Week 2: Project Management¶

Final Project¶

For this week I worked on defining my final project idea and started to getting used to the documentation process.

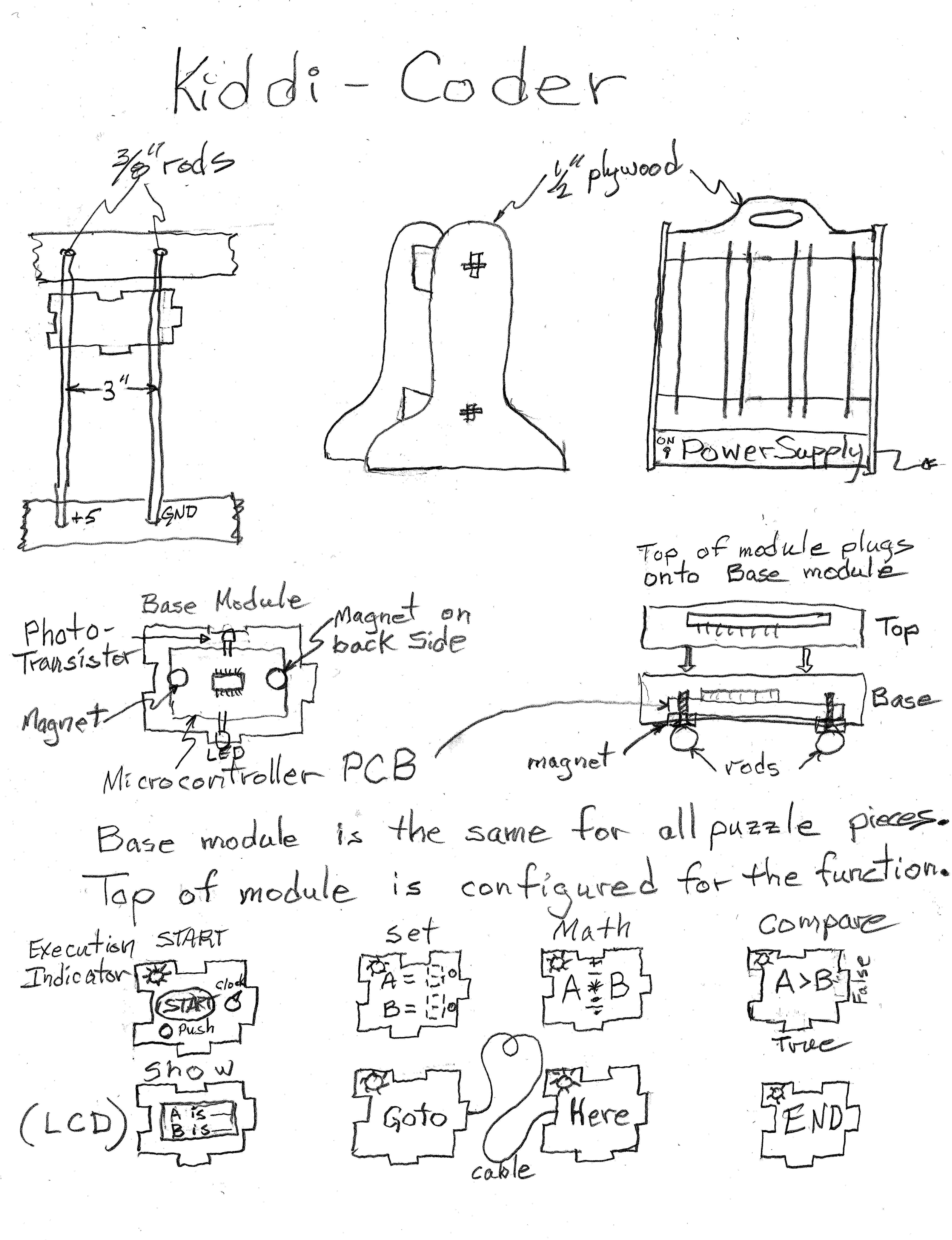

- Decided to produce a final project called: Kiddi-Coder The Kiddi-Coder is a hardware coding puzzle display, that introduces programming concepts to middle school students.

The pieces of the Kiddi-Coder will include:¶

- Start/Clock = A start block which has a pushbutton to start the processing. Included is a clock with a knob to control the speed of execution

- Set A, B = Initializes variables A and B to a user setting

- Show A, B = An LCD display shows the current values of A and B

- Math = A puzzle piece that can perform add, subtract, multiply and divide

- Compare = Compares A and B with comparisons >, <, <=, >=, and =. Directs the flow of the program.

- GoTo = Jumps to another location in the program

- Input A, B = Allows setting of the variables A and B

- Output = Allows the program to send information to a device, like DC motors, Stepper Motors, LEDs, and maybe an M&M dispensing device.

- End = The end of the program.

General Information¶

- The coding puzzle pieces will be magnetically attached to two vertical rods (one is +5 volts, the other ground) which powers each block.

- The base will hold the power supply.

- Each puzzle piece will be composed of a base part containing the microcontroller, and will be the same for all coding pieces.

- The top cover of the puzzle piece will have a daughter board that plugges into the base unit and wires up the specific function.

- Each puzzle piece will have a Photo transistor pointing up, that receives previous puzzle serial commands and an infared LED pointing down, to send commands to the next coding puzzle piece.

Research¶

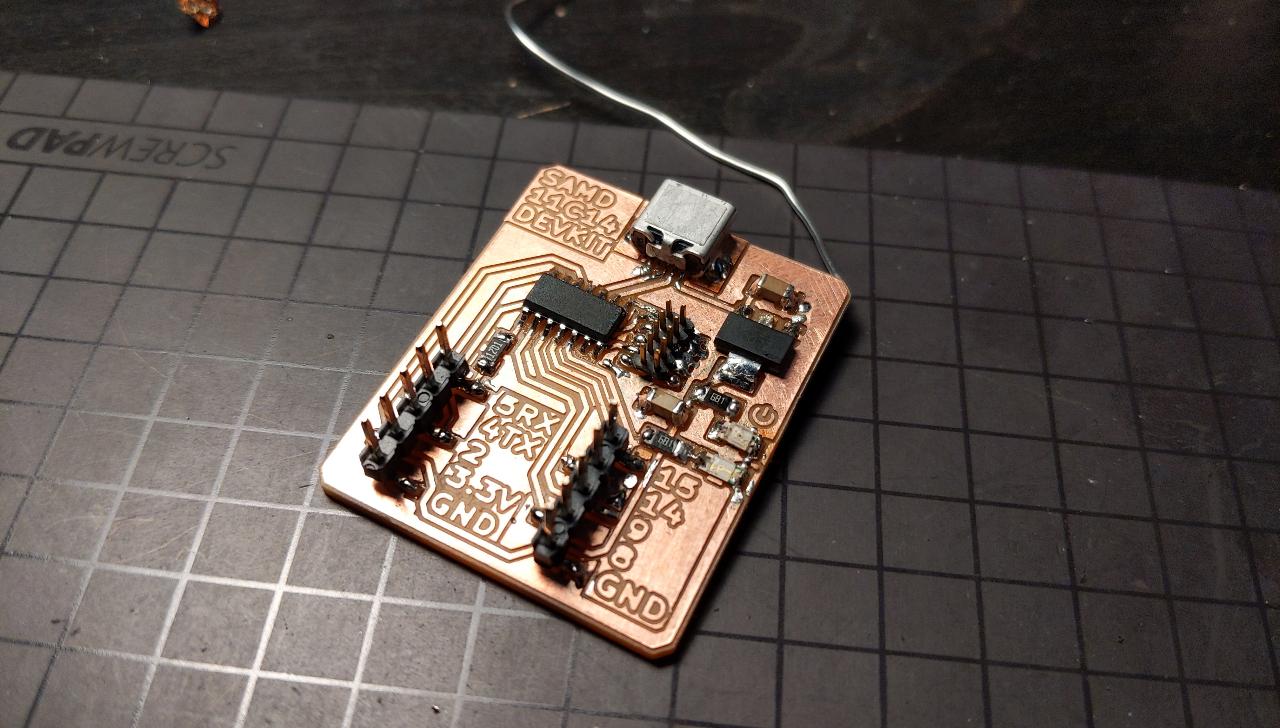

I got the idea for the base puzzle processor board from Quentin Bolsee (previous FabAcademy student):

https://fabacademy.org/2020/labs/ulb/students/quentin-bolsee/projects/samd11c_devkit/

The required technologies that will be used in the project include:¶

- Microprocessor design and coding.

- Schematic creation and PCB layout and routing.

- Milling the Printed Circuit Boards.

- CAD layout of the Mechanical components.

- Milling of the frame using the Shop Bot.

- Creating the 3D plastic frames of the coding puzzle pieces.

- Using the 3D printers form the many code puzzle Base and Tops.

- Use the Vinal cutter for graphics and wording.

2D and 3D Modeling¶

Modeling and design goes here.

Materials¶

- Plywood 1/2 inch, furnature grade, 4 foot by 4 foot.

- 6 chromed steel rods 3/8 inch in diameter, 24 inches long.

- PLA or ABS plastic for the 3D printer.

- Screws, nuts and bolts.

- BUD box to hold the Power Supply.

- Power Supply for the +5 Volts at 1 amp.

Last update:

February 23, 2022