15. Mechanical design

Design a machine that includes mechanism+actuation+automation and build the mechanical parts and operate it manually

What machine will do?

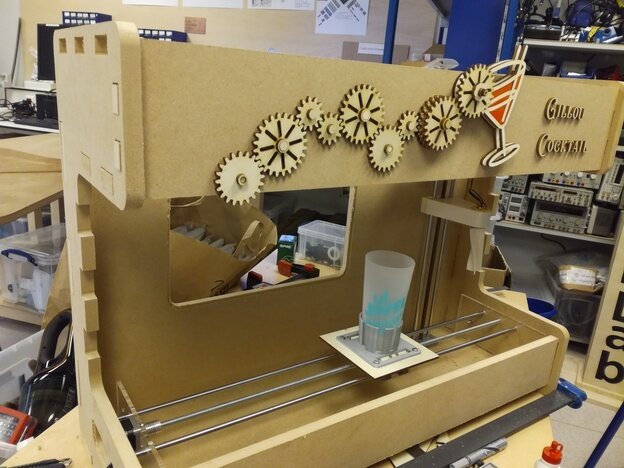

During this week, we want to create a cocktail machine called Gilou Cocktail.

Inspired by others projects, like this one:

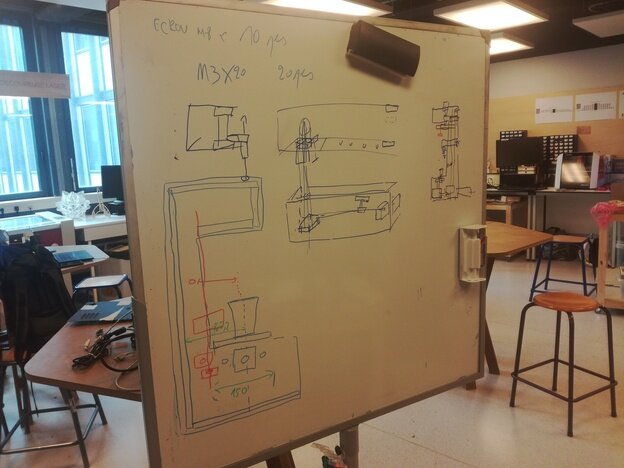

We start by planification and organisation of our work, each of the member team has a task to accomplish. For me, it was, to make a peristaltic pump.

The peristaltic pump

Inspiration

Great scott pump

This is, my favorite projects, he explain the concept of peristaltic pump and how it works perfectly.

The bolt-on peristaltic pump

The design of this pump, seems cool, but unfurtunnaly the source files was not there. More further, the pump was made to be precise in small quantity, and the debit was not enought high.

Process design

First try

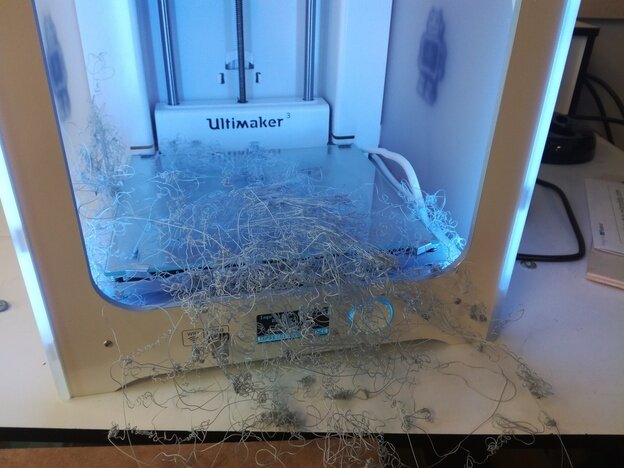

In the first time, I tried to print the Great scott pump, but I had some problems with the design, it does'nt fit with any Nema (14,15 and 17). Furthermore, we doen't have the right silicone tubing. The piece was designed for 6mm ODx4mm ID silicone tubing, but we just have 10mm as smaller siliconre tubing and we just have two bearings in the right size. So I need to redesign the piece, because we don't have supplier able to deliver what we need for this week.

![]()

Iteration work

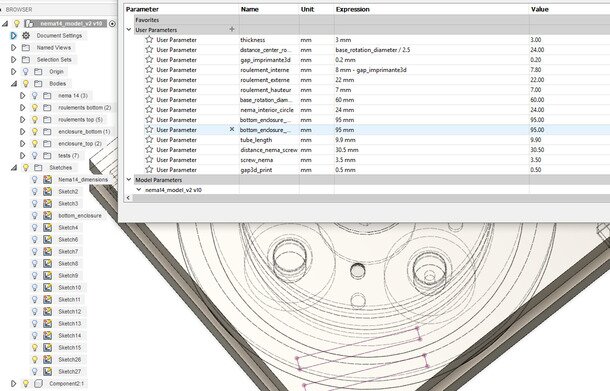

I think, I designed the most big and complexe part. I try to be the most parametric as I can. The idea was to have quickly the first version of the pump. I wanted to use 3d printing properties to use when I can pressfit fixation instead the screws.

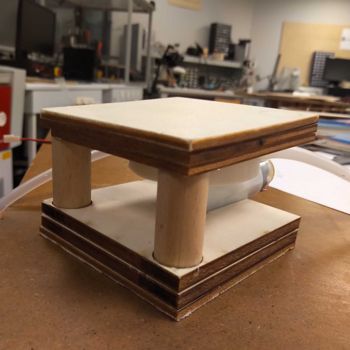

In the beginning, I printed big parts, and they tooks me lot of time, and it was borring. So I decide, to print small part and check the size before printing. As you can see, in this above example, I decide to print fist little square, before the complete piece.

I print lot of pieces, and made lot of iterations on my work.

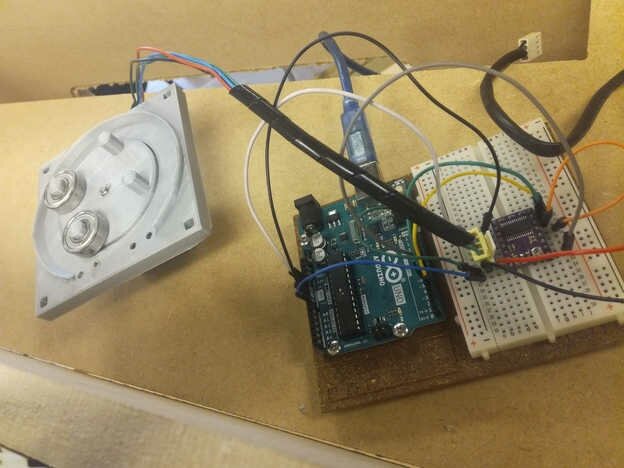

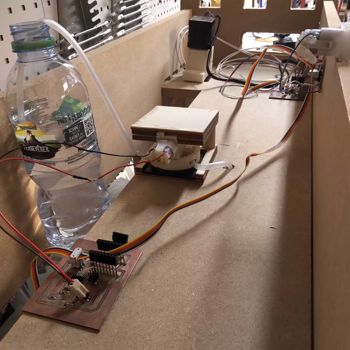

And for test it, I used an arduino board (because I didn't made my own, for now), with an pololu a4988 driver

Conclusion

The mechanism work if we apply enought forces on it, howerver when I test with the real motor and the silicone tube, they are some problems. I tried in diffrents way, 2 bearings, 3 or 4, doesn't matter it doesn't work.

I think, the Nema 17 has not enought couple to deal with this tube, the majority of commercial peristaltic pump that I found with this tube diameter, send much more voltage or the have smaller tube and bearings.

So, I will purchase this week, for new silicone tube smaller and less rigid to achieve machine.

The updated persitaltic pump

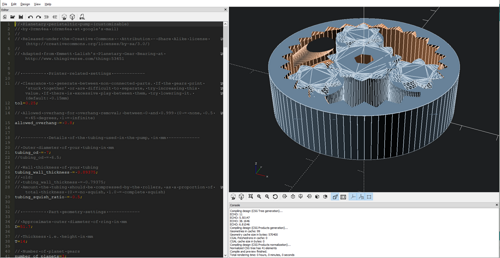

I bought silicone of 6mm, but unfortunatly, the result was not what was I expected with my previous design. So, because of time, I decide to change the plan and takes a good example that I saw in thingiverse. The project is really nice, because it's an openscad project, so it can be customized easly.

From this script and after some iterations, I updated the following parameters:

- Tolerence (

tol): From0.15to0.25, help to be sure that the geare are really separate - Outer diameter of tubbing (

tubing_od): From4.7625to7, the right size of the out diameter tube is 6mm but when I tried with this value, the gear was'nt able to move anymore, so I take some security and 7mm was a good compromise. - Width of hexagonal hole: from

6,7to5. Corresponding to the Nema 17 motor axes diameter.

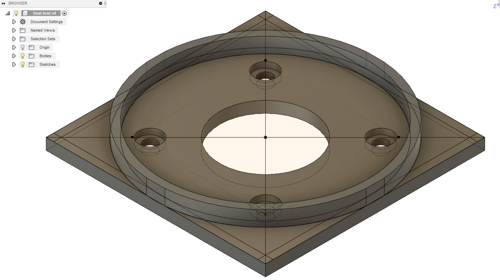

Then to be sure, that the motor will not move anymore from the gears, using Fusion360, I designed a fixer for the pump. Using the standard dimensions of the Nema 17, I made hole to fix the fixer with the nema. And using calipers, I made a pressfit container, this mechanisme suppose to block the motor to not turn enterly (but at the end, I added security, and fix it with some glue).

To put the tube inside the pump, I make it role by hand, pressing it inside, and turn the gear, by this way in few mouvement, you can set the tube. ⚠️ The fist time when you will do that can seems hard, but it will be ok.

Then I fixed the support of the pump on the Nema motor with some screws.

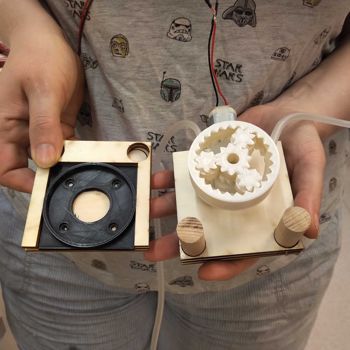

And here is the result when everything is put together ! Looks great isn't it ? 😃

We had one problem thoug, the motor had not a strong enough couple to push the liquid. We had to change the motor. Then, we used the same DC motor as in the decoration. And one of the first pump, that I printed with the width of hexagonal hole equal to 6.7, more adapted for this motor.

And this time it works perfectly !

We even tried with liquid, and it is for slow drinking but it pumps it 😃 It's not really perfect but I'm so happy to see the pump works after so many iterations.

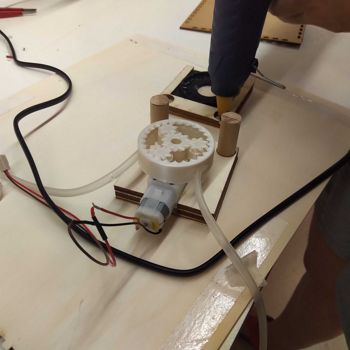

Then because I had'nt time to 3d print enclosure, I maid one using the laser cutter. The idea is to have support to fix the pump on the top of the machine and try to fix all elements of the pump to bee sure that only the gears move when the motor is on.

I failed to make many pumps at time, I didn't told that I will have all this problems. All this fails was a big frustration but at the end, I'm proud for what I've done, and I think, in the future I will try to improve more this pump.

Assembled machine

For more information please go in the group page

Need to reproduce the peristaltic pump

- 3D printer: to print the pump, I used PLA, but I think it will be interesting to see what's going on with other materials

- Laser cut (optional): to make the enclosure of the pump, can be designed in 3d printer.

- Silicone tube of 6mm

- DC motor 12v