Molding and Casting¶

Group Assignment¶

- Review the safety data sheets for each of your molding and casting materials

- Make and compare test casts with each of them

Group FAQ¶

- Should I mill a mould for the group assignment?

- Answer: No, group assignment is for you to get familiar with the materials and the processes.

- Should I read the MSDS and TDS this week?

- Answer: Yes, always. Document the main points.

- I want to only make a wax mould, and cast something in it. Is that acceptable?

- Answer: Yes, if the parts you need to cast are soft.

- What does 3-axis milling mean?

- Answer: You should have smooth tilted or curved surfaces instead of “steps” towards axis Z.

- Can I 3D print the mold? Can I do a lasercut?

- Answer: No, for this assignment you must mill the mould using a CNC milling machine. After fulfilling the requirements, please go ahead and experiment other techniques for fabricating moulds.

materials¶

Alan picked out Mold Star 16 FAST, Smooth-Cast 325, and Ecoflex 00-20 for further investigation.

Mold Star 16 FAST¶

Mold Star 16 FAST is a soft, silicone-based material that is used for creating soft molds to cast other materials. The samples I made are squishy.

Section 2 is empty.

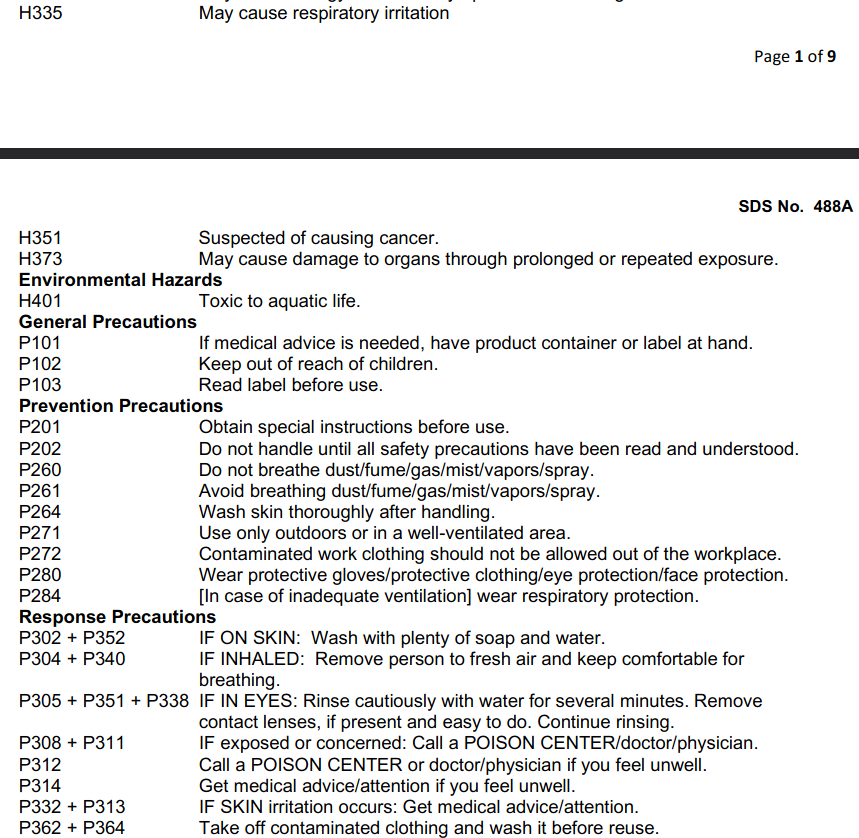

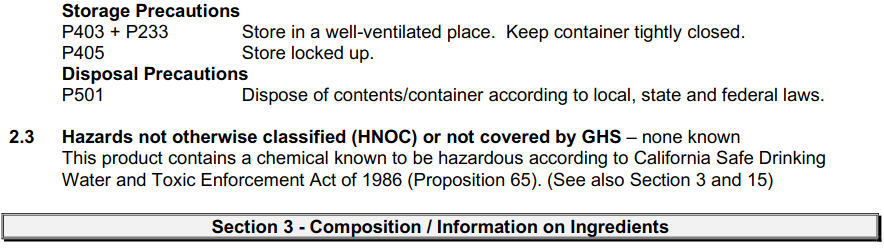

Smooth-Cast 325¶

Section 2 is so long, it takes up 2 pages of the SDS. (sorry about the formatting)

due to time constraints and safety constraints, didn’t end up using smooth-cast 325. Will revisit when I have time in the summer.

Ecoflex 00-20¶

I didn’t experiment with this material until much later, during wildcard week.

From testing the behavior of the samples I made, the shore hardness is much lower than the Mold Star 16 FAST, which makes it especially good for soft robotics.

Section 2 is empty.

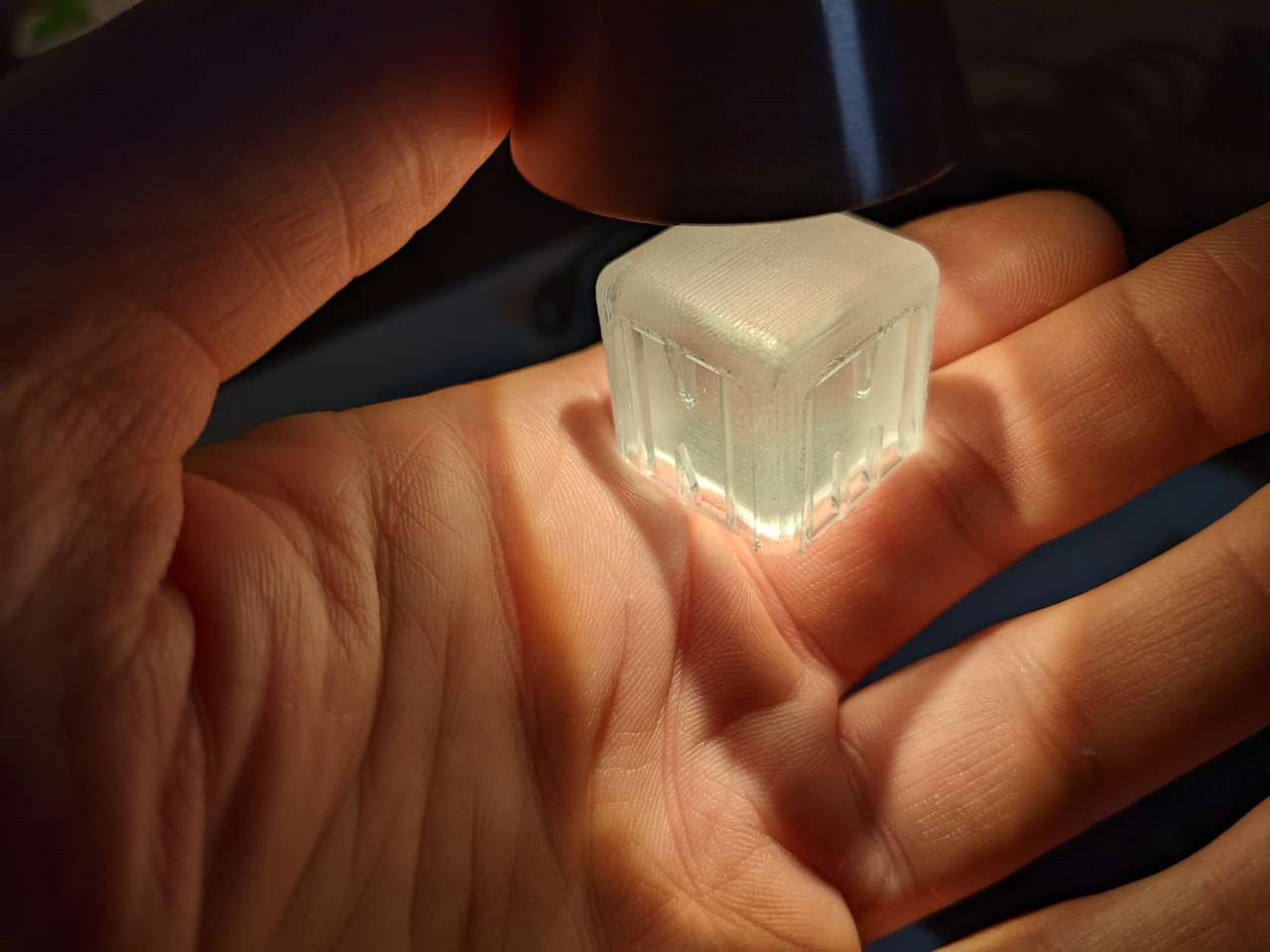

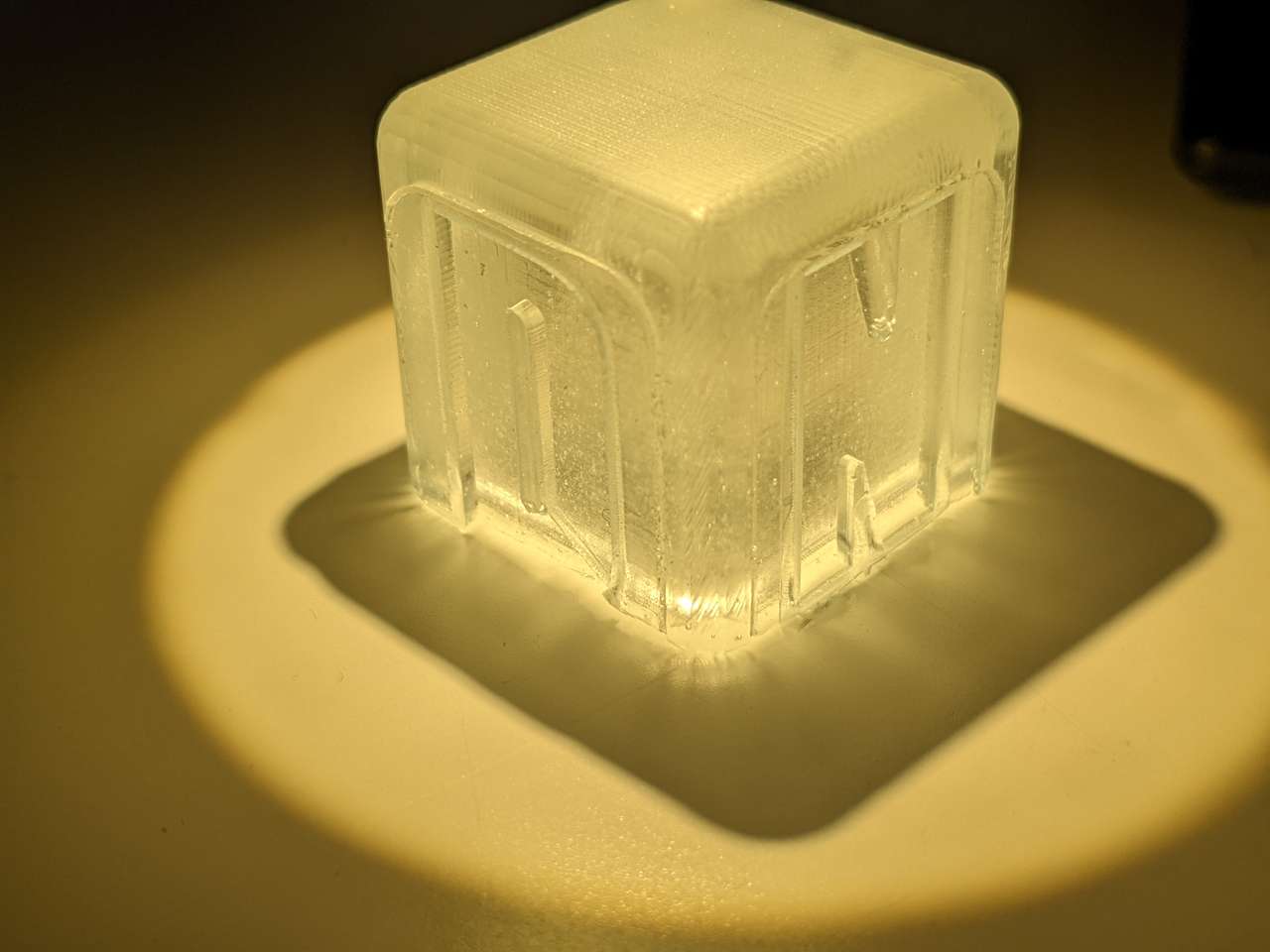

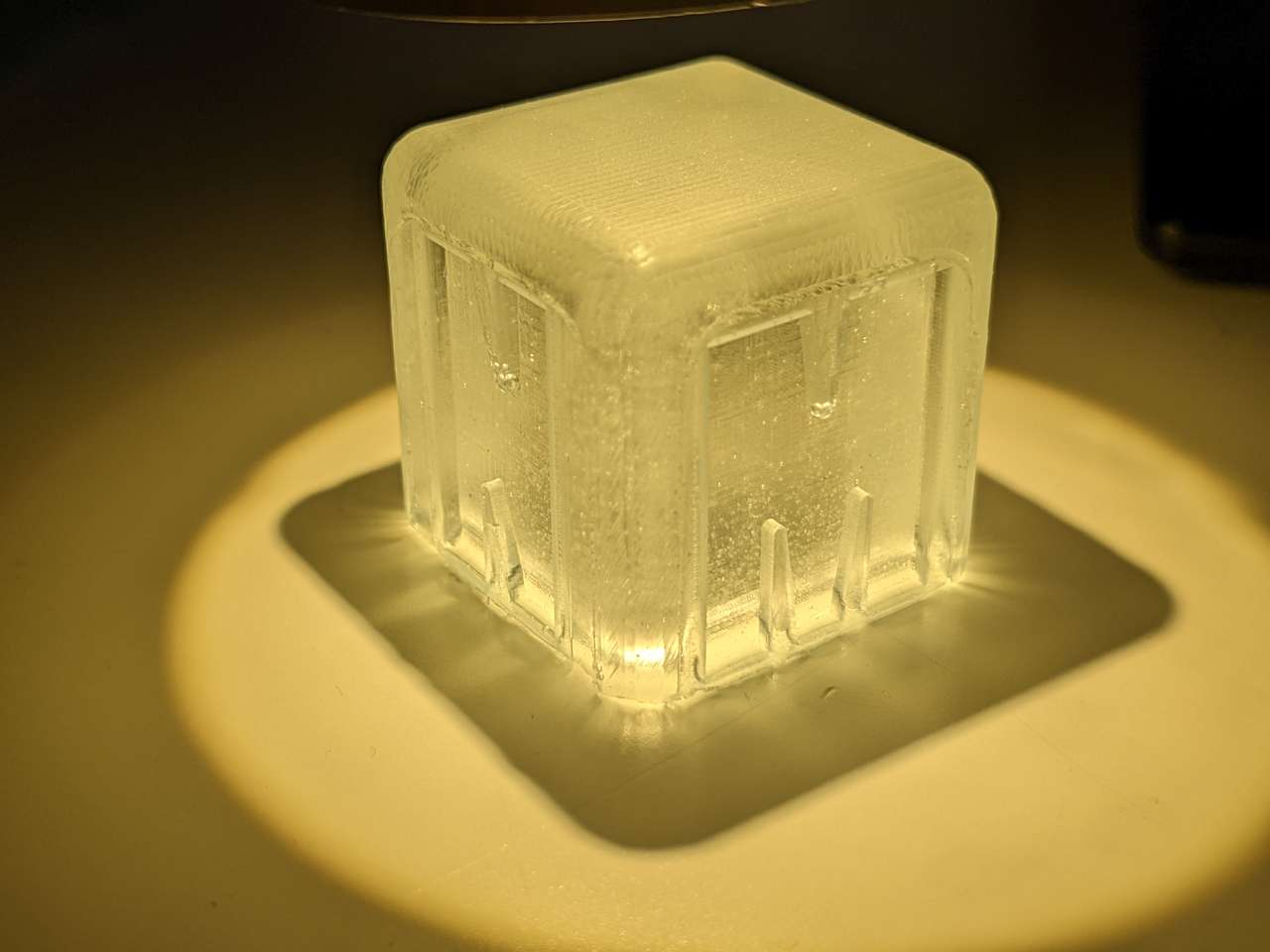

Amazing Clear Cast Resin¶

Dan Meyer decided to cast his part in Amazing Clear Cast. He reviewed the Amazing Clear Cast Safety Data Sheet, Technical Data Sheet and other info. The SDS listed the following PPE and procedures.

- Ventilation: Use with adequate general or local exhaust ventilation to minimize exposure levels.

- Respiratory Protection: If needed, an approved respirator with organic vapor cartridges may be used. Respirator selection and use should be based on contaminant type, form and concentration. For higher exposures or in an emergency, use a supplied-air respirator.

- Skin Protection: Wear impervious gloves, such as butyl rubber or nitrile rubber.

- Eye Protection: Wear chemical safety glasses/goggles.

- Other Protective Measures: Prevent skin contact and contamination of personal clothing. An eye wash facility and washing facility should be available in the work area. Follow applicable regulations and good Industrial Hygiene practice.

Dan’s Respirator

Dan Used a full face respirator with Organic Vapor Cartridges with prescription inserts. He also wore gloves and made sure to cover his work surface with a plastic garbage bag. Dan also put the mold with liquid resin in it in his bathroom shower stall with the exhaust fan running during the 72hr curing process.

casts¶

Machinable Wax¶

Safety Data Sheet for Machinable Wax After reading this SDS, Dan noted that around open flame the chips may ignite. So he avoided using lighters, heat guns and being near other sources of flame like a gas stove or water heater, while machining this wax. Dan kept the wax chips from machining in a covered container.

Dan will also use PPE when melting the chips and re-casting the blocks. A pot heated on a sealed electric hot plate will be used to heat the wax to melting point. A gas burner with open flame will not be used.