4. Computer controlled cutting¶

Group assignment:¶

High precision CO2 laser cutting machine, used to engrave and cut wood, acrylics, plastics, among other materials, with the highest quality. It is used to make high-speed cuts with custom designs, cuts to make custom accessories in different materials: Leather, fabrics, wood, acrylic, plastic and the possibility of generating prototypes of machines.

Features of The CNC Laser Cutter:

- Approximate dimensions (width x height x depth) of 730 x 562 x 298 mm

- Minimum working area 406 x 305 mm

- Min. workpiece height of 114 mm

- High-speed, continuous-loop dc servo motors using linear and rotary coding technology for precise operation

- Laser power 40 watts.

- Approximate weight 40 kg.

- CO2 laser tubes. Manual focus, 2” focus lens

- Optimized raster, vector or combined modes.

- Controlled user resolution from 75 to 1200 dpi.

- The automatic switching power supply accommodates 110 to 240 vols, 50 or 60 hz, single-phase.

- The automatic switching power supply accommodates 110 to 240 vols, 50 or 60 hz, single-phase.

- Sound level 59db.

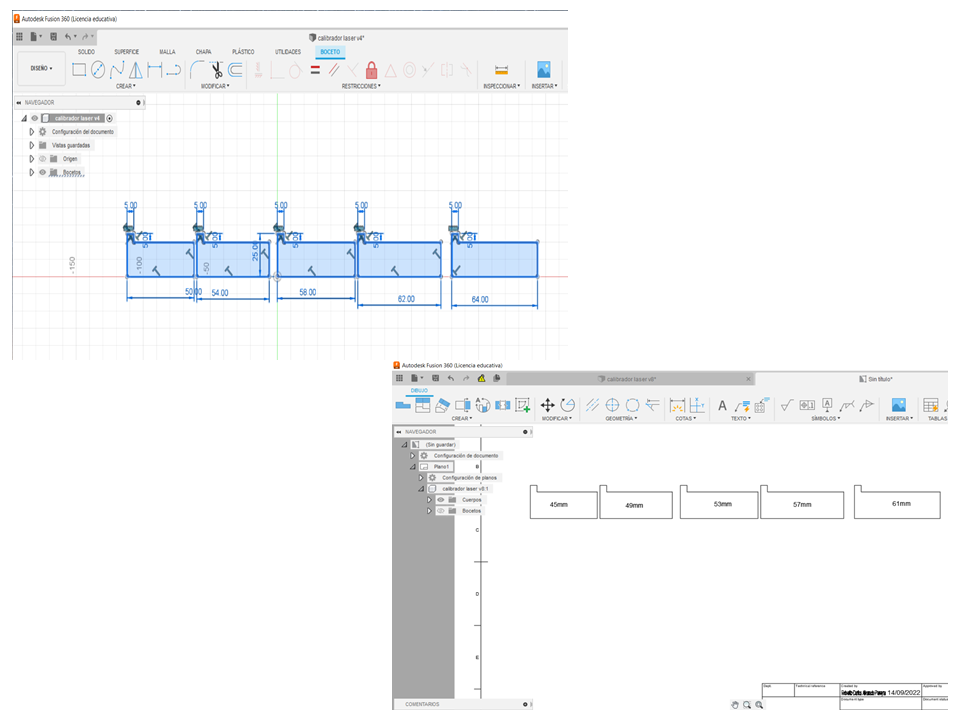

Design of laser focus calibration patterns

The laser cutter within the kits delivered by the manufacturer has a calibration pattern, but this experience will serve to corroborate the focus distance of our laser cutter and experiment with other distances for other projects.

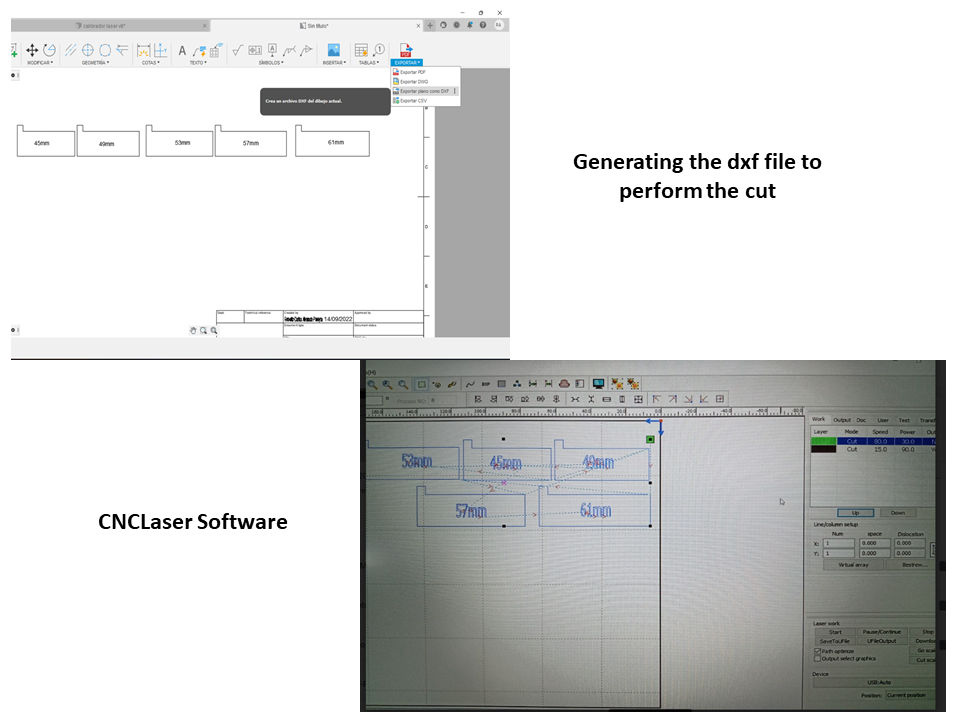

The design is made in the fusion 360 software, we will only manufacture 5 patterns with distances close to the calibration standard granted by the manufacturer.

Calibrating

For this process it is used as a 3 mm MDF sample material.

The cutting parameters chosen for this test are: power = 30% and speed = 70mm/s

The following pattern shows the variations in laser cutting when we calibrate the laser at different distances.

From the samples obtained it is observed that the best is the 53mm, it has good definition in the cut with little unevenness.

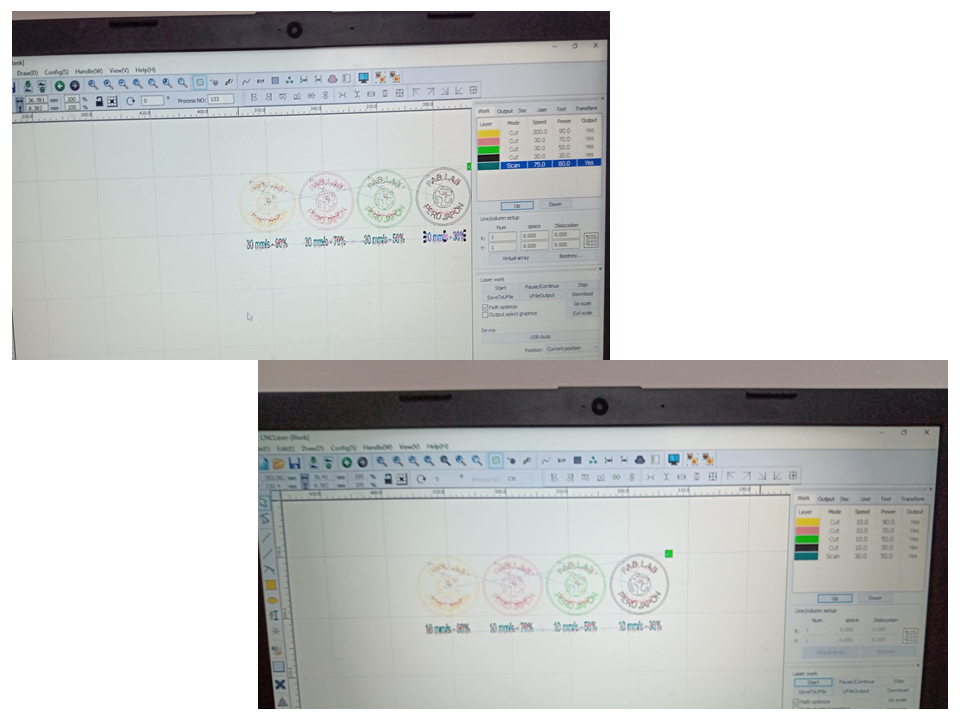

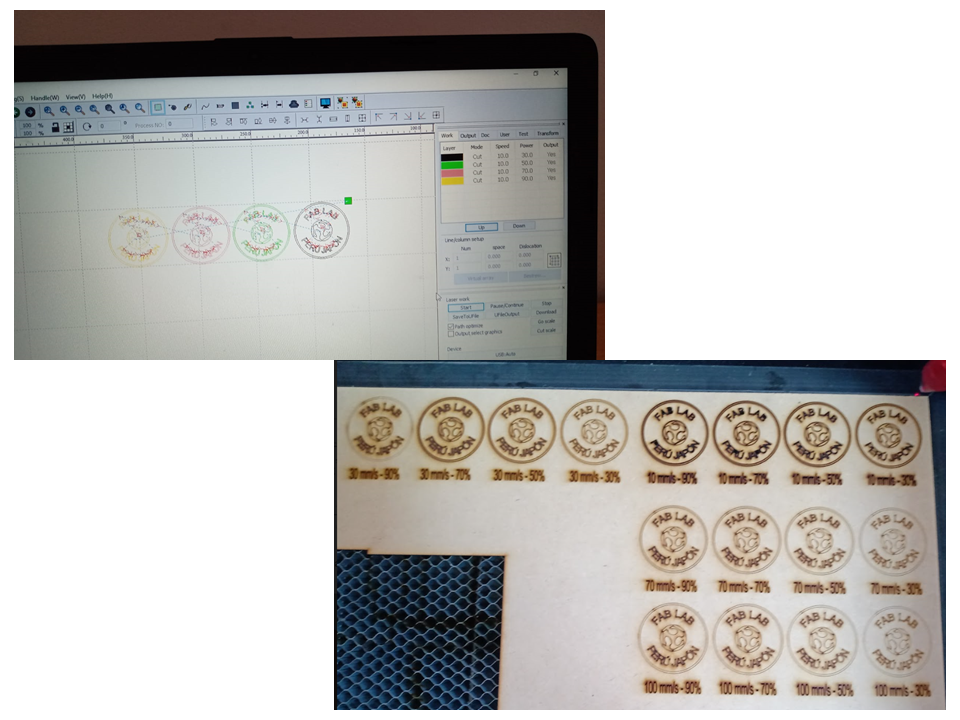

Laser cutter power and speed patterns

Once the ideal working distance of the laser has been defined, which is 53mm, we proceed to make patterns where the variables to be analyzed are speed and power.

Description of patterns

From the patterns made we can see that to have a deep and well-defined cote you have to lower the speed and increase the power, quite the opposite to make only light routes, it is preferable to use low powers to prolong the useful life of the machine.

Individual assignments¶

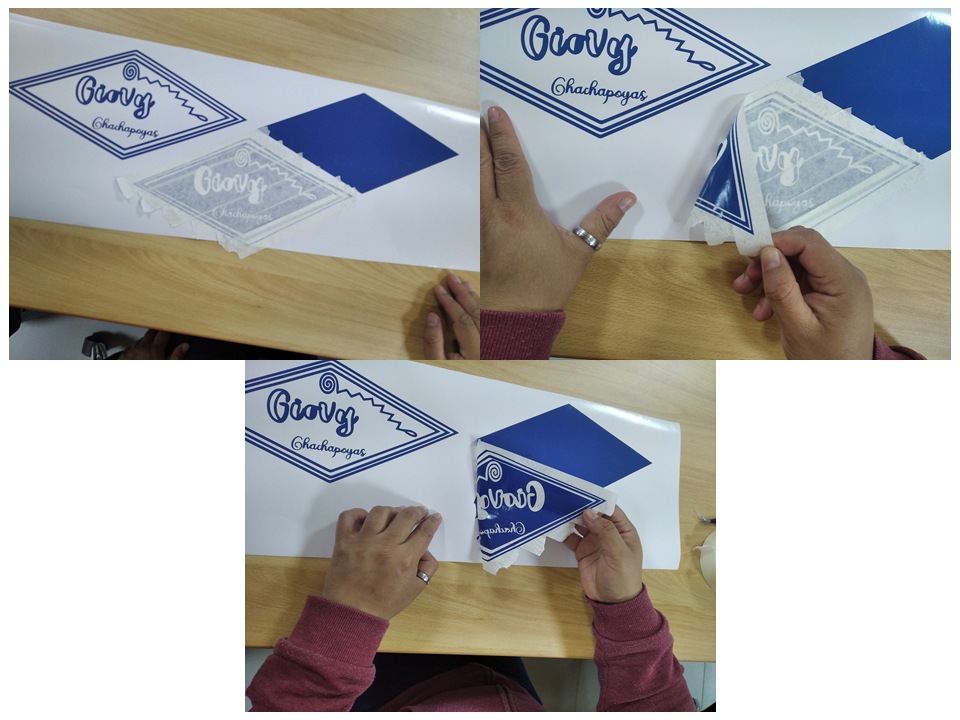

Vinyl cutting¶

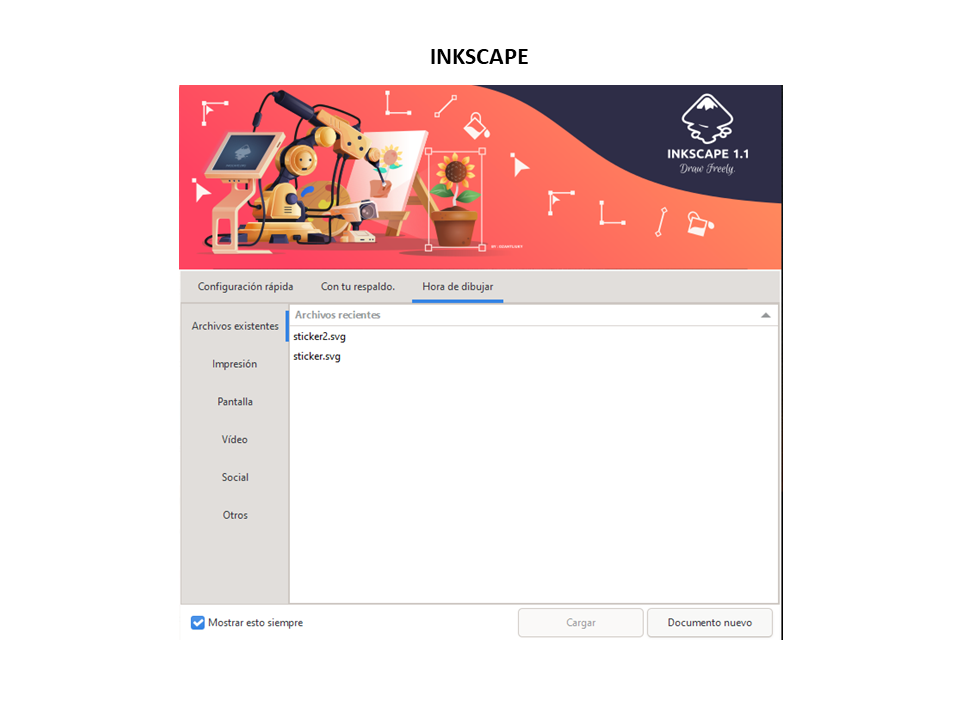

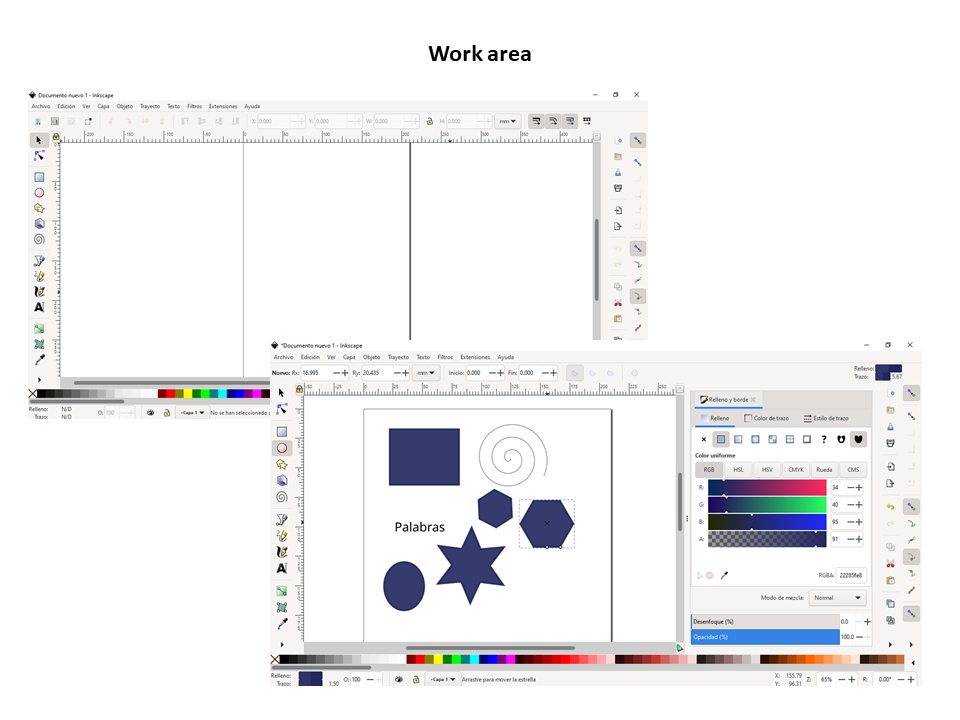

I made a sticker design in Inkscape

Find the right tools and features you need

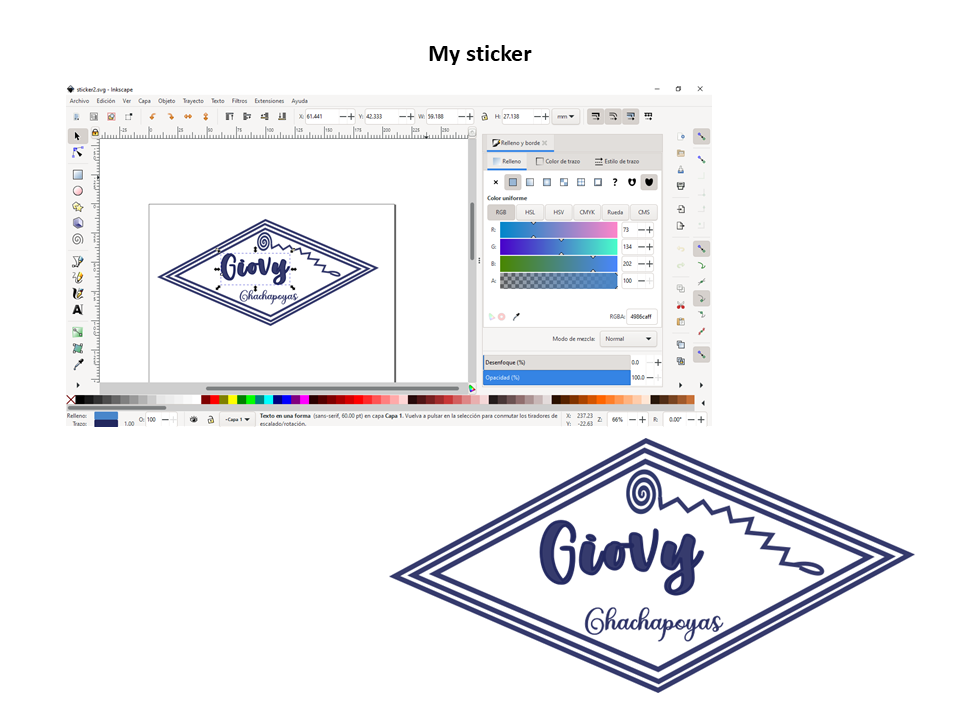

My sticker looked like this

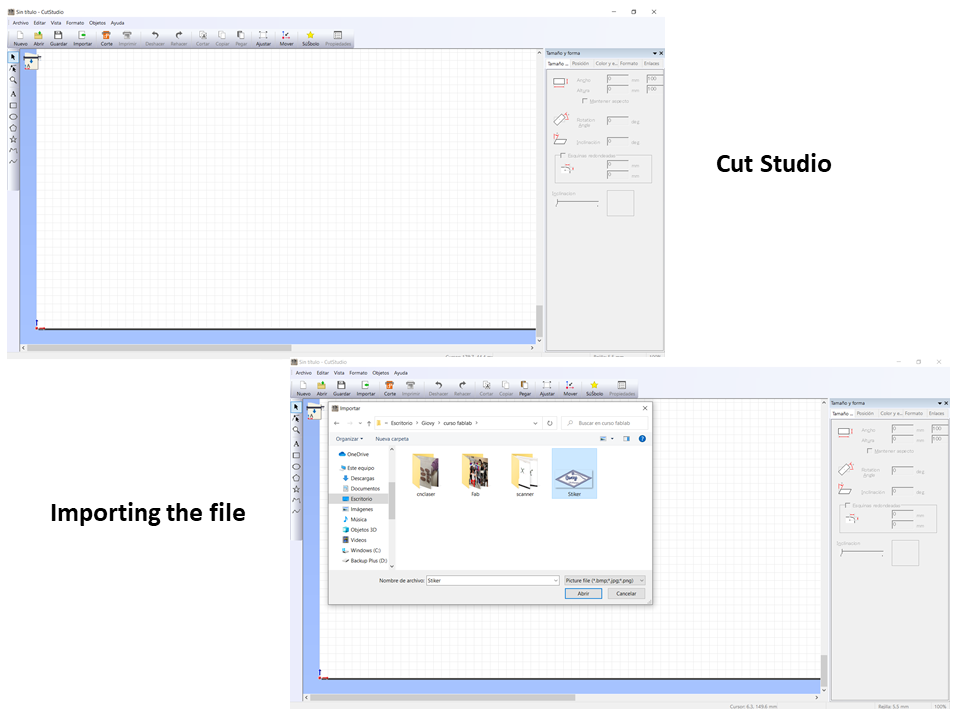

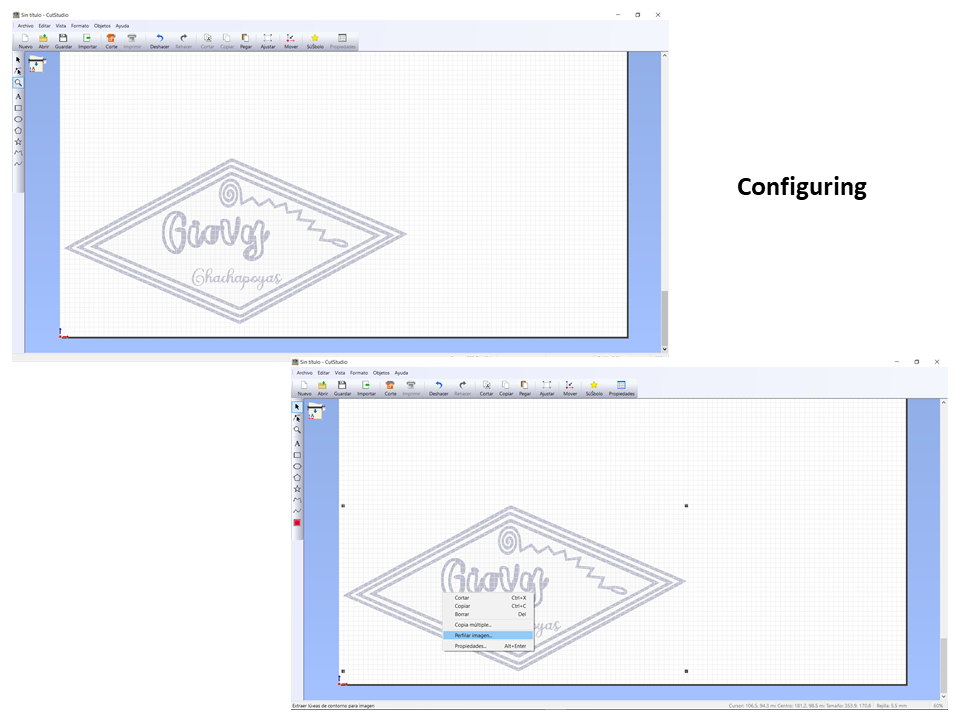

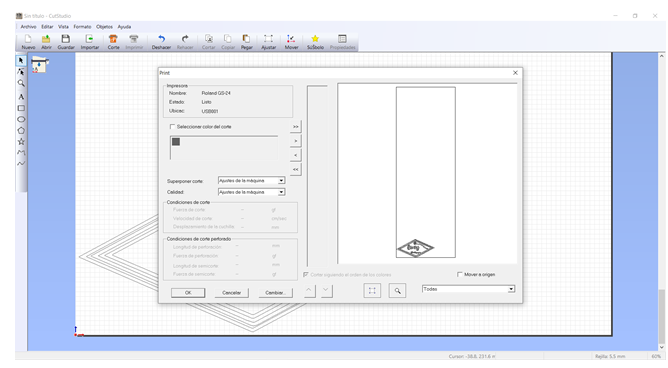

We run the Cut Studio software and import the Sticker file designed in Inkscape

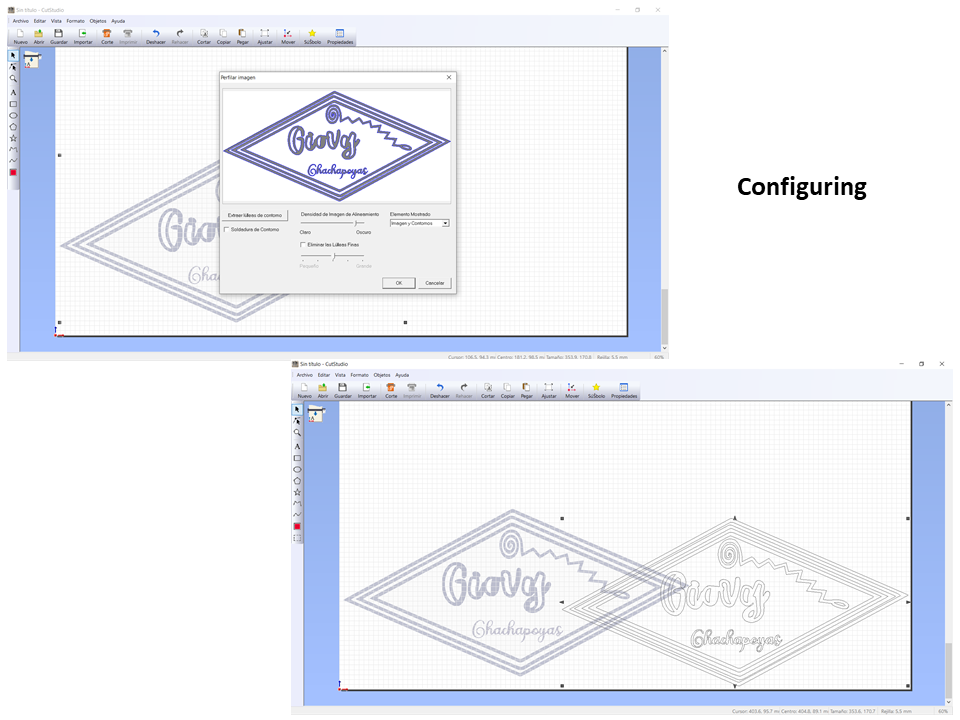

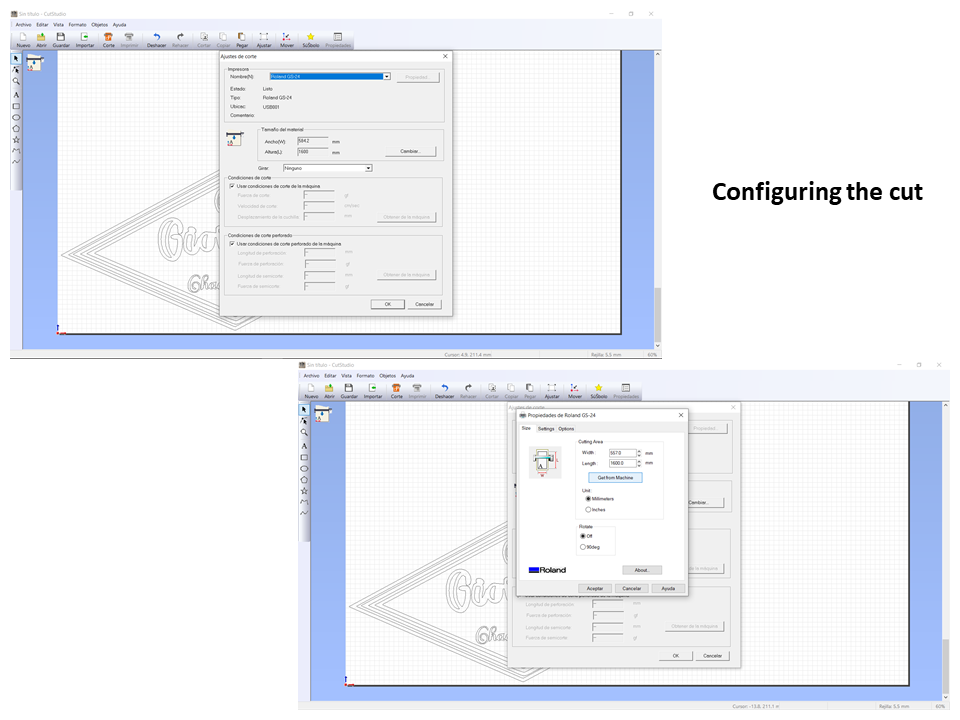

We configure the sticker to be able to cut

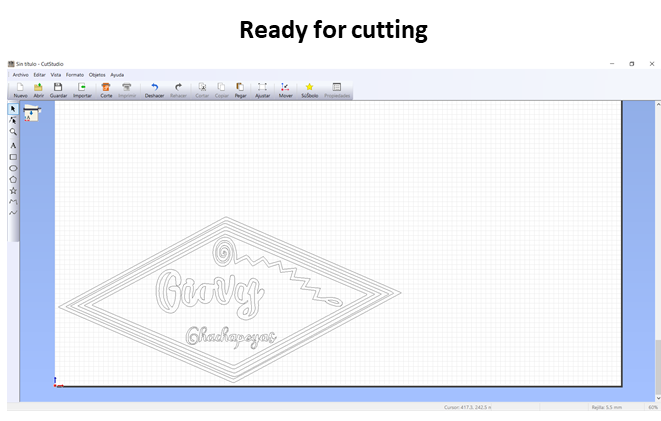

cutting the sticker:

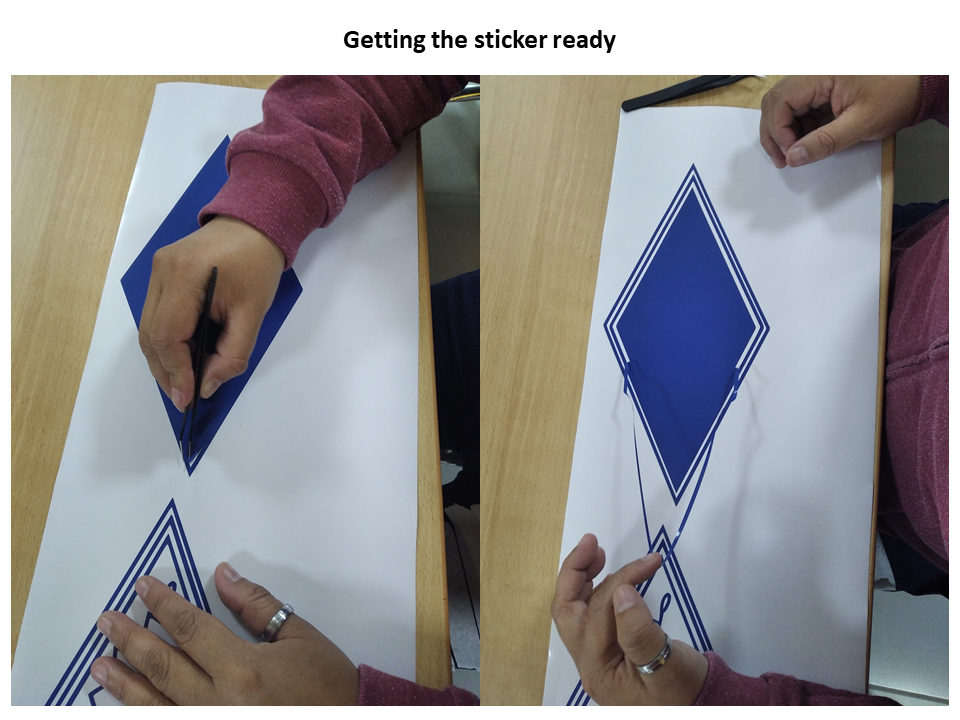

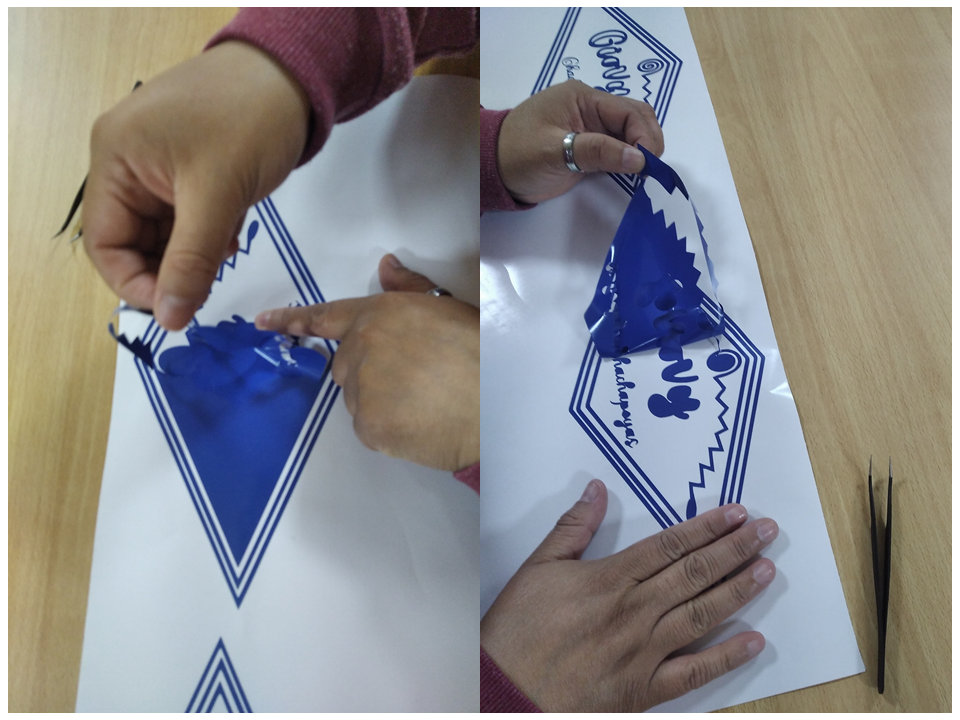

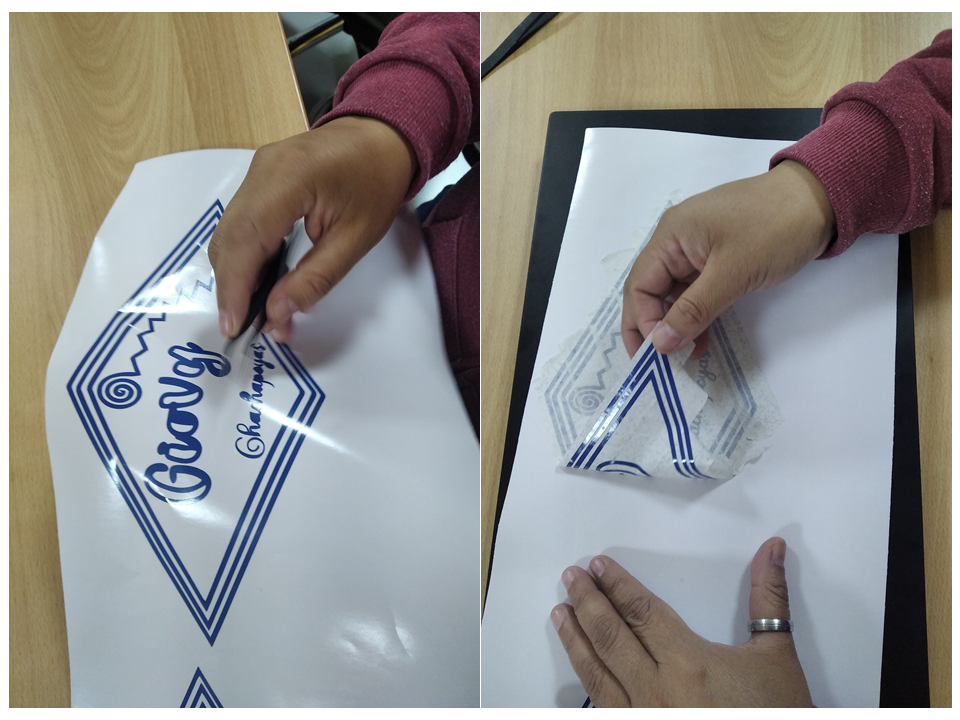

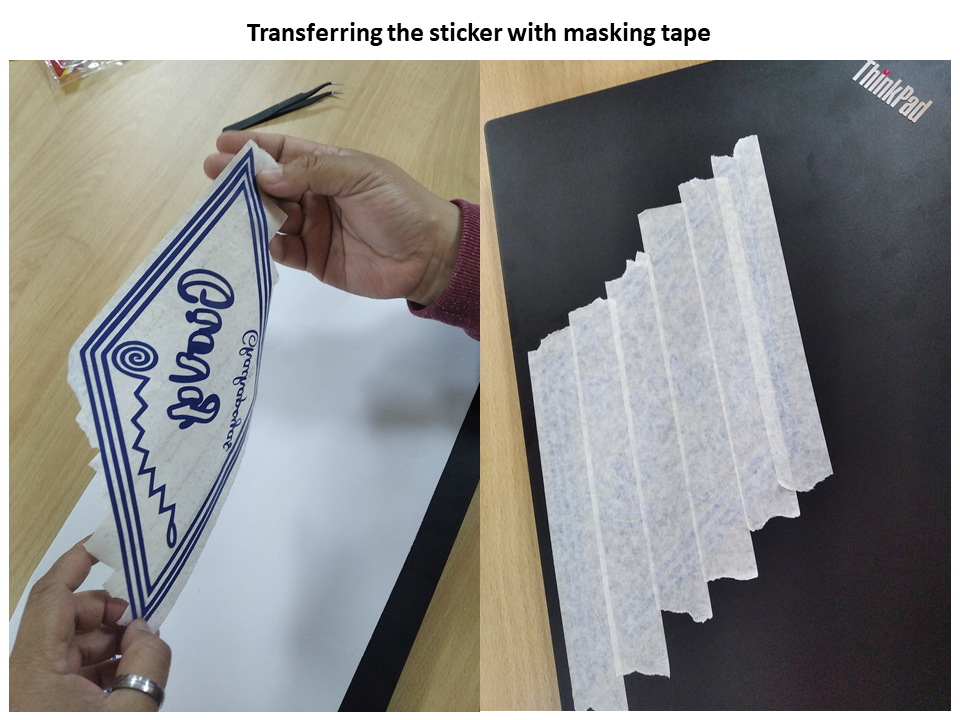

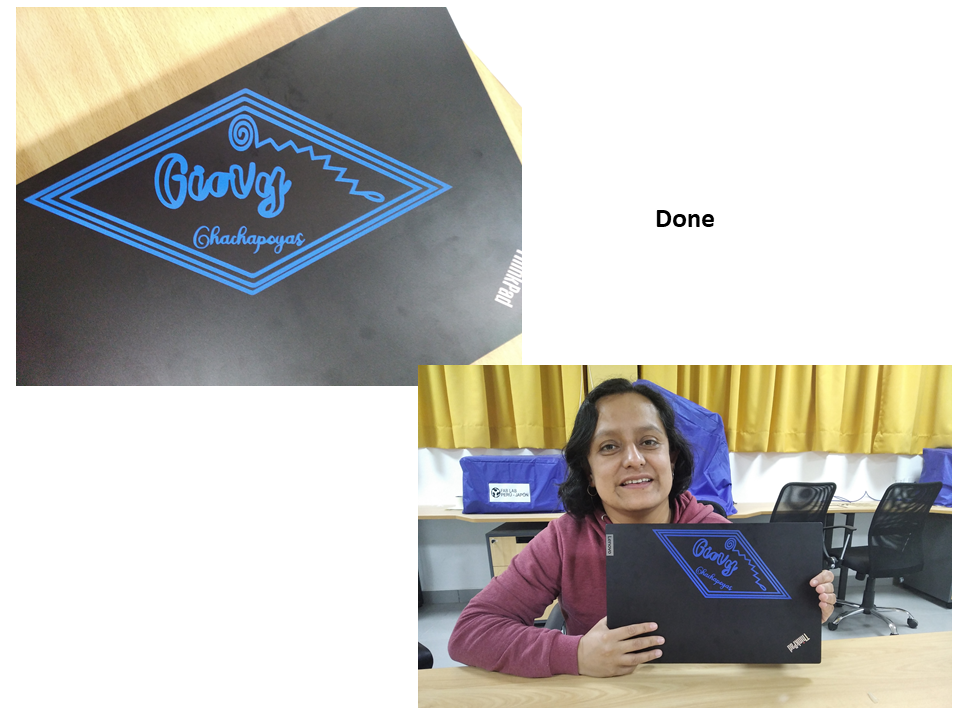

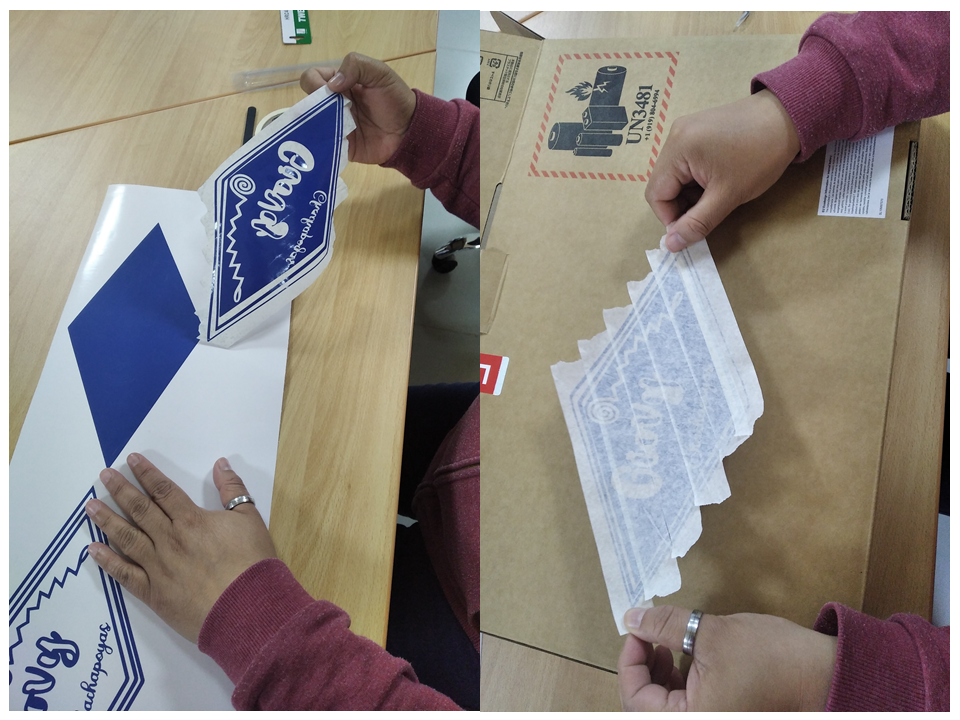

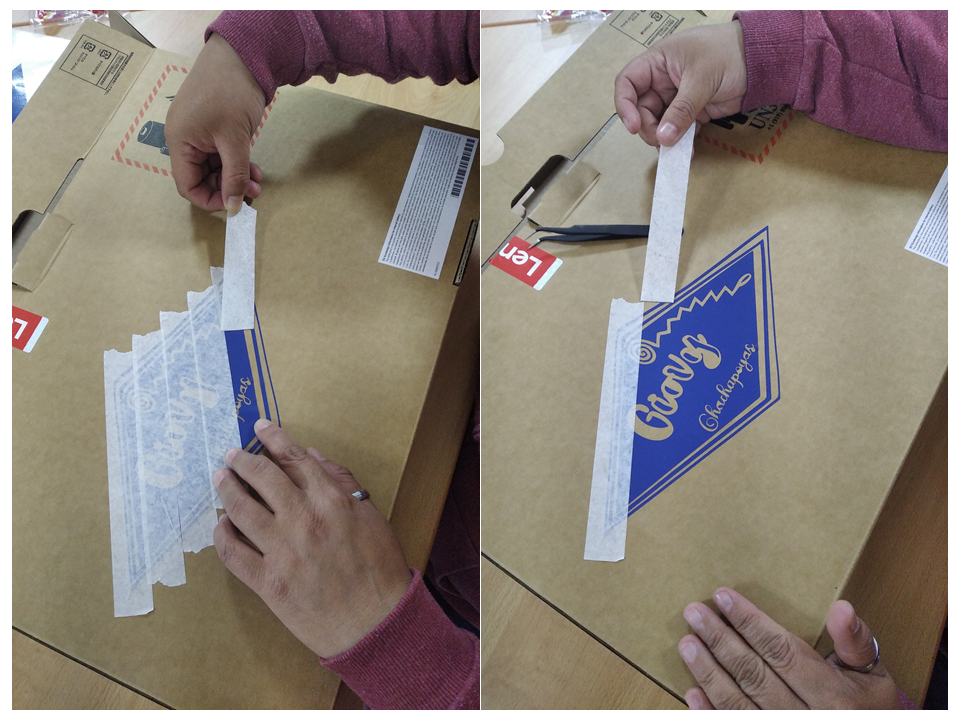

Getting the sticker ready

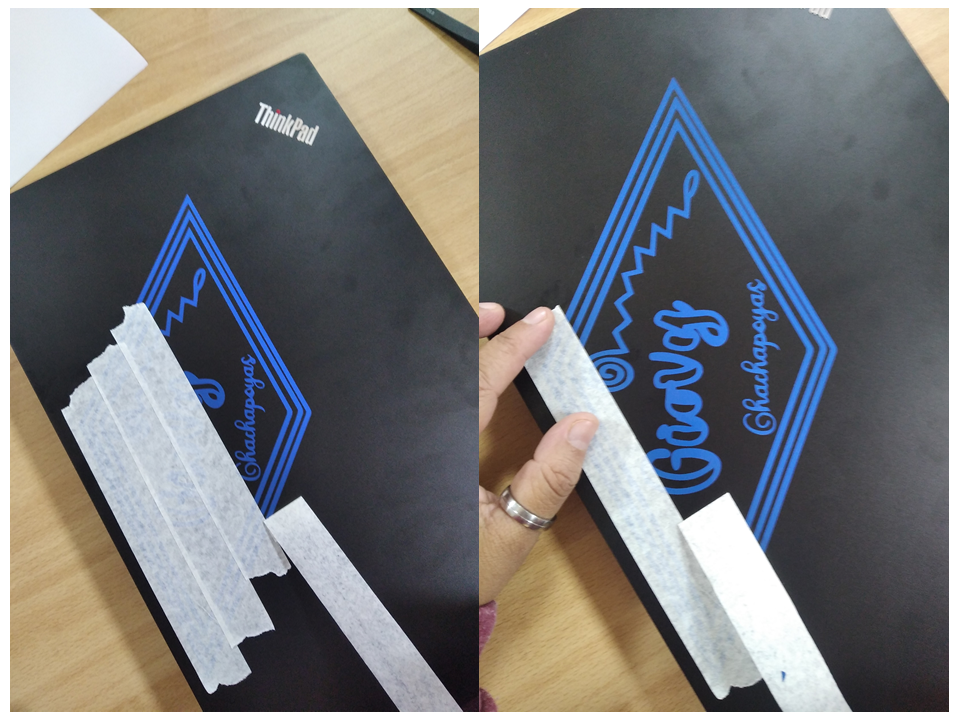

We place the sticker on the chosen surface… Done

Another sticker

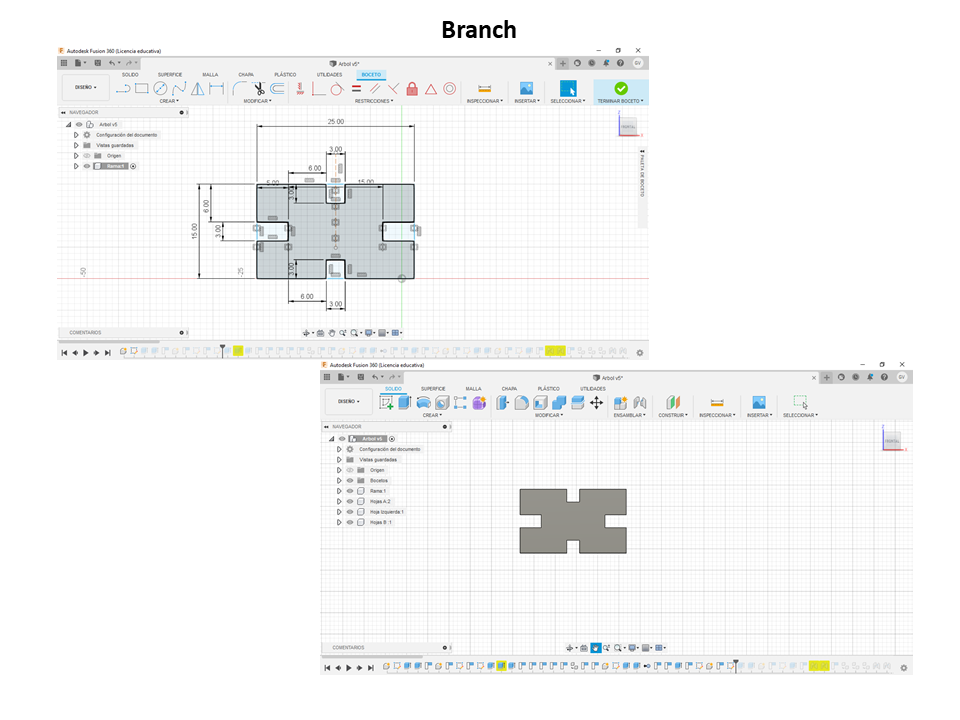

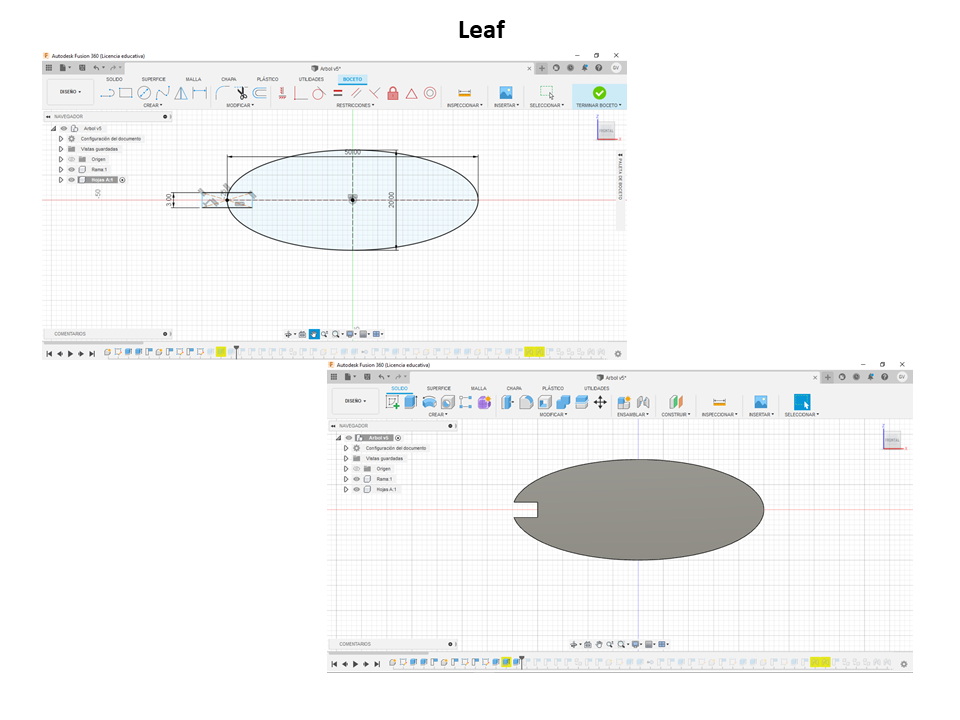

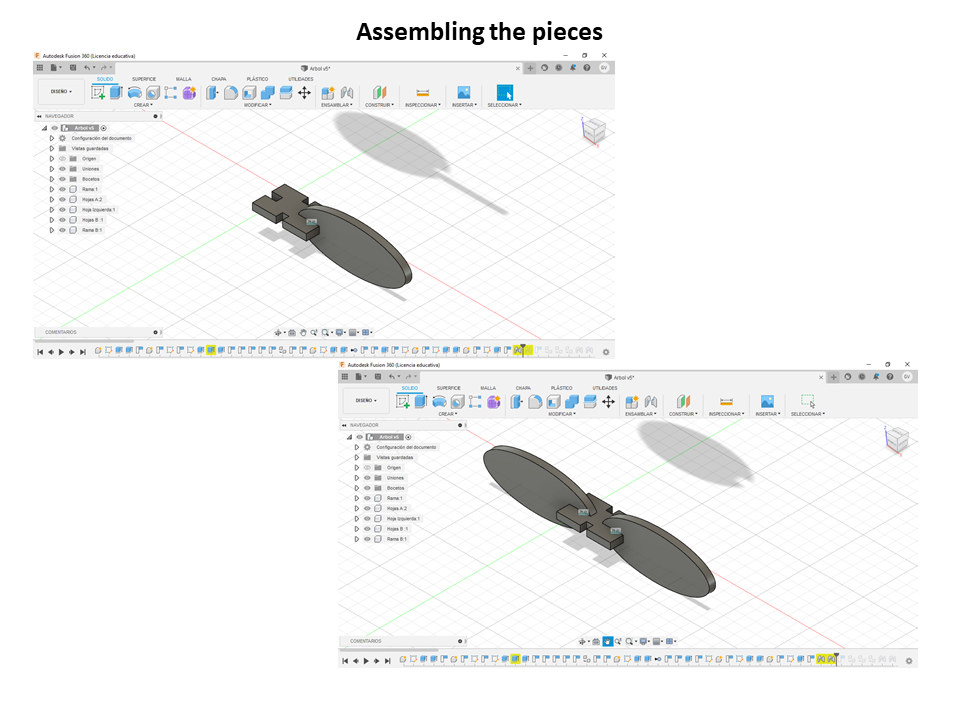

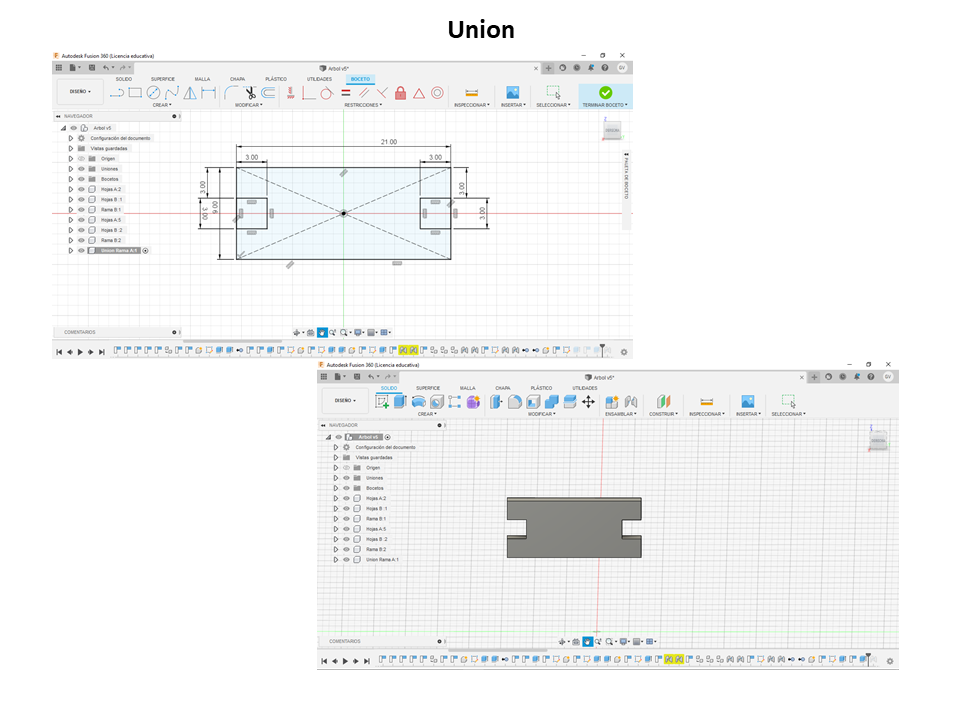

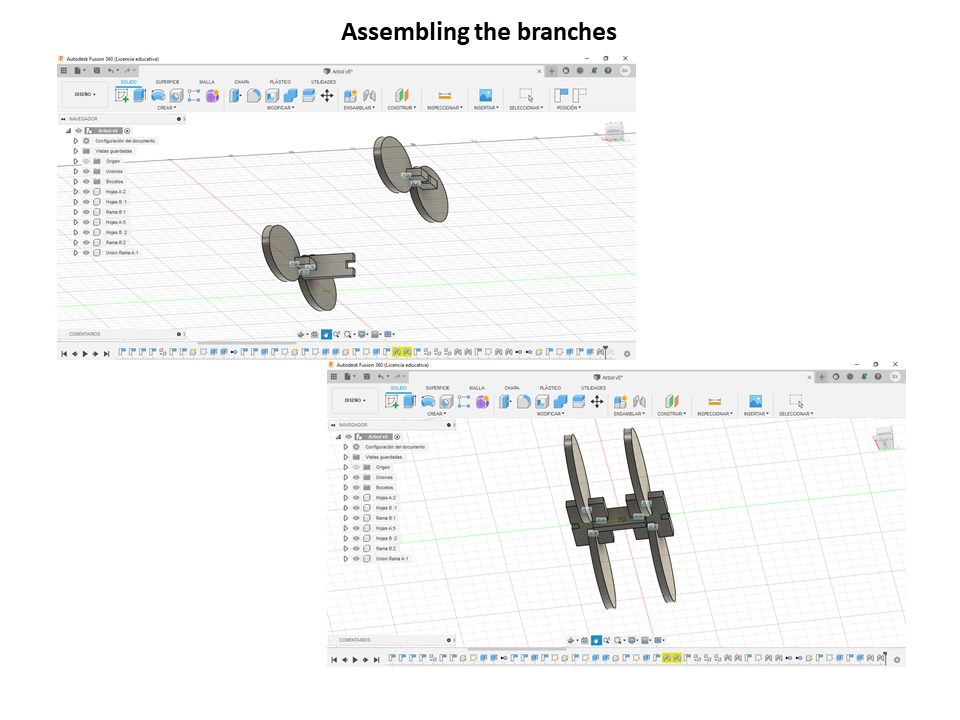

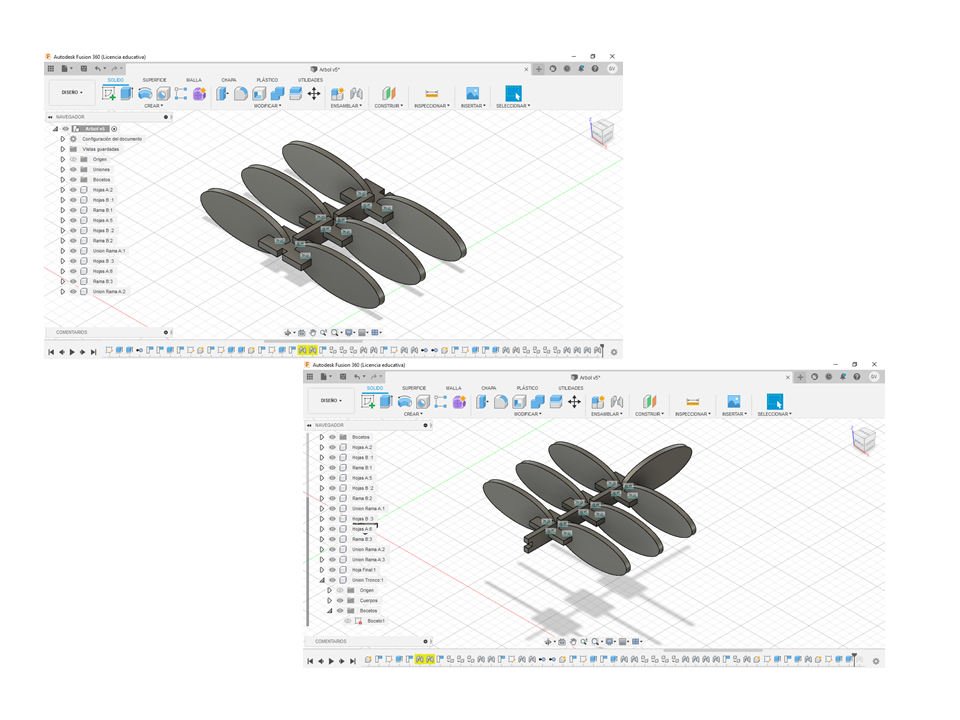

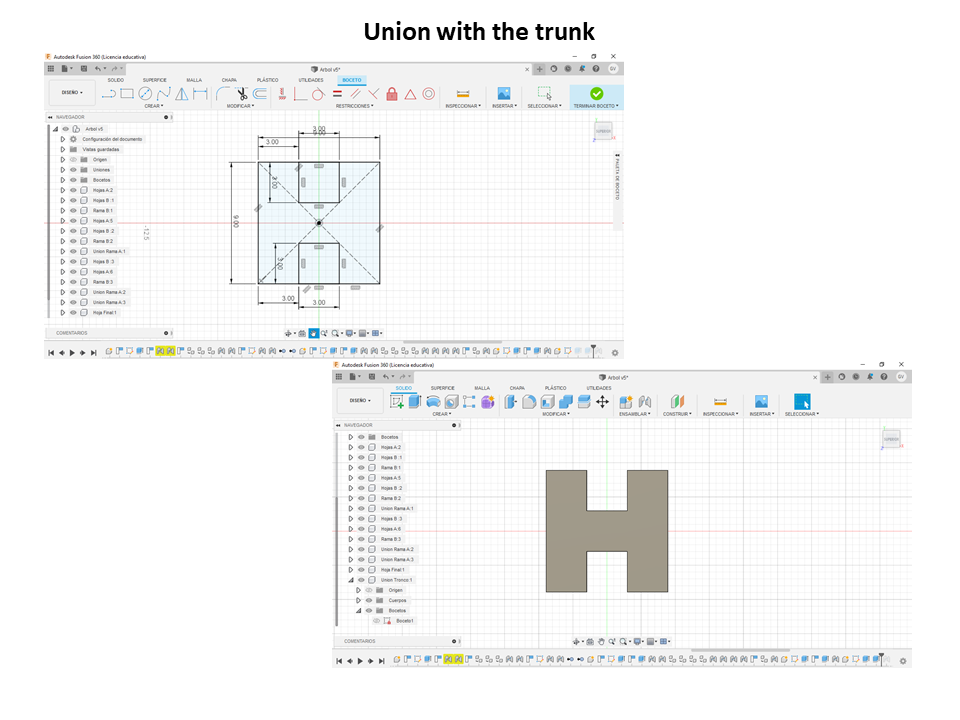

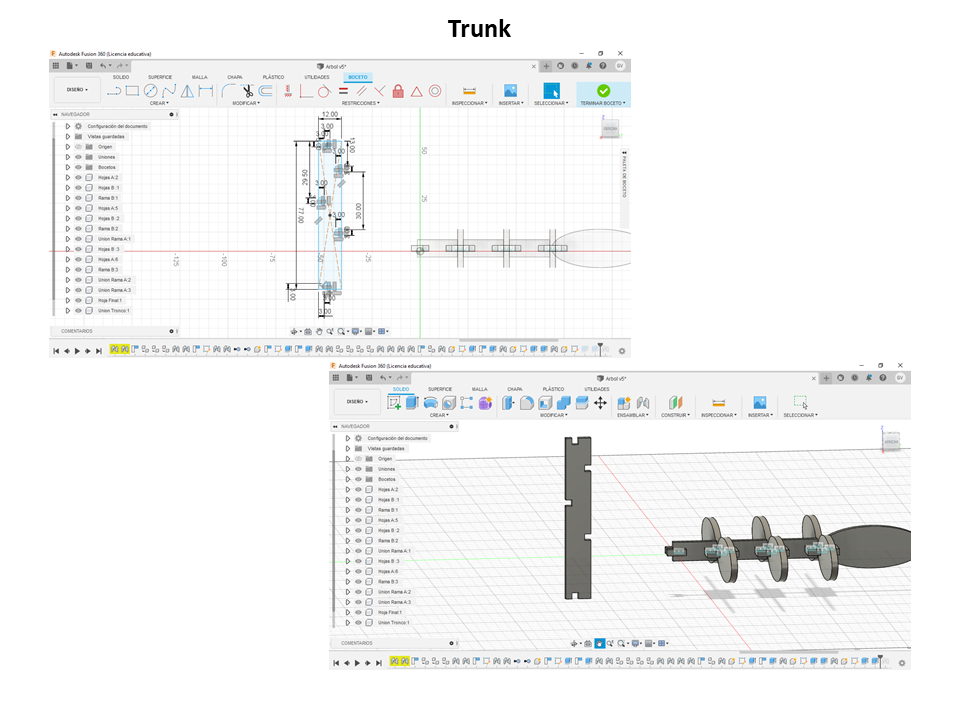

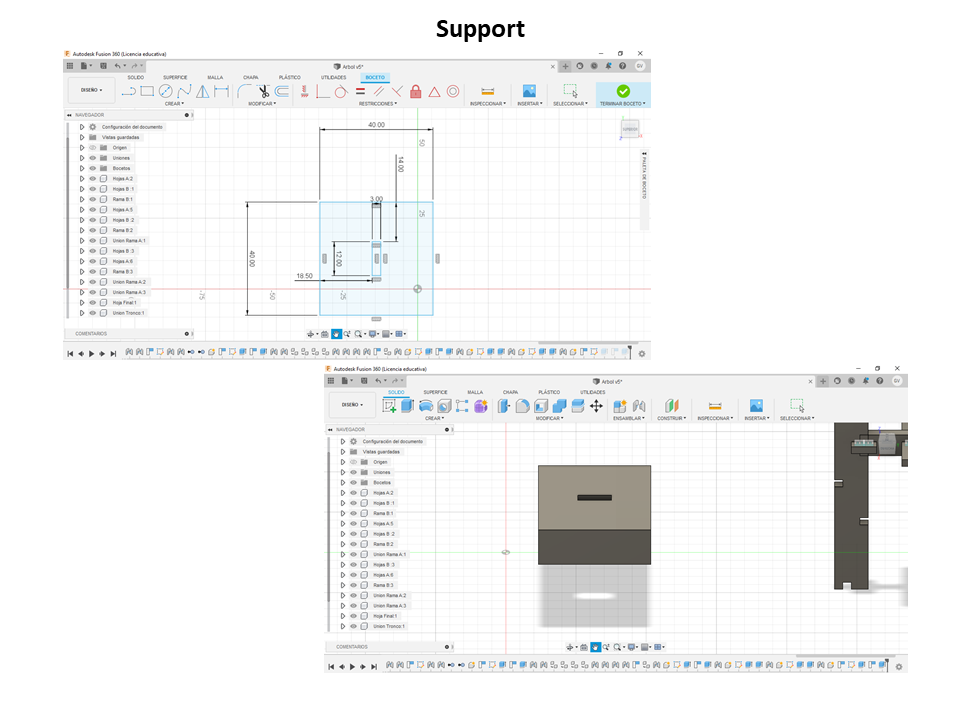

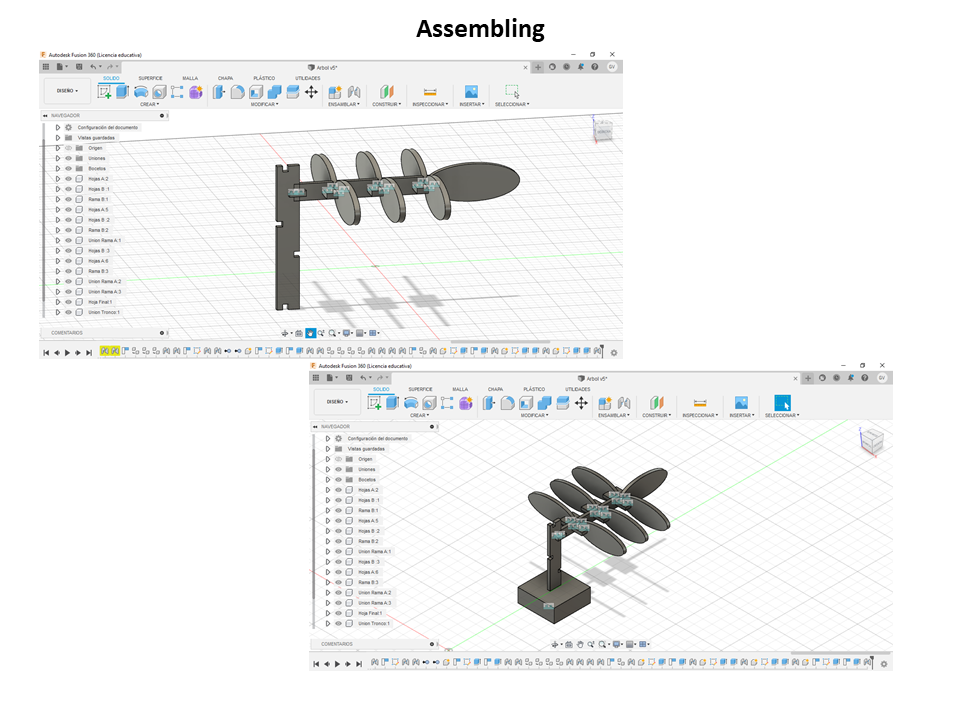

Parametric press-fit construction kit¶

I am going to design and assemble a coffee tree

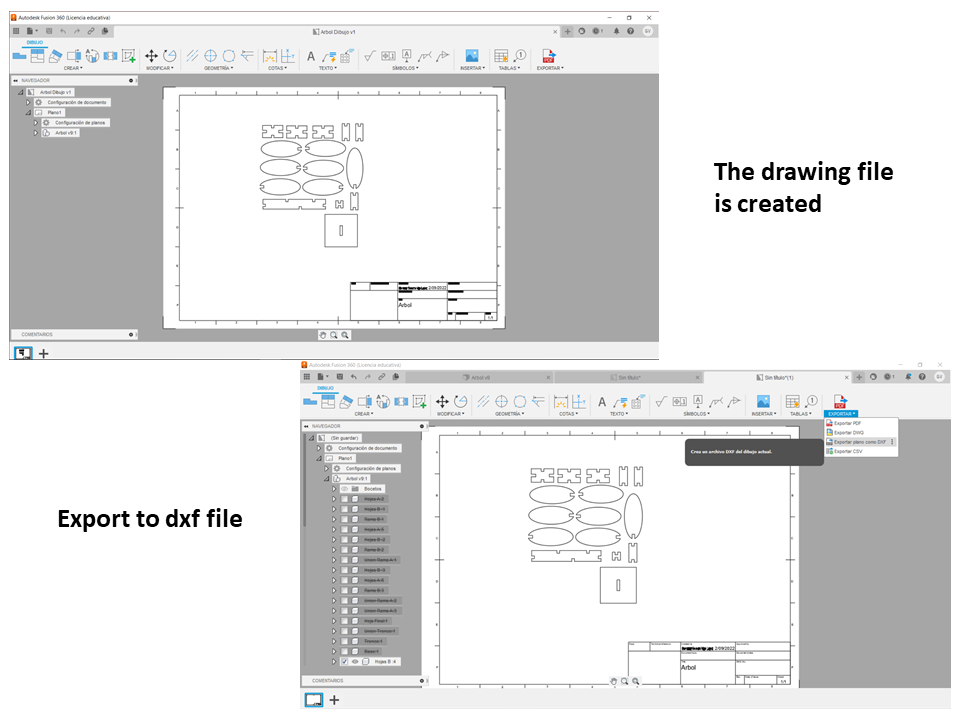

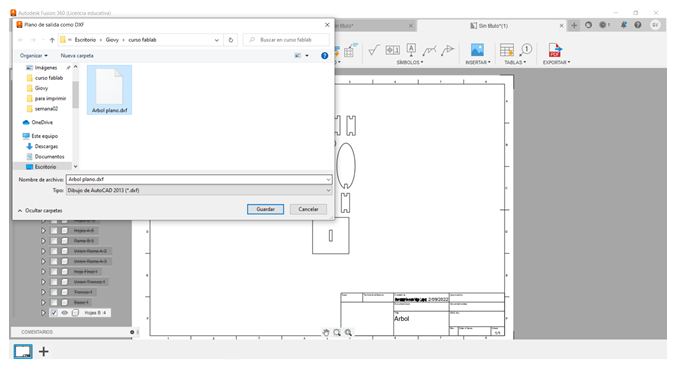

Drawing file

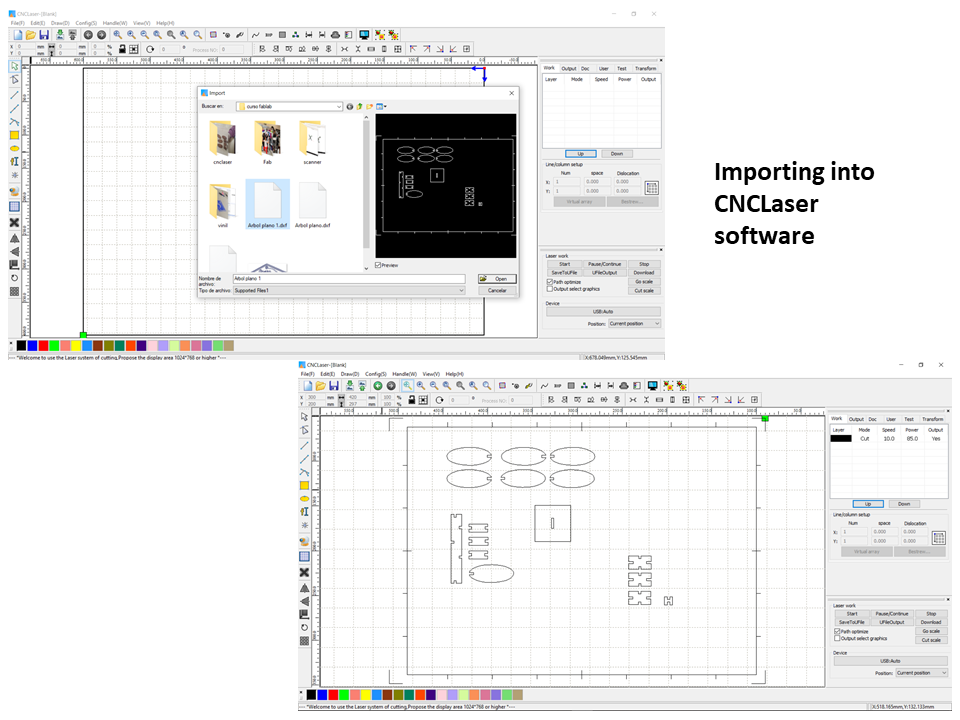

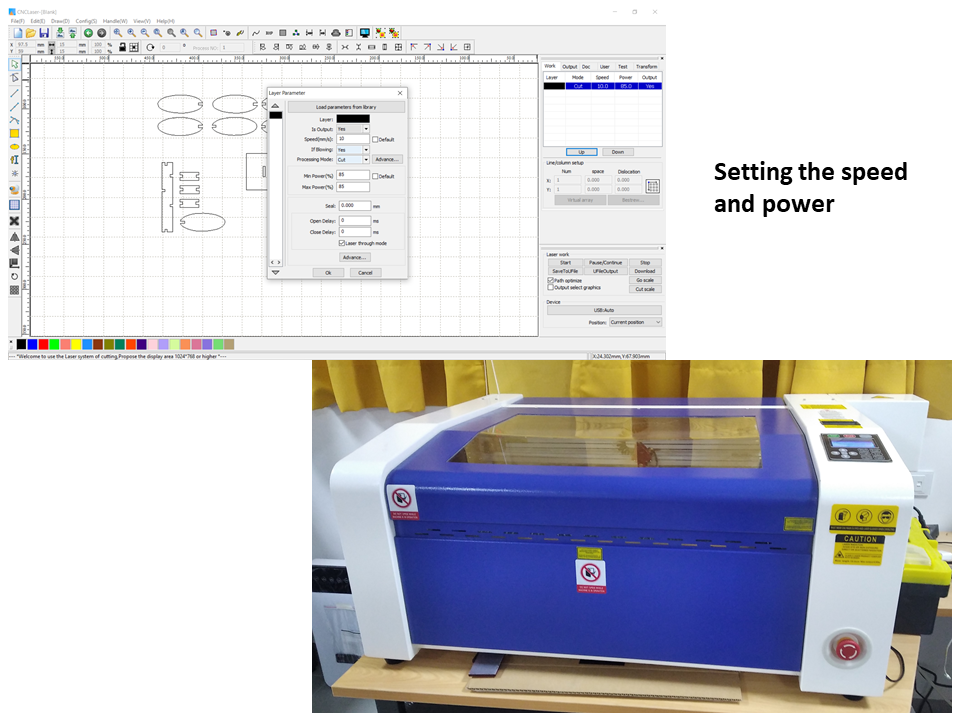

In CNCLaser Software

cutting the puzzle:

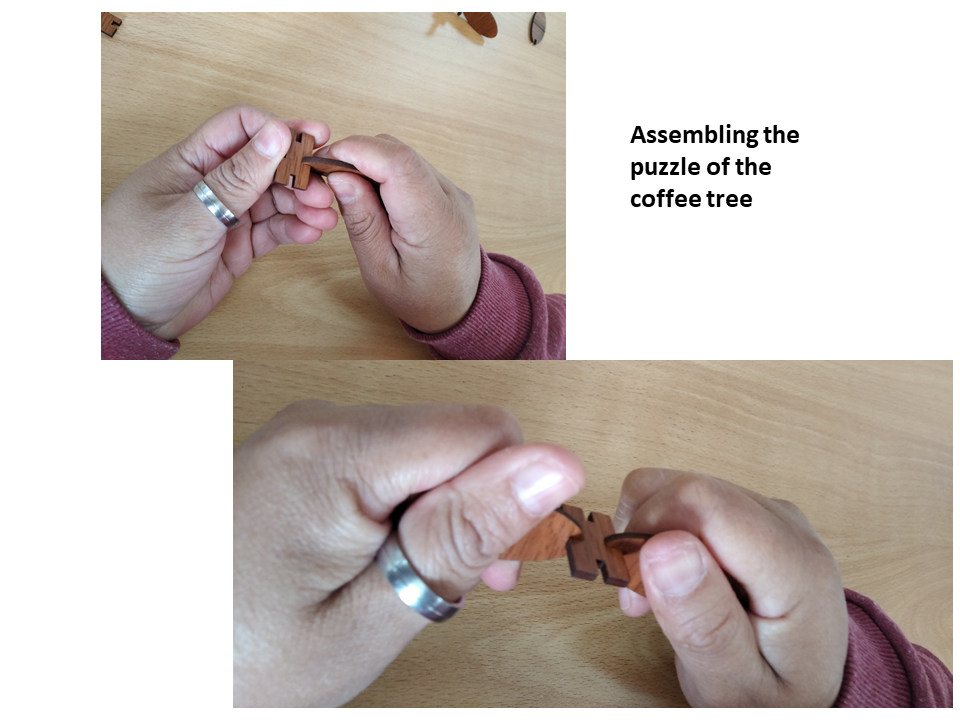

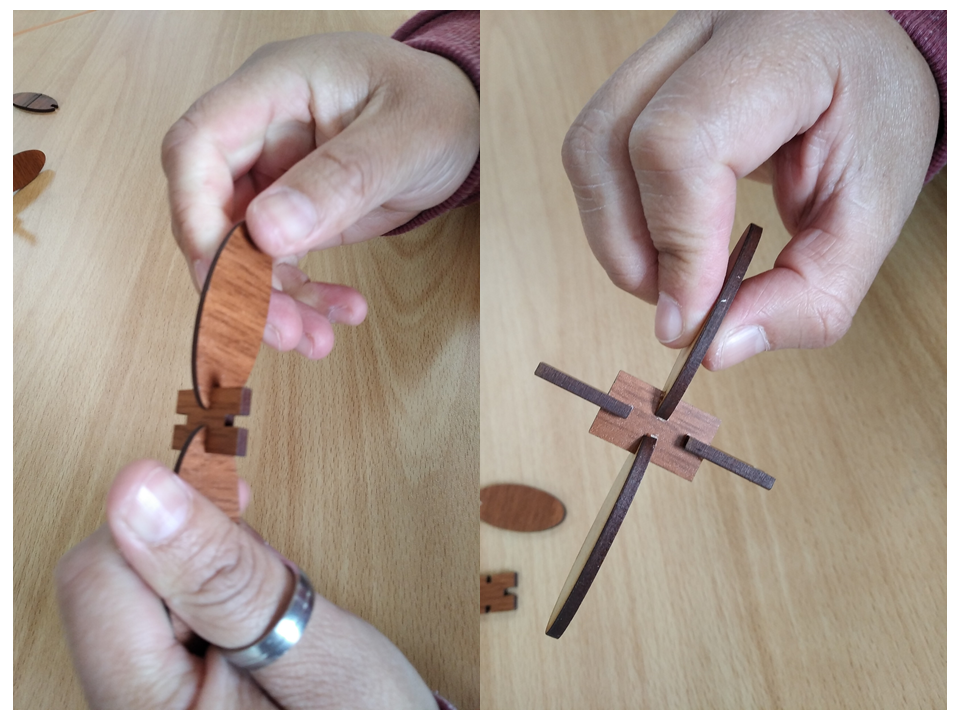

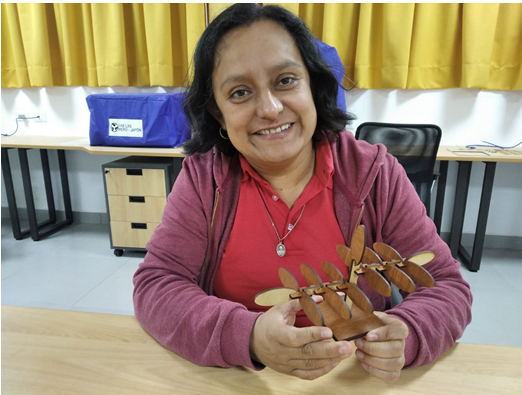

Assembling the puzzle

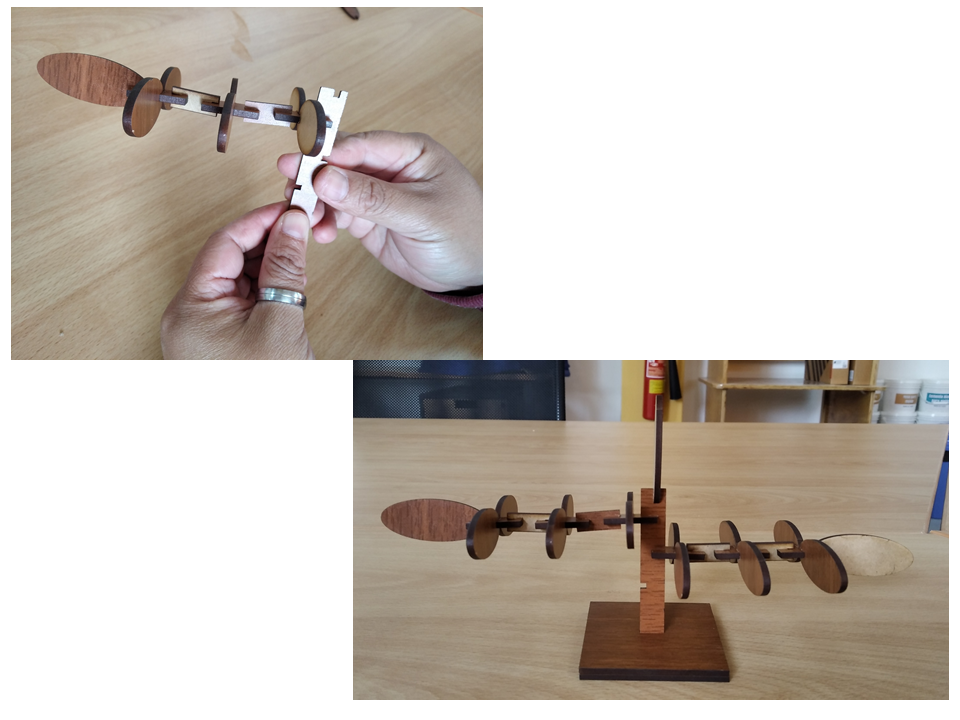

Coffe tree:

Draw Arbol

File Arbol - CNCLaser