17. application and implications¶

This week I worked on defining my final project, detailing its functions, what will it do, and how.

The FabLogger¶

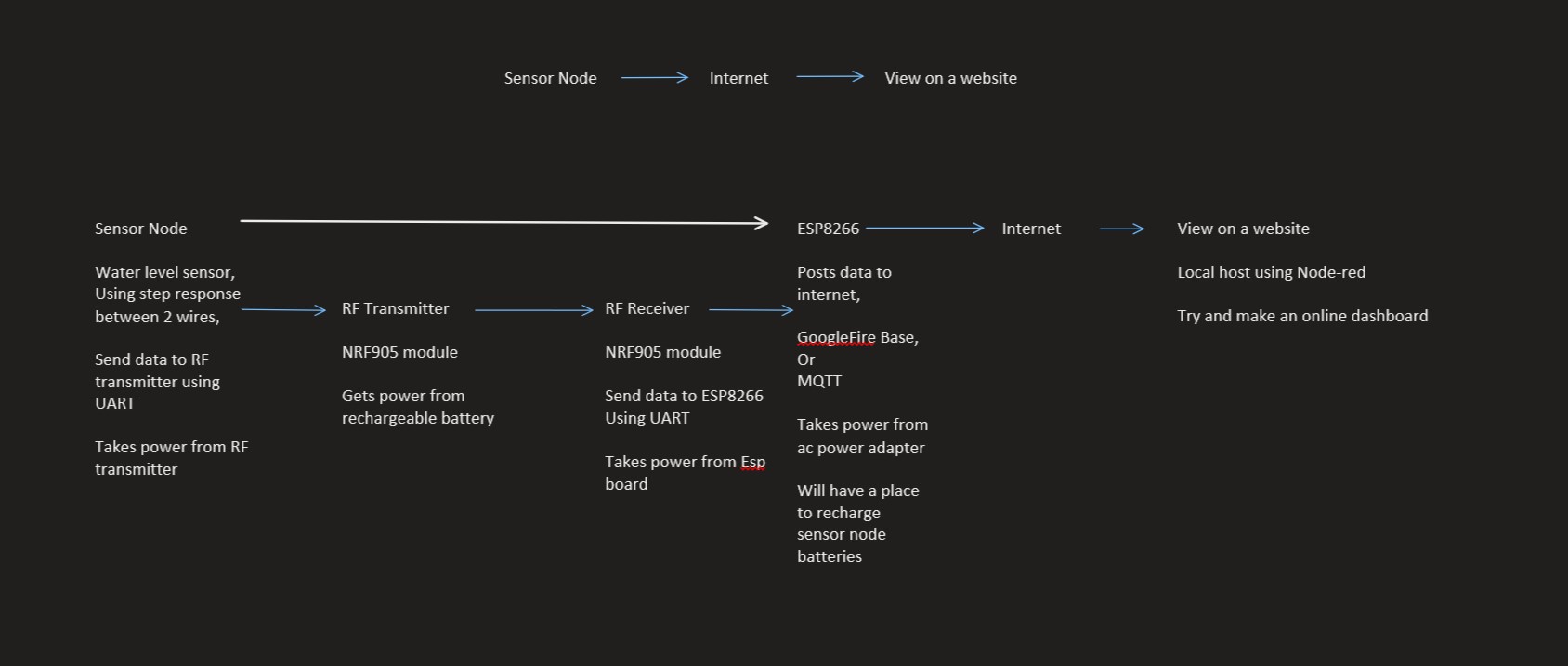

My final project is a general-purpose data logger, it will measure the data from a remote sensor; I will be using a water level sensor as a showcase, transmit the data using a long-distance RF communication to internet connect board which will send data online to be saved and viewed late.

Answering application and implications questions.¶

this section will be answering the questions in the application and implications assignment page to get to understand my project better.

What will it do?¶

My final project’s main purpose is to measure sensor data and save it on a cloud online, the main added value of my project is modularity.

FabLogger will be unique in its modularity, it will achieve this by splitting the electronics job between multiple PCBs, and if someone wants to measure and use a different sensor type they would only need to change the main sensor board. the main sensor PCBs job is to handle data measurement and send it through serial communication to a second board.

The main sensor PCB will either connect to an RF transmitter board, which will have battery handling capabilities, or connect to an ESP8266 board if it placed in a place with wifi connection, if the main sensor PCB is connected to an RF transmitter, there will be a second RF receiver that would connect to the ESP8266 PCB.

Who’s done what beforehand?¶

There are multiple commercialized data logging systems such as national instruments with their software labview, such systems are reliable but can be rather expensive and closed for special use cases.

There are open-source ones such as OperLog which focuses on saving the data on a microSD flash.

My project focuses on uploading the data to a cloud, where it can be procced directly rather than saving it and processing later, also my project is modular, any sensor can be placed in place of the one I used with the same system as it has its own electronics. My project is fluxable were the sensor can be indoor with the gateway or in a remote place where data is sent using radio communication.

What will you design?¶

First, I will start by designing the test sensor board and packaging, it will take power from a second board and will send the sensor readings to it using wired serial communication.

Second, I will design the RF communication PCBs, the transmitter will be battery powered to power the sensor PCB, and its job is to receive data from the sensor PCB and send it to the second RF PCB. I will be designing an outdoor casing for this PCB in case it needed to be placed outdoor, the RF receiver PCB’s job is to send the data it receives to the internet-connected PCB, its receiver PCB will be powered by the board it’s connected to.

Third, I will design the internet-connected PCB, it will receive serial data from the board connect it to it and post it online, it will be powered with an ac/dc power adapter, and will power the board connected to it, the main sensor PCB can be connected to it directly, or the RF receiver one using the same connector.

What materials and components will be used?¶

the PCBs will be made using the Roland SRM-20, they will have either ATtiny or ATmega microcontrollers, and the internet-connected one will use an ESP8266, for the RF PCBs I will use the NRF905 module as we have a good stock in the lab.

I will need a power adapter, rechargeable batteries with the needed electronics to handle their recharging and safety.

the cases will be a combination of 3D printed parts and resin casting.

Where the material will come from and How much will they cost?¶

all material needed for this project will be sourced from the lab stock, for more details please check this document for the material details.

What parts and systems will be made?¶

- the four PCBs.

- the packaging of each part.

- the cables needed to connect the PCBs to each other.

What processes will be used?¶

- PCB design.

- PCB production.

- embedded programming.

- networking.

- 3D design.

- 3D printing.

- molding and casting.

- CNC machining for mold manufacturing.

What questions need to be answered?¶

- how to export the data and save it to a file.

How will it be evaluated?¶

- project should be able to pass sensor reding through an RF moudule to another then to an ESP8266 board, and post it online

- all boards must be contained in nice packing

- a simple 1 cable should be able to connect boards, transfir data and power