| HOME | ABOUT ME | FABLAB UPM | FINAL PROJECT |

| week 1 Principles and practices, project management |

| week 2 Computer-aided design |

| week 3 Computer-controlled cutting |

| week 4 electronics production |

| week 5 3D scanning and printing |

| week 6 electronics design |

| week 7 computer-controlled machining |

| week 8 embedded programming |

| week 9 molding and casting |

| week 10 input devices |

| week 11 composites |

| week 12 output devices |

| week 13 networking and communications |

| week 14 mechanical design, machine design |

| week 15 interface and application programming |

| week 16 applications and implications |

| week 17 invention, intellectual property and income |

| week 18 project development |

| week 19 project presentation |

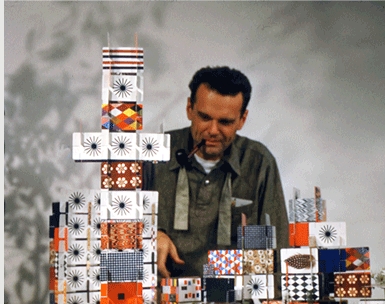

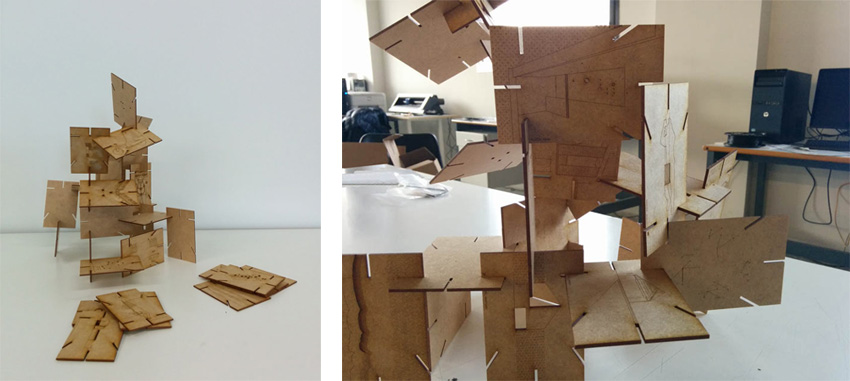

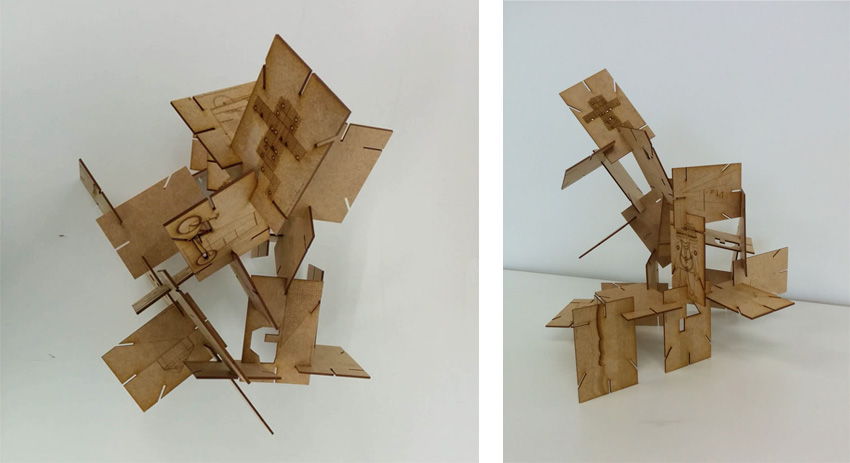

Week 3: Computer- controlled cutting Goal: design, make and document a press-fit construction kit

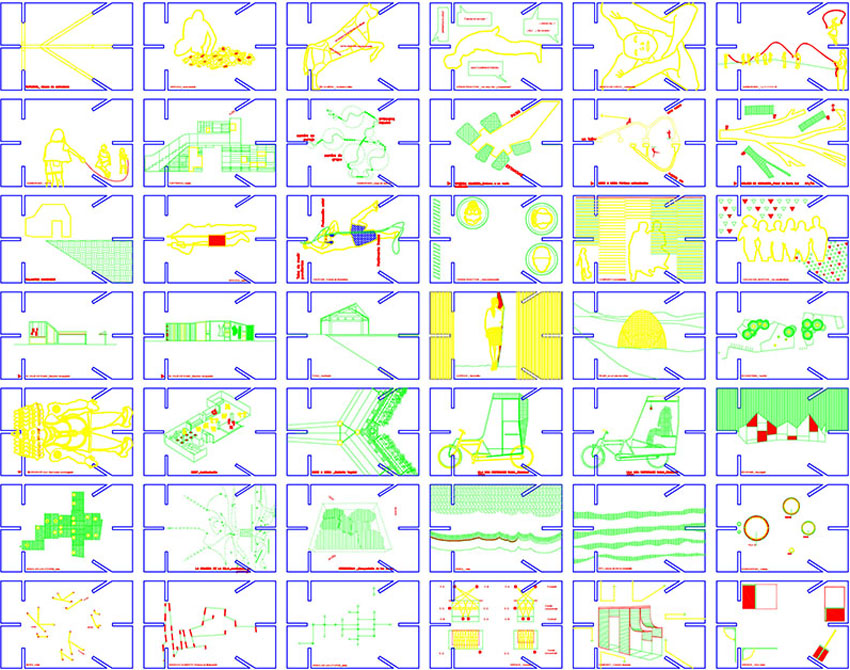

Template sheet: The CAD software used to design the cards was AutoCAD, This is the drawing template used for cutting

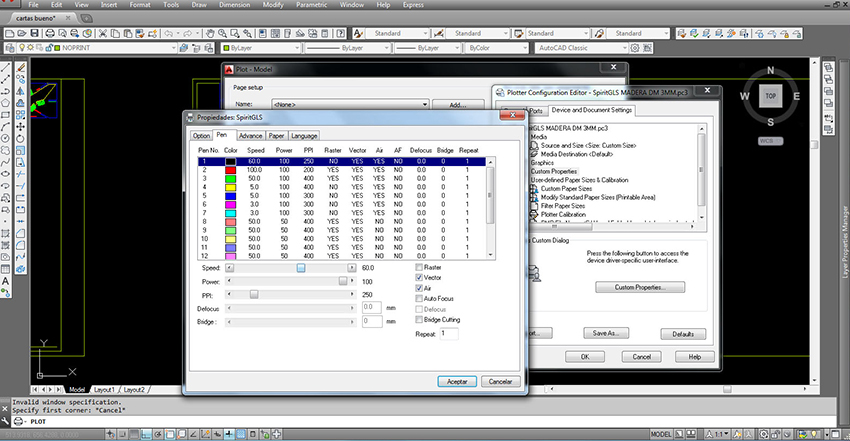

Cut Parameters: I used three cutting parameters divided into four layers. One for vector engraving (green layer), with power 100 and speed 50 , Other for raster engraving (red layer) with power and speed 100. And for inside and outside cuts (yellow and blue layers) a power of 100 speed of 5.

The laser machine we used in the FabLab UPM is the Spirit GLS with 80 Watts. Its work surface is 960 x 610 mm.

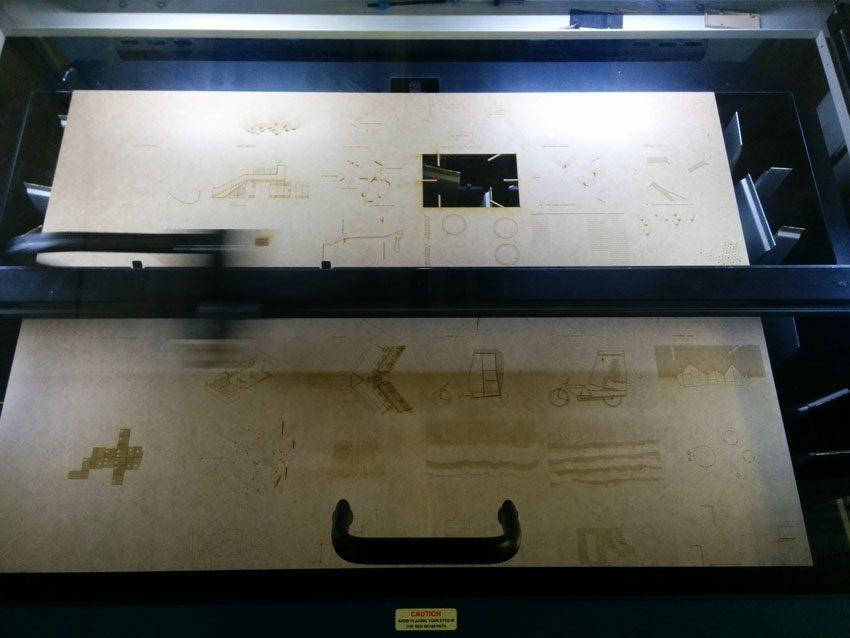

And the results:

|