1. Principles and Practices¶

The assignment for Week 1 of the Fab Academy was to “plan and sketch a potential final project”

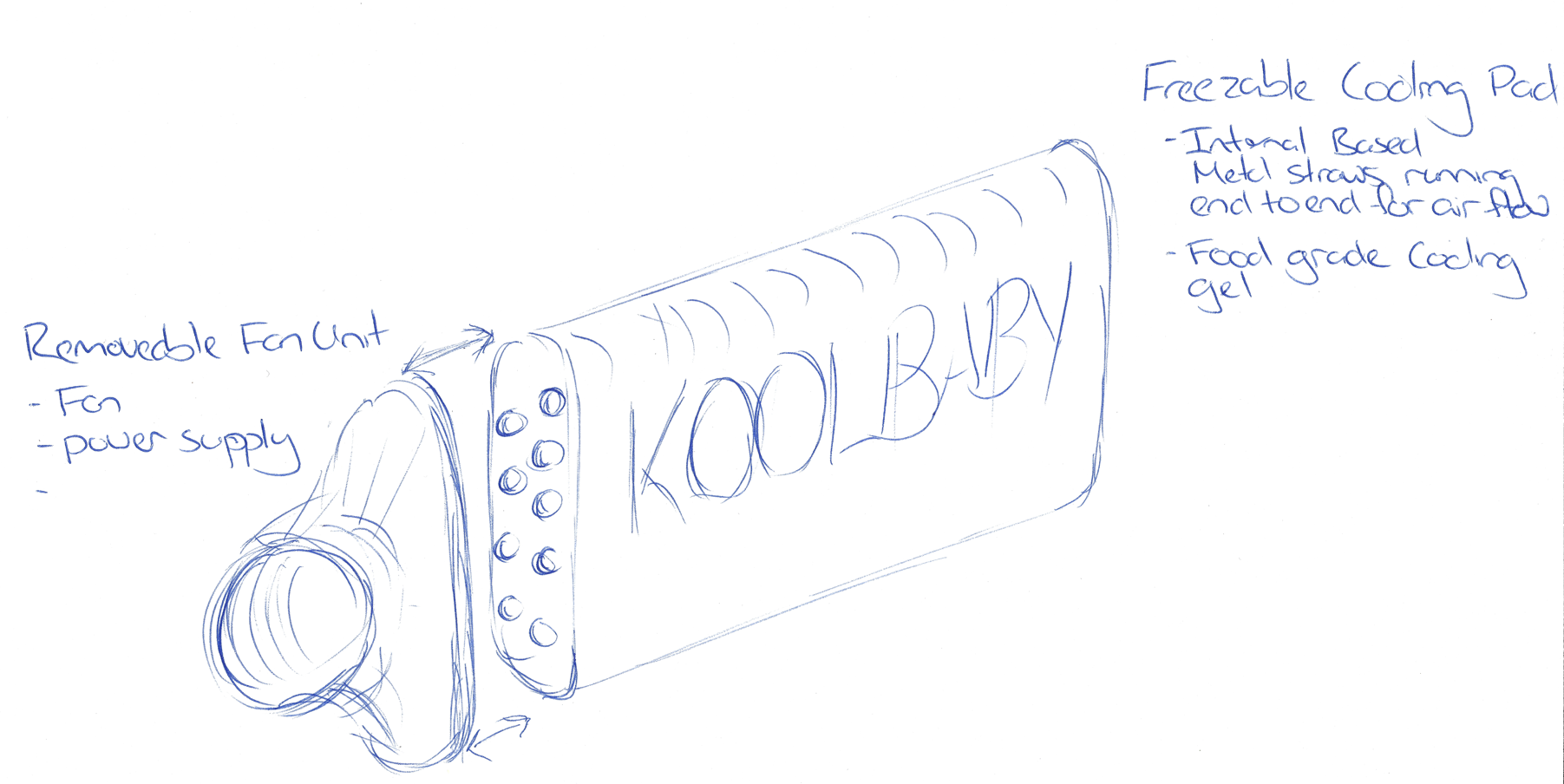

Coming into the first week, I had a project idea that I wanted to explore further. During a very hot afternoon in Berlin and struggling with the heat myself, I kept thinking how uncomfortable it must have been for young children, many of whom were sitting in a fully covered stroller. I thought a better cooling device for them (rather than the clip on fans) would be highly beneficial; Kool Baby.

A reusable cooling system used individually or in tandem for stroller based children providing temporary relief from hot weather conditions. Expected use is circa 20-30 mins ie a short walk to the shops / park, with product placement found within a sleeve on the inside of the stroller cover. Two units can be clipped together for increased cooling ability and / or duration.

Kool Baby’s cooling ability is initially enhanced and provided via the cooling gel (air being cooled as it passes through the internal metallic straws) found in the freezing pack, over time as the cooling gel’s effect diminishes, the programable fan will increase air flow, with cooling to the child provided via more traditional means; “fan mode”. The goal is to provide a consistent level of cooling to the child, with Kool Baby’s cooling capabilities coming from the smooth and incremental transfer from cooling gel to “fan mode”.

Week 1 - Initial Design¶

The biggest gain I think I’ve had so far in the course has come from the need to incorporate more of the course learning elements into my design, for example the need to include some form of MCU / programable feature into my design.

Initially, the head / fan unit of Kool Baby was to have a simple on/off function, with a consistent flow of air from the product. With the potential addition of a MCU, I would like to explore the possibility of variable air flow, this programable element to be modelled during the testing phase. I also think this MCU design feature could open the product up to additional capabilities such as, transitioning from cooling gel to fan mood (increased air flow) for cooling, different fan outputs if two Kool Baby products are operated in tandem together for increase duration, or maybe an alarm if the head / fan unit is placed accidentally into the freezer along with the main freezer unit.

Research & Testing¶

For the initial testing phase I have 2 main goals:

Firstly for the freezer unit, what is the best combination of metallic straws and cooling gel. My hypothesis is that more straws will increase the units cooling ability but reduce its cooling longevity through both speeding up the energy transfer process and while also reducing the volume of cooling gel in the unit (due to limited space). I will also test straws of different diameters to test for the above.

- Metallic straw selection will also be based on Cost / Availability, Safety and both Thermal Expansion (I don’t want the unit cracking in the freezer) & Conductivity properties.

Secondly, I would also like to experiment with the fan output, can I design a variable fan output that best achieves its cooling ability.

I would like to also understand if this product idea is practical, there’s no point continuing with the design if testing shows that I would need a freezer unit with 10kg of cooling gel for 5 mins of use!

1st Test Unit¶

The main body (frezzer unit) of the test unit will come in 4 pieces, Upper & Lower (as shown below) halves which will click together, with a set of interchangeable end unit pieces. I will design multiply end pieces with varying hole numbers and sizes for the metallic straw testing phase.

2. Project Management¶

Also this week, I worked on defining my final project idea and started to getting used to the documentation process.