-min.png)

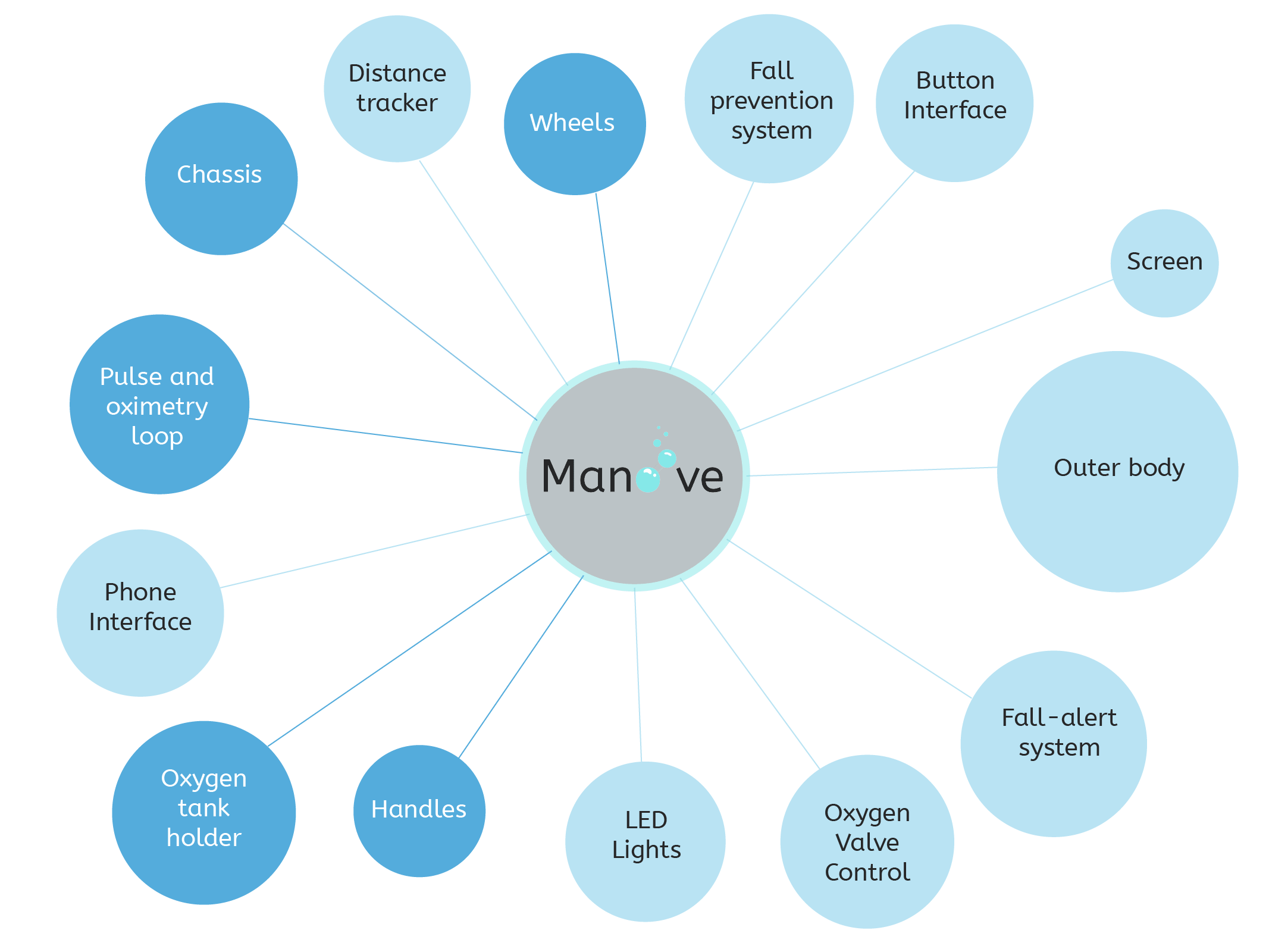

Brainstorming

Web Design

CAD and A/V Editing

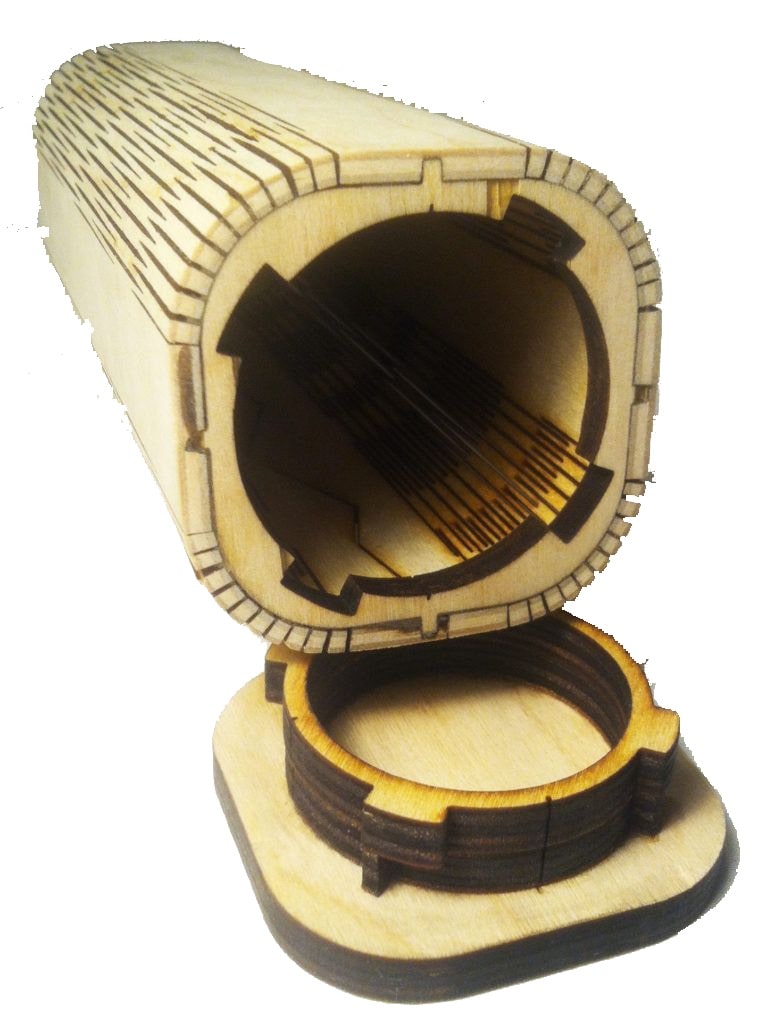

Computer controlled cutting

Electronics Production

3D Scanning/ Printing

Electronic Design

Computer controlled machining

Embedded programming

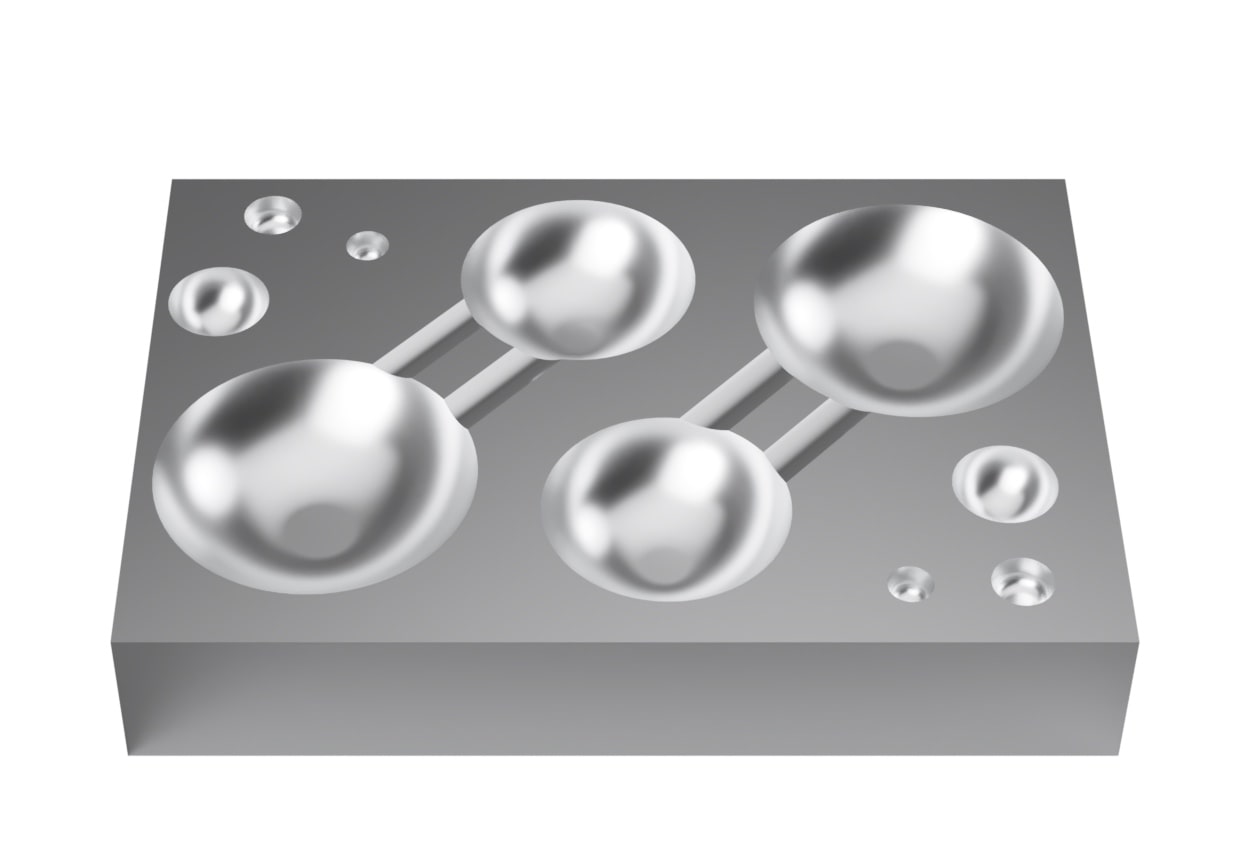

Molding and Casting

Input devices

Output devices

Applications and Implications

Networking and communication

Machine (Fablab 2.0)

Interfaces and Applications

Wild card week

Invention, Intelectual property and income

Project Management