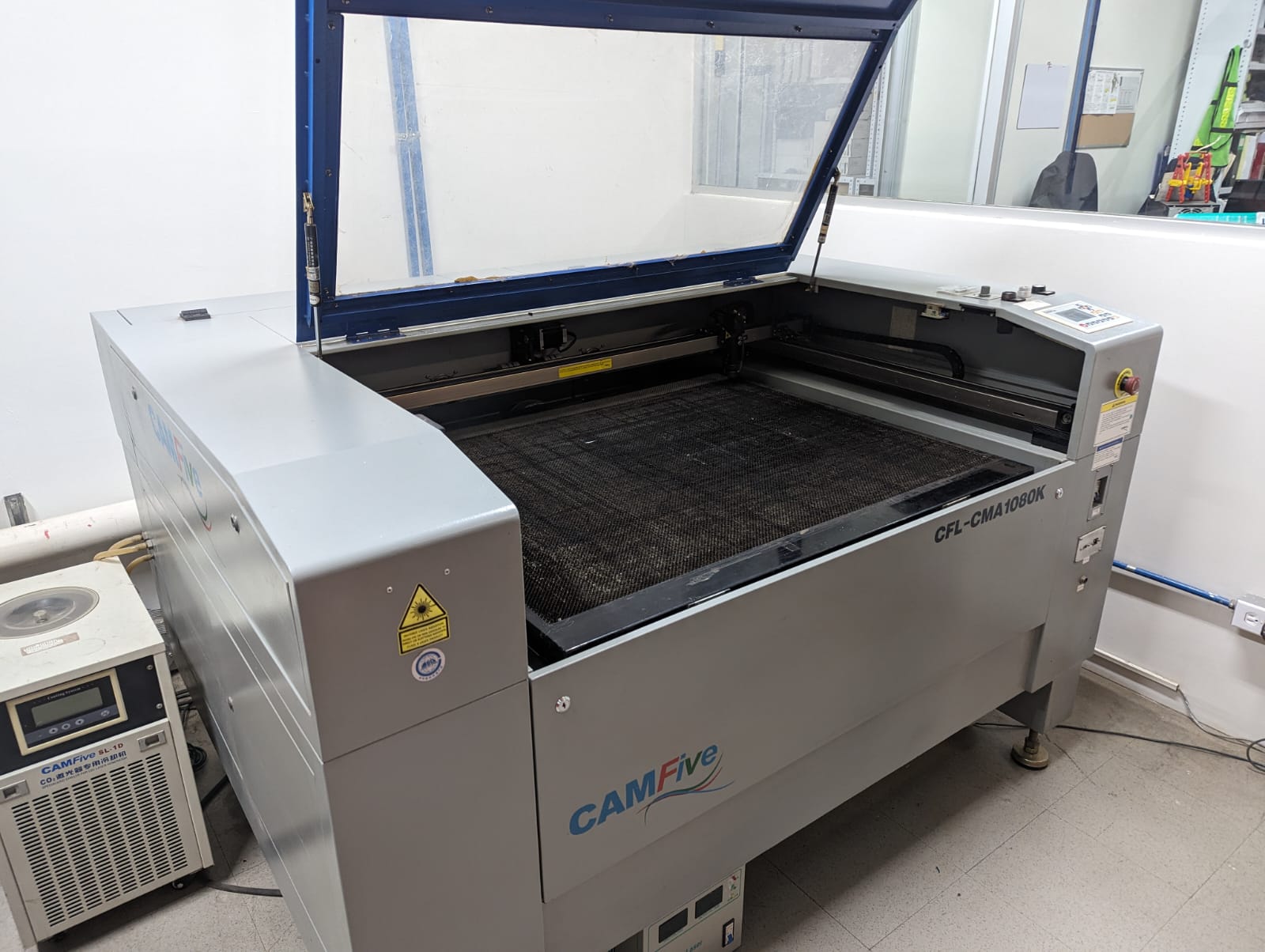

Laser Cutting

Laser Machine

The laser cutting machine used to cut the pieces is the CFL-CMA1080K machine.

This machine has the following features:

Work area

1.00 x 0.80 meters

Work table

Honeycomb or rod

Accessory

Double Tube

Cutting speed

0–36,000 (min/mm)

Engraving speed

0-64000 (min/mm)

Power

100 Watts

Cutting thickness

0–25 mm

Resolution

Up to 4000 DPI (600–2000 DPI typically)

Motion accuracy

0.01 mm

Setup and Preparation for Cutting

To cut the acrylic pieces, a speed of 15-20 mm/s was used, with a maximum power of 80-100% and a minimum power of 60-70% on the laser cutting machine. These settings allowed for precise, high-quality cuts on the material.

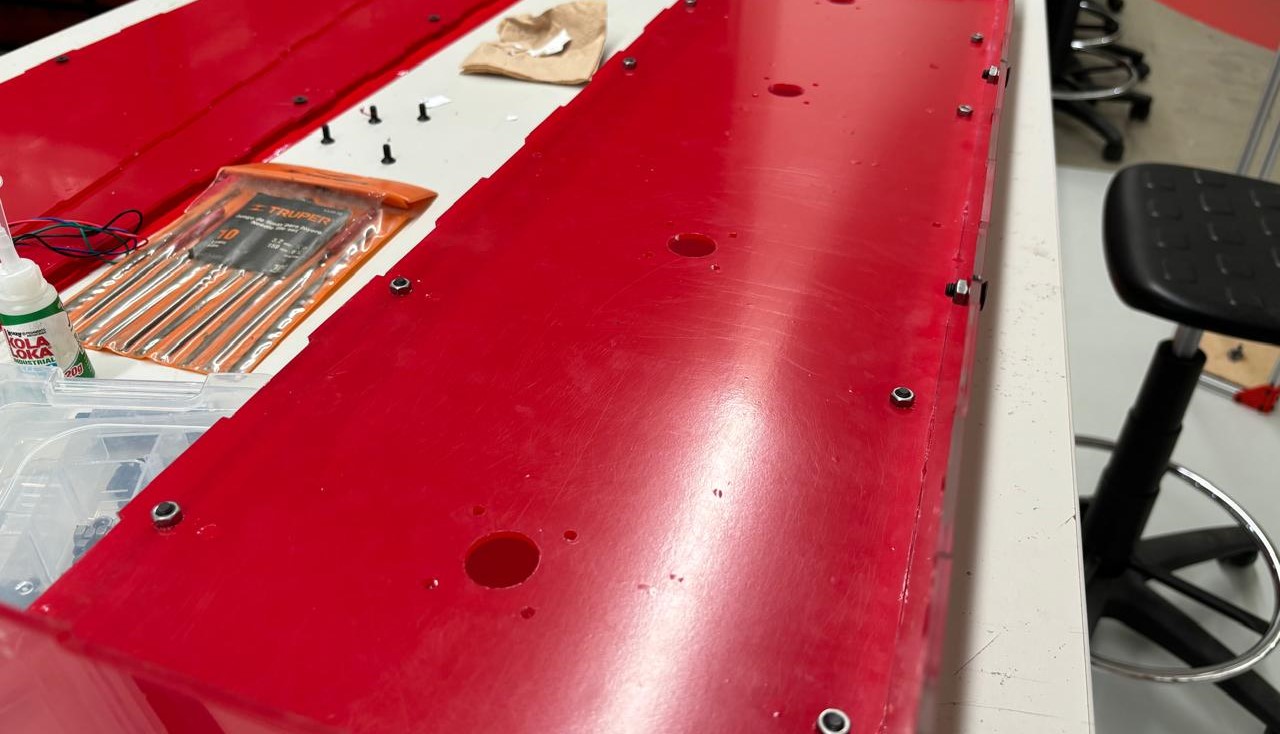

Application of Vinyl on the Pieces

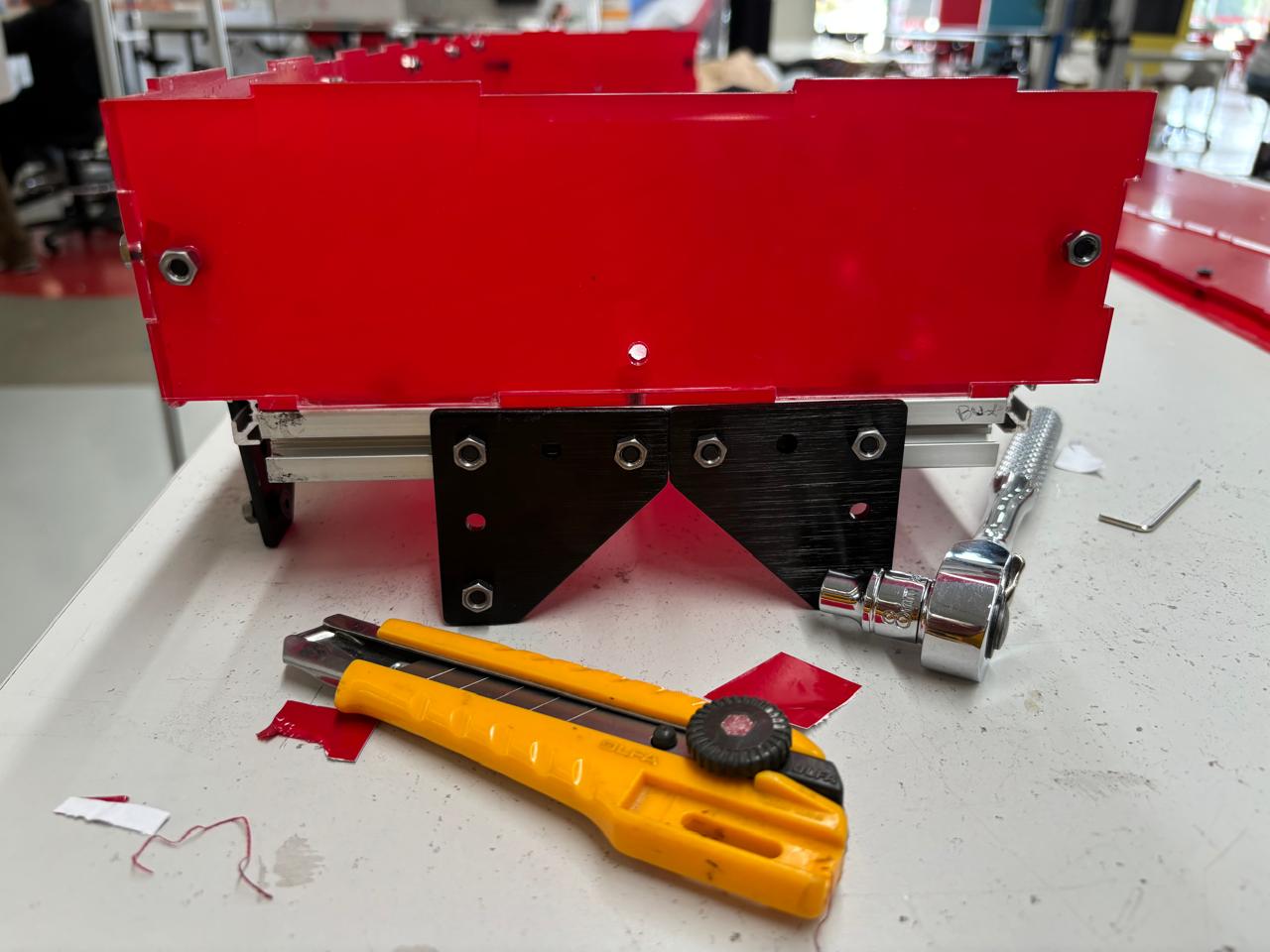

Once cut, red vinyl was applied to the acrylic pieces. This process not only improves the visual appearance of the project but also helps protect the acrylic surface, preventing scratches and surface damage. The vinyl adds an attractive aesthetic finish that aligns with the design of the prototype.

The design of these pieces is intended to aid in the main structure of the wall. That is to say, in these will go the motors that will be connected with couplings to the propellers.

The motors will be on the top, so the bottom will have the tubes to connect the propeller tubes.