11. Molding and Casting¶

This week I learn how to design a model by molding and casting. It’s pretty interesting.

Group Assignment¶

Different shapes of model need different materials of negative mold. For example , complicated mold need to be made by softer materials which can be pushed or easily moved.

Recently I tried to create a nice snow flower by several methods and failed. At first I decide to make a snow flower mold, however my instructor suggest me that the Roland CNC machine is more powerful and can cut a better 3 D mold which is better than 3 D printer product. So I use the laser cutting machine to cut the snow flower and cute panda cup bottom with hardboard. And I use the comma siliconica putty 45 (A: B = 1: 1 mix) and get two mold. The material should be mixed very well with each other fast. So the comp. B and comp. A could be pressed to be a very thin cookie, allow one totally cover another, mix them by folding them and pressing them into one cookie again, repeat the last steps several times quickly and do the negative mold.

![]()

The snow mold is strong enough but the raw materials didn’t mix well and merge well. And the second panda mold is softer and not strong enough which caused by the wrong mix method that bring air to the mold materials and leave bubbles in the mold. So the snow flower model looks good and the panda looks not good but still can be used for the coaster.

Individual Assignment¶

Design a positive mold¶

I want to make a Aladdin lamp as I like the cute decoration as soon as I saw it and couldn’t forget it. With Aladdin mold, I can cast with different materials for various usage.

Roland CNC machine is different from Shotpot we used before. The machine is hard to cut vertical angle shape,but it’s good at cutting curves. So I use Extrude the curve- tapered function to draw the mold of wax.

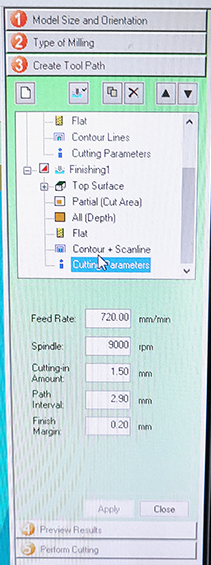

The parameters for the Roland machine

I want to get a good mold, so we decide to cut three times.

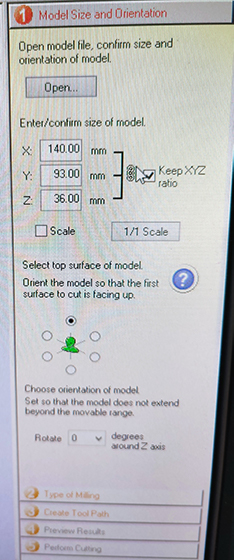

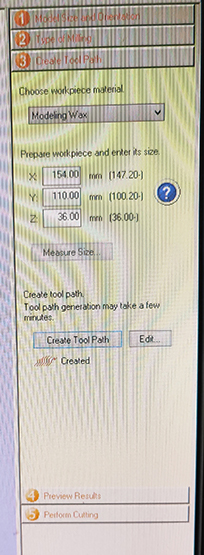

- As I use wax as the positive mold, and the size of the wax is 154 * 110 * 36 mm which is also the workplace size.

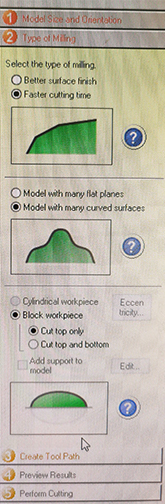

- Secondly, I choose the type of milling. For the 1st cutting is a faster cutting, the model has many curved surface. As the mold is one piece, so the mold only needs to cut top.

- Thirdly, I choose the material is Modeling Wax, and click “Create Tool Path”.

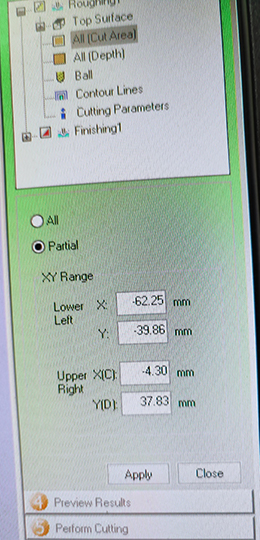

- As my Aladdin is small and it only needs half of the wax, so the cutting area is

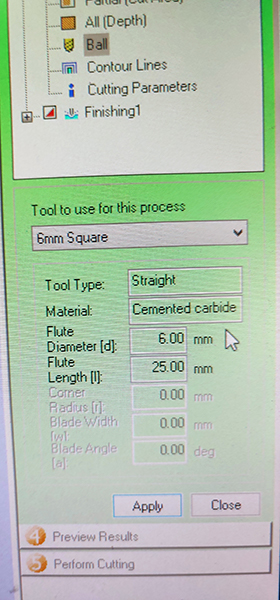

- The first cutting I use 6 mm square end mill with up cutting.

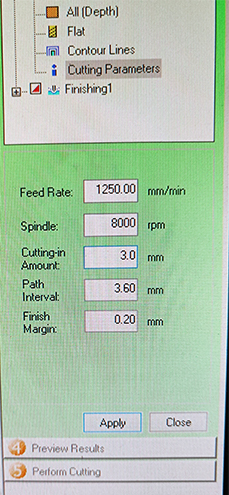

- The parameter for the 1st cutting is

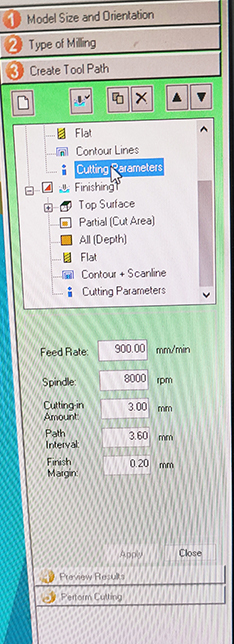

- The second cutting is a fast finish cutting, the parameter is

- The third cutting is a slow finish cutting, the parameter is

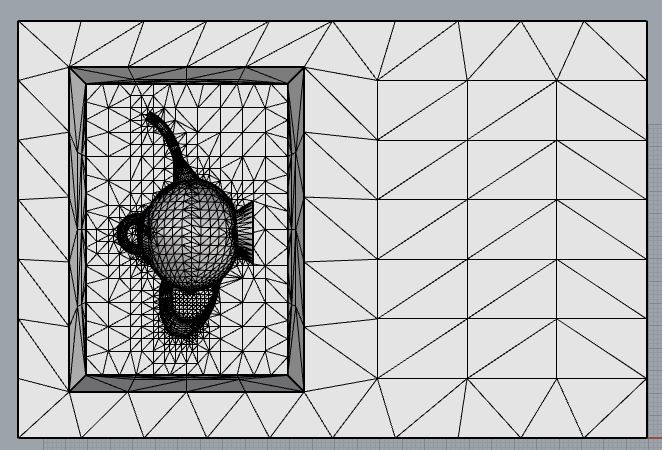

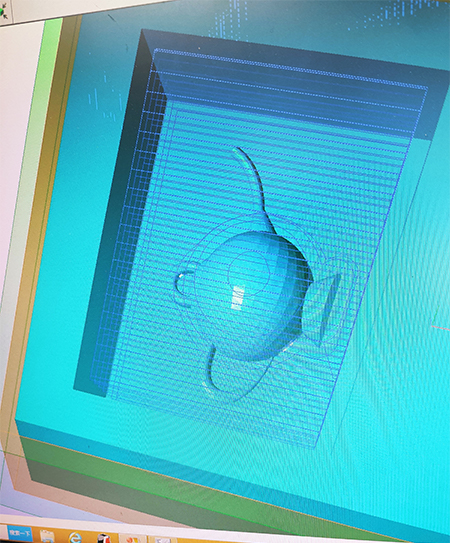

- The toolpath I get in the Roland software is

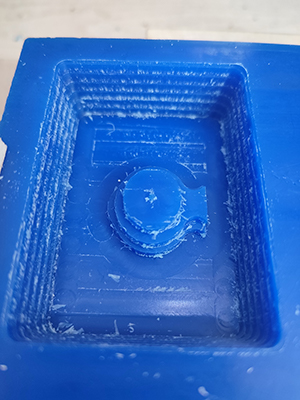

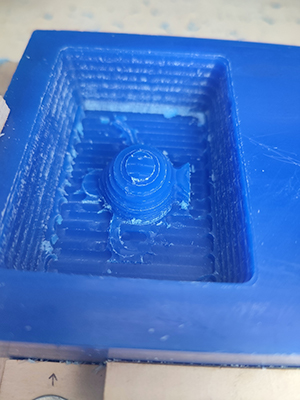

Cut the WAX by Roland CNC machine

Firstly,I choose fast rough cutting with D 6 mm square end mill.

Secondly, I choose the fast finishing cutting with D 3 mm square end mill.

Thirdly, I choose the slow finishing cutting with D 2 mm square end mill.

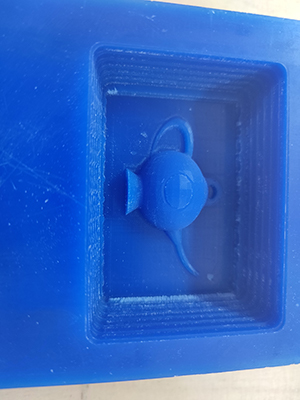

Make a negative mold by silicone rubber¶

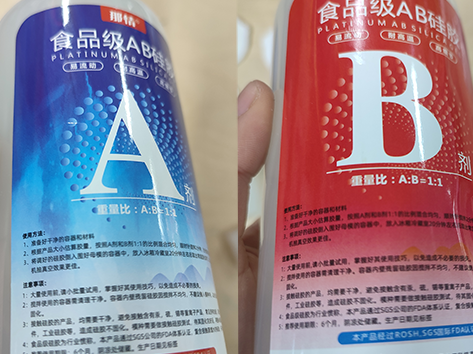

The silicone rubber I use is just bought from Taobao. It’s defoamable AB liquid food grade mold making silicone. AB liquid food grade mold making silicone is a food grade silicone suitable for making baking molds and trays, to use for craft and food. It cures at room temperature(25 degree) within 3-8 hours with negligible shrinkage. Cures faster when temperature is around (36 degree). Creates soft, flexible silicone molds which can withstand up to 200 degree. This mold is suitable to use for chocolate, fondant, clay and other crafting materials.

Mix silicone A and silicone B (1:1) in a clean paper cup, stir well the mixture for 2 minute. Pour the liquid to the positive mold slowly and freeze the mold 20 minutes, then take it out and wait the mixture dry totally.

Cast and receive a positive model by drystone (plaster)¶

I use three different materials to cast and get three different models. The material that the blue model used is fast cast polyurethane casting resin. FastCast™ is a two-component clear urethane casting resin, which turns white once set. Easy to use, 1:1 ratio and is odorless. Ideal for casting, quick prototyping, miniatures, models, taxidermy and more. FastCast™ sets to a hard cast in approximately 10 minutes at 70°F. Once cured, FastCast can be drilled, sanded, shaped and painted.

The second model is made by the metal with low boiling point. Its boiling point is lower than 100 temperature. And the third model is made by the gypsum powder. The gypsum powder could be mix with some water to form a liquid mixture similar with yogurt. Then pour the liquid mixture into the negative mold quickly and leave it to be dry totally.

Problems and errors that I met¶

-

I forgot changing the end mill, and faster finishing cutting used the D 6 mm end mill for several seconds, which created a ellipse shape.

-

The last finishing cutting should use D 2 mm ball end mill, however the bottom of the lamp is straight and forgot correct it. So I use D 2mm square end mill, as this end mill is long enough to cut the wax without destroying the mold.

-

There is something wrong with the collect with setting srew and the end mill fell down during cutting. The noise was bigger and only one line was cut deeply and depth is different.

Files aladdin.stlr