Project Development¶

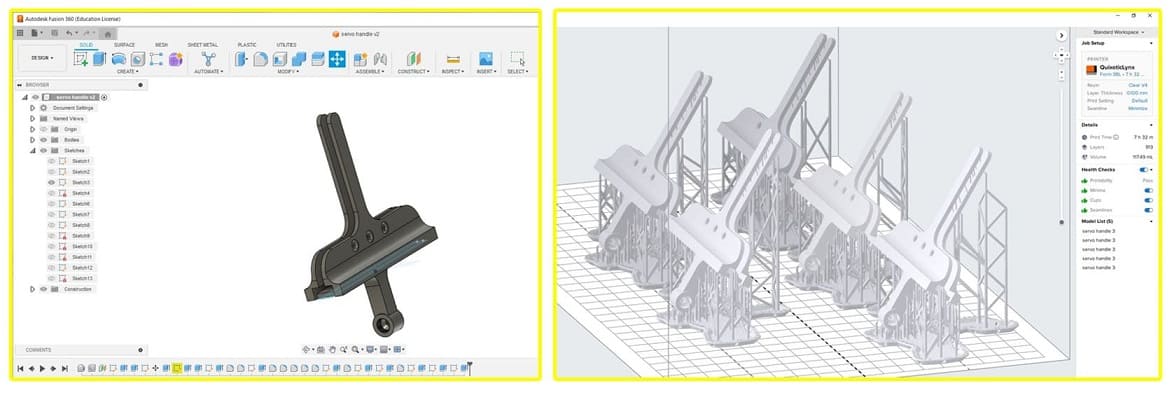

Computer design Design is complete! time for implimentation!

The Block I found a wooden block with the right dimension (30cm*8cm) I cut it and drilled it from the middle to start working on it.

I measured my block and drew lines where I’d like to make a hole. I used the manual drill after fixing my block. At first I used a hole-saw end mill to create the opening and then a flat end mill to take out as much wood as possible.

I also made three other holes using the manual drill, two on the back for power source wire and another one on front for the sensor, I used glue to attach the sensor on the wooden block. I used a 6cm flat end-mill on the manual drill.

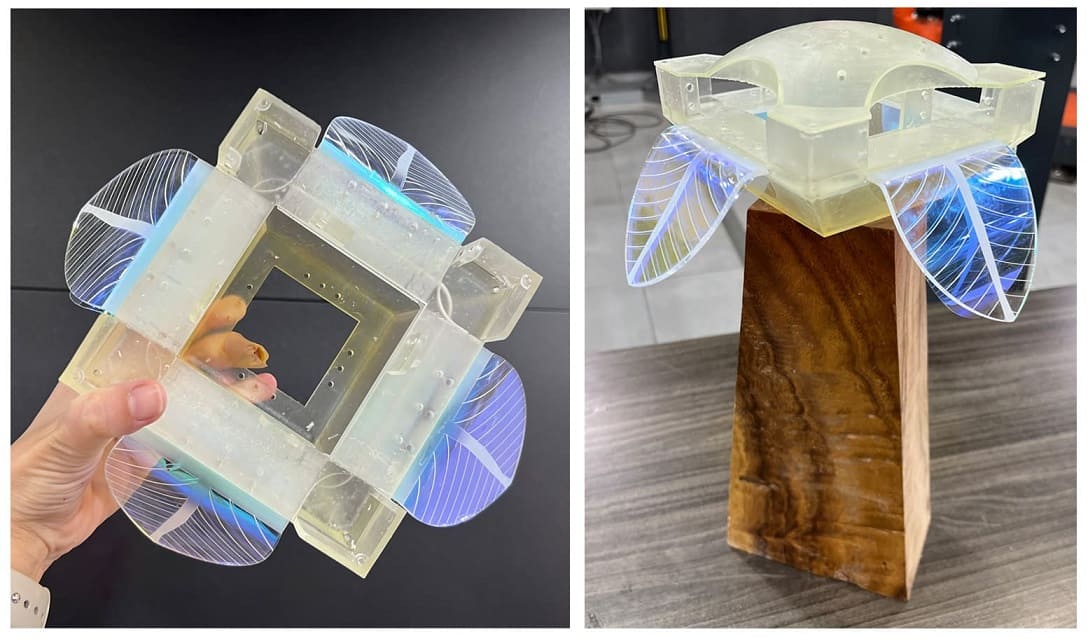

The Cone was 3d printed with transparent resin.

To bend the lower petals, I used a heat gun after taking safety measures of using heat-proof gloves and on a heat-proof table surface.

The Shaft was 3d printed with transparent resin. the screw hole is 3mm, i made 3 holes on each shaft and each petal.

The Petals were acrylic 3mm sheets, I cut them with the laser machine. I shaped them and gave them this organic look through heating them in the oven (they took about 3 minutes) and placing them on the curved surface I created from MDF. I put aluminum foil on the curved surface because MDF was melting from the heat.

What worked and what didn’t?¶

Motors worked well, but my shaft broke easily therefore I am changing the design to make the holder stronger and I will cut smaller petals.

I resolved the shaft and made smaller petals but integrating of all components in my design didn’t work well! I couldn’t fix the dome that was supposed to hide all motors below it, the shafts were in the way! I had to choose between the shafts and the dome! I had to make a last minute decision and attach a pvc film only which is still a see-through for all motors and wires.

I believe wooden base and cone were integrating well, they held the PVC and were connected well to my motors and to my sensor. the only part that didn’t serve as I wanted was the dome.

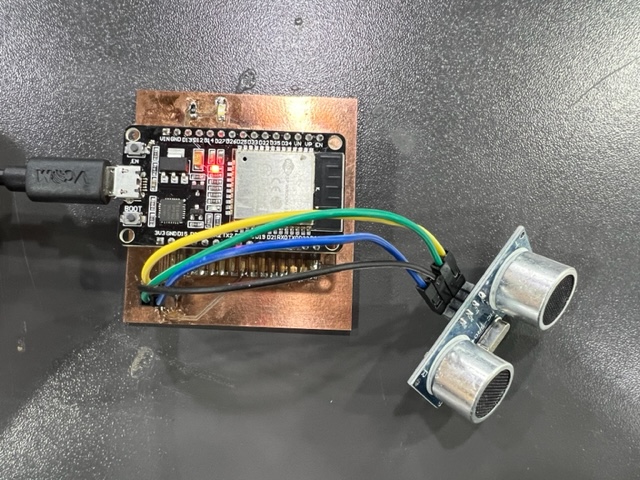

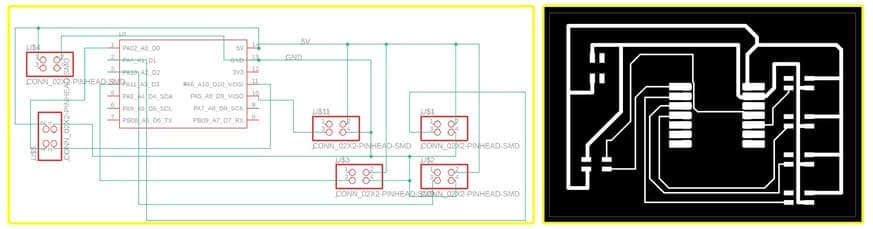

The Electronics

What questions need to be resolved?¶

-

What program do I use for my video? I ended up using “Movie maker”, it is free and very easy!

-

What program do I use for voice recording? I ended up using my phone and upload it as an MP3 to the video.

-

No other questions come to my mind.

What will happen when?¶

What will happen if my shaft breaks again before submission? I will print few extra ones from the new design.

What have you learned?¶

How casn I answer this without writing a book! This whole program has been a huge learning curve for me!

I learned that I love design! I want to focus on this aspect of product design in the future!

I learned that i am not very fond of electronics but I have to learn more about them to become a better designer! I will start by learning the different parts other than the ones I used in my assignments and final project!

I learned that testing is very vital for the success of the project! start testing with a bread board and a simple code.

I learned that I should simplify what I wish to make and after I make it I can add more stuff! spiral movement!

I learned that I function well under pressure! I didn’t expect to go through multiple family challenges (my child got sick multiple times) yet I was able to deliver my project!

I learned that I still cannot plan and put a schedule but I can start working ahead of time to avoid and delays.

What tasks remain?¶

Coding and testing of my code.

**NOTE: I am attaching the final code below after I submitted my project for documentaion purposes.

Coding

Below is the code I used with my PCB.

/*********

Rui Santos

Complete project details at https://RandomNerdTutorials.com/esp32-hc-sr04-ultrasonic-arduino/

Permission is hereby granted, free of charge, to any person obtaining a copy

of this software and associated documentation files.

The above copyright notice and this permission notice shall be included in all

copies or substantial portions of the Software.

*********/

#include <Servo.h>

// Create a new servo object:

Servo myservo1;

Servo myservo2;

Servo myservo3;

Servo myservo4;

const int trigPin = D0;

const int echoPin = D10;

//define sound speed in cm/uS

#define SOUND_SPEED 0.034

#define CM_TO_INCH 0.393701

#define servoPin1 9

#define servoPin2 3

#define servoPin3 2

#define servoPin4 1

int angle = 0;

long duration;

float distanceCm;

float distanceInch;

int angle_close = 100; //close when it starts

int angle_open = 140; //close when it starts

void setup() {

Serial.begin(9600); // Starts the serial communication

pinMode(trigPin, OUTPUT); // Sets the trigPin as an Output

pinMode(echoPin, INPUT); // Sets the echoPin as an Input

myservo1.attach(servoPin1);

myservo1.write(angle_close);

myservo2.attach(servoPin2);

myservo2.write(angle_close);

myservo3.attach(servoPin3);

myservo3.write(angle_close);

myservo4.attach(servoPin4);

myservo4.write(angle_close);

}

void loop() {

// Clears the trigPin

digitalWrite(trigPin, LOW);

delayMicroseconds(2);

// Sets the trigPin on HIGH state for 10 micro seconds

digitalWrite(trigPin, HIGH);

delayMicroseconds(10);

digitalWrite(trigPin, LOW);

// Reads the echoPin, returns the sound wave travel time in microseconds

duration = pulseIn(echoPin, HIGH);

// Calculate the distance

distanceCm = duration * SOUND_SPEED/2;

// Prints the distance in the Serial Monitor

Serial.print("Distance (cm): ");

Serial.println(distanceCm);

if(distanceCm < 50){

myservo1.write(angle_open);

myservo2.write(angle_open); //when someone is close, position open

myservo3.write(angle_open);

myservo4.write(angle_open);

delay(2000);

} else {

myservo1.write(angle_close); //

myservo2.write(angle_close); //

myservo3.write(angle_close);

myservo4.write(angle_close); //

}

}