Making Something Big

This week we got a chance to learn the ShopBot, a CNC machine that allows you to cut many materials in 4'X8' sheets, i.e. bigger stuff. I wanted to build a medieval style Trebuchet Launcher, and spent most of my time this week trying to design it. While I got a decent 3D design, I had a hard time translating that into a 2D design for the ShopBot, and ended up just cutting out a simple table. Here's what happened:

The Setup We used 4'X8' 3/4" thick Poplar plywood (bought from Home Depot). The sheet was secured to the bed simply using screws.

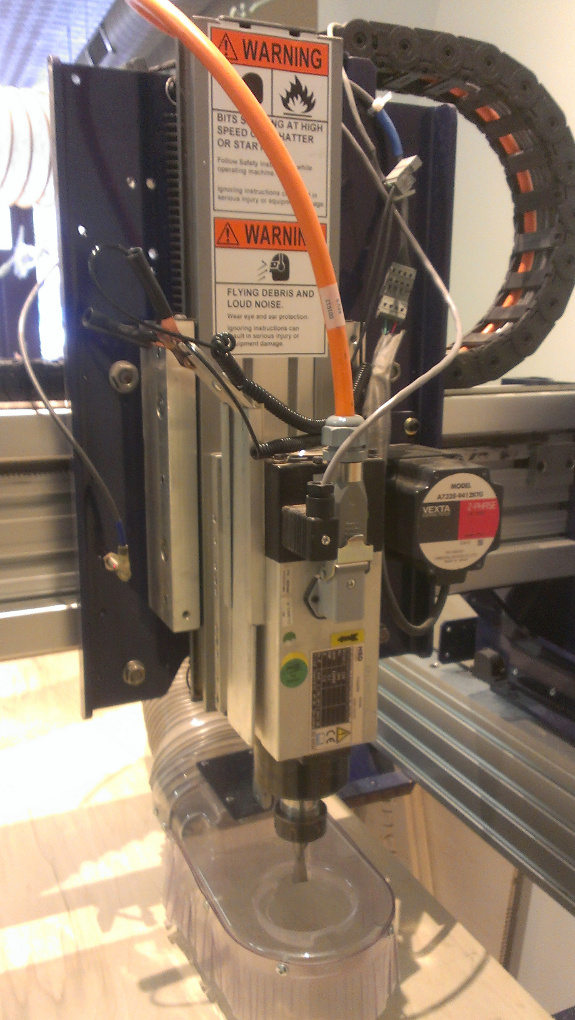

Since my file was so simple, I decided to use one bit for both the pocket and profile cuts, and used a bigger, 1/2" bit to save time (pictured right):

Preparing the files With the machine set up, the next step is to prepare the necessary files and toolpaths that will be sent to the ShopBot. Basically, at the end of the process, you will have three kinds of files: (1) Your original design file, (2) Pathworks files that determine the toolpaths for both pocket and profile cuts, and (3) ShopBot files that will be sent directly to the machine.

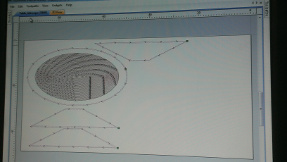

Below is the area selected to be cut as a pocket cut, and the resulting preview in Pathworks (which is a nice feature).

r

And here are the selections for the profile cut-outs:

Since I wasn't using different bits for the pocket and profile cuts, I saved both Pathworks files to a single ShopBot file. After zeroing out the machine and taking necessary safety precautions, it's pretty much "File, Print" (just much bigger).

Here is a shot of the pocket cut in action....

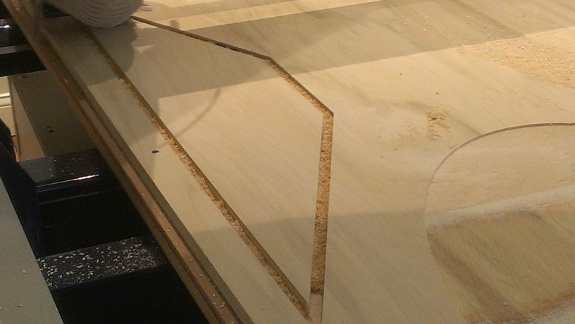

and the profile cuts.

The end result The tabletop actually looked decent with the Poplar plywood; however, I didn't realize how short I made the legs. I was thinking of an Ikea style table, which uses free legs and a glass tabletop over it, but I definitely need to add something for support (press-fit would be best I think). It could also use sanding and some sort of coating. These things aren't too hard to do, and I still have material left....I'll try to do it soon!