#include <Wire.h>

#include "MAX30105.h"

#include "spo2_algorithm.h"

MAX30105 particleSensor;

#define MAX_BRIGHTNESS 255

#if defined(__AVR_ATmega328P__) || defined(__AVR_ATmega168__)

//Arduino Uno doesn't have enough SRAM to store 100 samples of IR led data and red led data in 32-bit format

//To solve this problem, 16-bit MSB of the sampled data will be truncated. Samples become 16-bit data.

uint16_t irBuffer[100]; //infrared LED sensor data

uint16_t redBuffer[100]; //red LED sensor data

#else

uint32_t irBuffer[100]; //infrared LED sensor data

uint32_t redBuffer[100]; //red LED sensor data

#endif

int32_t bufferLength; //data length

int32_t spo2; //SPO2 value

int8_t validSPO2; //indicator to show if the SPO2 calculation is valid

int32_t heartRate; //heart rate value

int8_t validHeartRate; //indicator to show if the heart rate calculation is valid

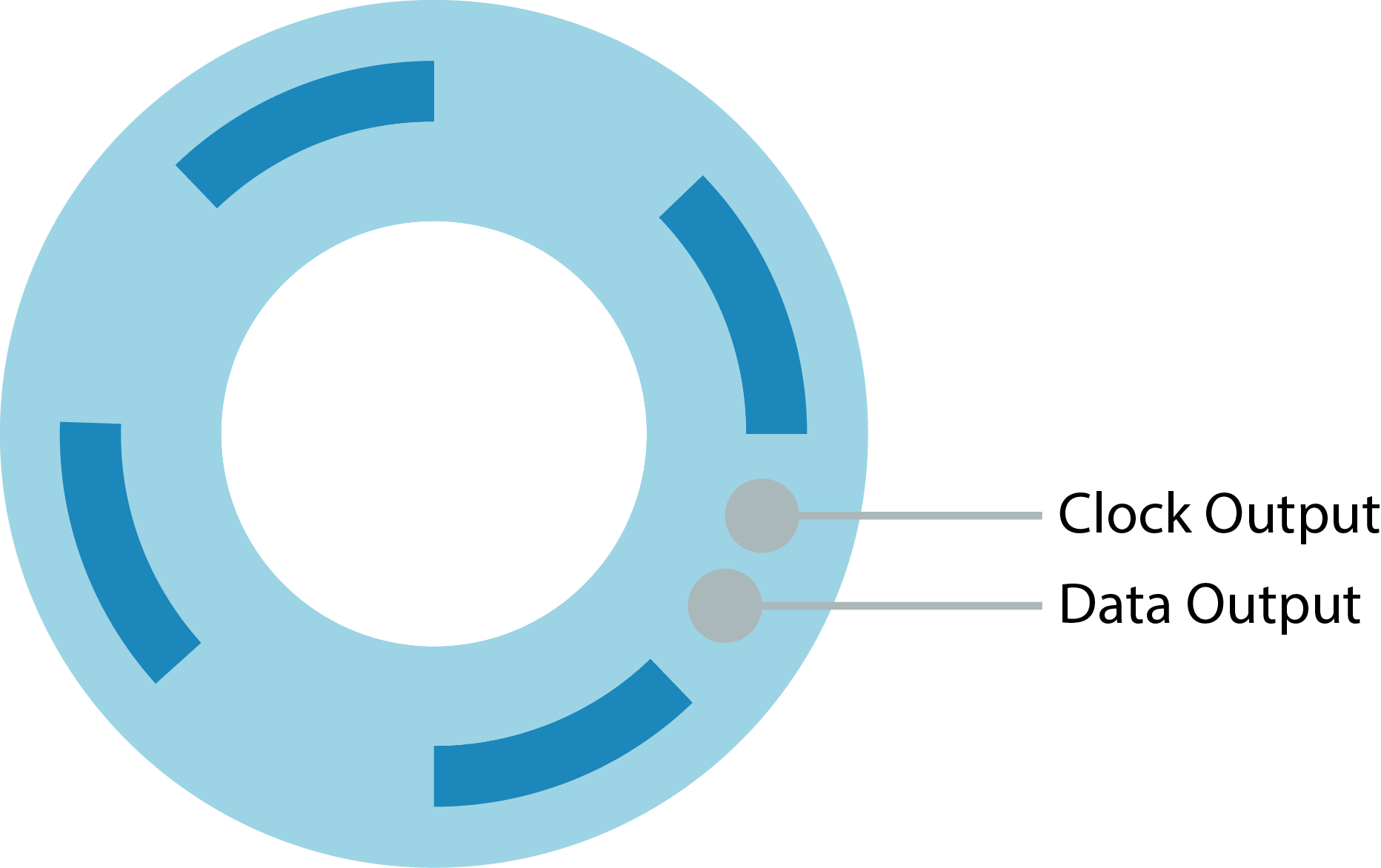

byte pulseLED = 11; //Must be on PWM pin

byte readLED = 13; //Blinks with each data read

void setup()

{

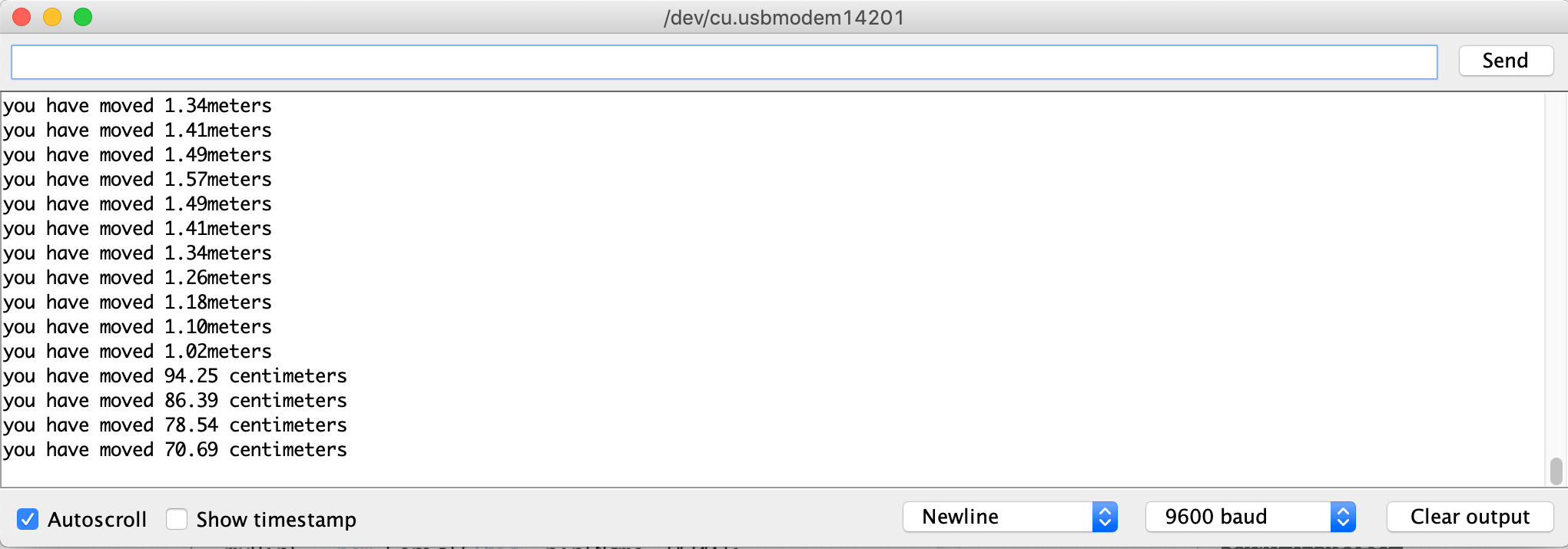

Serial.begin(115200); // initialize serial communication at 115200 bits per second:

pinMode(pulseLED, OUTPUT);

pinMode(readLED, OUTPUT);

// Initialize sensor

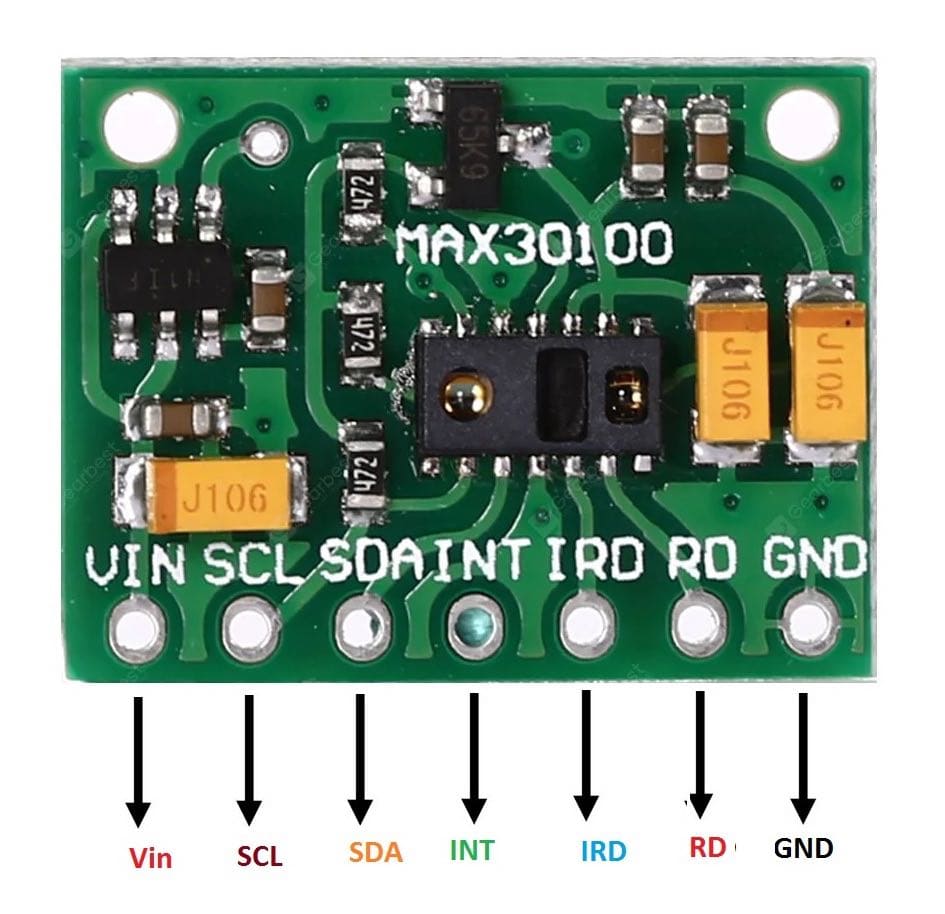

if (!particleSensor.begin(Wire, I2C_SPEED_FAST)) //Use default I2C port, 400kHz speed

{

Serial.println(F("MAX30105 was not found. Please check wiring/power."));

while (1);

}

Serial.println(F("Attach sensor to finger with rubber band. Press any key to start conversion"));

while (Serial.available() == 0) ; //wait until user presses a key

Serial.read();

byte ledBrightness = 60; //Options: 0=Off to 255=50mA

byte sampleAverage = 4; //Options: 1, 2, 4, 8, 16, 32

byte ledMode = 2; //Options: 1 = Red only, 2 = Red + IR, 3 = Red + IR + Green

byte sampleRate = 100; //Options: 50, 100, 200, 400, 800, 1000, 1600, 3200

int pulseWidth = 411; //Options: 69, 118, 215, 411

int adcRange = 4096; //Options: 2048, 4096, 8192, 16384

particleSensor.setup(ledBrightness, sampleAverage, ledMode, sampleRate, pulseWidth, adcRange); //Configure sensor with these settings

}

void loop()

{

bufferLength = 100; //buffer length of 100 stores 4 seconds of samples running at 25sps

//read the first 100 samples, and determine the signal range

for (byte i = 0 ; i < bufferLength ; i++)

{

while (particleSensor.available() == false) //do we have new data?

particleSensor.check(); //Check the sensor for new data

redBuffer[i] = particleSensor.getRed();

irBuffer[i] = particleSensor.getIR();

particleSensor.nextSample(); //We're finished with this sample so move to next sample

Serial.print(F("red="));

Serial.print(redBuffer[i], DEC);

Serial.print(F(", ir="));

Serial.println(irBuffer[i], DEC);

}

//calculate heart rate and SpO2 after first 100 samples (first 4 seconds of samples)

maxim_heart_rate_and_oxygen_saturation(irBuffer, bufferLength, redBuffer, & spo2, & validSPO2, & heartRate, & validHeartRate);

//Continuously taking samples from MAX30102. Heart rate and SpO2 are calculated every 1 second

while (1)

{

//dumping the first 25 sets of samples in the memory and shift the last 75 sets of samples to the top

for (byte i = 25; i < 100; i++)

{

redBuffer[i - 25] = redBuffer[i];

irBuffer[i - 25] = irBuffer[i];

}

//take 25 sets of samples before calculating the heart rate.

for (byte i = 75; i < 100; i++)

{

while (particleSensor.available() == false) //do we have new data?

particleSensor.check(); //Check the sensor for new data

digitalWrite(readLED, !digitalRead(readLED)); //Blink onboard LED with every data read

redBuffer[i] = particleSensor.getRed();

irBuffer[i] = particleSensor.getIR();

particleSensor.nextSample(); //We're finished with this sample so move to next sample

Serial.print(F(", HR="));

Serial.print(heartRate, DEC);

Serial.print(F(", HRvalid="));

Serial.print(validHeartRate, DEC);

Serial.print(F(", SPO2="));

Serial.print(spo2, DEC);

Serial.print(F(", SPO2Valid="));

Serial.println(validSPO2, DEC);

}

//After gathering 25 new samples recalculate HR and SP02

maxim_heart_rate_and_oxygen_saturation(irBuffer, bufferLength, redBuffer, spo2, & validSPO2, & heartRate, & validHeartRate);

}

}-min.png)