Molding and Casting

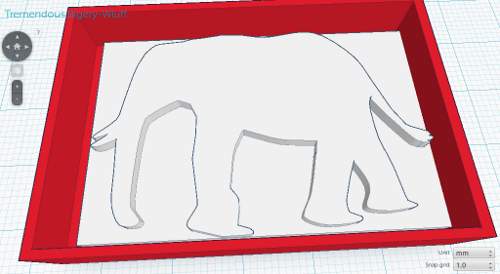

This week I played around with Tinkercad a bit to design a mold to be machined out of wax. I took an SVG i made of an elephant and extruded it with Tinkercad. Then I created a plate below it and a box around it. The plate is to be a base for the elephant (to make a keychain type thing) and the box around it is intended to be a wall for the molding material to fill.

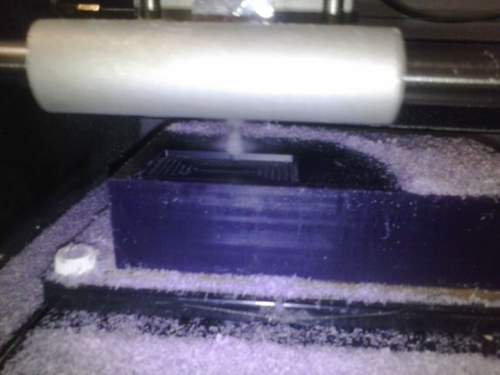

In Tinkercad this was measured in millimeters and I found it very difficult to picture how big 50 mm actually was. Anyways I made this much too small for the 1/8" bit to pass alot of the sections. (The tusks, between the back legs and down all the way around the white rectangle.) For the finish cut I switched to the 1/16" bit and I had a little bit more success but still not quite the definition I was looking for. I will have to resize this in tinkercad and re-mill it for a better mold, but for the purpose of experimentation I continued with this mold.

I then created a negative mold of the elephant using oomoo rubber. I used 2 cups to measure the two parts (supposed to be mixed with equal parts by volume). I only eyeballed the levels of the mixture then poured both parts into one cup and began mixing. Oomoo seems to be very prone to air bubbles so I did my best to mix slowly to aviod this as much as possible.

Waiting time! 75 minutes until time to demold from the wax. After 75 minutes it still doesn't seem to be quite ready to be demolded so I'll give it some more time.

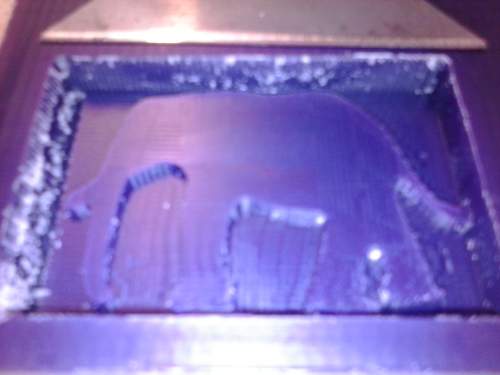

You can see that the raised border is only on the right side of the negative mold so I had to improvise a bit in order to contain the hydrostone.

Toothpicks! After mixing a bit of hydrostone and water I poured it into the mold. Due to the mold lacking a suitable raised border the cast came out pretty uneven.

Sorry about the poor picture quality, but the cast came out slightly better than I expected. (The front side anyway, the back side is pretty uneven). A small bit of the tail was chipped off and so were the tusks but everything else had a nice smooth finish.