18. Wildcard week - WaterCutter Machine¶

This week is Wildcard Week, giving me the opportunity to experience another machine type. Given Aalto University’s exceptional facilities, my list of options were a Waterjet Cutter, Zund Cutter, Wire EDM Machine & Vacuum Forming Machine. I really liked the possibility of viewing the Wire EDM Machine (maybe another time!), but due to the predicted nature of my future projects, and what I’m assuming as having greater accessibility, I decided on the Waterjet Cutter.

“The OMAX 55100 JetMachining® Center is the industry standard workhorse for high speed precision machining. From prototyping to full scale manufacturing, the 55100 can cut materials up to 4’x 8’ quickly and efficiently. The simple programming takes DXF or CAD drawings and quickly creates cutting paths, making the Omax 55100 ideal for short-run part production and just-in-time manufacturing. From small job shops to large production facilities, the 55100 JetMachining Center reduces cutting times and increases profitability”

This abrasive water-jet cutter can be used on a wide range of materials including metals (aluminium, brass, titanium etc), plastics, carbon fibre composites and glass (not tempered) and even tungsten! The Omax 55100 is said to be able to cut most things upwards of 12 inches thick, ideally upwards of 3 inches for a better quality cut. This machine has so many applications, being used on such a variety of materials that under Omax’s FAQ section, they even felt it necessary to advise against using it on food products!

It’s erosion process “cutting” ability is produced by way of highly pressurised water being fired through a mixing chamber, creating a vacuum and drawing in garnet sand into the stream, this jet stream is then fired onto the material, with the sand particles “cutting” out your design.

While being used in multiples industries, this machine is thought of as being very versatile but based on the comments made by our tutor, the OMAX 55100 seems to be a machine that one must be an expert on to both get the best out of it but also to keep it up and running. Maybe it’s the nature of water and sand to find its way into spots it shouldn’t be, but being able to quickly trouble shoot problems, any blockages etc throughout it multiple components, is absolutely crucial.

The Tour of the Omax 55100¶

A well timed photo, moments after as the tutor discusses the need for the recent addition of the white splash blinds, water is sprayed all over the blinds, making up close photos of the cutting process less detailed, but we remained dry!

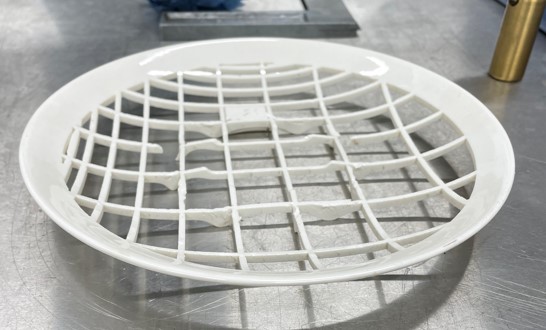

The above photo is a great example of some of the limitations on many waterjet cutters. While I believe some waterjet cutters can adjust the Z axis by way of elevating or lowering the cutting bed, the Omax 55100 cuts a flat 2D design outline. You can see in the above photo that as the jet nozzle moves across the plate via a level plane, cuts closer to the nozzle are more accurate, with the lower (central part) of the place showing less accurate cuts. Given this machines ability to cut upwards of 12 inches, maybe this problem is less pronounced while cutting harder materials, but with what I believe to be a brittle ceramic like material used for this concave plate, the Omax 55100 is clearly not the machine for this job.

Useful links¶

- Omax Homepage - Omax 55100 Precison Jetmachining Centre

- Omax Waterjet Frequently Asked Questions

- Markdown