Prototype Assembly

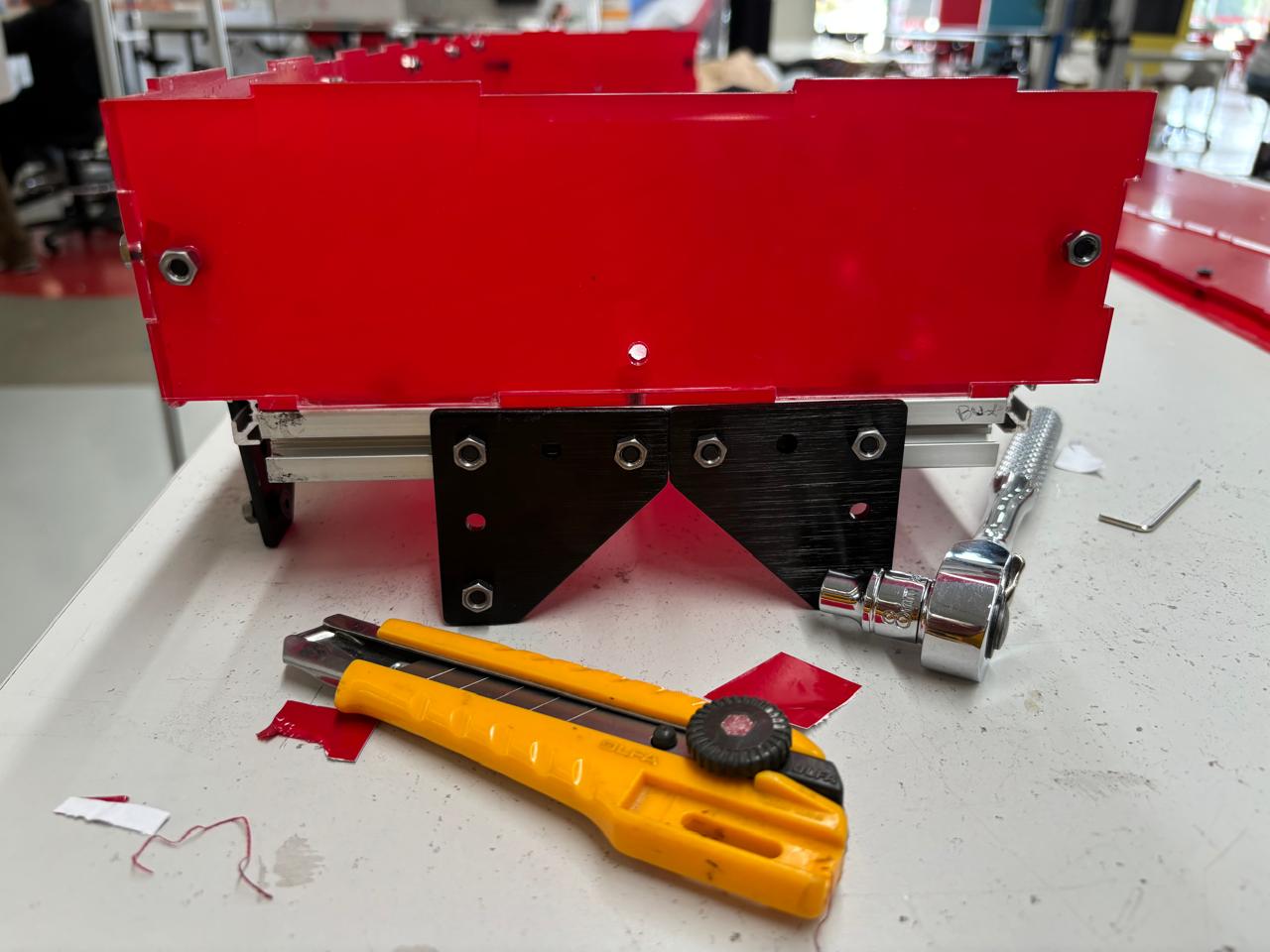

Main Structure Assembly

1. Structure and Support

The main structure was assembled using aluminum profiles, to which specific joints were added to improve stability. Angular joints were used to reinforce the corners and areas where more weight would be supported.

2. Screws and Nuts

Screws were used to secure the joints to the aluminum profiles. These screws fit directly into the profiles and are then tightened with nuts, ensuring a solid and sturdy assembly.

Propeller Installation

1. Tube Mounting

The propellers were mounted on tubes connected directly to the motor couplings. This allows the propellers to spin when powered by the motors.

Bottom Bearings

Bearings were installed at the bottom of each tube, helping to keep the tube in position while allowing it to spin freely, facilitating smooth and unobstructed movement.

Alignment

It is crucial that the propellers are perfectly aligned to ensure efficient rotation and prevent mechanical friction or issues.

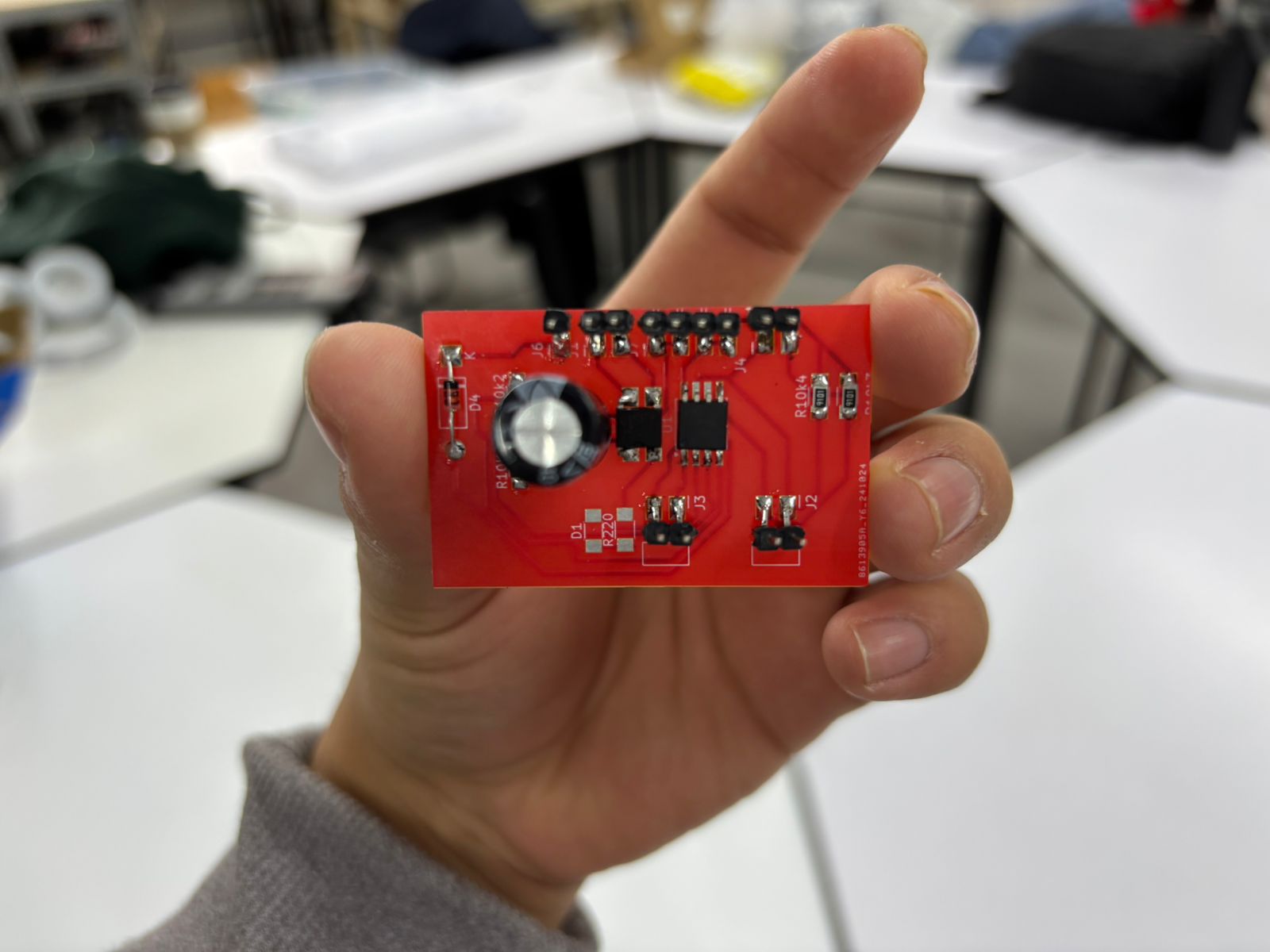

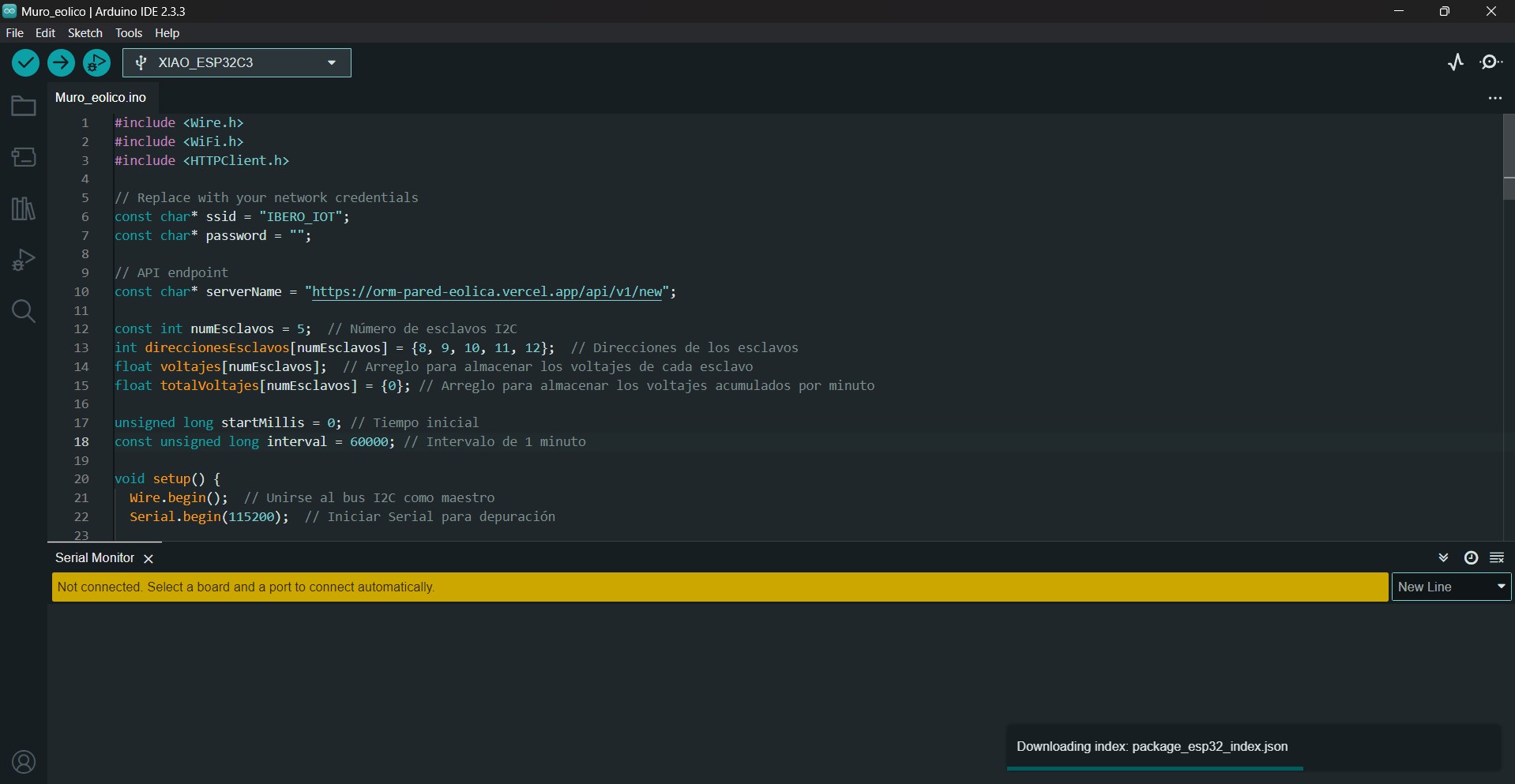

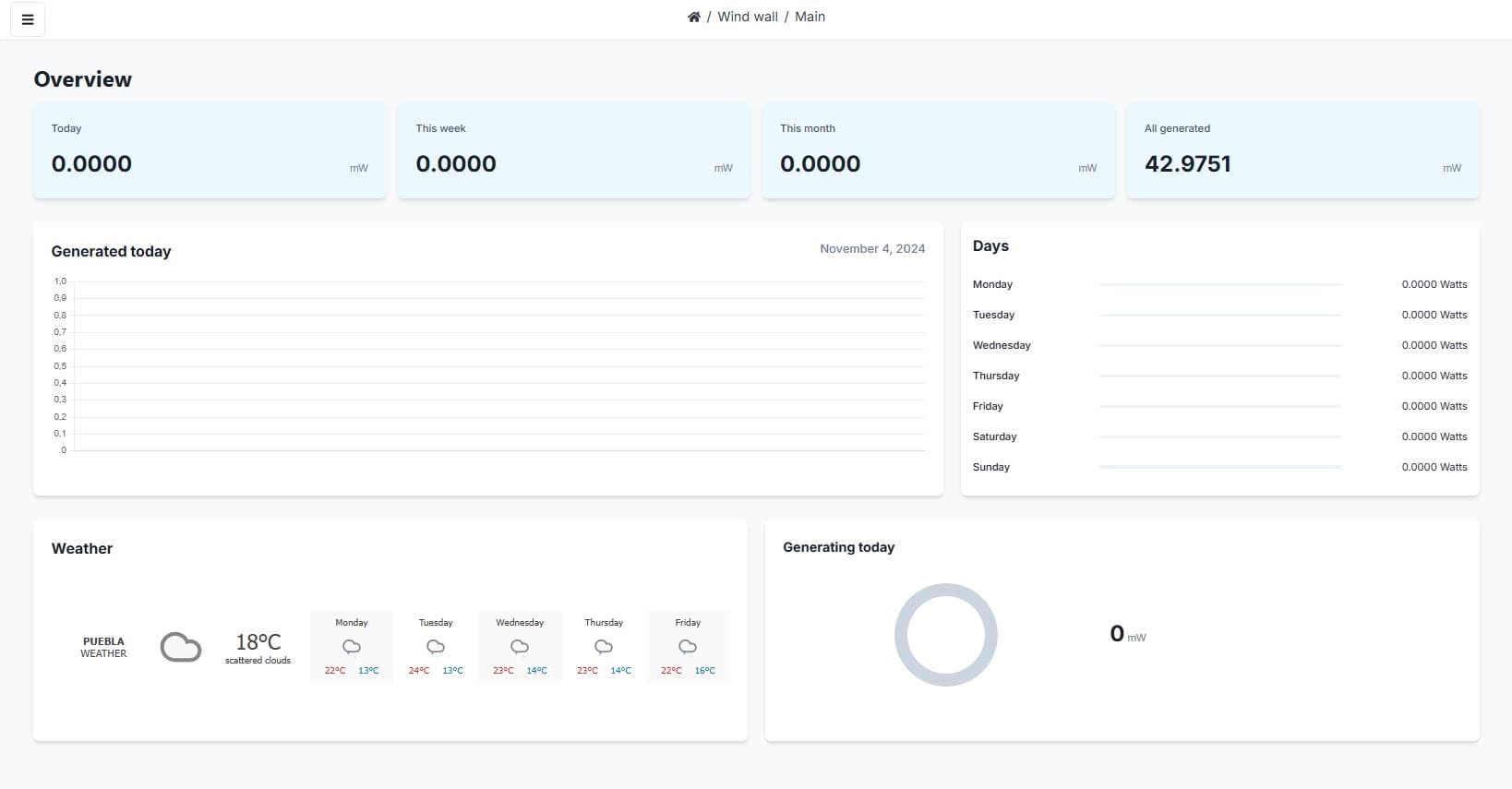

Integration of Electronic Components

Motor Installation

NEMA17 motors were installed at the top of the structure, oriented downward, each coupled to the propeller tubes through couplings. The motors were firmly attached to prevent unwanted movement.

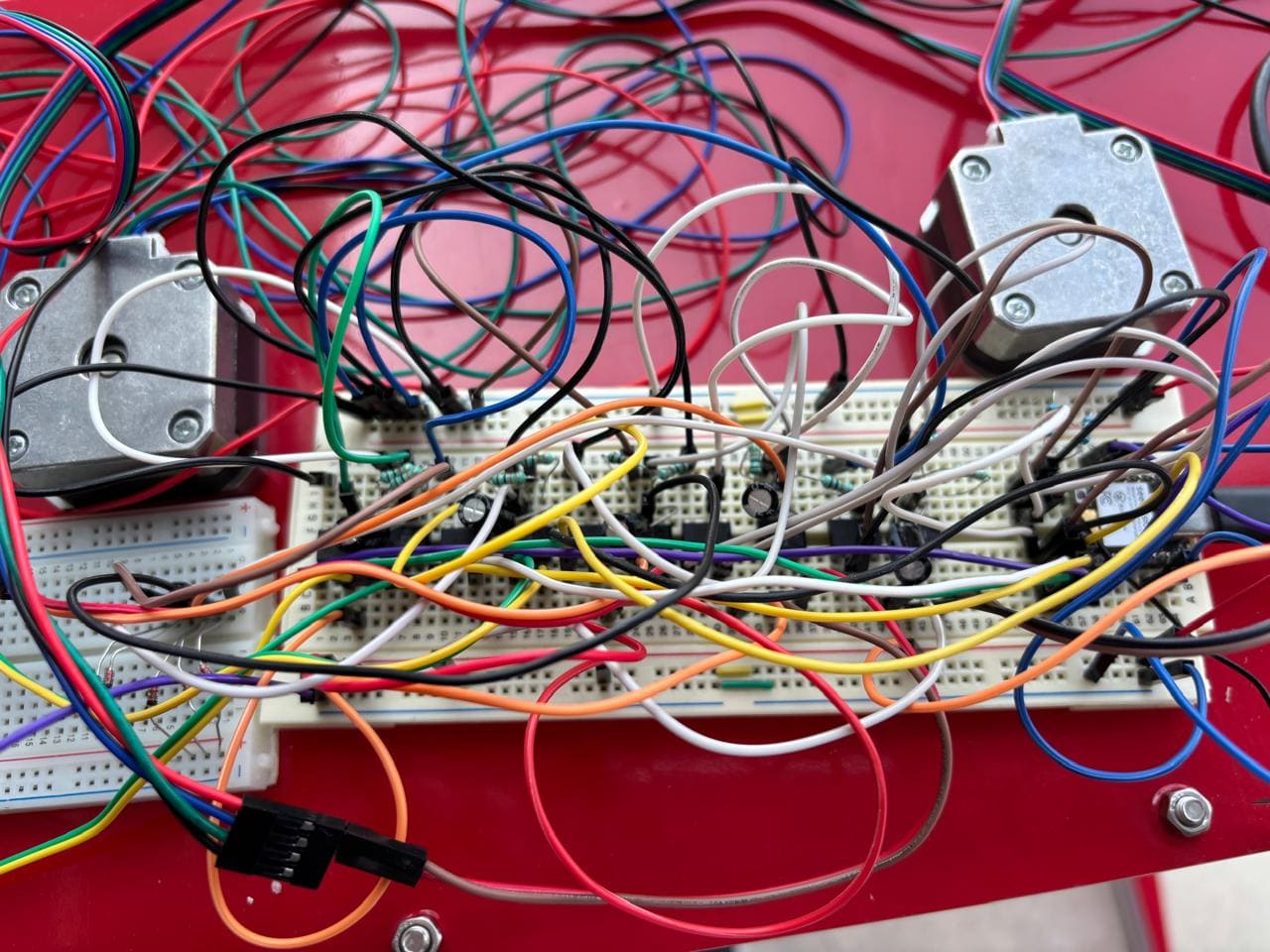

Wiring and Organization

The wires were carefully organized to avoid interference with the propellers and other moving parts.

Alignment Verification and Physical Adjustments

Propeller Alignment

Tests were conducted to ensure each propeller was properly aligned and rotated without interference. This involved manually adjusting the tube position and performing rotation tests.

Additional Adjustments

The couplings were checked to be securely fastened, and no loose parts were found in the structure.

Assembly Issue Solutions

Extensive Wiring

One of the main challenges was managing the number of cables needed for the motors and sensors. They were carefully organized to avoid tangling.

Additional Reinforcements

Extra joints were added in critical areas to increase stability, especially in points where excessive movement was detected during initial tests.

Final Adjustments

Before the final test, all connections, screws, and supports were inspected to ensure the assembly was completely secure.

Assembled prototype