Week 7 - Computer controlled machining¶

Group Assignment: * Do your lab’s safety training * Test runout, alignment, fixturing, speeds, feeds, materials, and toolpaths for your machine

Knowing machine and safety guide¶

Instead of using MDX-540, we went to another maker space and try a bigger machine which is made by someone.

Ted tells us the machine safety guide with poewerpoint slides (the first time like a class!) and then we spent a lot of time try to figure out how to use Fusion360 to generate g-code for the CNC. Which really takes time because we are not sure about the parameter of machine and need to ask the one made it.

Fusion 360 CAM: Introduction & Toolpaths

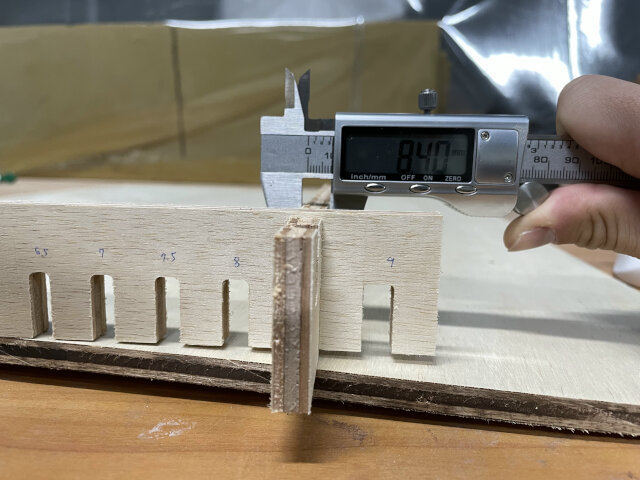

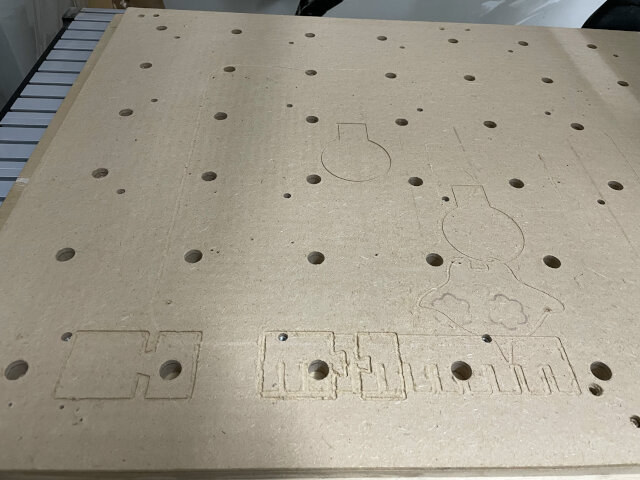

Several hours pass we finally made a successful test! Using the same site to generate “combs”. But we encountered a problem that Fusion may import SVG file in different size, you need to solve it manually.

Reference: SVG file imports with a wrong scale into Fusion 360

We Found out the CNC cut don’t need to set kerf! But on the other hand it requires Dog-bone or T-bone design to solve the right angle problem. So it’s a trade off I guess.

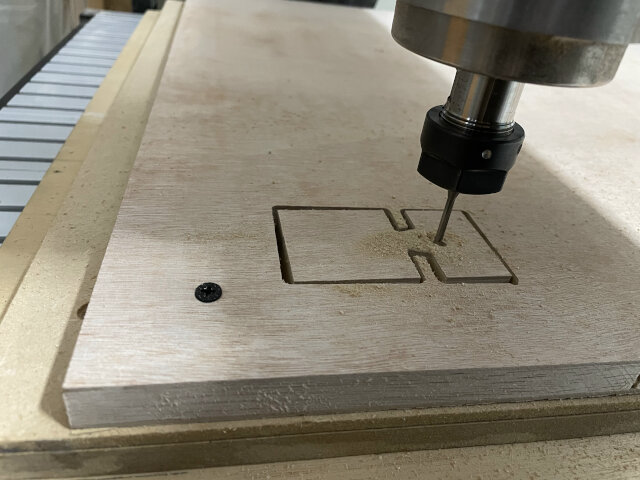

Another finding is we found a test from Adrian’s site, and surprisingly Fusion won’t set the sequence of the frame of the pattern and holes inside. So when pattern was cut of first, the following hole cut would able to mess up…

The machine is controlled by Artsoft Mach3 CNC Control software. In Mach3, we can manually position the CNC head by using the arrow keys. There is a number pad bluetooth keyboard so that the head can be moved “remotely” while standing next to the machine.