Electronics Production¶

Group assignment:¶

By Alan Han, Kyle Pierre NFR, Dan Meyer

Characterize the design rules for your PCB production process: document feeds, speeds, plunge rate, depth of cut (traces and outline) and tooling.

document your work (in a group or individually)

vocabulary¶

This CBA page provides context for terms.

quick reference:

- xy feed rate: speed at which the machine moves the machining spindle across the part

- spindle speed: speed at which the tool spins

- plunge (z feed) rate: speed at which the tool plunges into material

- cut depth: depth of material plunged per layer

MSI Chicago Fab Lab¶

Modela MDX 20 Mill¶

| Machine | Feedrate | Speed | Plunge Rate | Cut Depth | Tool | TIR |

|---|---|---|---|---|---|---|

| Modela MDX-20 | 10 ipm | 6500rpm | 4 in/min | .004 in | 0.0156” (1/64”) 2FL CU 129974 | .0015 in |

| Modela MDX-20 | 24.8 ipm | 6500rpm | 4 in/min | .004 in | 0.015” PreciseBits EM3E8-0150-15V Tapered Stub End Mill | |

| Modela MDX-20 | 16.3 ipm | 6500rpm | 4 in/min | .004 in | 0.010” PreciseBits EM3E8-0100-15V Tapered Stub End Mill |

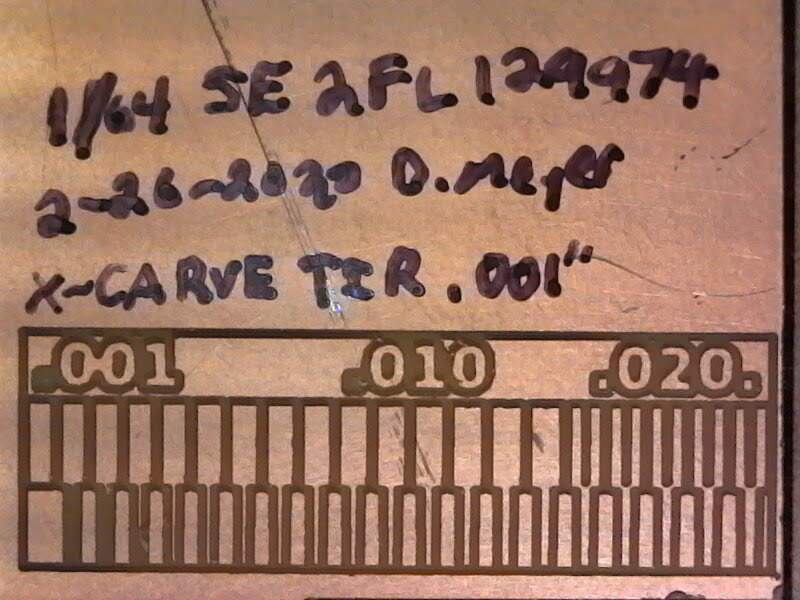

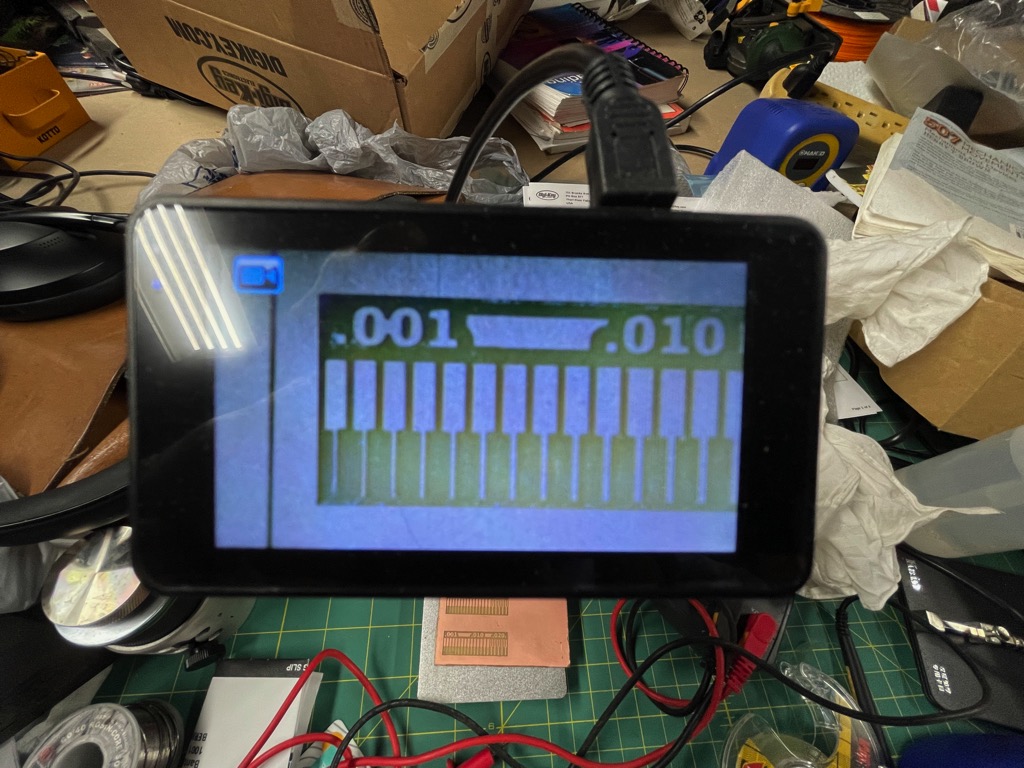

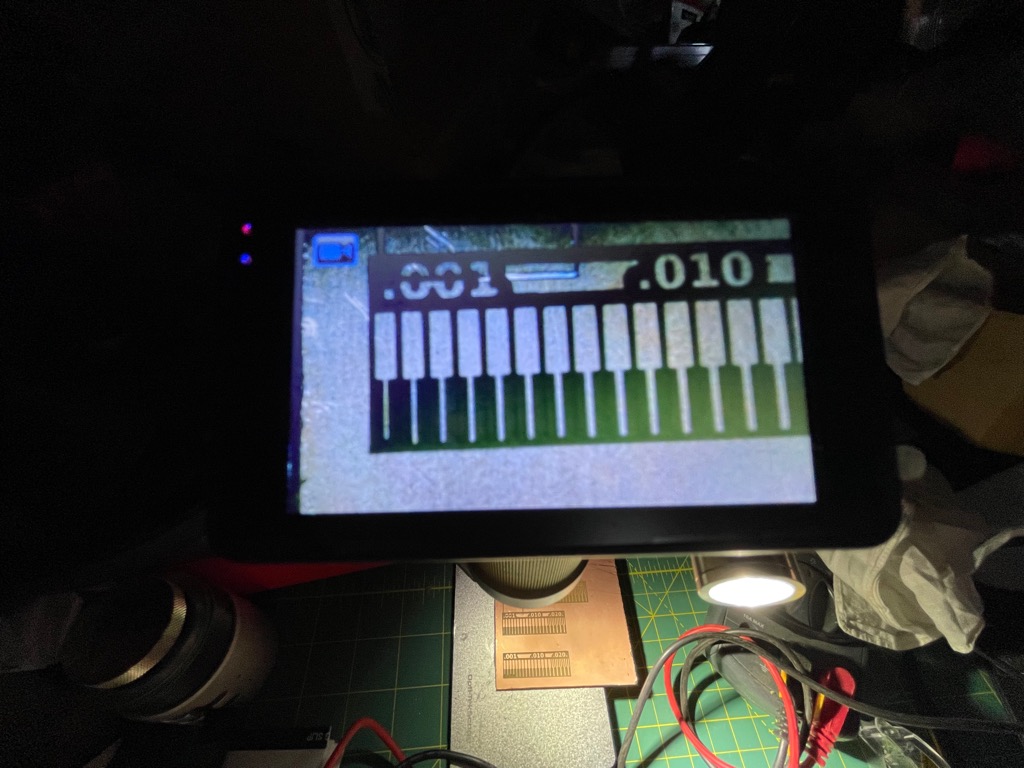

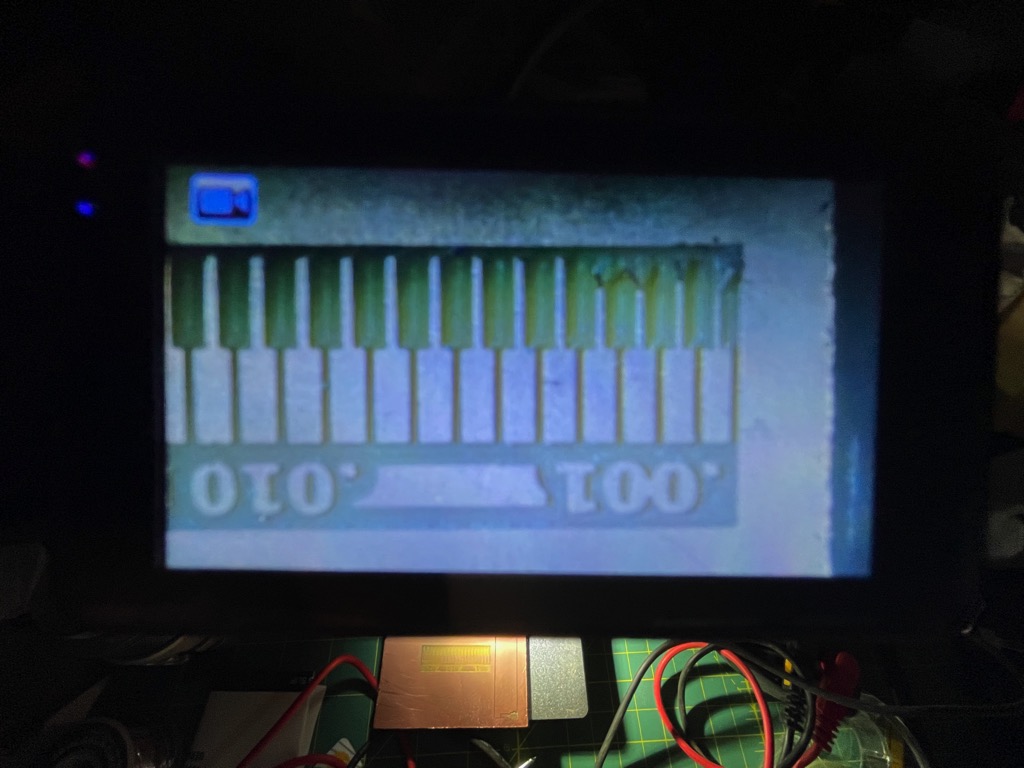

0.0156” (1/64”) 2FL CU 129974 trace benchmark above

X-Carve Mill 400 x 400 mm¶

| Machine | Feedrate | Speed | Plunge Rate | Cut Depth | Tool | TIR |

|---|---|---|---|---|---|---|

| X-Carve 400x200mm | 46 ipm | 12000rpm | 20 in/min | .004 in | PreciseBits Taper Stub End Mill 0.0150” (0.38mm) dia, 2 Flutes | .0015 in |

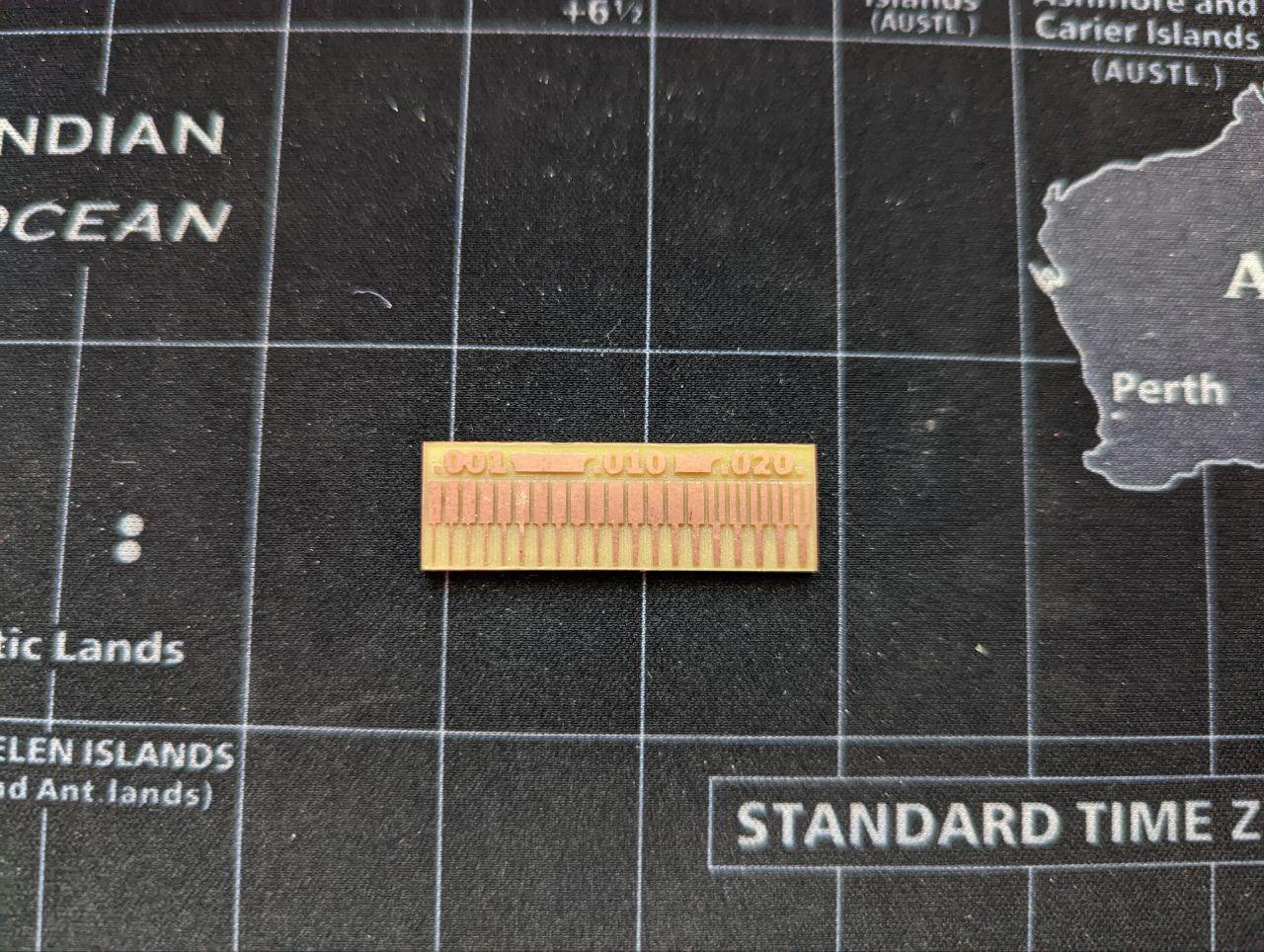

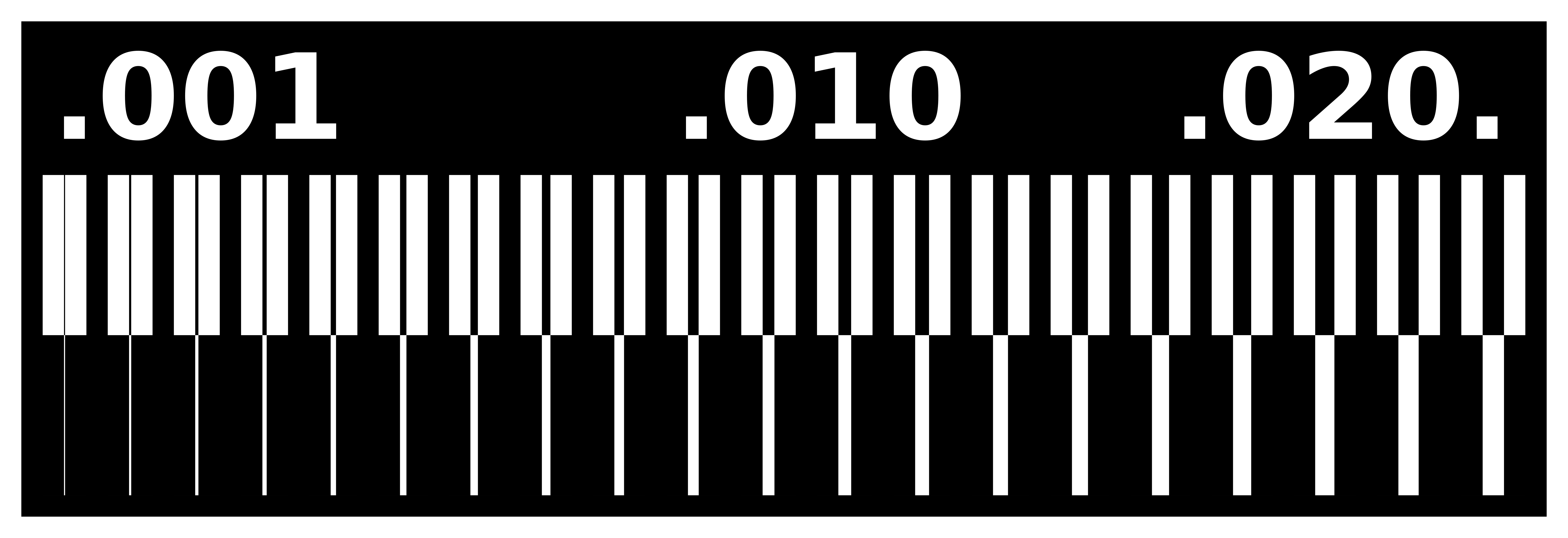

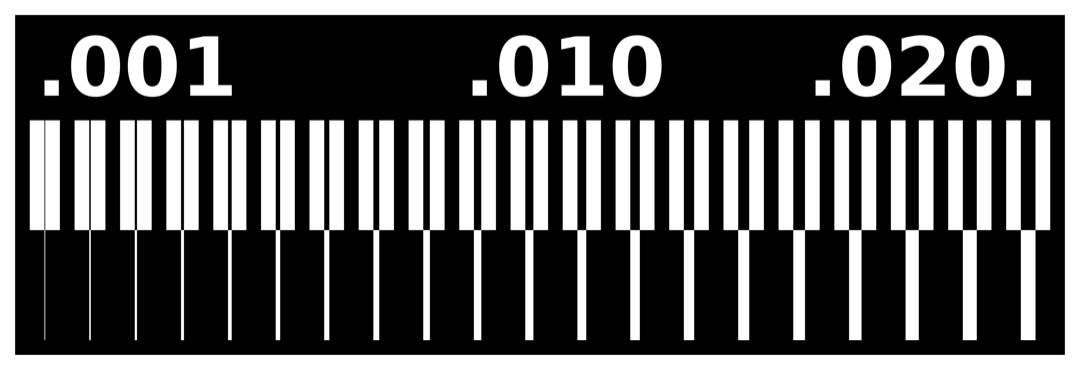

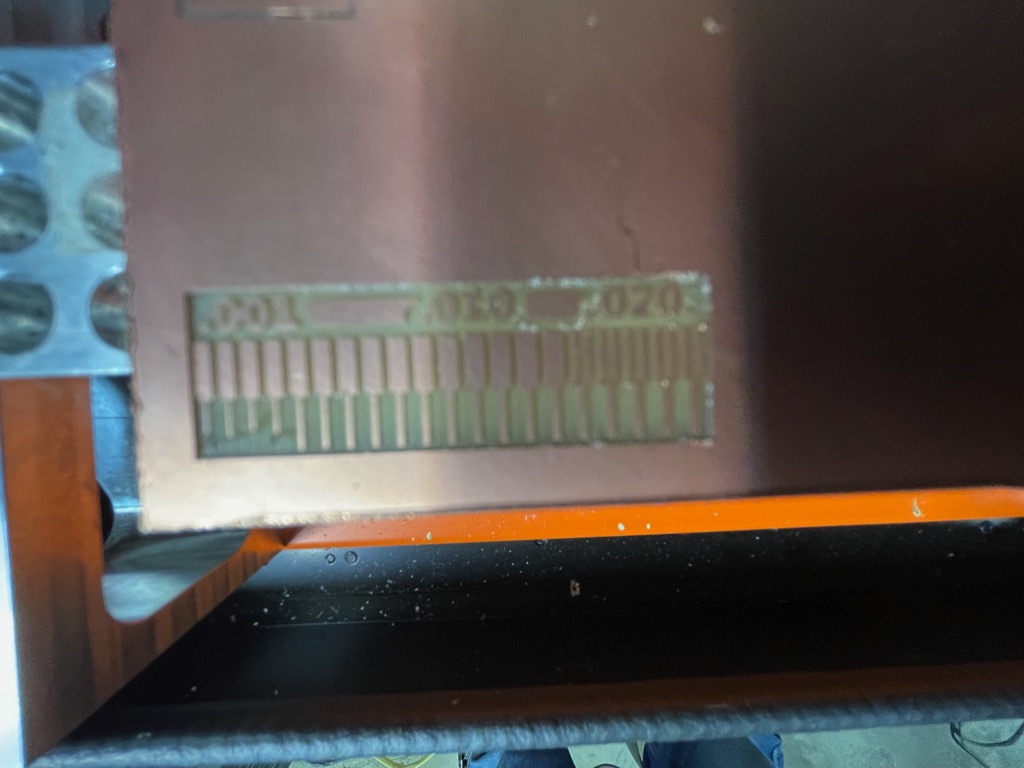

Mill Test Traces¶

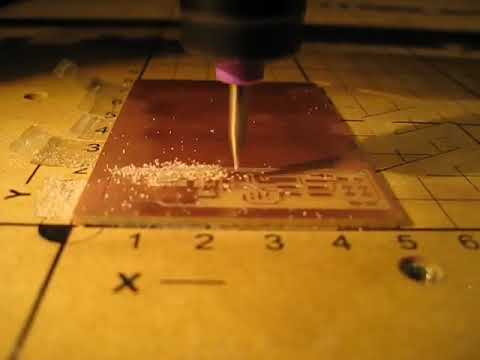

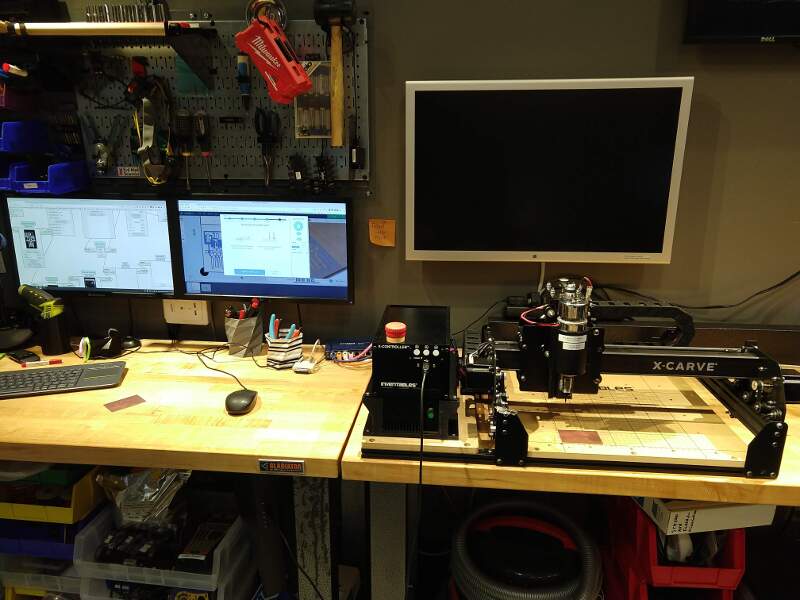

The fab academy test trace file above was use to create cam to test our X-Carve 500mm size milling machine. We purchased the smallest 500mm model of the X-Carve mill because it would be more rigid and so it would fit on a normal work bench top.

We had been told that it was impossible to micro-machine or mill a circuit board on a lower cost (sub $1000) milling machine like an x-carve. We suspected that this was not true, so we proceeded in the following way. It seemed to me the mass of the spindle, small cutting diameter, and rigidity of the machine was capable. We did know that vibration and concentricity of the tooling in the spindle may be important.

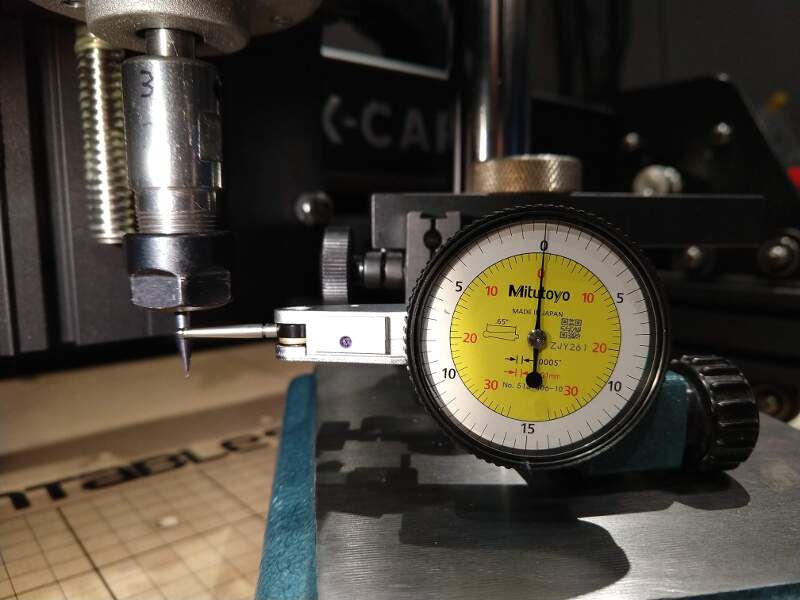

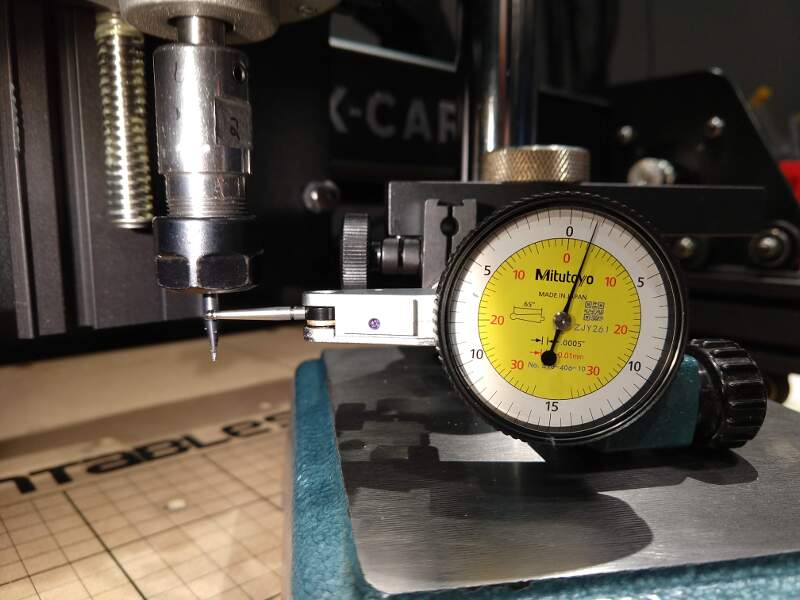

We wanted to make sure my x-carve spindle was ready for micro-machining. The first few times We tried to machine my circuit board on my x-carve it broke the 1/64” diameter end mill almost immediately. The bit also seemed to be vibrating a lot despite the fact that the spindle itself was runny vibration free and quietly. Being trained as a machinist years ago, We knew we should check the spindle and tooling run-out of the 400watt 48vdc quiet cut spindle we have installed on our x-carve mill. Below you can see photos where we am using a Mitutoyo 513-406-10E Dial Test Indicator to check the runout. This specific Dial Test Indicator was suggested by Ron Reed at Precise Bits a micro machining supplier we called in the process of researching micro-machining.

After rotating the tooling, collet and spindle the Total Indicated Run-out (TIR) measures a max of .0015” which is OK for a 1/64” diameter bit, but could be improved. We am waiting for some new collets from Precise Bits and we will see if they can improve TIR.

The above test trace file was cut with the following parameters:

| Feedrate | Speed | Plunge Rate | Cut Depth | Tool | TIR |

|---|---|---|---|---|---|

| 10 ipm | 12000rpm | 4 in/min | .004 in | 1/64” 2FL CU 129974 | .0015 in |

The test traces came out quite good for the purposes of the Fab Academy and matched the typical output of a Modela mill. The traces stayed in place into the 4th segment from the left, this means all typical trace widths will be easily machined on our x-carve. If we have time we will further optimize the x-carve with a focus on further reducing TIR.

Roland DG SRM-20¶

- Roland DG SRM-20 is a highly capable mill with an air-cooled spindle capable of speeds in excess of 10,000 rpm.

- For SRM-20, we can use Mods Project or Neil’s Mods from the CBA to set feeds, speeds, plunge rate, and depth-of-cut. Both versions use a separate module to save machine code in an RML file.

- For this assignment, we characterized speeds by cutting the line test pattern at 2, 4, and 6mm/s using a 1/64in square and stub end mill with two flutes to determine the maximum speed at which the machine could maintain 0.001in resolution.

- 2mm/s

- 4mm/s

- 6mm/s

- 6mm/s experienced tearing at 0.004in and below; neither 4mm/s nor 2mm/s experienced tearing.

- 6mm/s machines about three times as fast as 2mm/s. I can probably run the machine at 5mm/s and maintain resolution down to 1/1000 in for traces.

- For this assignment, we characterized speeds by cutting the line test pattern at 2, 4, and 6mm/s using a 1/64in square and stub end mill with two flutes to determine the maximum speed at which the machine could maintain 0.001in resolution.

The section above satisfies the group assignment assessment requirements of: 1. Characterize the design rules for your PCB production process: document feeds, speeds, plunge rate, depth of cut (traces and outline) and tooling. 2. Document your work individually

Establishing Feed Rate¶

Calculations for a PreciseBits EM3E8-0150-15V Tapered Stub End Mill were completed using:

PreciseBits Taper Stub End Mills under the Feeds / Speeds Tab

For a 0.0150” (0.38mm) dia - multiply your peak spindle RPM by 0.00381 (dry) or 0.00492 (with ME Lube ) with 20 IPM z-axis plunge rate

Mods suggest 4 mm/s feed, which is 9.5 ips. We are guessing that this is a recommended starting speed?

The calculated feed rate for my 0.0150” (0.38mm) dia Tapered Stub End Mill is:

Multiply your peak spindle RPM by 0.00381 (dry) or 0.00492 (with ME Lube ) with 20 IPM z-axis plunge rate.

Dry: 12000 * 0.00381 = 46 IPM (19.5 mm/s) Lubed: 12000 * 0.00492 = 60 IPM

We will tried dry machining first: 46 IPM (19.5 mm/s)

19.5/4 mm/s= 4.875 IPM

So a feed rate of 46 IPM (19.5 mm/s) is ~4.875 times the feed rate of 4mm/s We was using originally on mods. TIR checks and using the feed calculations to obtain the correct chip load for my 0.0150” (0.38mm) dia 3 flute Tapered Stub End Mill Part Number EM3E8-0150-15V really paid off. Circuit boards will be much faster to make on my x-carve 500x500 mill going forward. The x-carve costs around $1,900 with all the parts needed to get started. The PreciseBits EM3E8-0150-15V mill we used costs $16.15 It is very durable due to its 15deg taper geometry. We think this new setup will be better for beginners and will prevent bit breakage. It is also faster than our previous process.

| Machine | Feedrate | Speed | Plunge Rate | Cut Depth | Tool | TIR |

|---|---|---|---|---|---|---|

| Modela MDX-20 | 10 ipm | 12000rpm | 4 in/min | .004 in | 1/64” 2FL CU 129974 | .0015 in |

| X-Carve 400x200mm | 46 ipm | 12000rpm | 20 in/min | .004 in | PreciseBits Taper Stub End Mill 0.0150” (0.38mm) dia, 2 Flutes | .0015 in |