Molding & Casting¶

General¶

This week’s group assignment was to review the safety data sheets of several different types of molding and casting materials, and then testing them out and comparing the results.

Data Sheet Reading¶

As repeatedly described throughout the data sheet, it is crucial to always practice the correct safety measures. This includes some very obvious things like not ingesting the material, but also has other important details such as performing any casting in a well ventilated area. We casted with each of the materials in the room where we have all our soldering irons and the laser cutters, so we already had a professional filtration and ventilation system in that room. Another important thing is that to remove any material that may have spilled on our hands during the mixing process, the only thing you need to use is soap and warm water. On the Smooth Cast 300 website, there is more information about curing. Since the Smooth Cast 300 cures in about 5 minutes, the reaction is highly exothermic and can reach very high temperatures as seen at the bottom of this site.

Molding & Casting Tests¶

Milling¶

Once we had the vectors created we started to work on the toolpaths. the first step was to set up the material. We were using 3/4th inch wood and the length and width were made a little bigger than what we needed. Once we verified that everything could fit, We used the 2d outline tool and selected the edge of each vector. The bit was already setup on the machine so we selected the 1/2th inch flat end tool and Aspire generated the toolpaths. We then exported the toolpaths from Aspire using the .SBP format after simulating. As mentioned in our week 5 page (characterizing the CNC machine), this is the format of files that the ShopBot can read.

20T¶

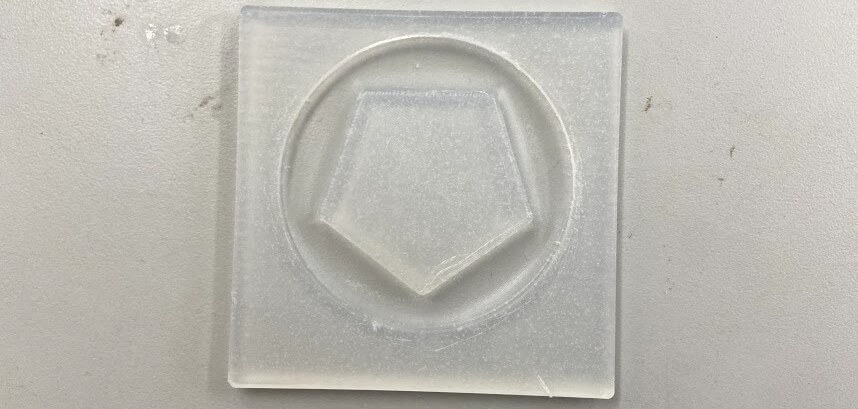

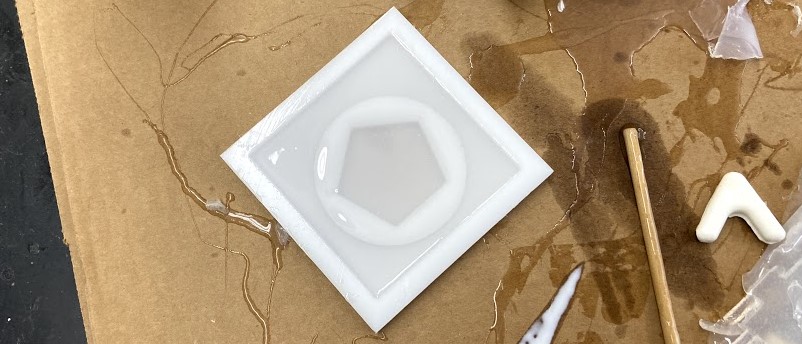

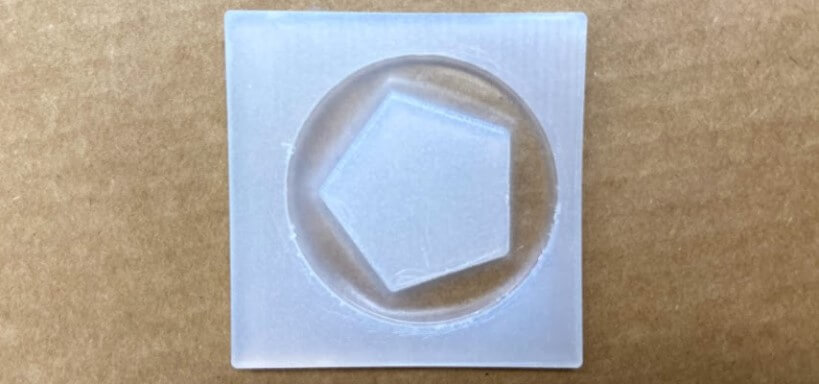

The first type of casting material we tried was Mold Star 20T by Smooth-On. This is a silicone rubber, meaning it is a soft and flexible material. As you can see in the picture below, there is a “Part A” and a “Part B”. To cast this material, you need a ratio of 1:1 (by volume) between the two parts. Applicable to all types of casting materials, we have to mix these two parts thoroughly. It is also very important to remember to always stir horizontally, meaning not moving the dowel (or any other mixer) up and down to prevent air bubbles.

Dragon Skin¶

Dragon Skin 10NV, like the Mold Star 20T, is a silicone rubber. It is very common to have tiny bubbles with this material specifically. This is usually not a problem if you gently shake the mold

Smooth-Cast 300 Casting¶

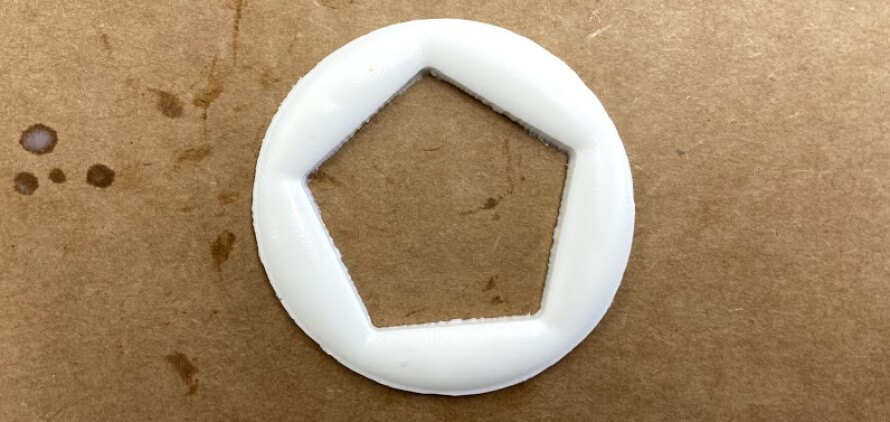

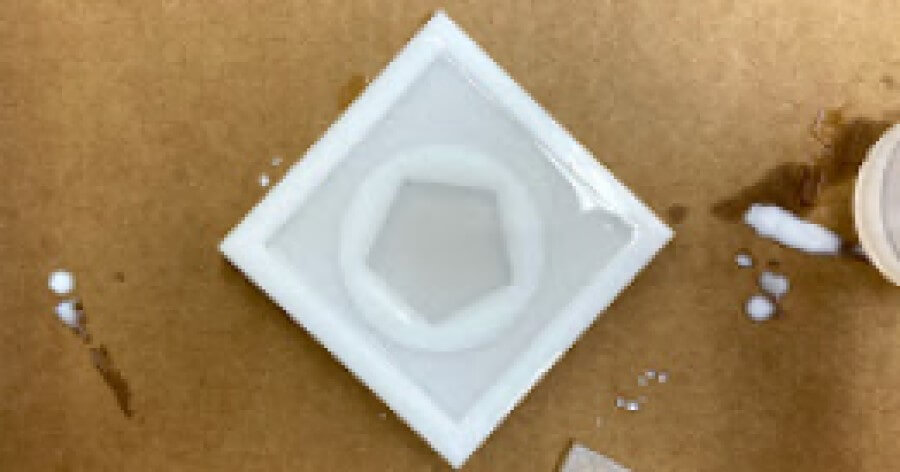

The Smooth-Cast 300Q, unlike the 2 previous materials, is a hard material. This means that once it has cured, it will be solid and completely rigid. As you can see from the 3rd image below, the only slight issue was just a bit of overflow which can easily be resolved by sanding down that edge.