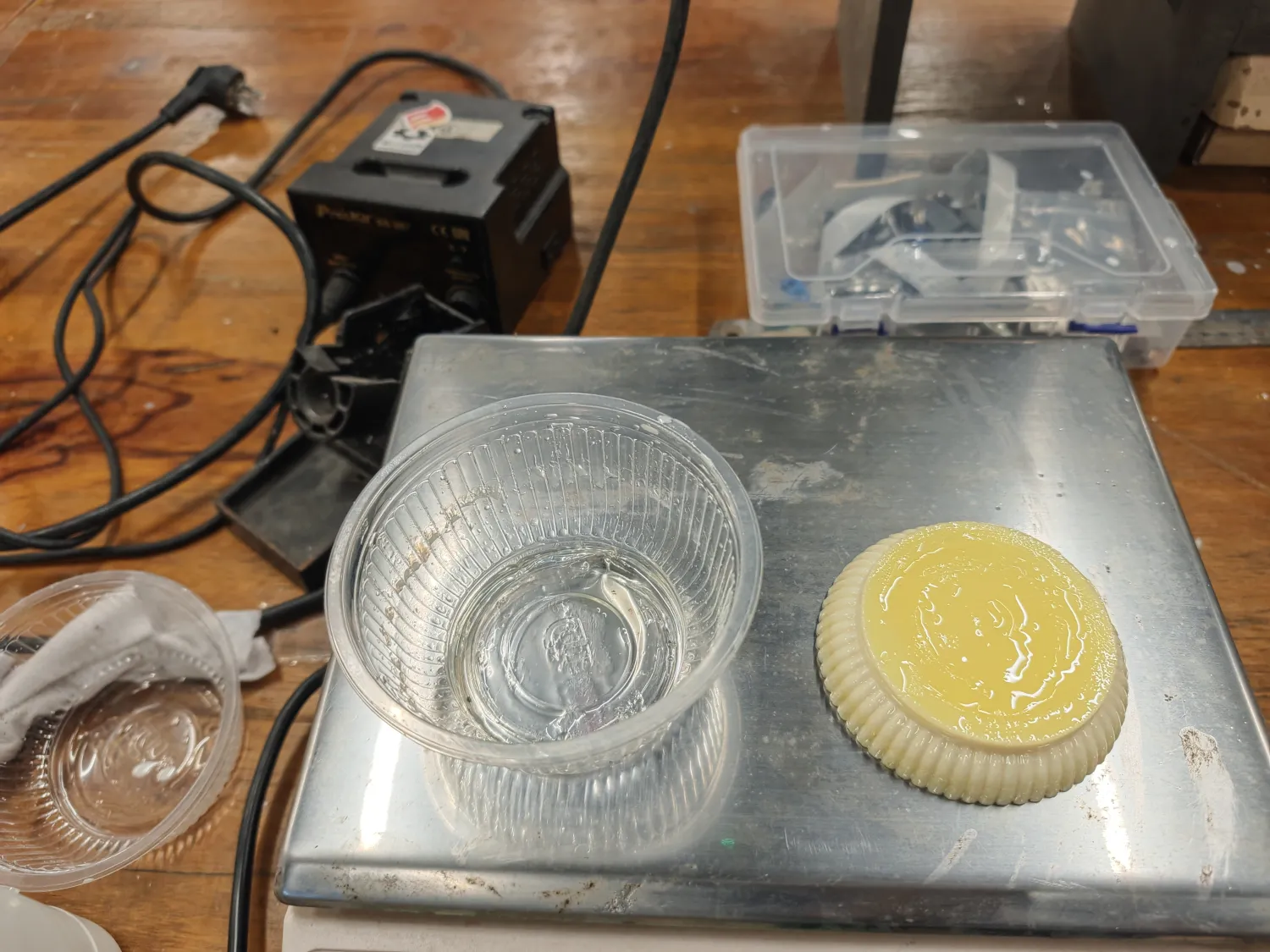

Unexpected Discovery: Smooth Surface Cast

After casting with AB resin above, the leftover resin in the plastic bowl also solidified. We tipped it out and were surprised to find that the "disc" had extremely smooth and rounded edges. This means that if the mold surface is smooth enough, the model obtained through AB resin will also have an excellent finish.

The smooth surface of the plastic bowl created this smooth surface on the leftover material.

Indium-Tin-Bismuth Alloy Tin Soldier Production Process

Preparation

- Check the indium-tin-bismuth alloy material

- Prepare the blue silicone mold (LEGO minifigure shape)

- Prepare hot water for melting the alloy

Alloy Melting

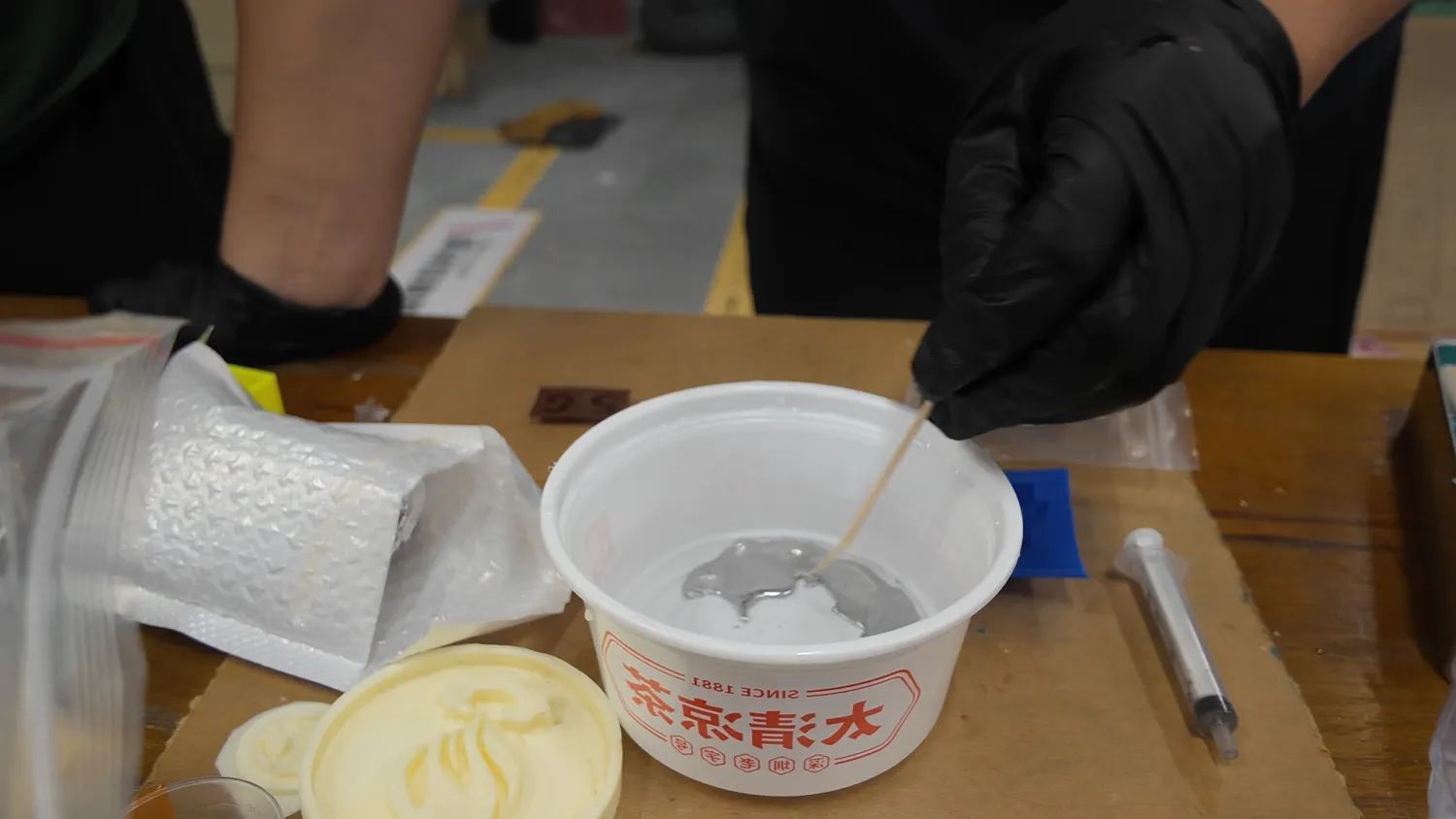

- We found a used plastic soup container, filled it with hot water, and placed the indium-tin-bismuth alloy in it

- Used hot water to indirectly heat the alloy

- Waited for the alloy to completely melt into liquid state (indium-tin-bismuth alloy has a melting point of only 47°C)

We found a used plastic soup container, filled it with hot water, then put the indium-tin-bismuth alloy in. It quickly turned into liquid metal.

Mold Preparation

- Ensure the mold surface is dry and clean

- Apply an appropriate amount of release agent (vaseline) to the inside surface of the mold

- Check if the detailed parts of the mold are intact

Casting Process

- Use a syringe to draw an appropriate amount of melted indium-tin-bismuth alloy

- Carefully inject the liquid alloy into the mold

- Gently shake the mold to ensure the liquid alloy fills all details

- Wait for the liquid alloy to cool and completely solidify (about 10-15 minutes)

Demolding and Post-Processing

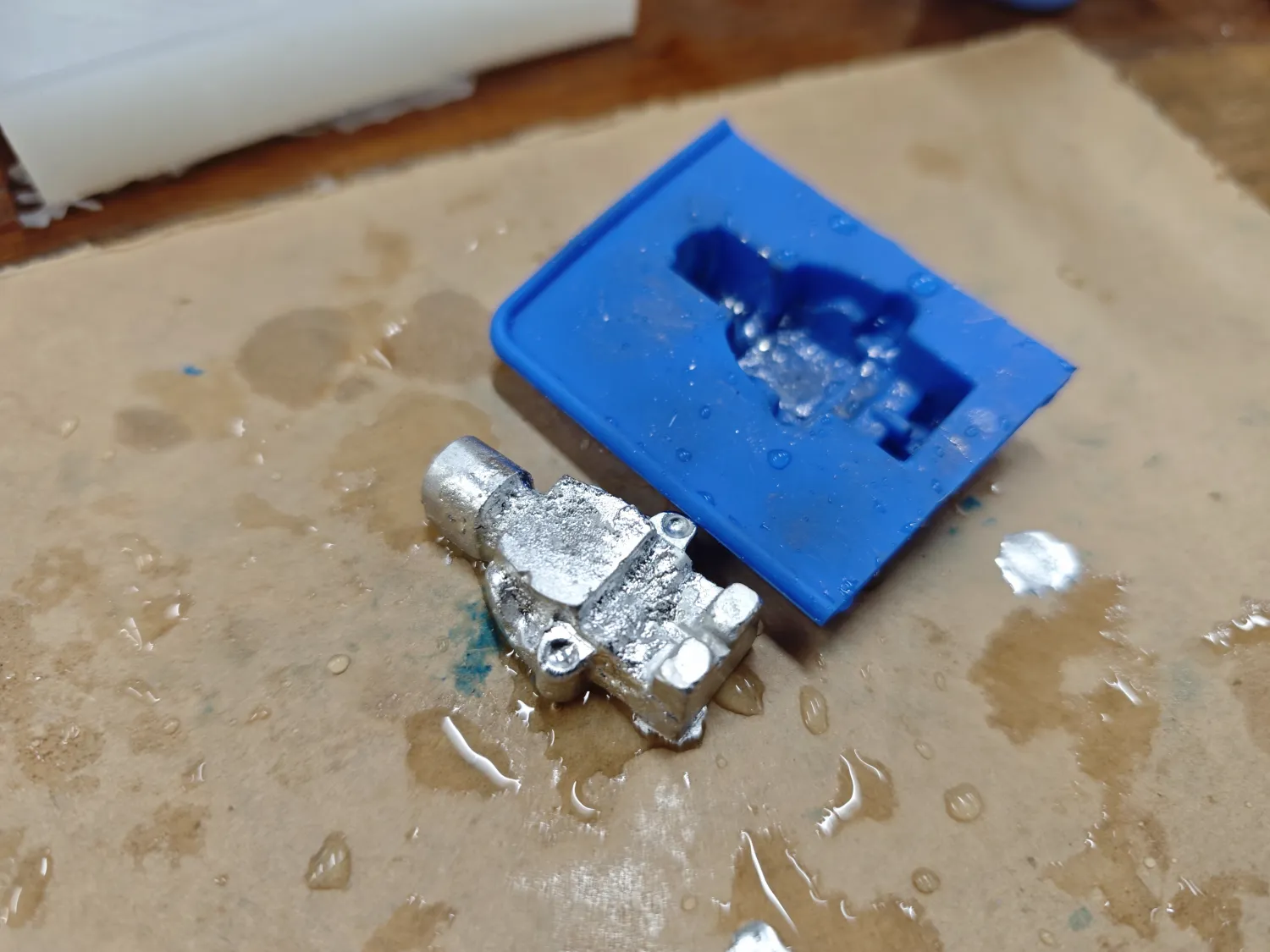

- Carefully remove the metal tin soldier from the mold

- Use metal files or other suitable tools to remove burrs and excess parts

- Check the completeness and detail reproduction of the finished product

The completed metal tin soldier and the mold. Unfortunately, there were still some bubbles causing surface imperfections. We tried several times but found it difficult to eliminate them completely.

Technical Points and Precautions

Silicone Mold Making Technical Points

- Accuracy of Mixing Ratio:

- Strictly follow the 100:2 ratio when mixing silicone and curing agent

- Incorrect ratios will affect curing effectiveness and strength

- Bubble Control:

- Stir in one direction to reduce bubble entry

- First brush a thin layer of silicone on the master mold, wait for bubbles to disappear before pouring the remaining silicone

- Gently shake the mold to help bubbles rise

- Consider reducing the curing agent ratio to extend curing time, allowing bubbles to naturally dissipate

- If available, use a vacuum machine to extract bubbles

- Operation Time: Silicone working time is about 5 minutes, sufficient for detailed molding

- Release Agent Usage: White vaseline should be applied thinly and evenly, as excess will affect detail reproduction

AB Resin Casting Technical Points

- Accuracy of Mixing Ratio:

- Strictly follow the 1:1 weight ratio when mixing components A and B; note that it's best to achieve 1:1 through weighing rather than using measuring cups

- Large weight discrepancies will lead to incomplete surface curing or color deviation

- Time Control:

- Complete the pouring operation within 1.5-2 minutes after mixing

- Control stirring time to 15-20 seconds

- Avoiding Bubbles:

- Use horizontal shear mixing rather than vertical stirring

- Pour in a thin stream

- Gently shake the mold to help bubbles rise

- Curing Time: About 10-20 minutes for complete curing at room temperature

- Moisture Prevention:

- Avoid AB liquid contact with moisture

- Especially component B, which easily reacts with moisture to produce white cloudy substance

- Safety Protection:

- Maintain good ventilation during operation

- Avoid direct skin contact, wear gloves if necessary

- The curing process generates heat, be careful to avoid burns

- Avoid early demolding that could cause product deformation

Low-Temperature Alloy Casting Technical Points

- Temperature Control:

- Heating temperature should not be too high, 47°C is sufficient for melting

- Maintain liquid state without overheating to avoid oxidation

- Injection Technique:

- Use a syringe to slowly inject the liquid alloy

- Avoid generating bubbles

- Cooling Time: Allow the alloy to cool completely before demolding to avoid deformation

- Safety Precautions:

- Although it's a low-temperature alloy, still handle carefully to avoid burns

- Maintain ventilation in the work environment

- Thoroughly clean tools and hands after operation

Results and Discussion

Dog Pen Holder Result Analysis

- Advantages:

- LEGO bricks provided a flexible and easy-to-disassemble mold frame

- The silicone mold well replicated the details of the prototype

- The silicone mold had good elasticity, making demolding easy without damaging the prototype

- The silicone mold can be reused multiple times

- AB resin cast products are easy to sand, convenient for post-processing

- Challenges:

- Silicone is prone to bubble formation during pouring

- LEGO frames need to be carefully constructed to ensure no leakage

- AB resin has a short working time (1.5-2 minutes) after mixing, requiring quick and accurate operation

- Need to avoid moisture contact with AB resin, especially component B

Indium-Tin-Bismuth Tin Soldier Result Analysis

- Advantages:

- Low-temperature alloy is easy to work with under simple conditions

- Excellent metallic appearance

- High detail reproduction

- Can be repeatedly melted and reused, environmentally friendly and economical

- Challenges:

- Injection process requires steady hand technique

- Small details (such as hands) are easily incomplete

- Demolding requires care to avoid damaging detailed parts

Comparison of the Two Techniques

- Material Comparison:

- Silicone molds have good elasticity, suitable for complex shapes, with long service life

- AB resin cures quickly, suitable for rapid product production, but has a small operation time window

- Low-temperature alloy is moderately priced and can be recycled multiple times

- Applicable Scenarios:

- Dog pen holder is suitable for making functional decorative items

- Tin soldier is suitable for making delicate decorative small objects

- Process Complexity:

- Silicone mold making process is relatively simple, but with long curing time, ample operation time

- AB resin casting requires high time control and operation speed

- Low-temperature alloy casting requires higher temperature control, but with less time pressure for operation

CNC Milling Mold Making Process Example

Wax Mold Milling Practice Flow

Below is my detailed process of making a badge wax mold using a CNC milling machine:

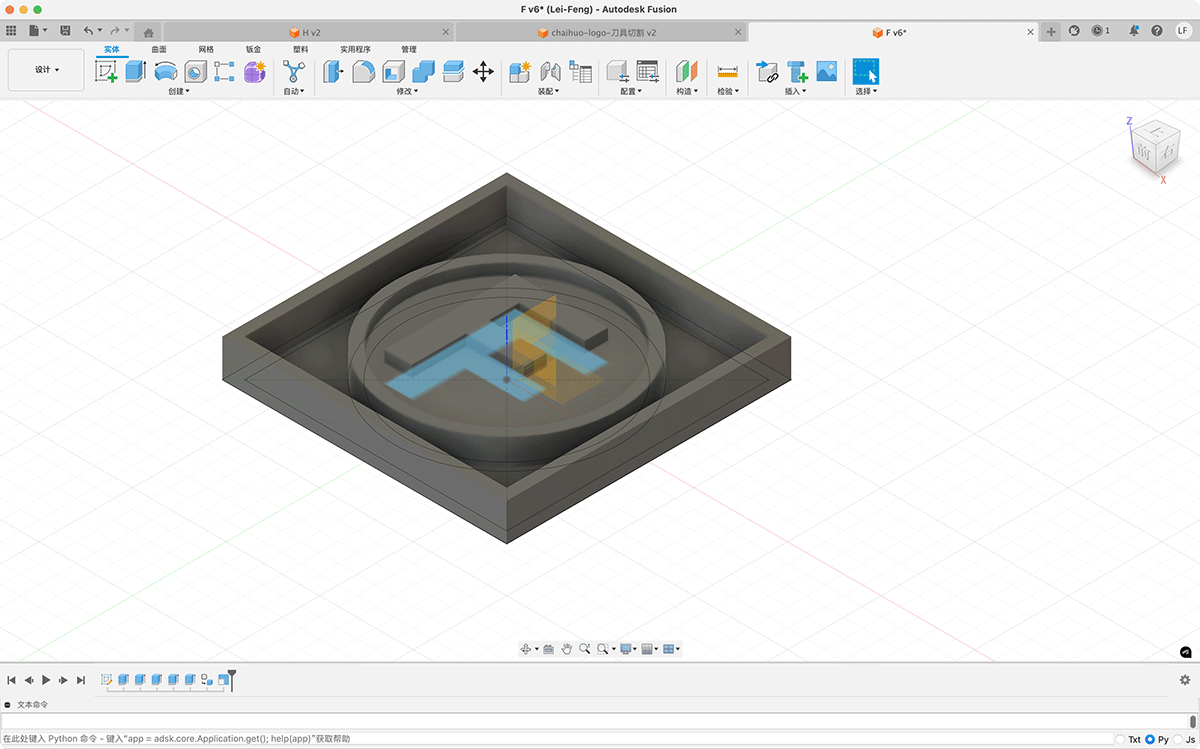

- Design Phase:

- Designed a badge with the letter "F" in Fusion 360

- Designed a 70mm square outer frame (the edge length range of our wax block), with the badge pattern in the middle

- Exported as STL file format

Designing F letter badge in Fusion 360

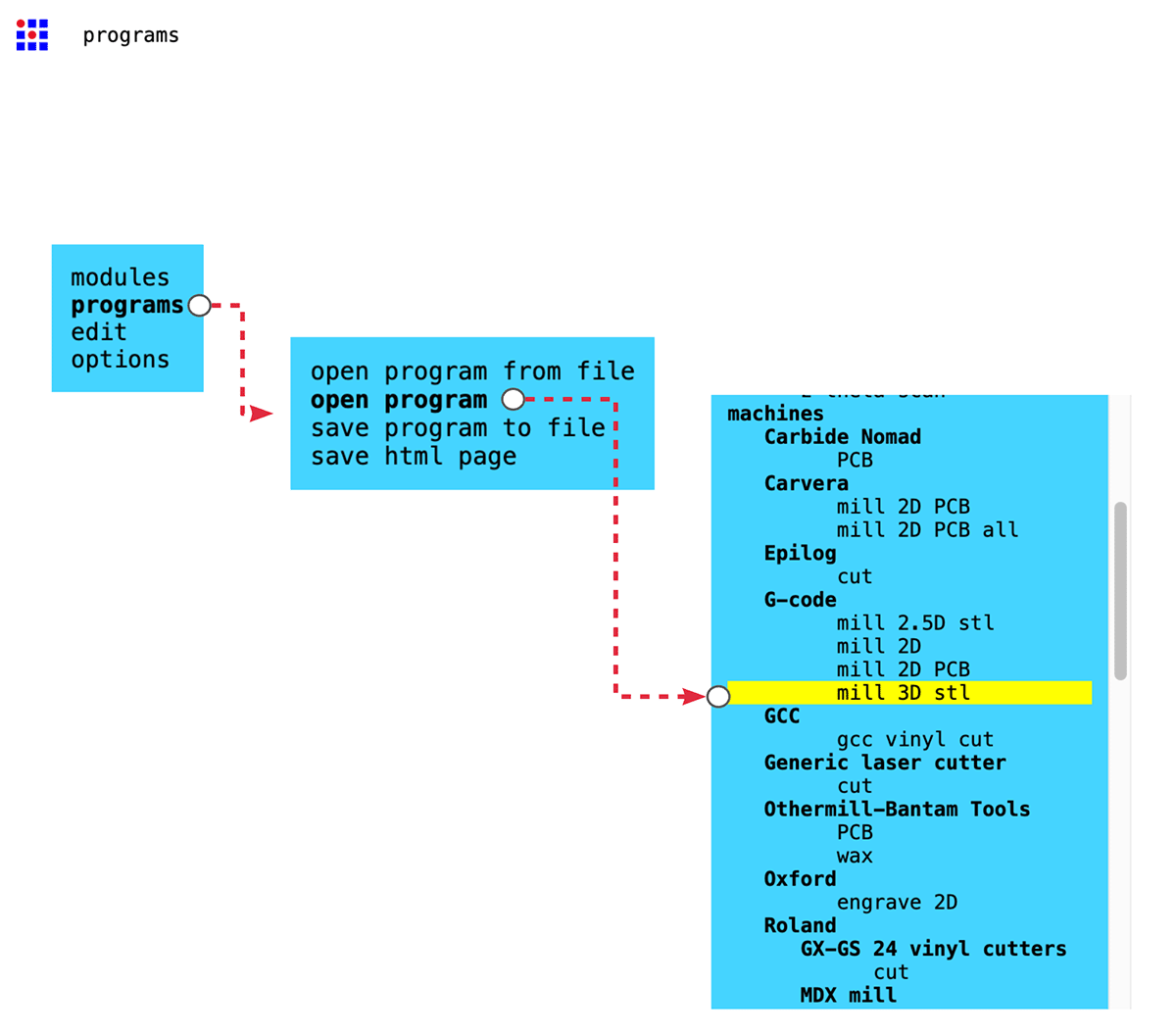

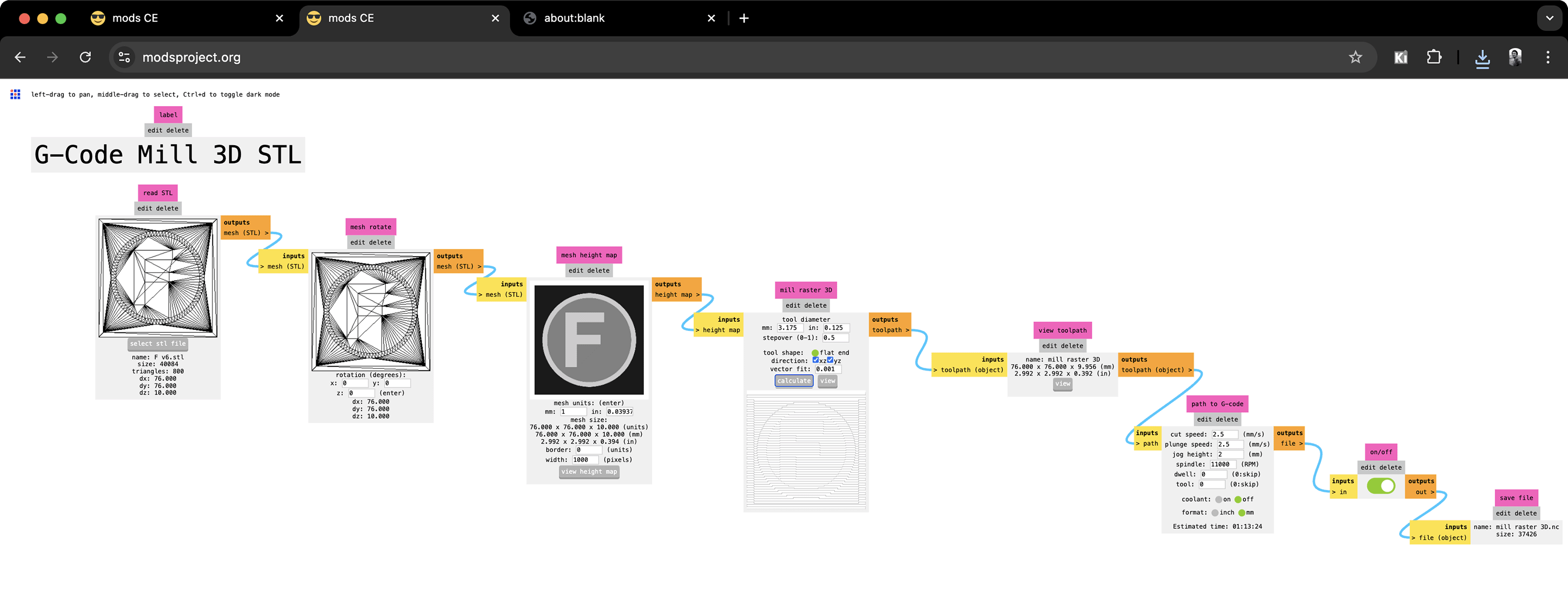

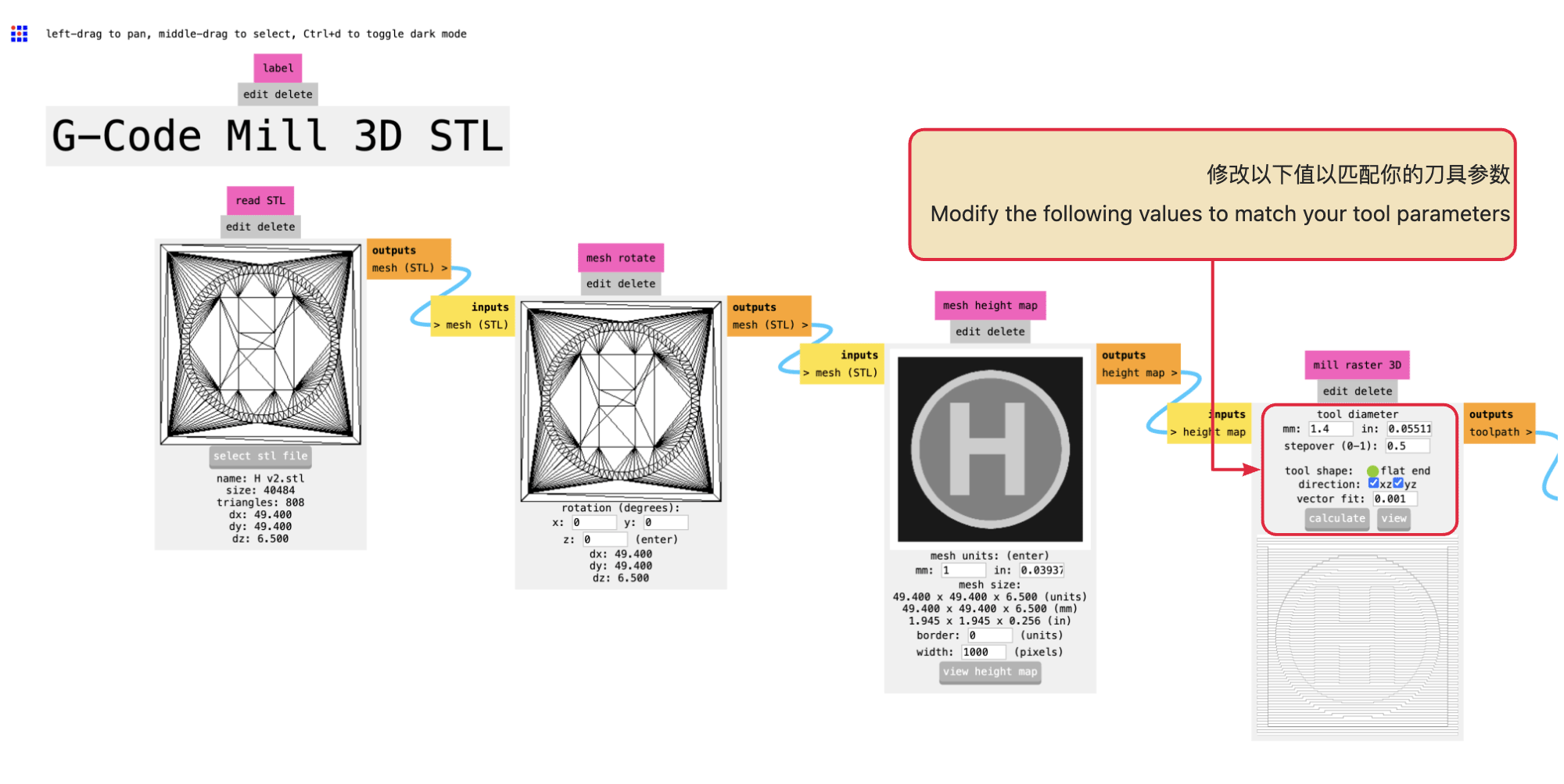

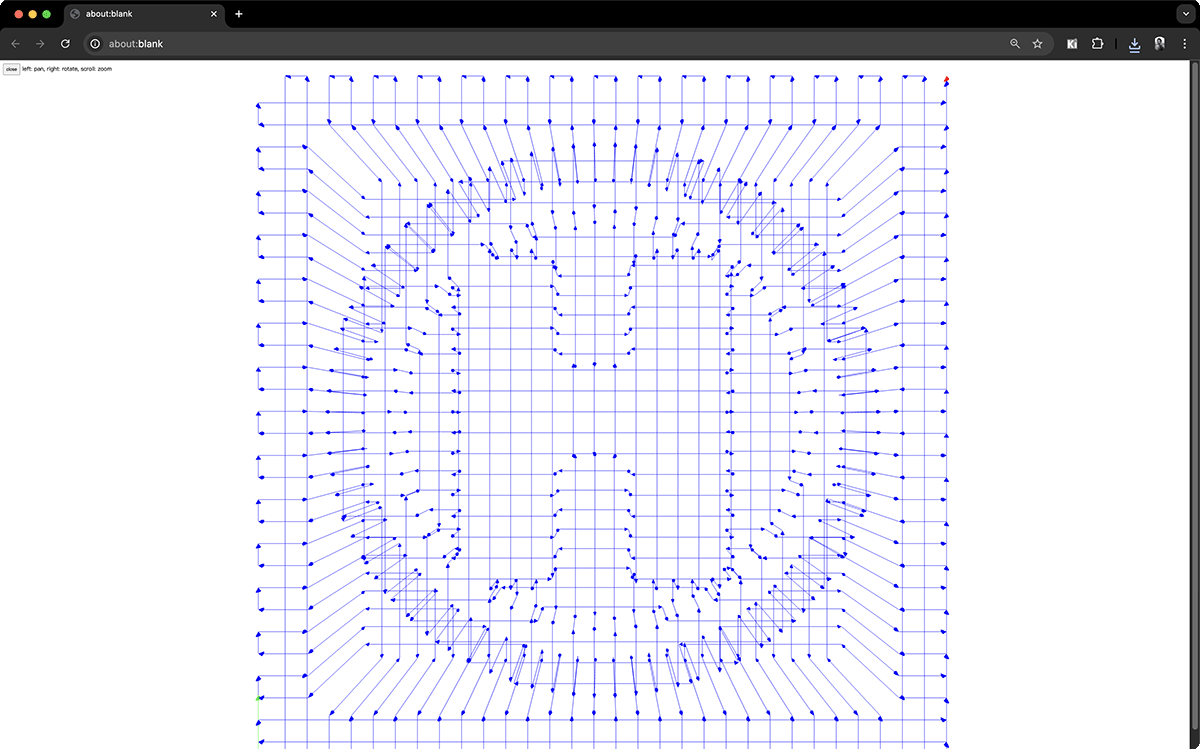

- Tool Path Generation:

- Visited the ModsProject website

- Right-clicked and selected: programs/open program/G-code/mill 3D stl/

Accessing programs/open program/G-code/mill 3D stl tool from the right-click menu

- In the program window, clicked "select stl file" to choose the exported STL file

- In "mesh units: (enter)", changed the value in the "mm:" field to 1, ensuring the model loads at original scale

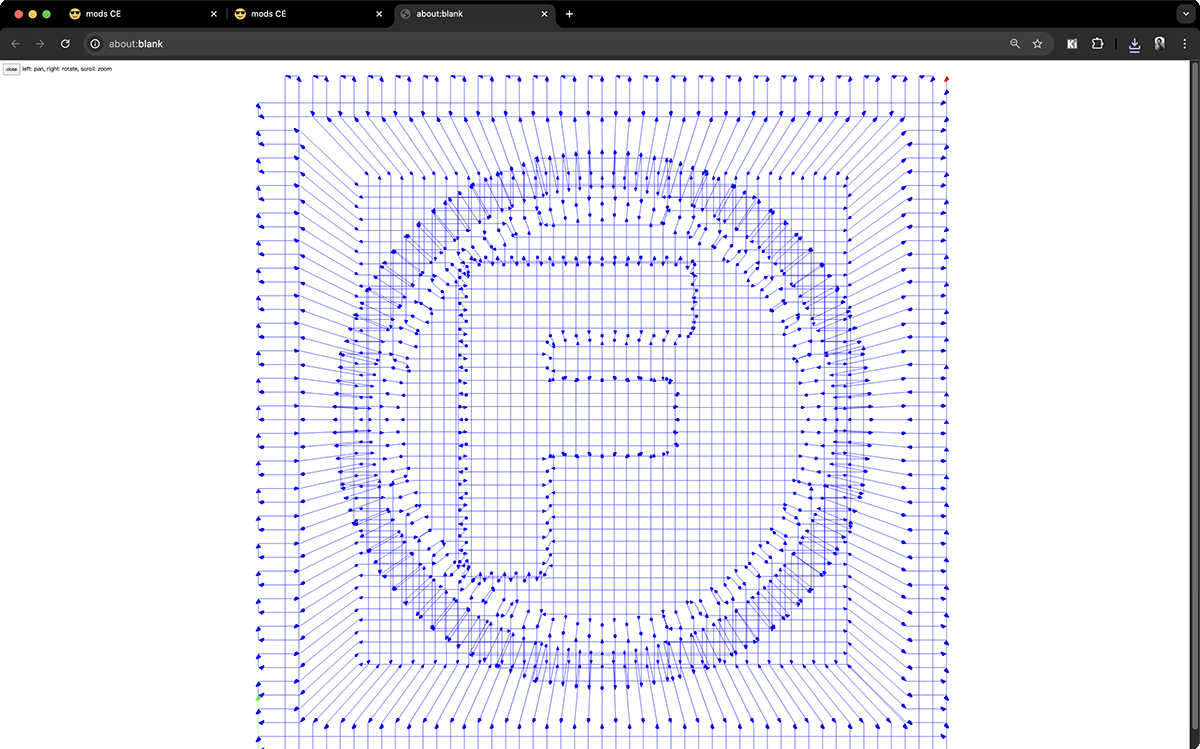

- Clicked the "calculate" button to preview the tool path and automatically download the .nc file

Loading STL file and calculating tool path

The calculated tool path is automatically downloaded as a .nc file

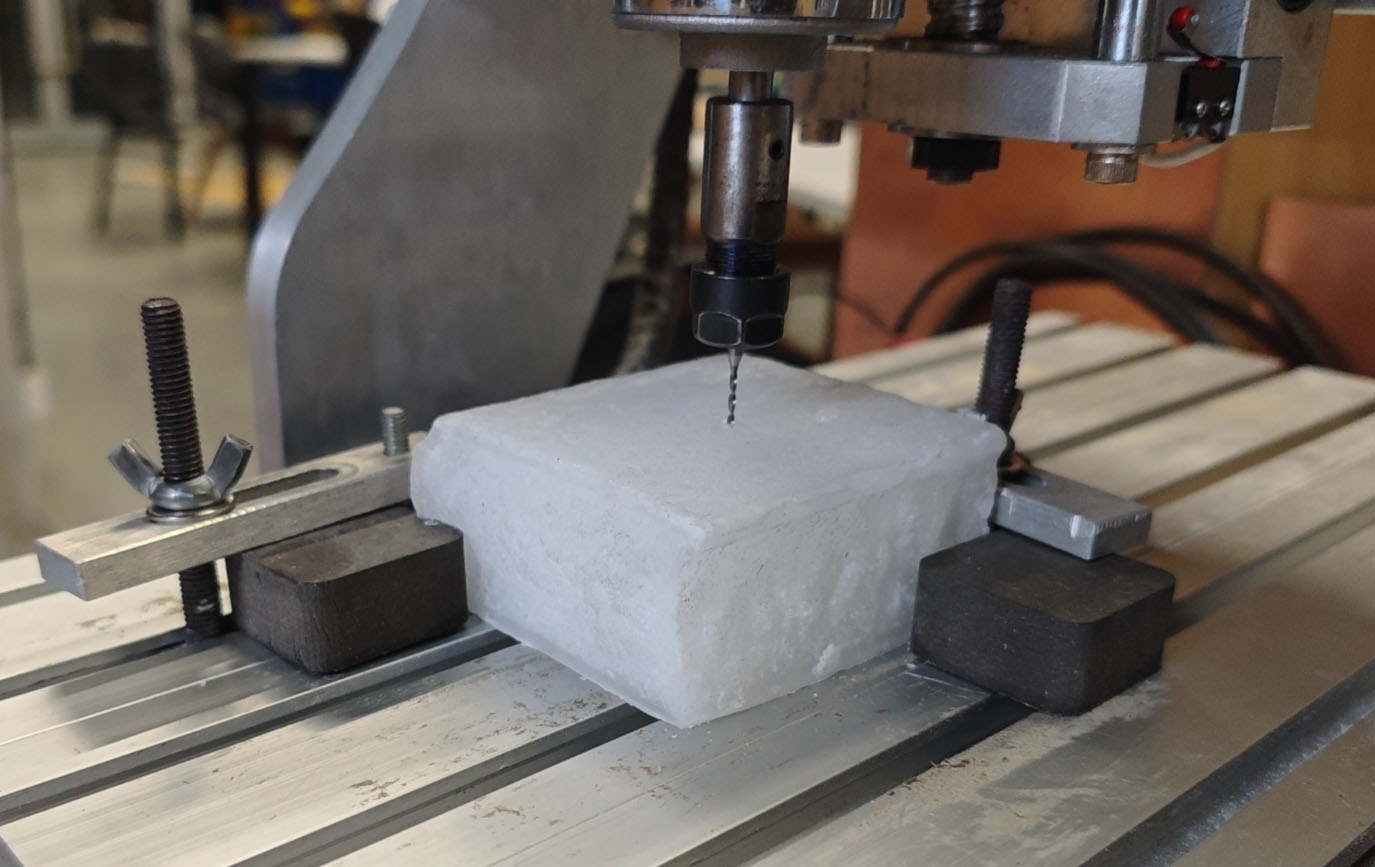

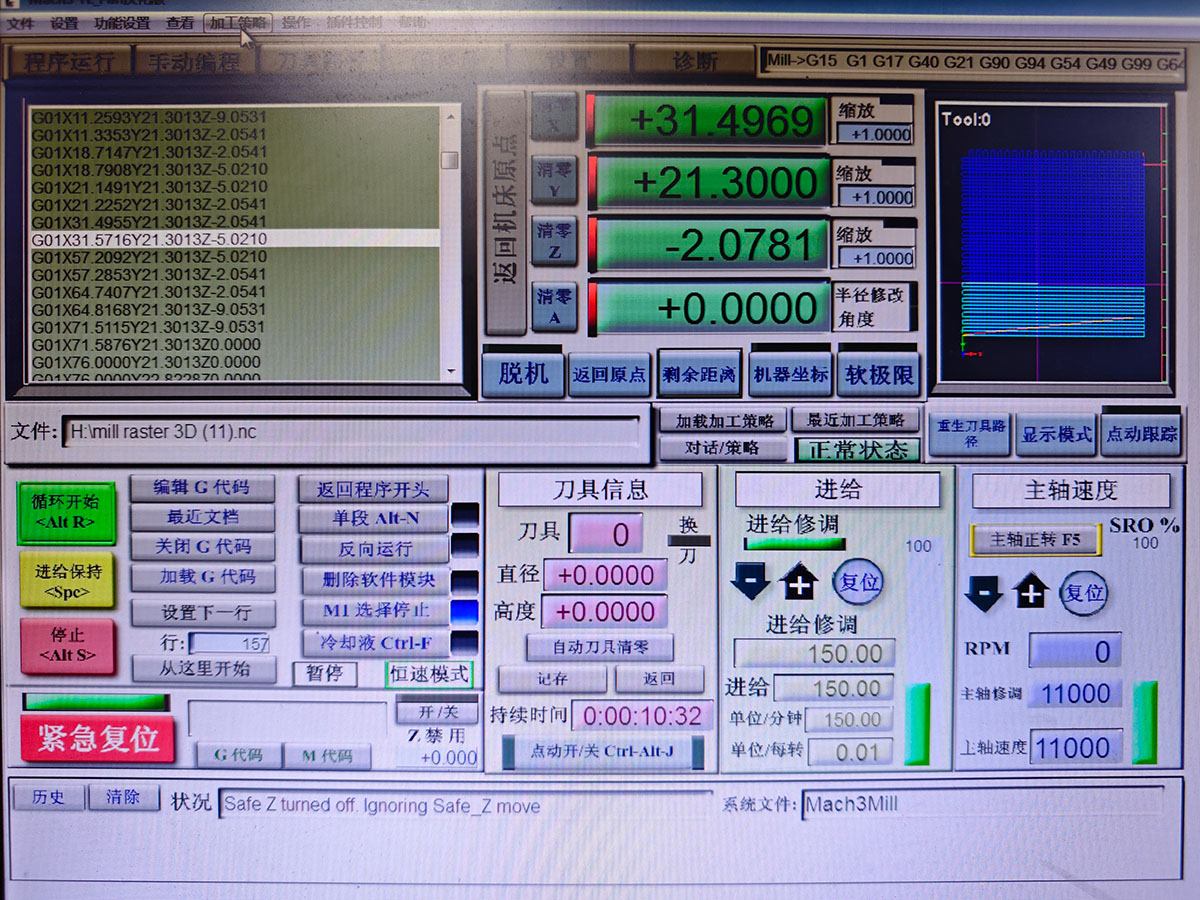

Machine Setup and Processing:

- Started Mach3 software on the computer connected to the CNC milling machine

- Loaded the generated .nc file

- Found a good method to secure the thick wax block

Securing the wax block with 4 wooden blocks and clamps

- Selected and installed an appropriate tool: 38mm long, 1.4mm blade diameter, 10mm blade length, 3mm shaft diameter flat end mill

This time trying a φ1.4mm tool

- Set the machining origin and parameters

- Started the cutting process

Starting cutting in Mach3

First Processing and Adjustment:

- Discovered the wax block width was slightly insufficient, causing one edge of the model's barrier to be missing

- Used a brush and small scraper to carefully clean the mold surface

Using a brush and small scraper to carefully clean the mold surface

Looks good, except the tool path marks are a bit obvious

Making a Slightly Smaller H Badge Again

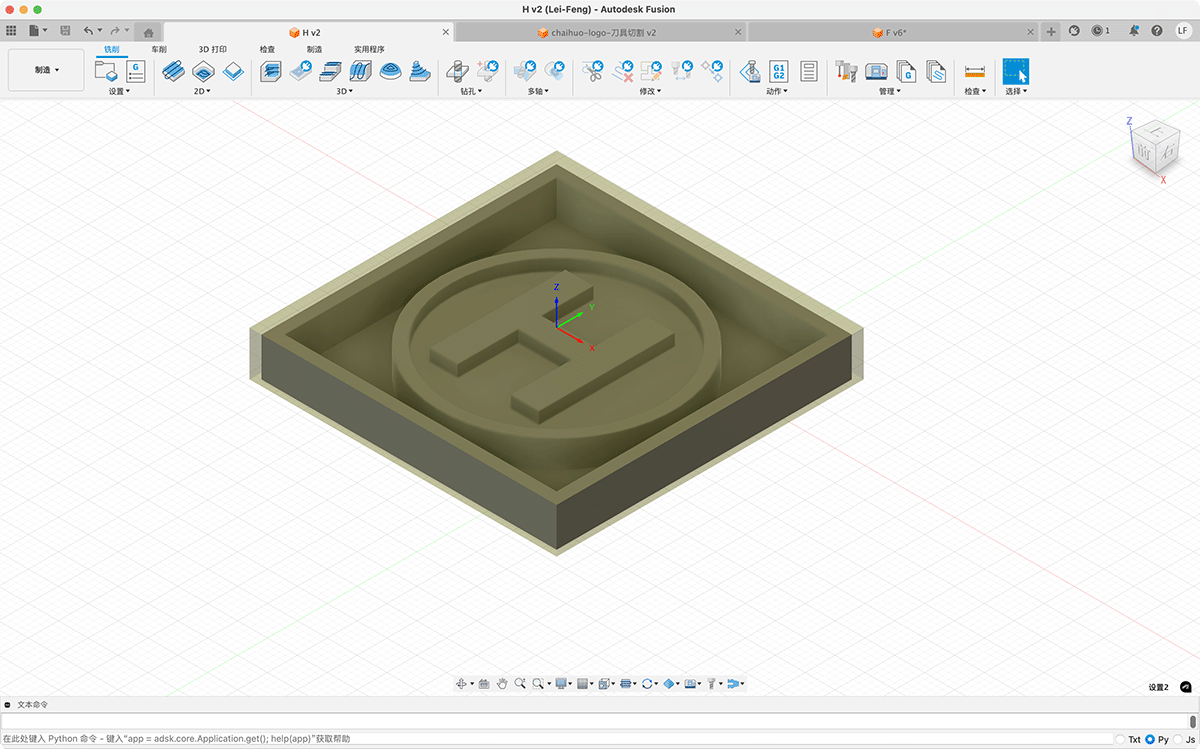

- Returned to Fusion 360, modified design parameters, created a smaller "H" letter badge

- Reduced the model to a 50mm square outer frame, exported STL again

Creating another 50mm frame H badge

- Repeated the tool path generation steps, remembering to modify tool settings, then obtained a new .nc file

Modify the following values to match your tool parameters:

- tool diameter: Change the value in the "mm:" field from the default 3.175 to 1.4 (your blade diameter)

- stepover: Can be adjusted as needed, default is 0.5 (indicating each lateral movement is 50% of the tool diameter)

- tool shape: Ensure "flat end" is selected, the interface has already selected this option

- direction: Keep the default xyz/z setting unless you have specific requirements

- vector fit: Keep the default value of 0.001, this is a precision setting

After modifying all parameters, click the "calculate" button below to recalculate the tool path.

Exporting the H badge tool path

- Used Mach3 for the second cutting, this time the cutting range didn't exceed the wax block boundaries

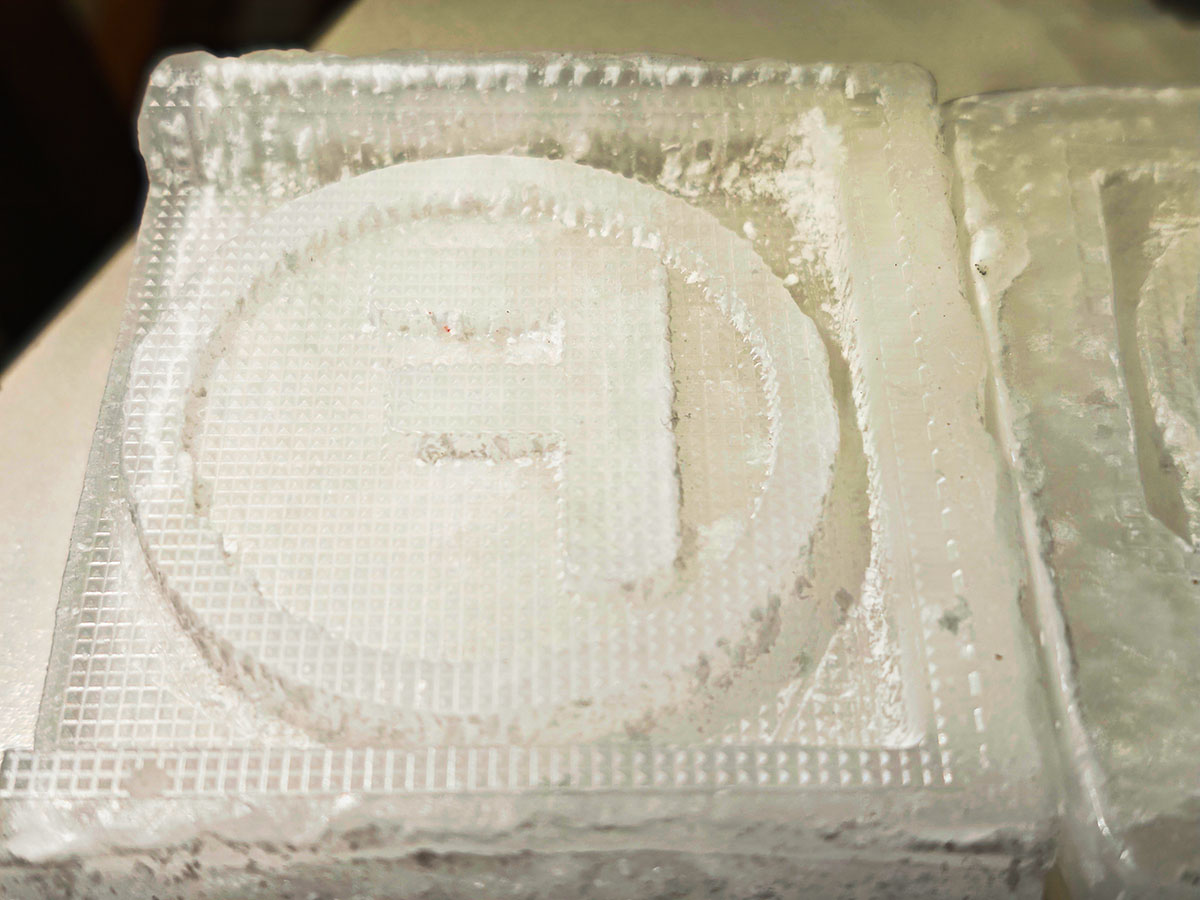

The range control was better when cutting the H badge mold

Post-processing:

- Due to the soft nature of wax, processing residue sticks to the mold

- Used a brush and small scraper to carefully clean the mold surface

Silicone Mold Making:

- For the "F" badge missing a barrier, manually added a barrier using clay

- Mixed silicone and hardener, poured onto the 2 wax molds

On the left is the slightly smaller H badge wax mold, on the right is the slightly larger F badge wax mold. Since the F badge wax mold was missing a barrier, I built a barrier with clay and LEGO bricks, then poured silicone mixed with hardener on both wax molds

- Waited 24 hours for complete curing

- Removed the silicone molds

The wax molds above and the cured silicone molds below. From the mold quality, I think the larger F badge quality is better

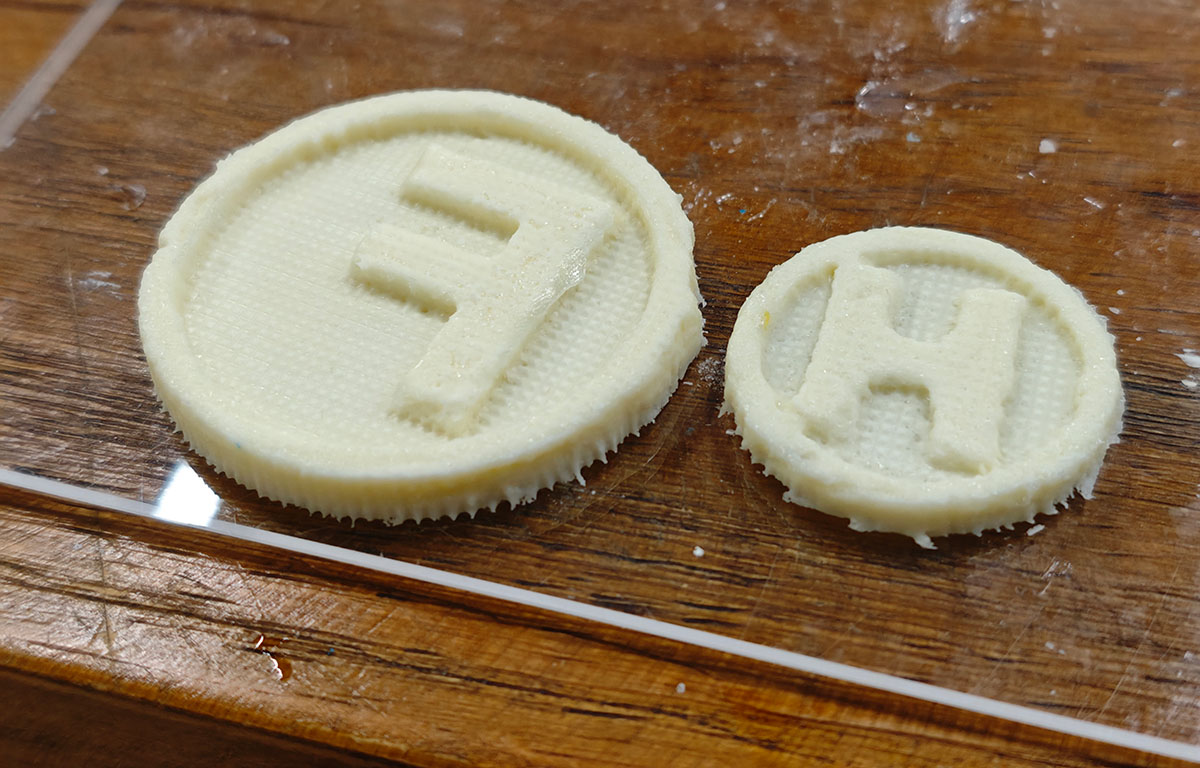

Final Casting:

- Used polyurethane resin mixed 1:1 by weight to pour into the silicone molds

Pouring 1:1 weight-mixed polyurethane resin into silicone molds

- Obtained the final "F" and "H" badge products, but at this point we discovered that the cut wax molds had become negative molds, causing the final F badge to also be reversed.

Strangely, our F badge was clearly a positive model, but the cut wax mold became a negative mold, and the final badge cast with polyurethane resin also became reversed

The larger F badge effect seems to be a bit better, though the surface cutting path marks are obvious.

The larger F badge effect seems better, though the cutting path marks are obvious on both badges

3D Printing Mold Making Process Example

See personal assignments:

- Lei Feng: Personal Assignment: Molding and Casting (Chinese version)

- Hongtai Liu: Molding and Casting: Fabricating FabLab Badge Coins

Detailed Comparison of 3D Printing and Milling Molds

Geometric Complexity and Precision

| Feature | 3D Printing | CNC Milling |

|---|---|---|

| Complex Geometric Shapes | ✅ Can create almost any complex shape, including internal structures, overhangs, curves, and organic shapes | ⚠️ Limited by tool accessibility, difficult to process deep grooves, sharp angles, internal cavities, etc. |

| Fine Details | ⚠️ Depends on printing technology, FDM precision is lower, SLA/DLP/SLS can achieve higher precision | ✅ Can achieve extremely high precision (0.01mm level), good surface smoothness, but tool path marks may be obvious if not well controlled |

| Dimensional Accuracy | ⚠️ May be affected by material shrinkage, warping, etc., requires calibration | ✅ High precision, good stability |

| Surface Quality | ⚠️ Layer lines obvious (FDM) or requires post-processing | ✅ High surface smoothness, can be used directly as molds |

| Internal Structure | ✅ Can create complex internal structures and channels | ❌ Difficult to create invisible internal structures |

Materials and Durability

| Feature | 3D Printing | CNC Milling |

|---|---|---|

| Material Selection | ⚠️ Limited, mainly various plastics, some metals and ceramics | ✅ Extensive, almost all solid materials: metals, plastics, wood, wax, stone, etc. |

| Material Strength | ⚠️ Weak interlayer bonding strength, anisotropic | ✅ Maintains original material strength, isotropic |

| Heat Resistance | ❌ Most printed materials have limited heat resistance | ✅ Can process high-temperature materials such as metals, ceramics, etc. |

| Durability | ⚠️ Medium, depends on material and process | ✅ High, especially metal molds |

| Water Resistance | ⚠️ Requires post-processing | ✅ Good, determined by material properties |

Production Efficiency and Cost

| Feature | 3D Printing | CNC Milling |

|---|---|---|

| Preparation Time | ✅ Short, only requires 3D model and slicing | ⚠️ Longer, requires CAM programming and tool planning |

| Production Speed | ⚠️ Slow, especially high-precision printing | ✅ Fast, especially for simple shapes |

| Prototype Iteration | ✅ Rapid, easy to modify designs | ⚠️ Each iteration requires reprocessing |

| Small Batch Production | ✅ Economically efficient | ⚠️ Higher cost |

| Large Batch Production | ❌ Uneconomical, slow speed | ✅ Fast speed, reduced cost |

| Equipment Cost | ✅ Low to medium (home printers are inexpensive) | ❌ High (professional CNC equipment is expensive) |

| Material Cost | ⚠️ Specialized materials relatively expensive | ✅ Standard materials, controllable cost |

| Labor Cost | ✅ Low, simple operation | ❌ High, requires professional skills |

| Waste Generation | ✅ Little, mainly support structures | ❌ High, cutting process generates substantial waste |

Operation and Maintenance

| Feature | 3D Printing | CNC Milling |

|---|---|---|

| Operation Complexity | ✅ Simple, low entry barrier | ❌ Complex, requires professional knowledge |

| Equipment Size | ✅ Small, desktop devices usable | ❌ Large, requires dedicated space |

| Noise and Pollution | ✅ Low noise, slight odor | ❌ High noise, dust or cutting fluid pollution |

| Equipment Maintenance | ✅ Relatively simple | ❌ Complex, requires regular servicing |

| Safety Risk | ✅ Low | ❌ Medium to high (high-speed rotating tools) |

| Supervision Requirements | ⚠️ Medium, may need to monitor printing process | ✅ Once set up, lower supervision needed |

Suitable Mold Types

| Mold Type | 3D Printing | CNC Milling |

|---|---|---|

| Prototype Verification Molds | ✅ Excellent | ⚠️ Feasible but costly |

| Low-Pressure Injection Molds | ✅ Suitable for small batches | ✅ Suitable for medium to large batches |

| Silicone/Soft Mold Masters | ✅ Very suitable | ✅ Very suitable |

| Metal Casting Molds | ⚠️ Only suitable for low-temperature alloys | ✅ Suitable for various metal castings |

| Food-Grade Molds | ⚠️ Requires specialized food-grade materials | ✅ Can process food-grade stainless steel, etc. |

| Large Molds | ❌ Limited by printing space | ✅ Can process large molds |

| Precision Molds | ⚠️ Depends on printing technology | ✅ High precision |

| Transparent Molds | ⚠️ Limited choices | ✅ Can process transparent materials like acrylic |

Lessons Learned in Wax Mold Making

Advantages of Using Wax Material for Milling

In practical operation, using wax material for milled mold making has the following advantages:

- Easy to Process: Wax material is soft, processing is fast, and tool wear is minimal

- Low Cost: Wax material is inexpensive, suitable for multiple attempts and learning

- Easy to Modify: After processing, can be fine-tuned or repaired with hand tools

- Environmentally Friendly: Waste can be recycled and reused

- Good Detail: Soft wax can achieve good surface smoothness

Challenges Encountered in Practice and Solutions

During the wax mold milling process, I encountered several challenges and took corresponding solutions:

- Size Planning Issue:

- Challenge: The wax block size was insufficient in the first processing, causing missing model barrier

- Solution: Redesigned a smaller model and confirmed adequate material size before processing

- Experience: Always reserve sufficient edge space for models

- Material Cleaning Issue:

- Challenge: Wax is relatively soft, after cutting it sticks to the mold

- Solution: Used brush and small scraper to carefully clean

- Experience: Prepare appropriate cleaning tools, patiently perform post-processing

- Local Defect Repair:

- Challenge: One model was missing a barrier

- Solution: Used clay to manually add a barrier to the F badge missing an edge

- Experience: Combining digital manufacturing and manual craftsmanship can be complementary

- Tool Selection:

- Challenge: Need suitable tools for soft materials

- Solution: Used a 38mm long, 1.4mm blade diameter, 10mm blade length, 3mm shaft diameter flat end mill

- Experience: Select appropriate tool parameters based on material characteristics

Decision Guide for Choosing Appropriate Technology

When to Choose 3D Printing

In the following situations, 3D printing is a better choice for mold making:

- When the mold has extremely complex geometric shapes or internal structures

- When budget is limited, without access to professional CNC equipment

- When rapid prototype iteration is needed

- When batch size is small and customization requirements are high

- When the operator lacks CNC programming and operation experience

- When there are strict limitations on noise and dust

- When all work needs to be completed in a small space

When to Choose CNC Milling

In the following situations, CNC milling is a better choice for mold making:

- When high precision and high surface smoothness molds are needed

- When molds need to use special materials (such as metals, high-strength plastics, etc.)

- When molds need to withstand higher temperatures or pressure

- When mold size is relatively large

- When large batch production of identical molds is needed

- When mold design is relatively simple (no complex internal structures)

- When project budget is sufficient, focusing on final quality

Application of Mixed Methods

In practical projects, combining both technologies often achieves the best results:

- Use 3D printing to quickly verify design concepts

- Use milling technology to make high-precision molds for final use

- 3D print complex parts, mill simple parts, then assemble

- 3D print sacrificial models, then use for casting processes

Material Safety Data Sheet Assessment

In the process of mold making and casting, correctly understanding and following the guidance of material safety data sheets (SDS) is very important, not only for the operator's health and safety but also affecting the quality of the final product. Below is a safety information assessment of the main materials used in this project:

Silicone Rubber Safety Assessment

The silicone rubber hardener usage ratio is 100:2, with an operation time of about 5 minutes. According to safety data sheet analysis:

Hazard Identification:

- Low toxicity, but avoid prolonged skin contact

- Releases small amounts of volatile substances during curing, operate in ventilated environments

- Not flammable, but avoid contact with open flames

Protection Measures:

- Wear nitrile or latex gloves for operation

- Work in a well-ventilated environment

- If accidental skin contact occurs, immediately wash with soap and water

- Avoid eye contact during operation, recommend wearing goggles

Storage Requirements:

- Shelf life is 6 months

- Store in a cool, dry place, avoid direct sunlight

- Seal container to prevent air and moisture entry causing curing

Polyurethane Resin (AB Liquid) Safety Assessment

AB liquid weight mixing ratio is 1:1, curing within 1.5-2 minutes after mixing. The safety data sheet shows:

Hazard Identification:

- Component B contains isocyanates, may cause respiratory and skin sensitization

- Curing reaction releases heat, may cause temperature rise leading to burns

- Reaction with water produces carbon dioxide gas, may cause pressure increase in sealed containers

Protection Measures:

- Must wear protective gloves and goggles

- Operate in a well-ventilated environment

- Moisture adversely affects the quality of both A/B liquids, absolutely avoid introducing water

- Component B will react with moisture to produce white turbidity or cure

First Aid Measures:

- Skin contact: Immediately wash with plenty of water and soap

- Eye contact: Rinse with flowing water for at least 15 minutes, seek medical treatment

- Inhalation: Move to fresh air, seek medical attention if symptoms persist

Storage Precautions:

- Recommended to use the product within 3 months of receipt

- Component A will shrink, component B will expand, do not store for long periods to avoid bottle cracking and leakage

- After use, please clean the bottle mouth, seal it, and store in a dry, dark place away from direct sunlight

White Vaseline Release Agent Safety Assessment

Hazard Identification:

- Low toxicity, high chemical stability

- Not flammable, not corrosive

Protection Measures:

- Avoid prolonged skin contact

- Use dedicated tools (clean soft brush) to apply evenly

- Wash hands after operation

Storage Requirements:

- Store sealed at room temperature

- Avoid contamination

Indium-Tin-Bismuth Low-Temperature Alloy Safety Assessment

This alloy has a melting point of only 47°C. Safety data sheet information is as follows:

Hazard Identification:

- Molten state may cause minor burns

- Vapor may contain metal oxides, excessive inhalation is harmful

- Long-term contact may cause skin sensitization

Protection Measures:

- Despite being a low-temperature alloy, using heat-resistant gloves during operation is still recommended

- Avoid contact between molten alloy and water, splashing may occur

- Operation environment should be well-ventilated

- Avoid inhaling possible fumes

First Aid Measures:

- Skin burn: Immediately rinse with cold water, do not use ice

- Fume inhalation: Move to fresh air

- Accidental ingestion: Drink plenty of water, seek medical treatment

Environmental and Disposal:

- Metal can be 100% recycled and reused

- Waste should be collected and remelted for use

- Avoid release into the environment

Industrial Wax Safety Data Sheet Assessment

Industrial wax is a commonly used material in milled mold making, with easy processing and low cost characteristics. According to safety data sheet analysis:

Hazard Identification:

- Low toxicity, stable at normal temperature

- May release hydrocarbon vapors when heated to high temperatures, avoid inhalation

- Molten state may cause minor burns

- Not flammable in solid state, but combustible in molten state

Protection Measures:

- Wear dust mask when milling to avoid inhaling wax dust

- Ensure good ventilation when heating to melt

- If manual adjustment is needed, gloves are recommended to avoid skin contact

- Avoid prolonged skin contact, may cause mild allergies

- Wear protective goggles during milling to prevent debris from entering eyes

First Aid Measures:

- Skin contact: If in contact with molten wax, immediately rinse with cold water, do not tear off wax adhering to skin

- Eye contact: Rinse with plenty of clean water, seek medical attention if discomfort occurs

- Inhalation: If large amounts of dust are inhaled, move to fresh air

Cleaning and Disposal:

- Wax chips can be recycled and reused, melted then reshaped

- Waste should be disposed of according to local regulations

- When cleaning tools and work area, avoid using solvents that may react with wax

Storage Requirements:

- Store in a cool, dry place, avoid direct sunlight

- Keep away from heat sources and open flames

- Storage temperature should be below its melting point (usually 60-80°C)

In our milled mold making practice, we particularly noted the following safety characteristics of industrial wax:

- Processing Characteristics:

- Wax material is soft, chips produced during processing easily adhere to the mold surface

- Need careful cleaning to avoid damaging mold details

- Cutting speed should not be too fast to prevent wax softening due to friction heat

- Usage Precautions:

- Before contact with silicone or other materials, ensure the wax mold surface is clean, free of residual chips

- When wax molds contact silicone directly, silicone may have a slight dissolving effect on wax, appropriate release agent is recommended

Through reasonable protective measures and operation procedures, industrial wax can be safely and effectively used for mold making. Its low toxicity and reusable characteristics make it an environmentally friendly mold material choice.

Safety Operation Summary

During the implementation of this project, we strictly followed the above safety guidelines and took multiple measures to ensure safety:

Personal Protective Equipment Use:

- Wore gloves, masks, and protective goggles throughout the process

Work Environment Management:

- Maintained good ventilation in the work area

- Covered the workbench with paper to prevent chemical contamination

- Operated in separate areas according to material type to avoid cross-contamination

Waste Disposal:

- Treated cured silicone and polyurethane resin waste as general solid waste

- Collected and reused indium-tin-bismuth alloy residue

- Separately collected waste liquid produced during tool cleaning

- Industrial wax cutting fragments can be collected and melted for reuse

By carefully reading and implementing the guidance in material safety data sheets, we not only ensured the operator's health and safety but also improved product quality and work efficiency. In future projects, we will continue to improve safety measures and explore safer, more environmentally friendly materials and processes.