Dog Bone Joints

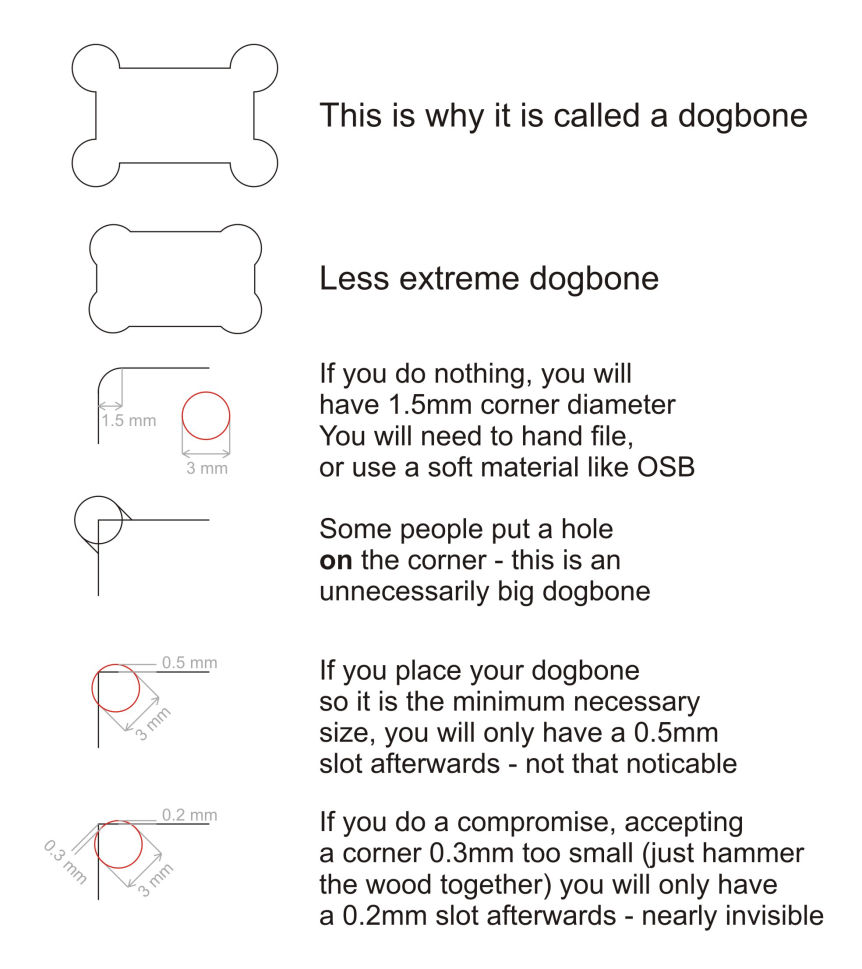

I found a very nice explanaition about how to make Dog Bone Joints that I will share below.

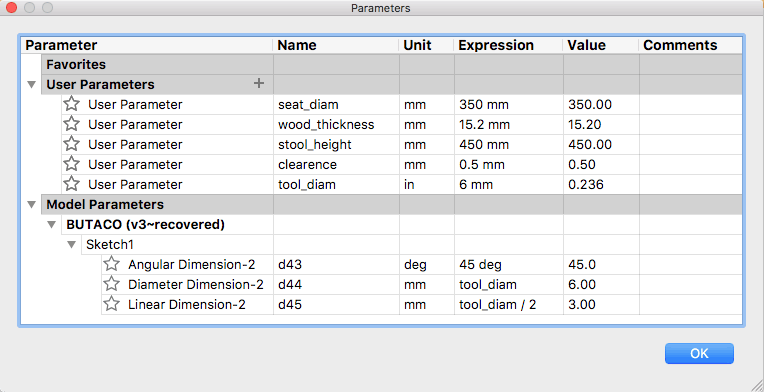

Basically what I did was to create a cilinder with the diameter of the tool, and snap one of the borders to the corner of the object I´m cutting and then extrude it.

As it says here, you sould also snap the center of the ciliner to the corner, but that will create a bigger unnecesary joint, compared to the smaller one I´m telling you which is much cleaner in the design.

After creating the cilinder, you can also mirror it to do exactly the same cut in the other side.

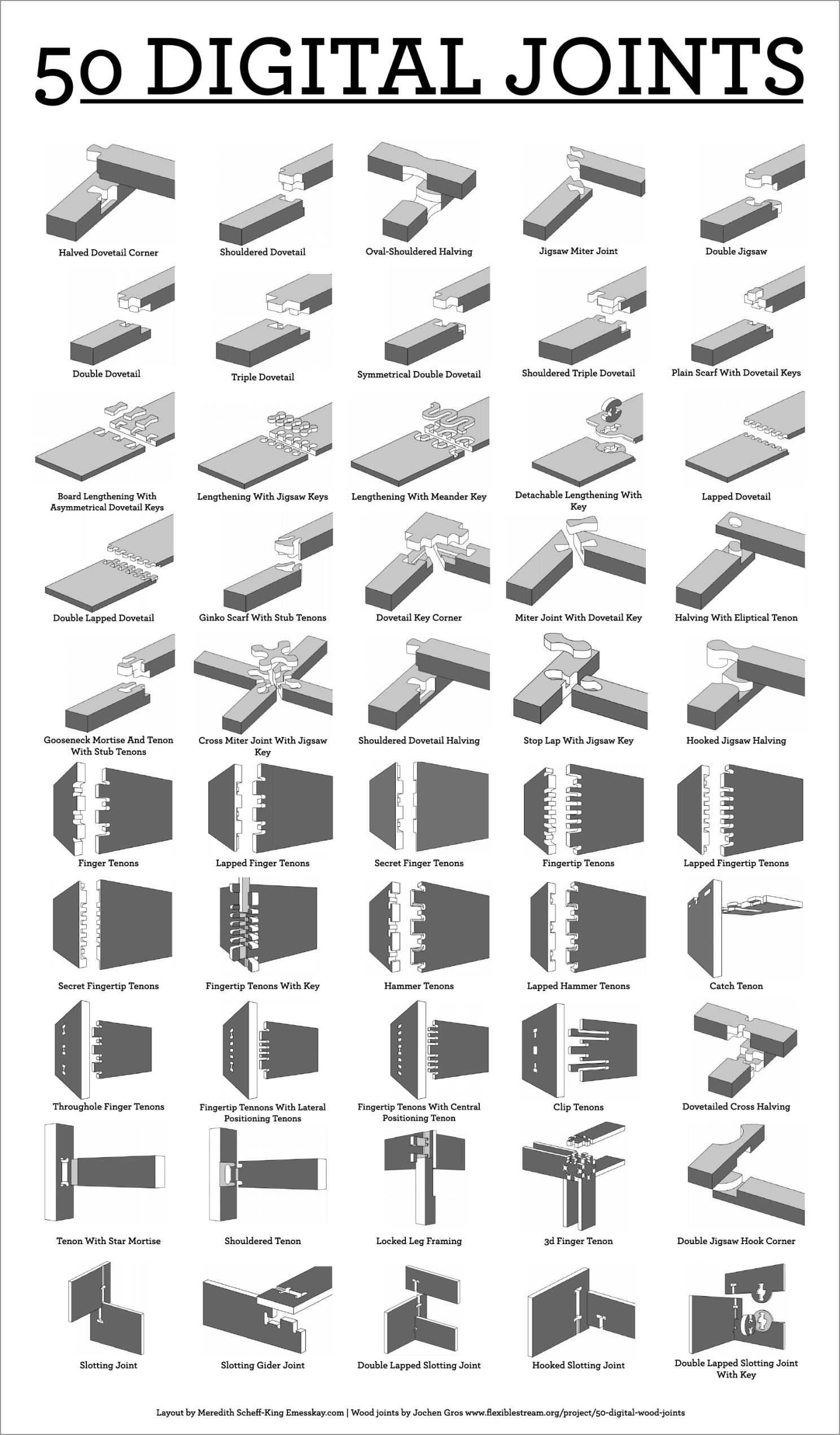

There are a lot more kind of pressfit joints, but this are the ones I used.