5. Electronics production

The goal of this week is to make an in-circuit programmer by milling the PCB, and to program it.

PCB preparation

For this week, I choose to made the FabTinyISP of Brian.

After reading the documentation closely. I decide, to prepare a list of all the electronics stuffs and keep it in side.

Electronics stuff

- 1x ATtiny45

- 2x 1kΩ resistors

- 2x 499Ω resistors

- 2x 49Ω resistors

- 2x 3.3v zener diodes

- 1x red LED

- 1x green LED

- 1x 100nF capacitor

- 1x 2x3 pin header

Files machine preparation

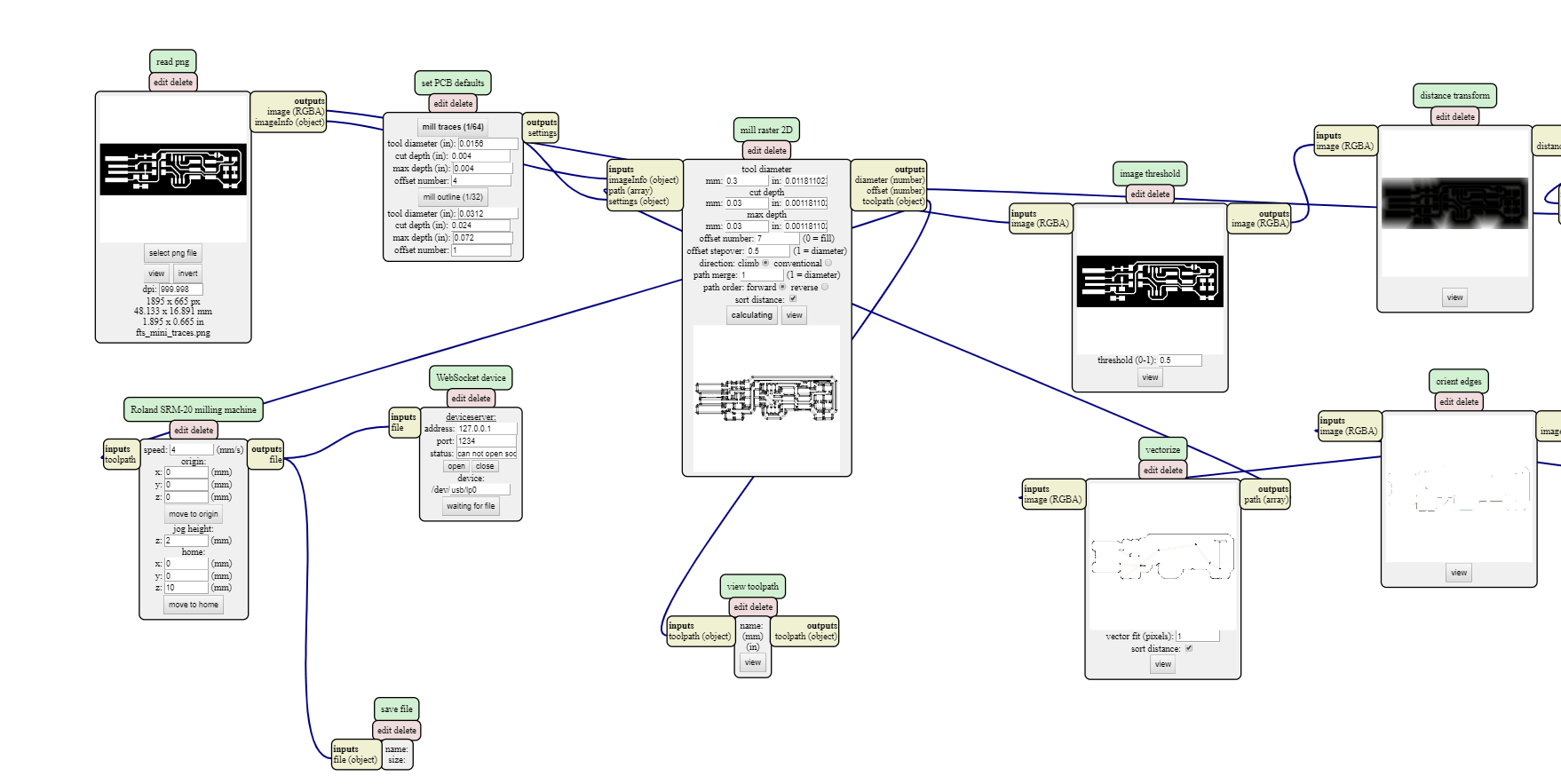

I download the traces and the outline cutout to process them in mods.

Note

In our fablab, we have a Roland machine, we get caracterize it just there.

Init

Right click

programs > open server program > machines > Roland > mill > SRM-20 > PCBNear the

Roland SRM-20 milling machinemodule, right click

modules > open server module > file > save

This module will help you to save the calculate file on your personal machine.

Configure

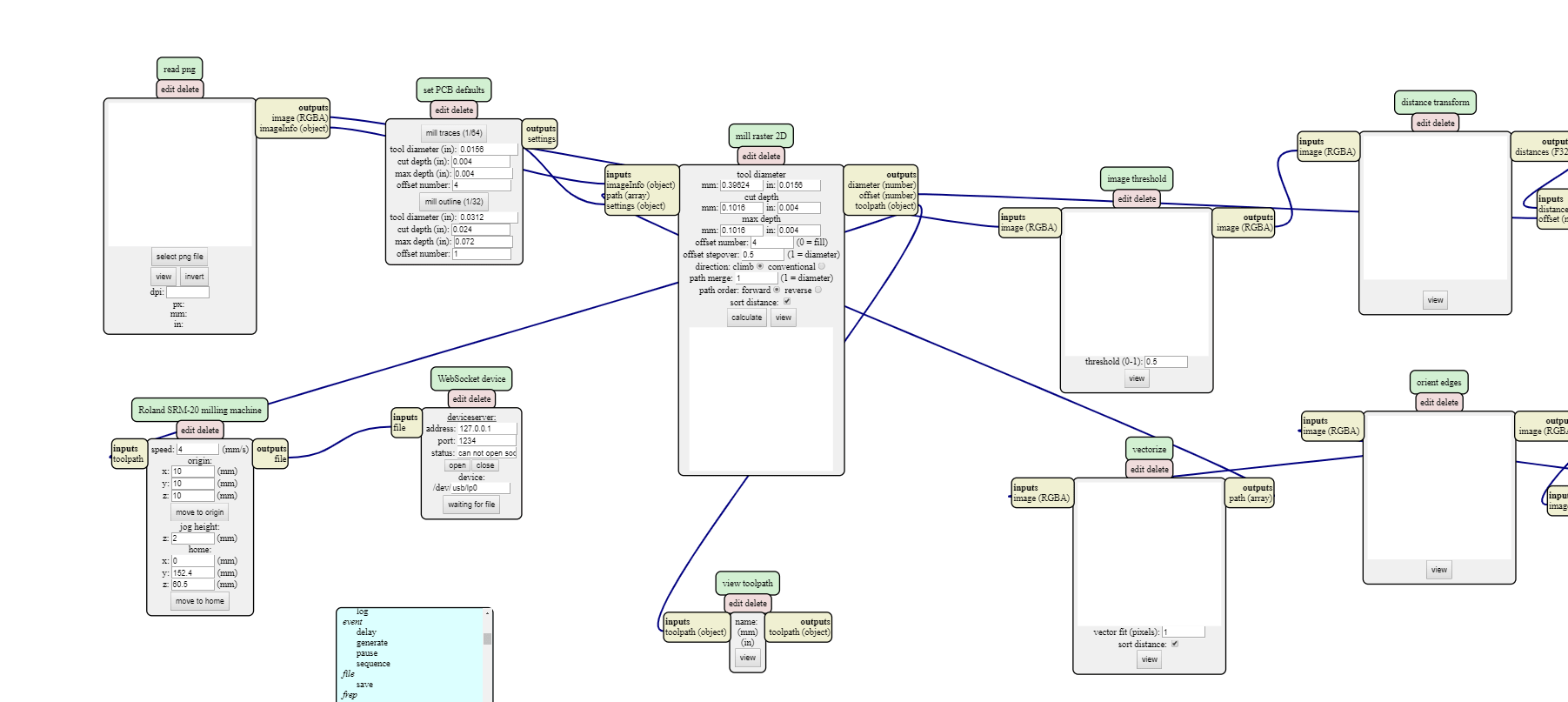

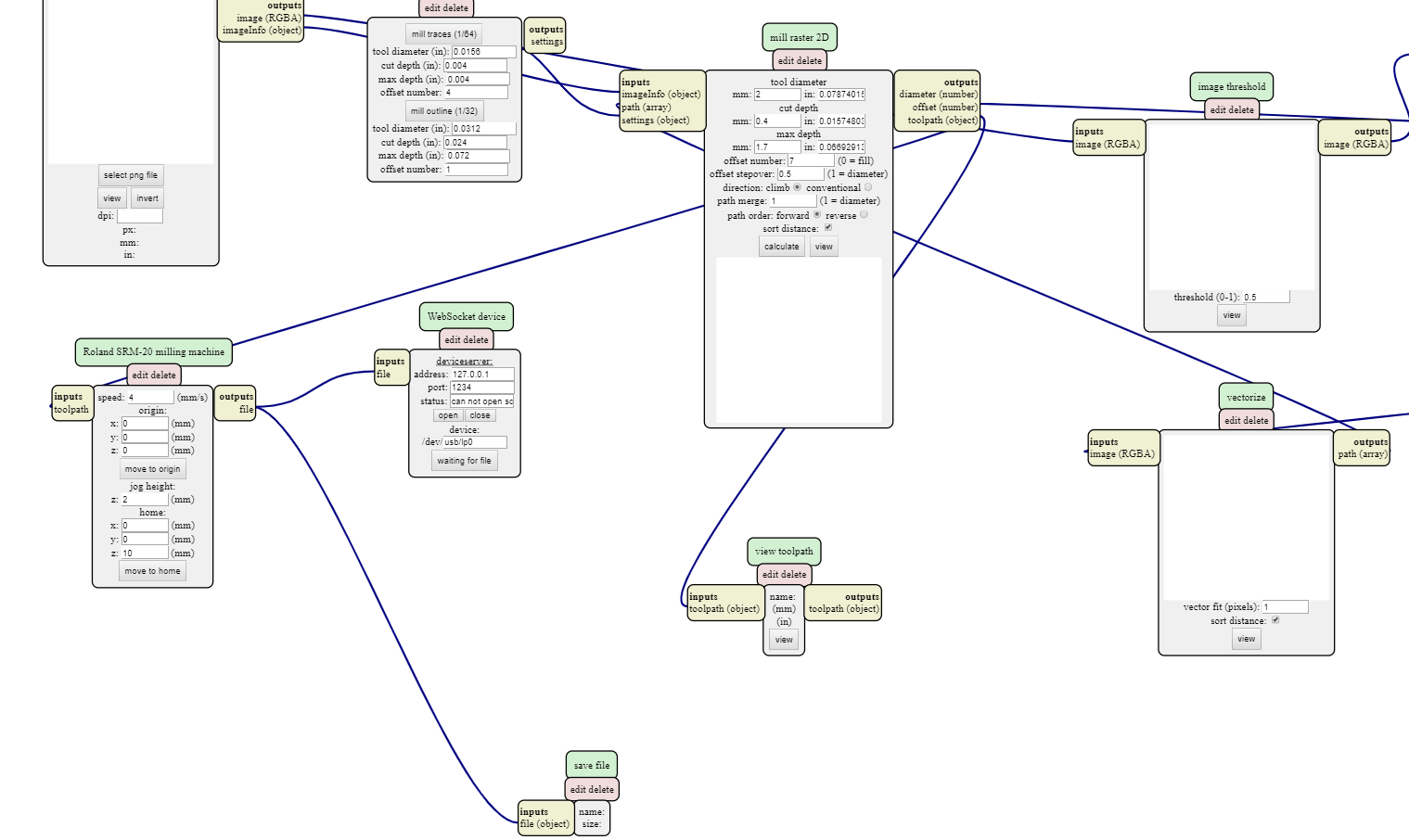

We don't have our machines in the network, so we need to configure only two modules (mill raster 2D and Roland SRM-20 milling machine) for calculating and downloading the files for the machine.

Roland SRM-20 milling machine module configuration

This module will have the same configuration for the two modes.

speed: 4 mm/sorigin:X: 0 mmY: 0 mmZ: 0 mm

jog height:Z: 2 mm

home:X: 0 mmY: 0 mmZ: 10 mm

mill raster 2D module configuration for traces

tool diameter: 0.3 mmcut depth: 0.03 mmmax depth: 0.03 mmoffset number: 7

mill raster 2D module configuration for outlines

tool diameter: 1.5 mmcut depth: 0.4 mmmax depth: 1.4 mmoffset number: 7

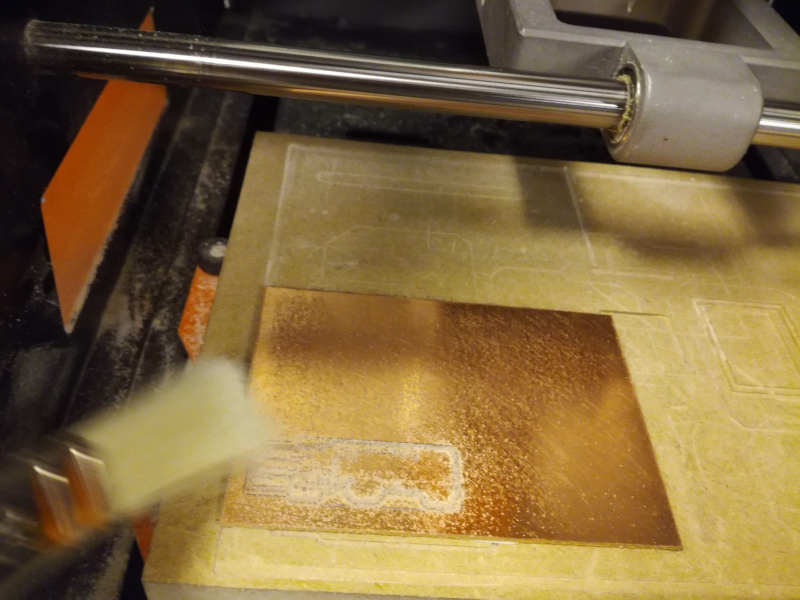

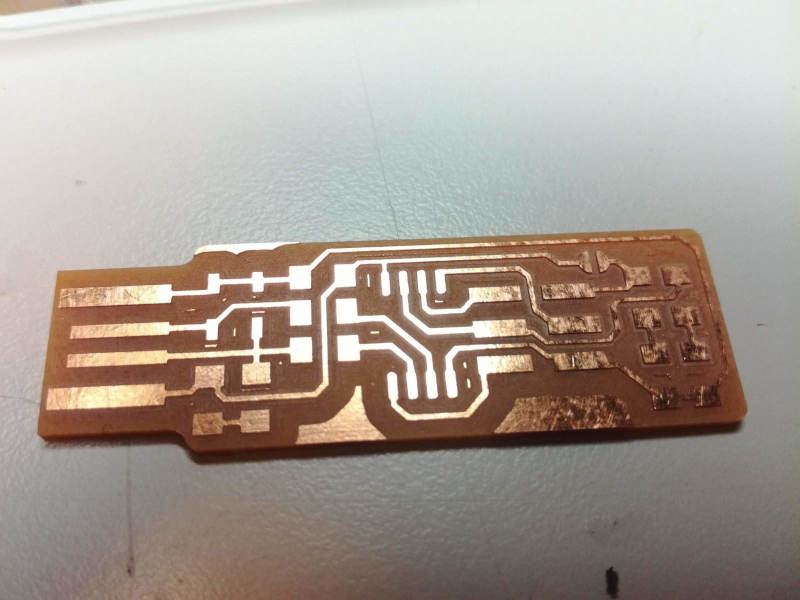

Milling PCB

Roland SRM-20 milling machine

Software

I used the V-Panel software, he's integrated in the machine.

Traces

I used the [1/8″ 30 degree engraving bit] end mil for the traces.

Outlines

I used the [1/8″ 30 degree engraving bit] end mil for the traces.

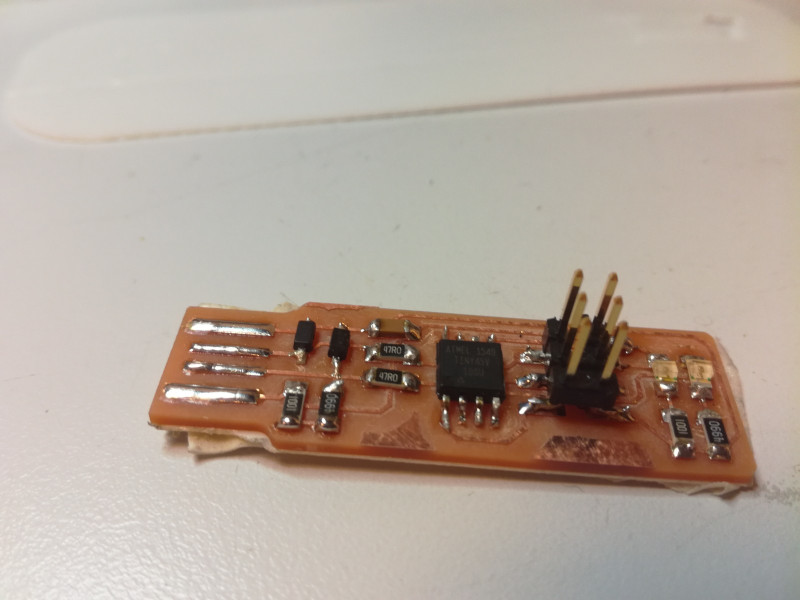

PCB fabrication

Preparation

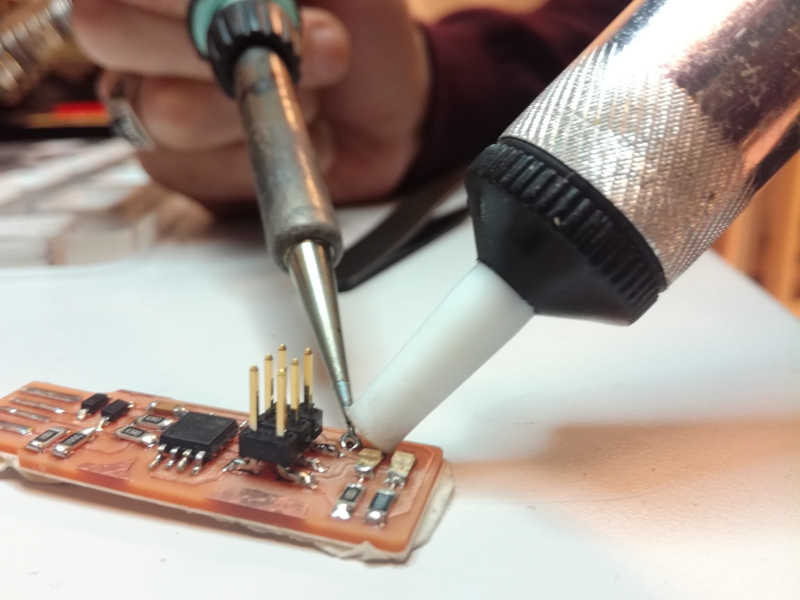

I took my box where I put all my preparation, and start to setup the soldering gun for 380°. I put my laptop near me to get easly the schematics, get on the leds and the air aspirator.

Soldering

Soldering flow

I start to solder one by one each elements:

- attiny45

- 1kΩ resistors

- 499Ω resistors

- 49Ω resistors

- 3.3v zener diodes

- 100nF capacitor

- LEDs

- 2x3 pin header

Testing

- Using the multimeter

- Connect it in usb port to see if the led work

Some mistakes

- The soldering gun was too hot, so my solder was not so shinny

- I invert the place of LEDs

- Solder the wrong resistance in the wrong place

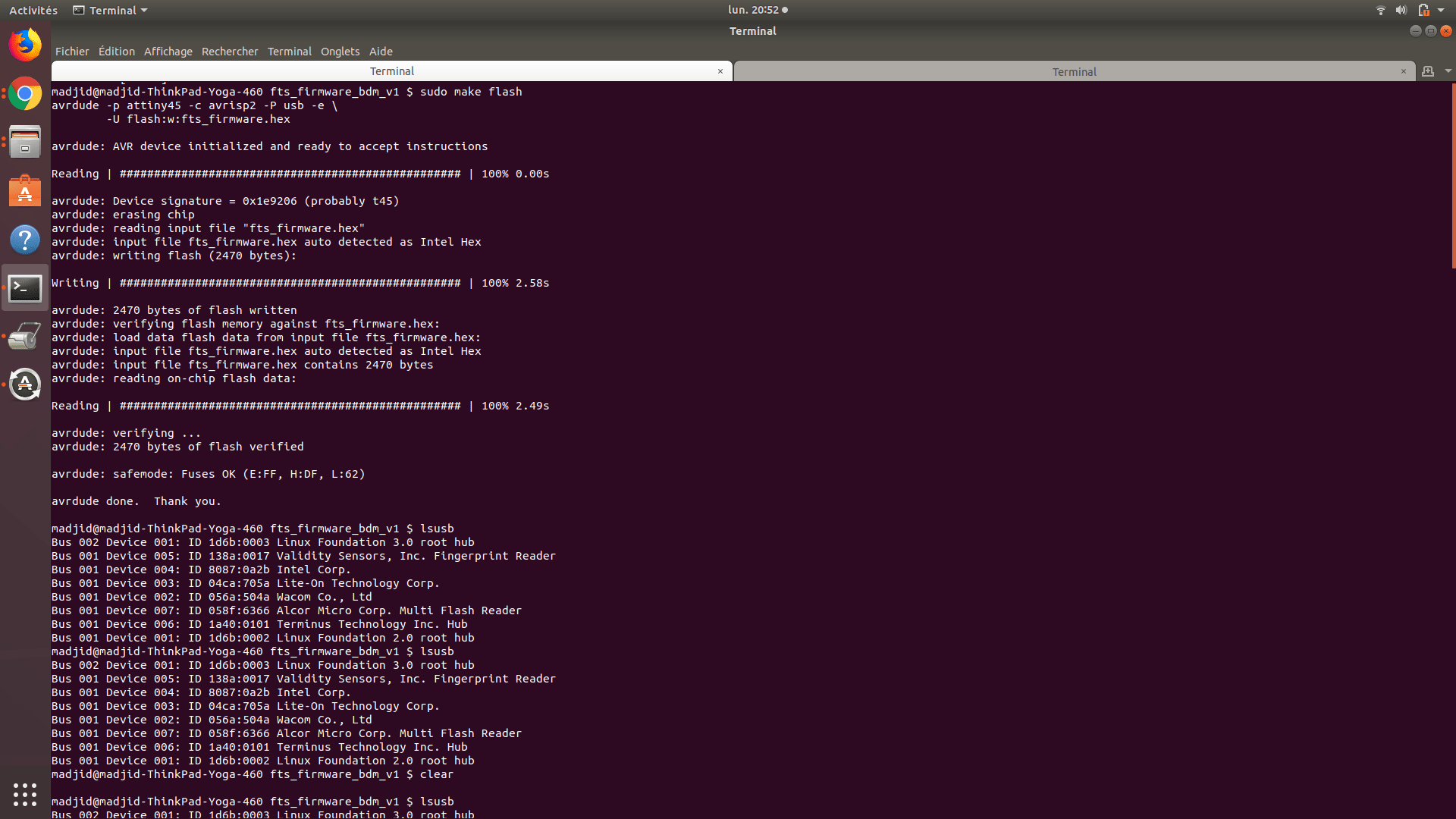

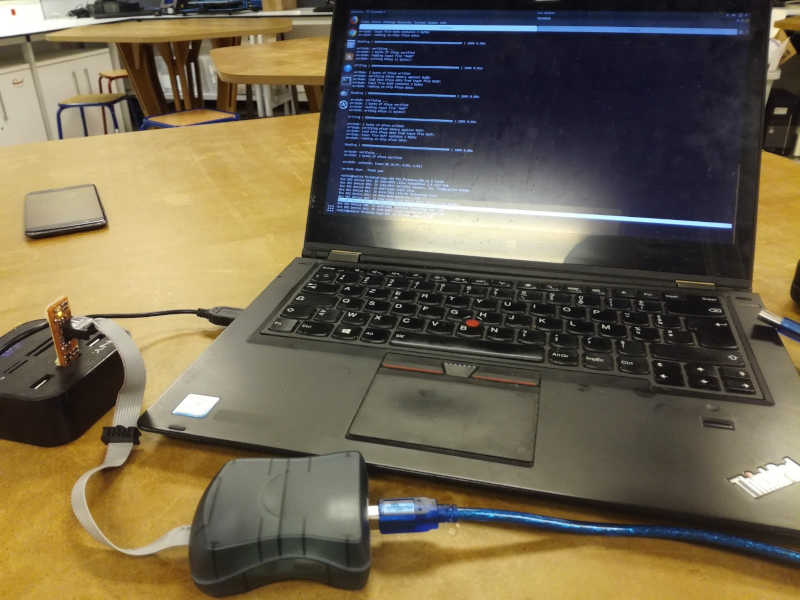

Program the FabIsp

Now it's time to program the board to transform it to ISP 😄

Connect the AvrISP

AvrISP is not well connected

The led is orange 🍊

AvrISP well connected

The led is green 🍏

Prepare the downloaded program for the build

I switch my laptop in ubuntu (I have dual boot, and I already have all stuff to develop in ubuntu), and I download the firmware and I extract it in my documents.

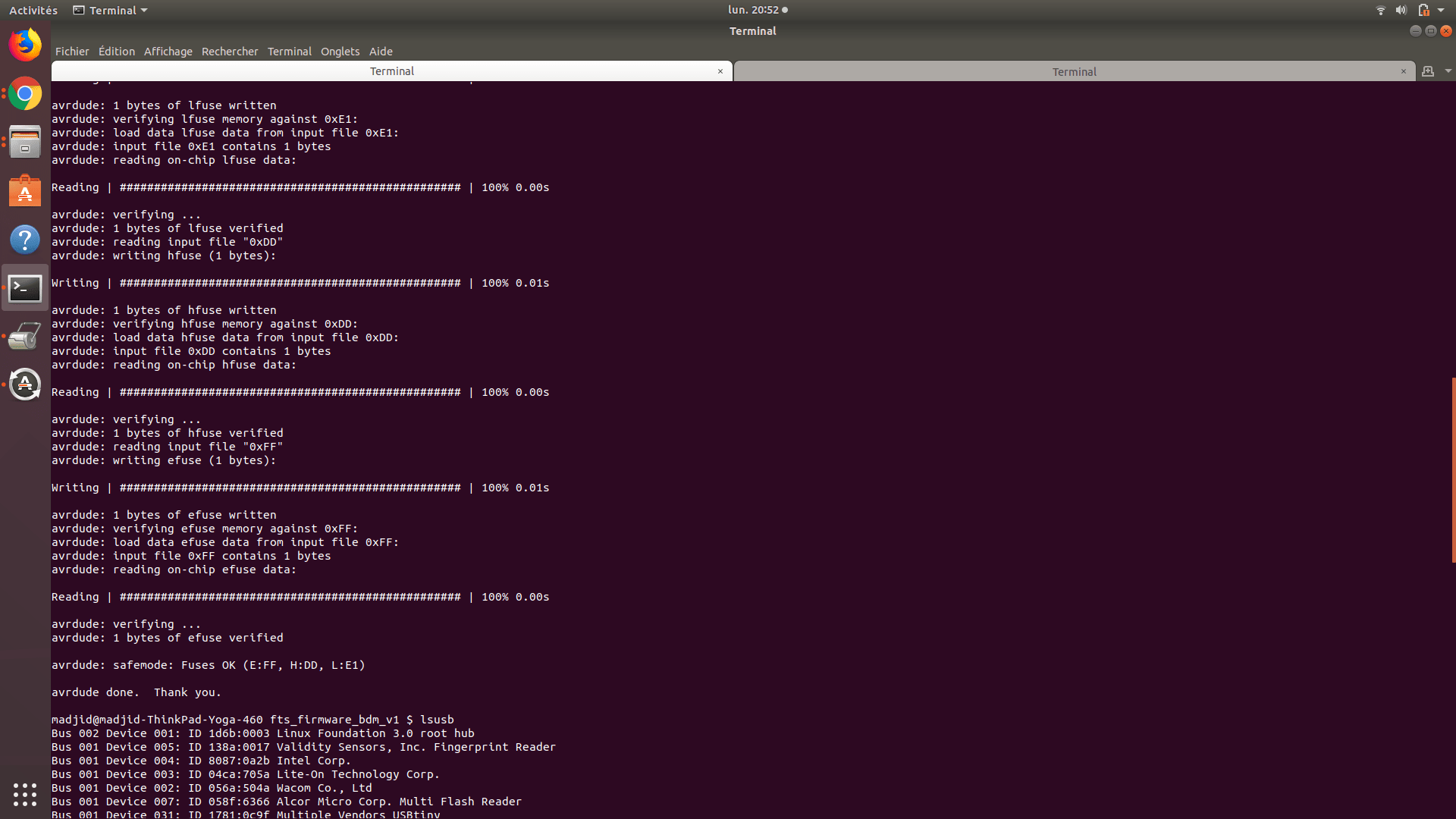

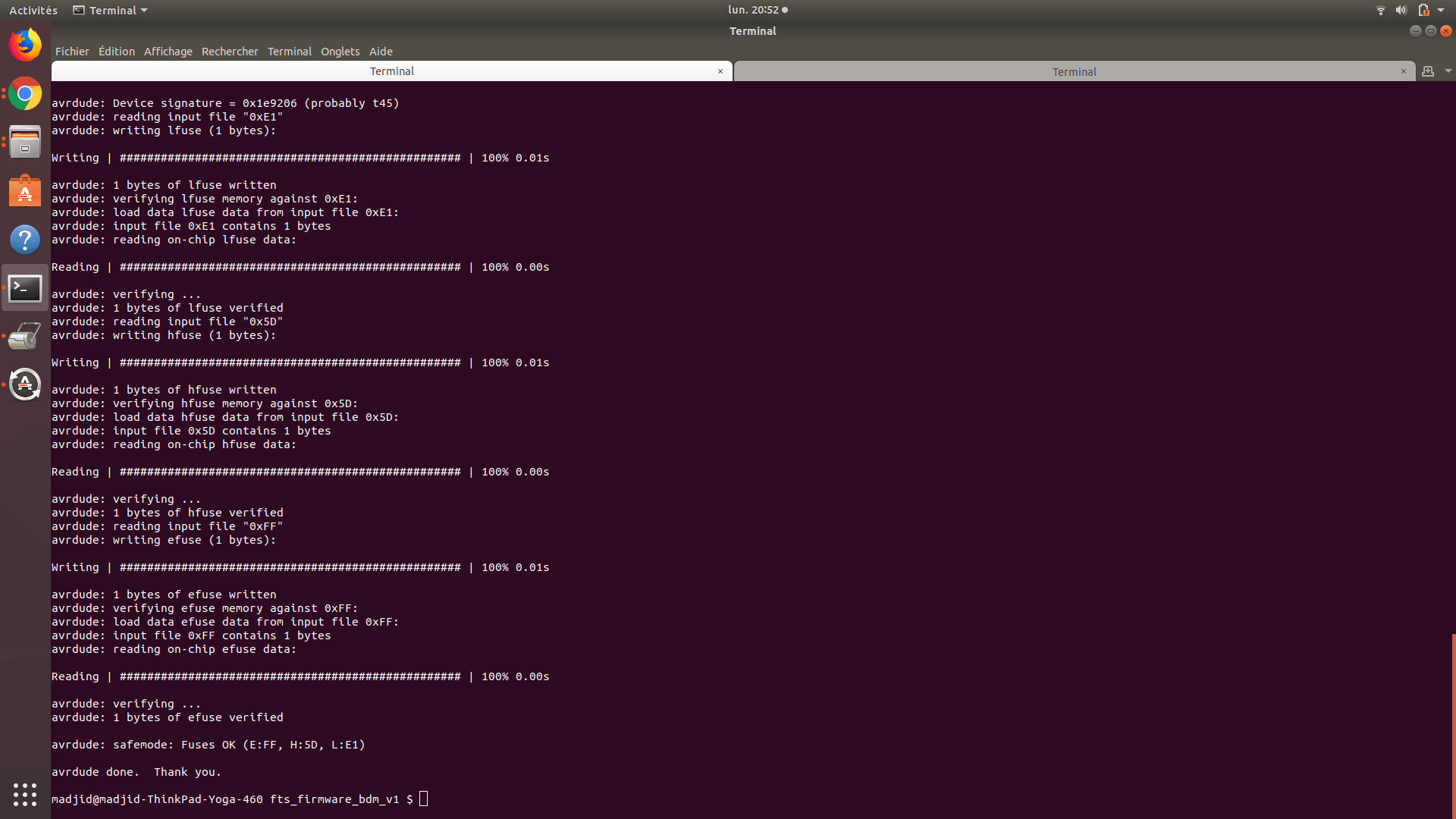

Launch the commands

Open

Makefilewith vsCode update variablePROGRAMMERtoavrisp2Run

sudo make flash

Run

sudo make fuses

Test the usb functionnality

Run

sudo make rstdisbl

Removing the bridge on the solder jumper

Test programmer