17. Wildcard week¶

assignment

Design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it. Possibilities include (but are not limited to):

Research¶

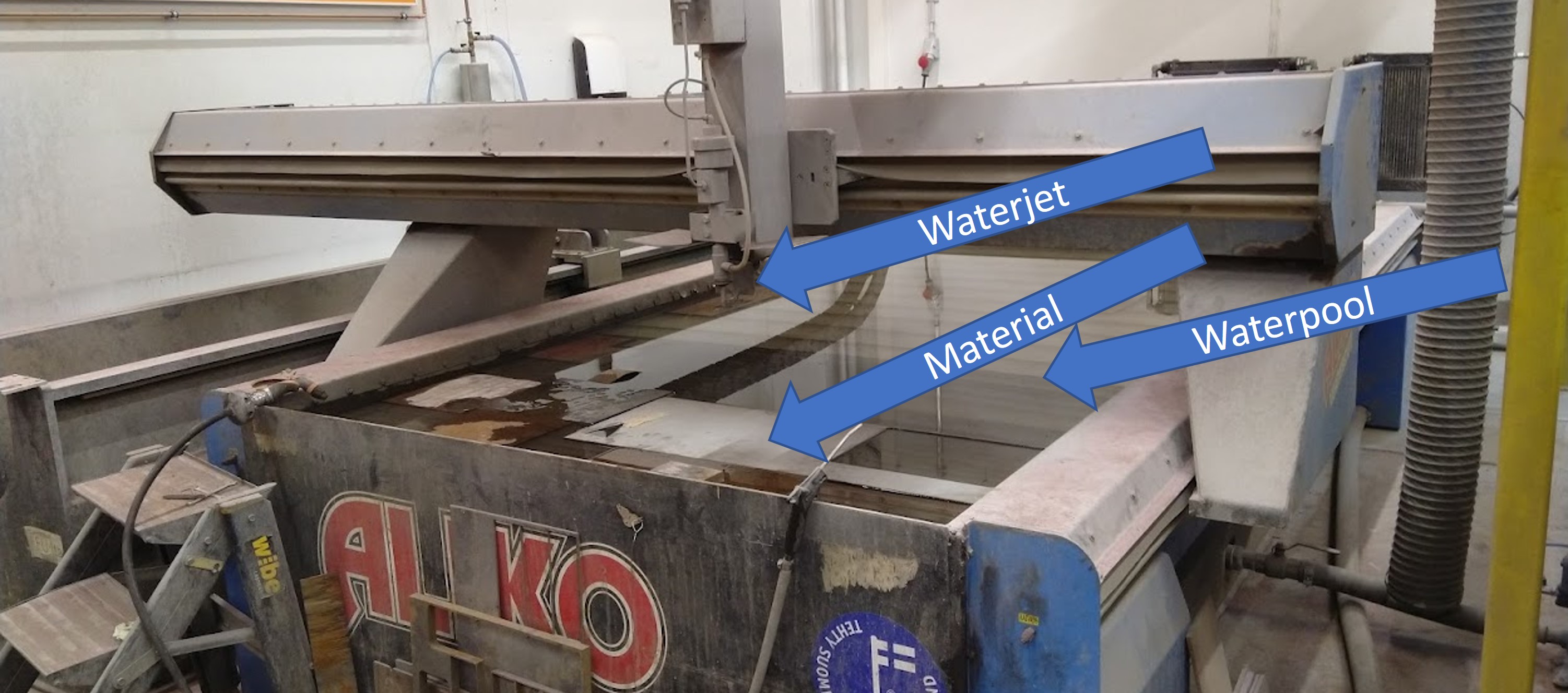

I got into familiarize Waterjet cutting process. In the University of Oulu in the Machineshop there is Aliko waterjet cutter. The first I made work plan

Work plan

1 - Object desing 2 - Tool path file 3 - Waterjet cutting

1 - Object desing¶

I designed the object with Autodesk AutoCAD design program. I have documented CAD desingn prosess on Computer Aidid Desing week

2 - Tool path file¶

The next I made tool path file to waterjet cutter. I used IGEMS-program. In the Machineshop they use Finish version of that program.

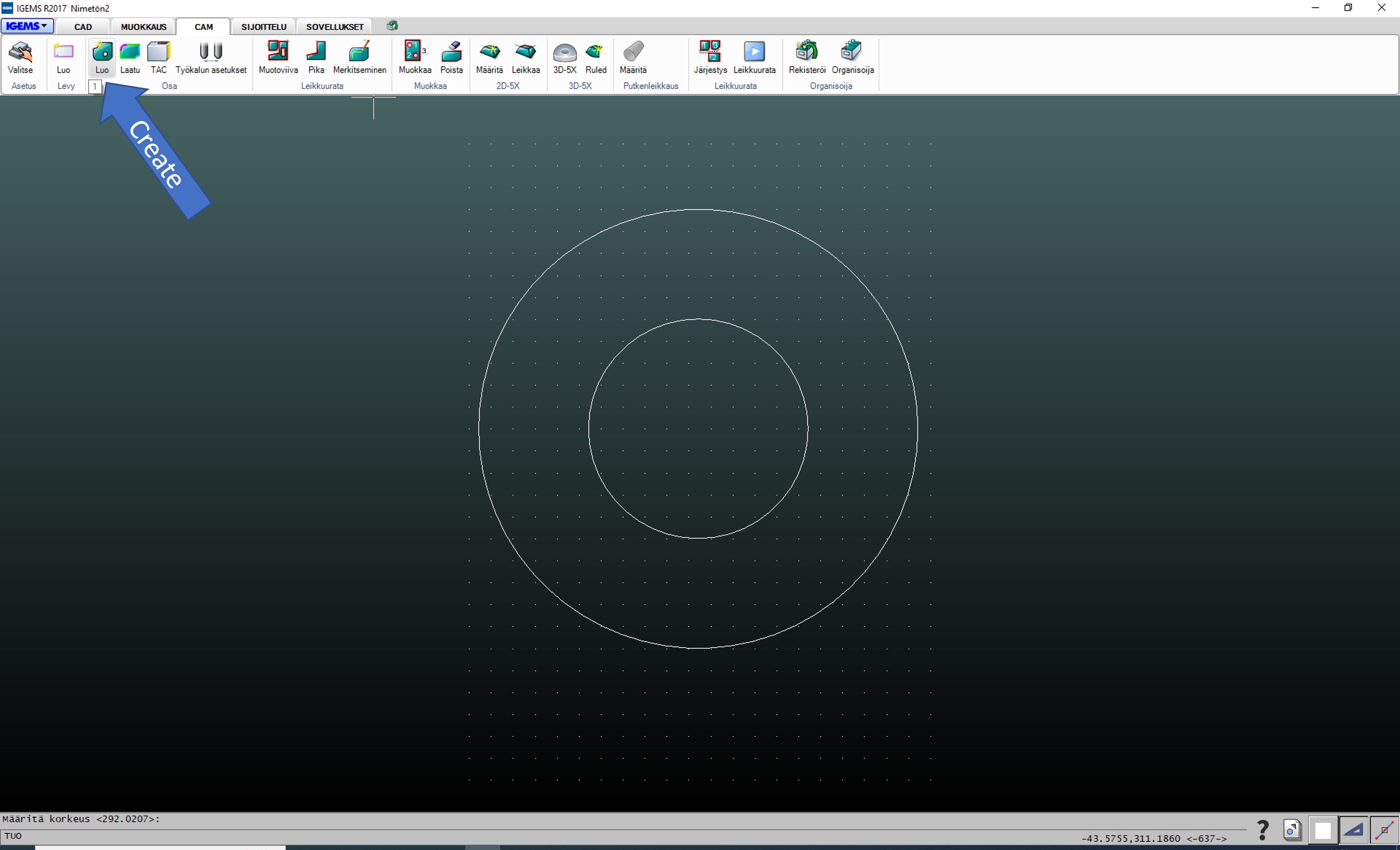

Step 1. I Open IGEM-program. The first I clicked IGEMS on the left.

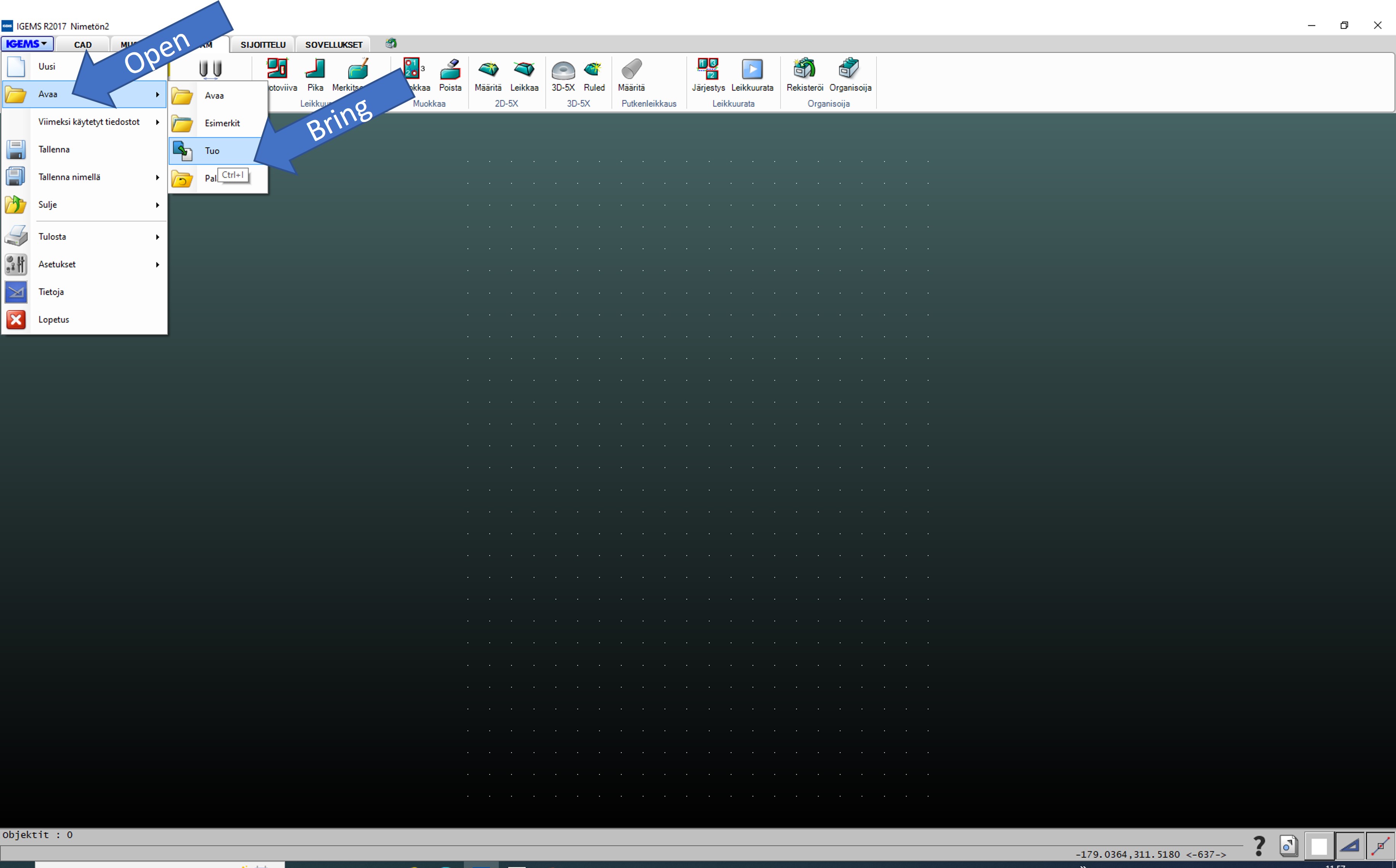

Step 2. I clicked Avaa (“Open”) and then Tuo (“Bring”).

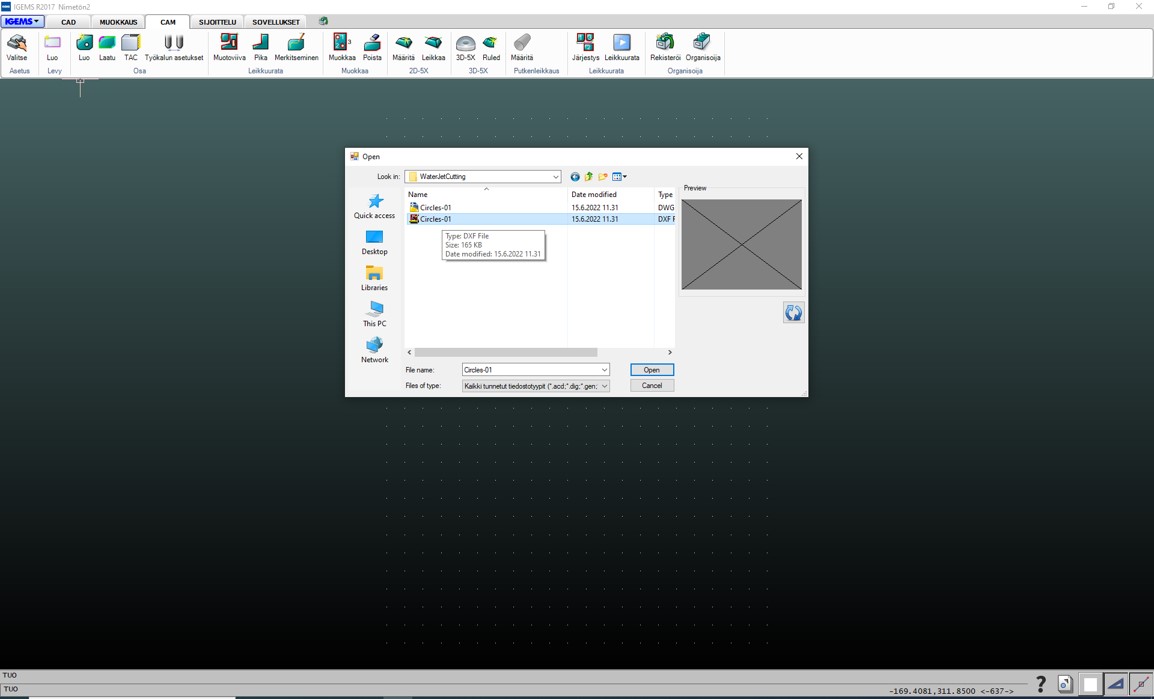

Step 3. Then popped up Open window. I chose Circle-01.dxf file and picked Open button.

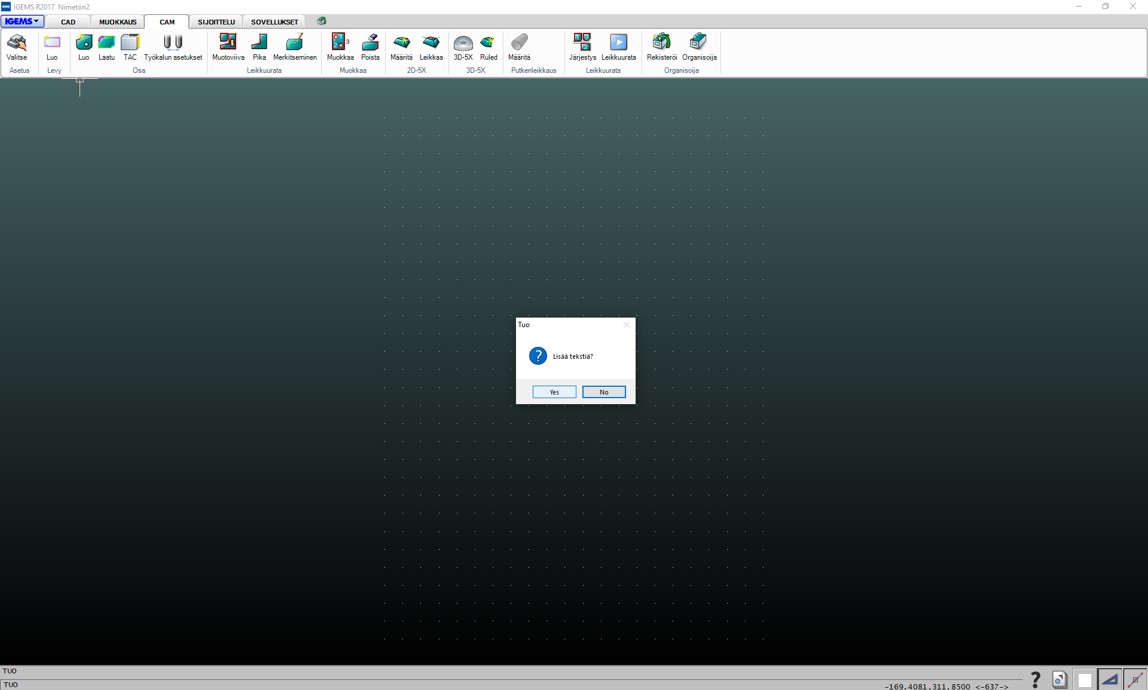

Step 4. Then popped up Tuo (“Bring”) window. I picked Yes button and located picture of object onto sheet.

Step 5. I cliced Luo (“Create”) button

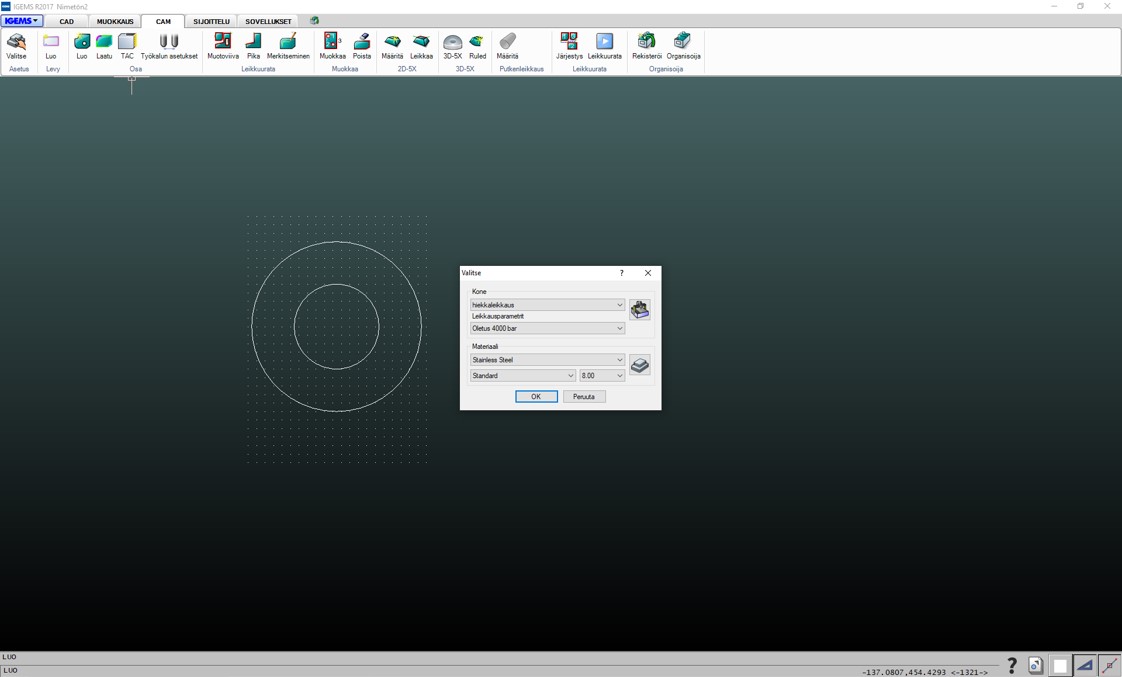

Step 6. Then popped up Valitse (“Choose”) button. I chose right values such as material: Stainless Steel and thickness: 8.00 mm. I clicked OK button.

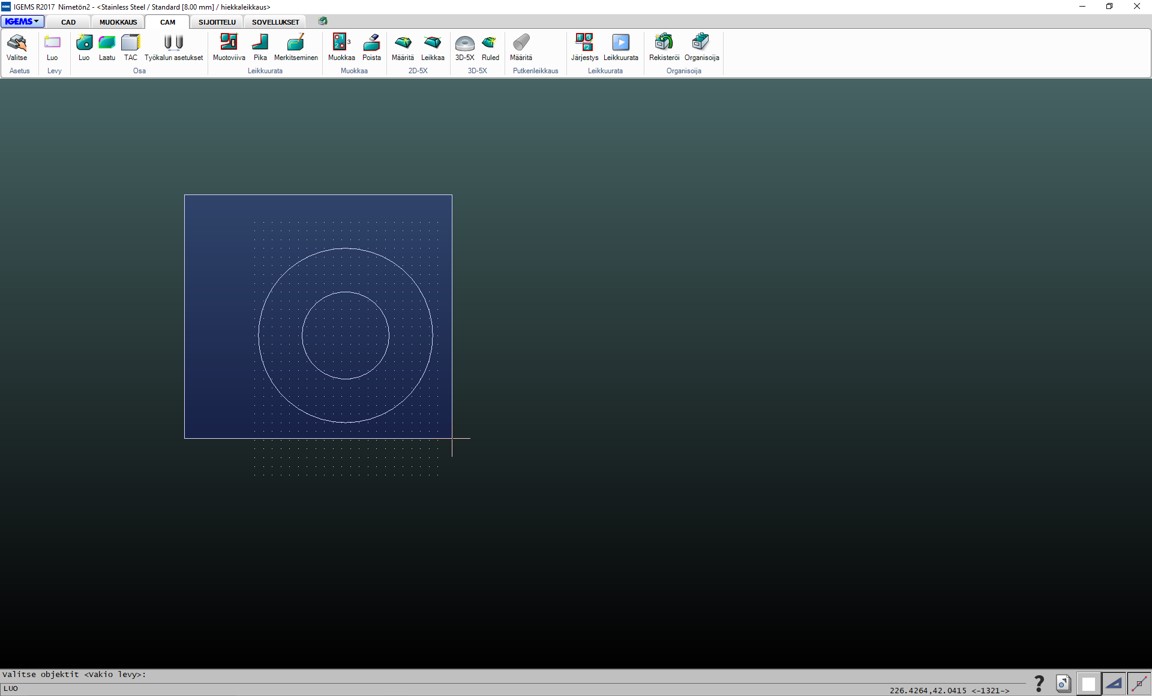

Step 7. I chose the object and clicked Enter key.

Step 8. I clicked Luo (“Create”).

Step 9. Then Luo arkki (“Create sheet”) popped up. I clicked Ok button.

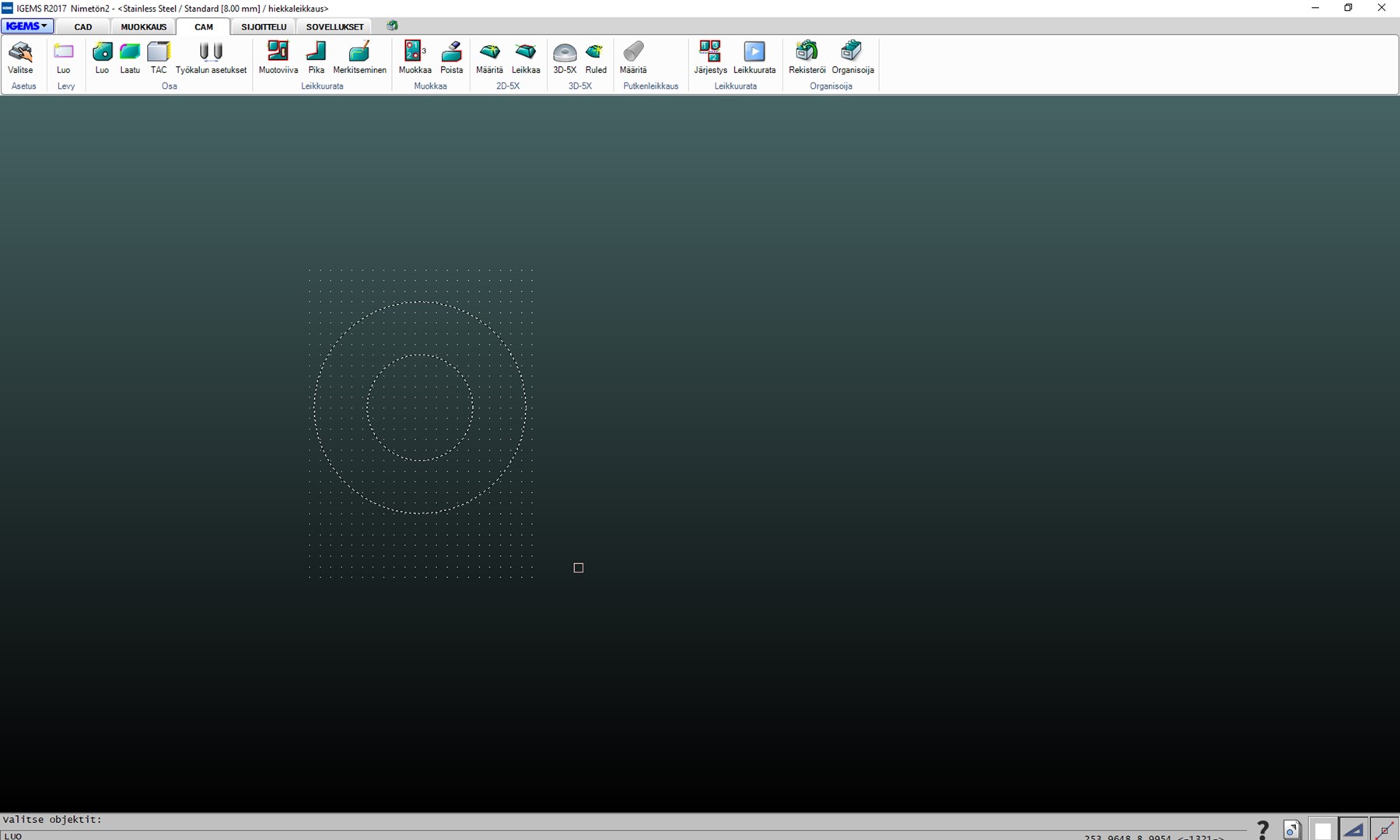

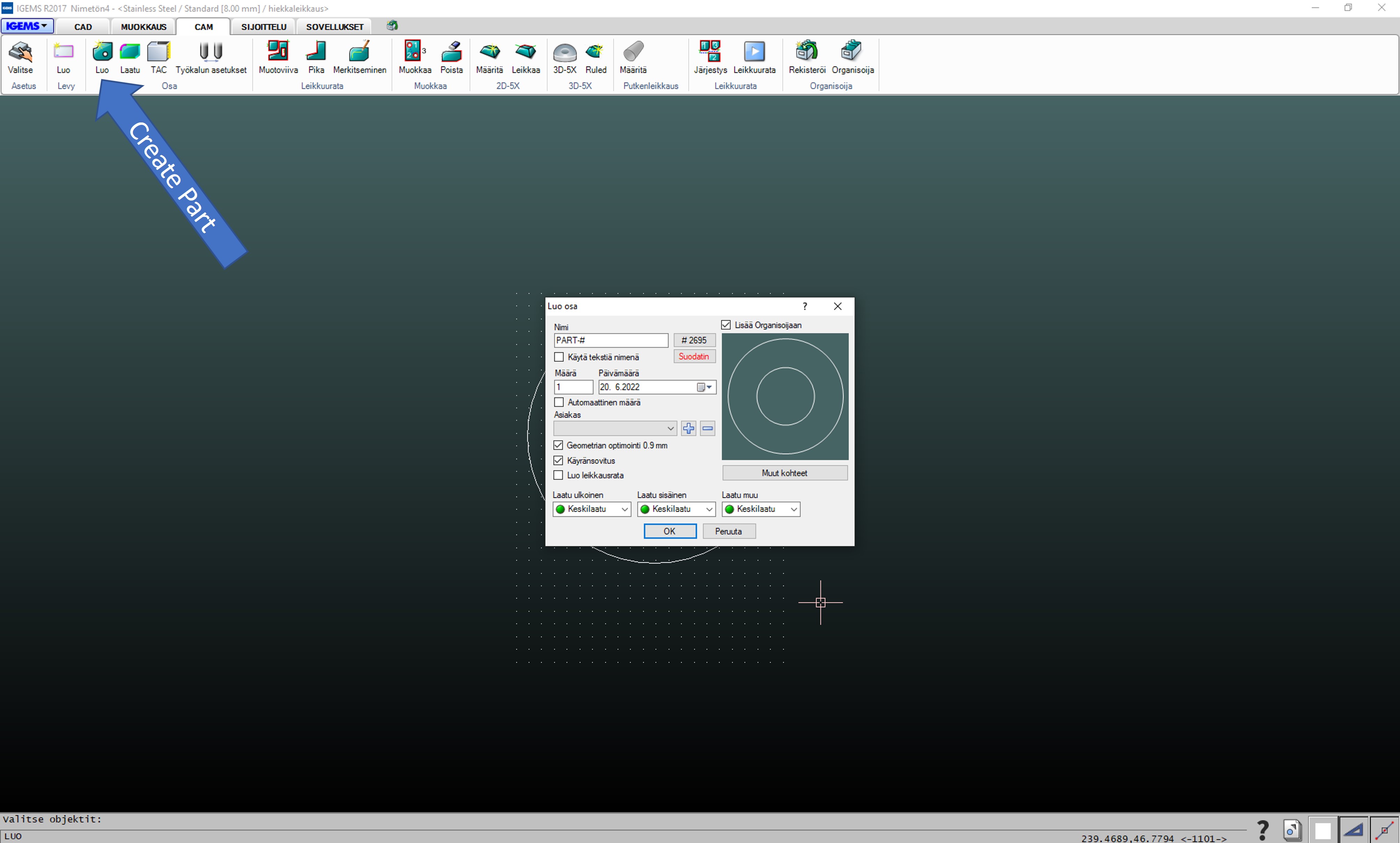

Step 10. Then I clicked Luo osa (“Create part”)

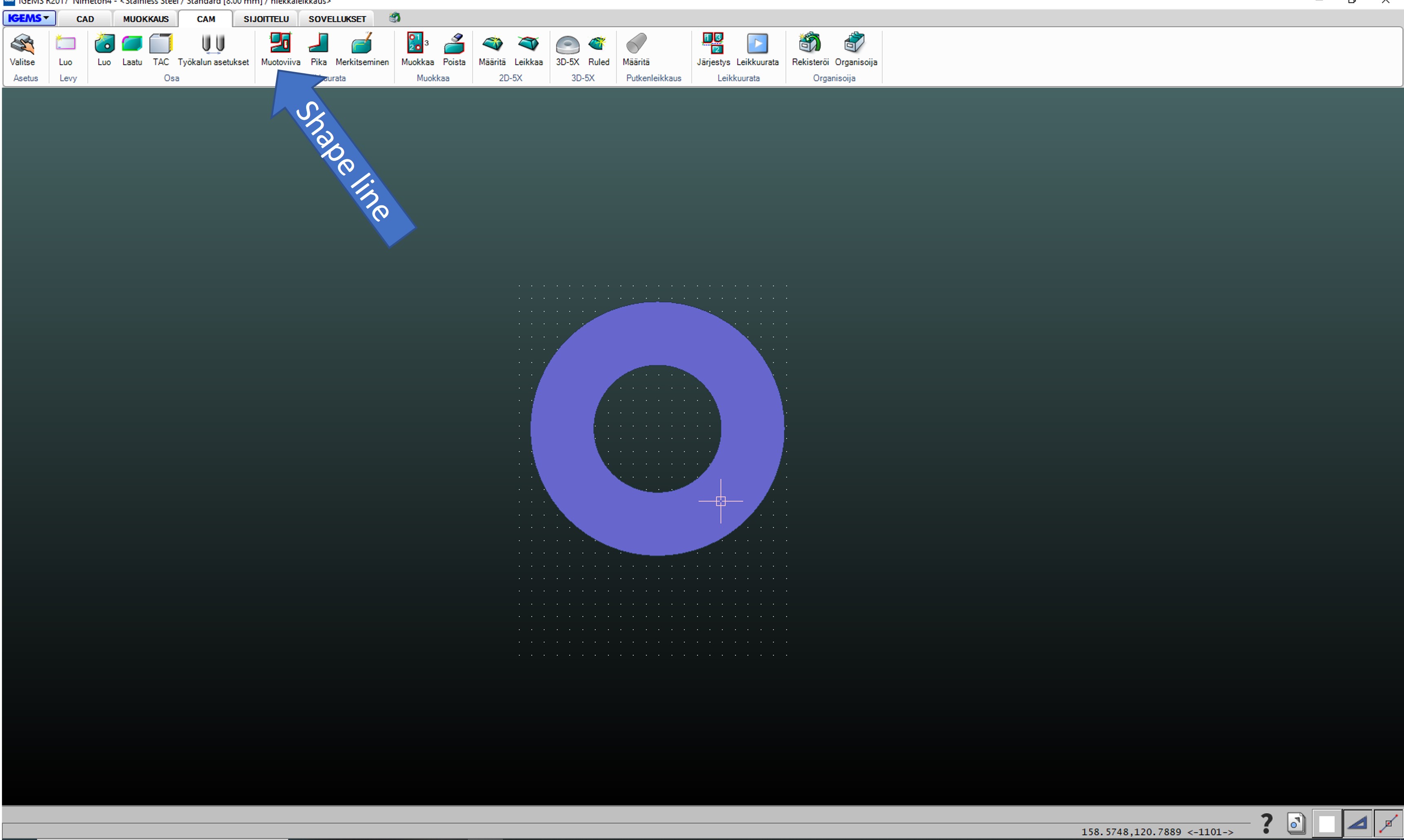

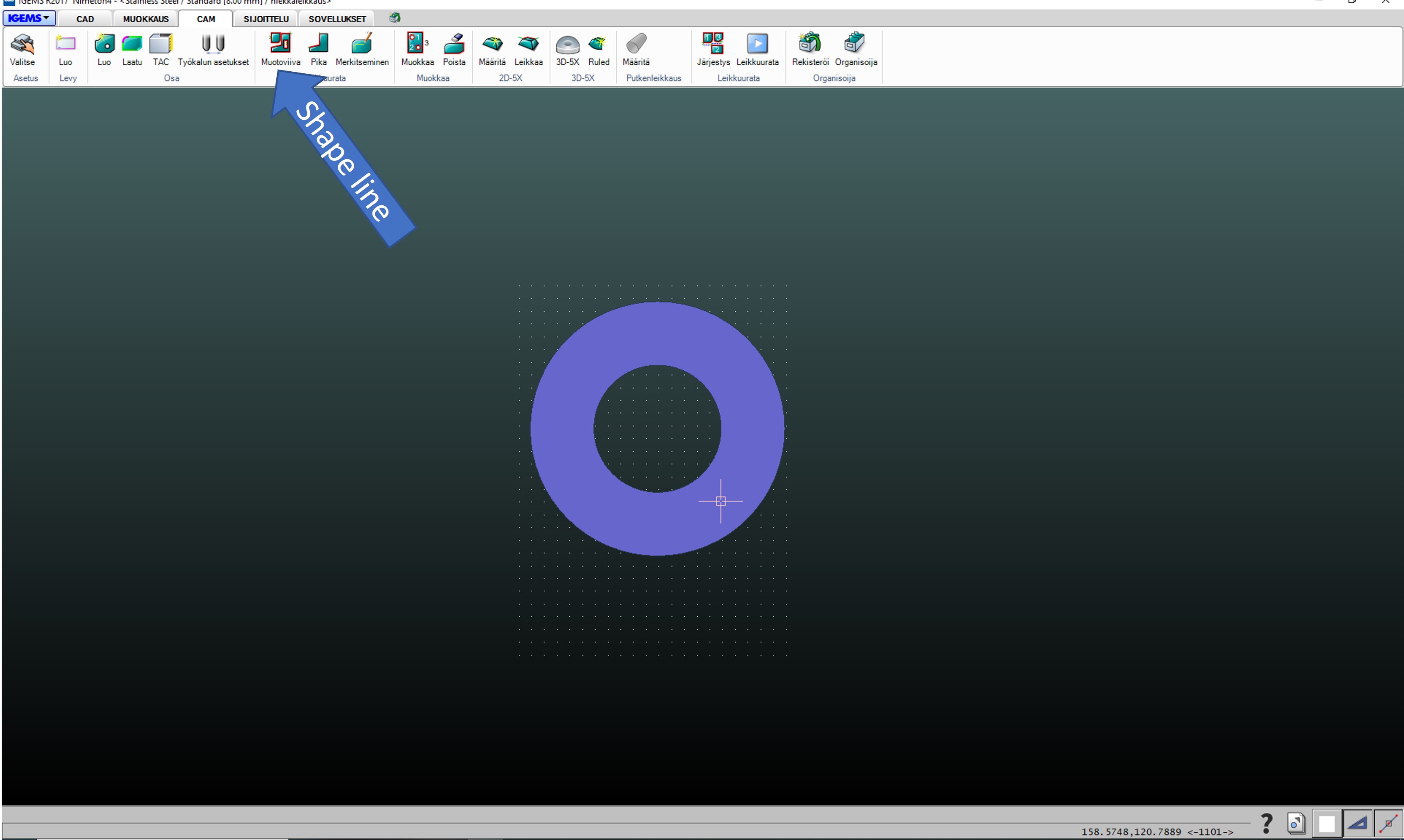

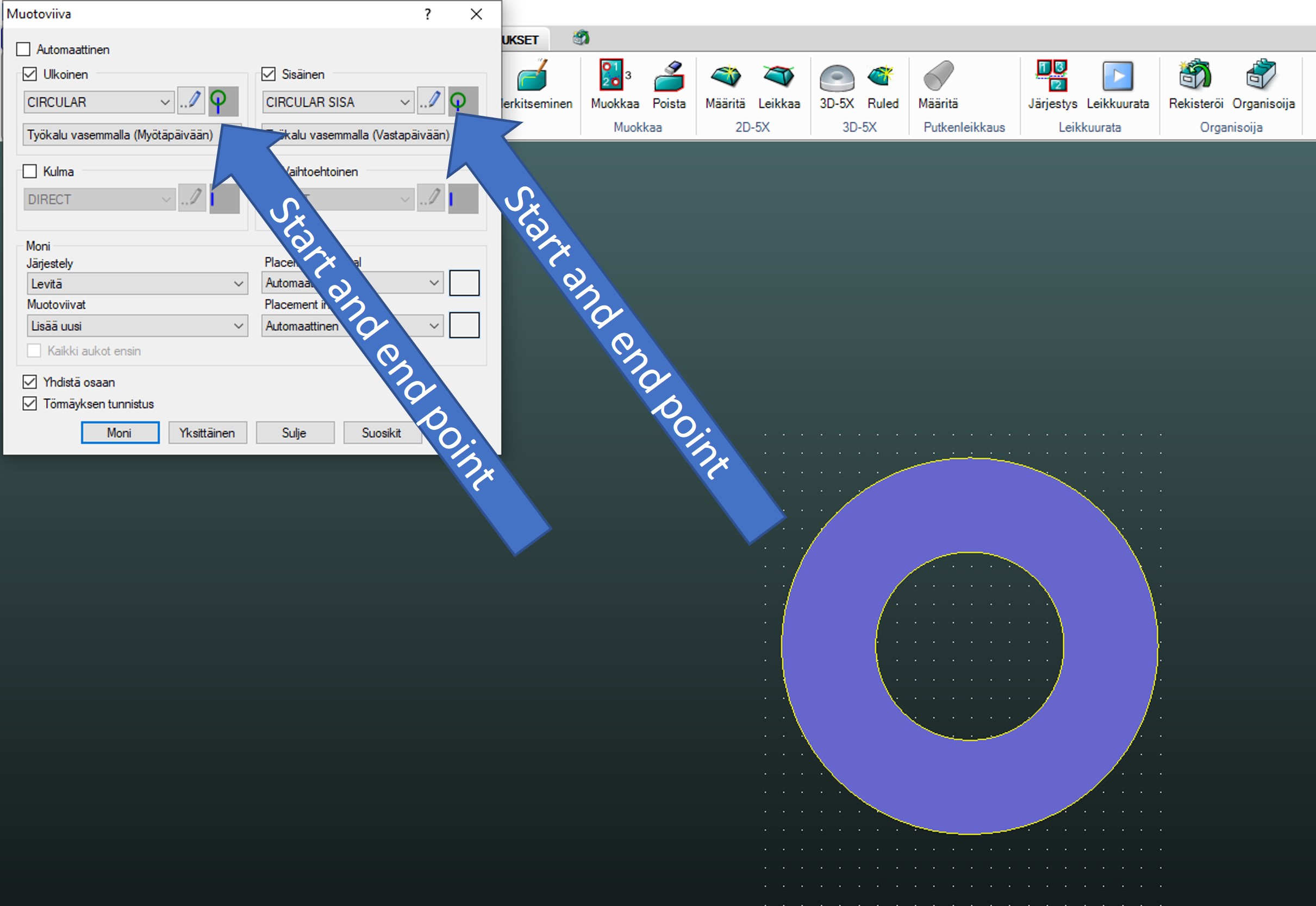

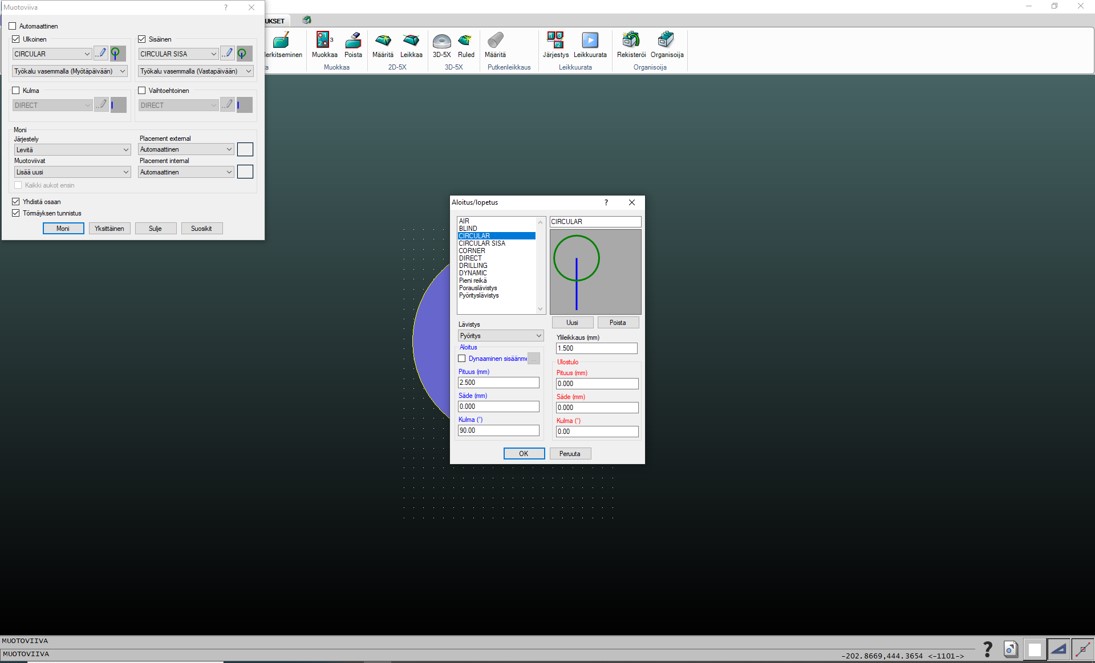

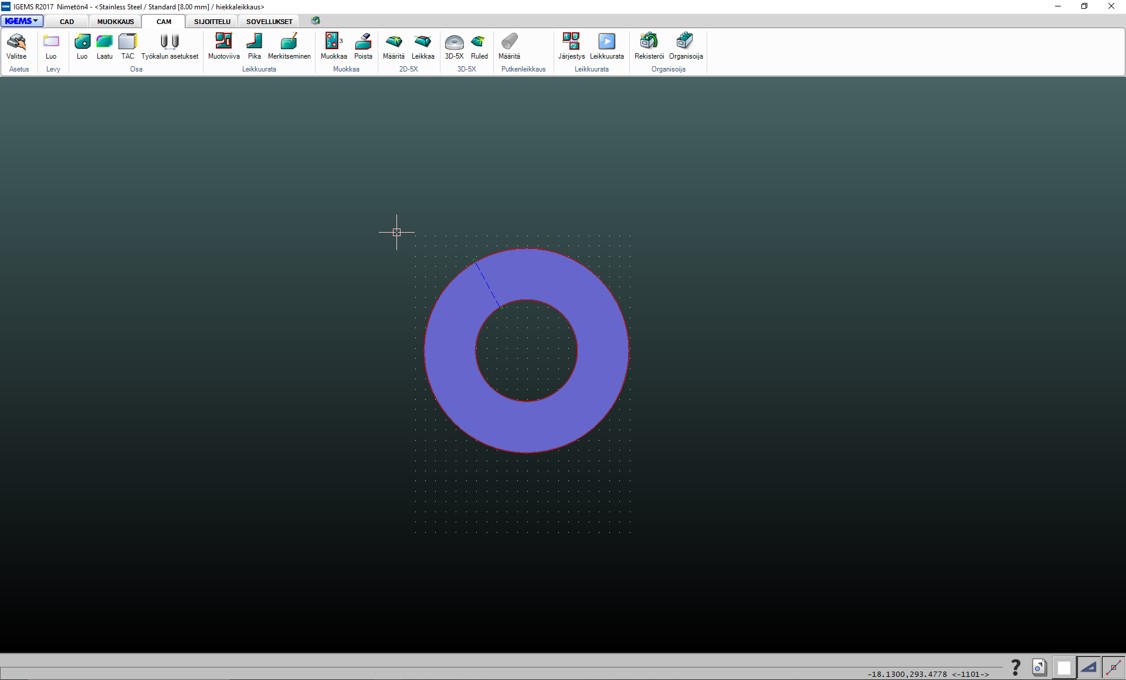

Step 11. I clicked Muotoviiva (“Shape line”) and popped up Muotoviiva windows

Step 12. Then popped up Muotoviiva windows.

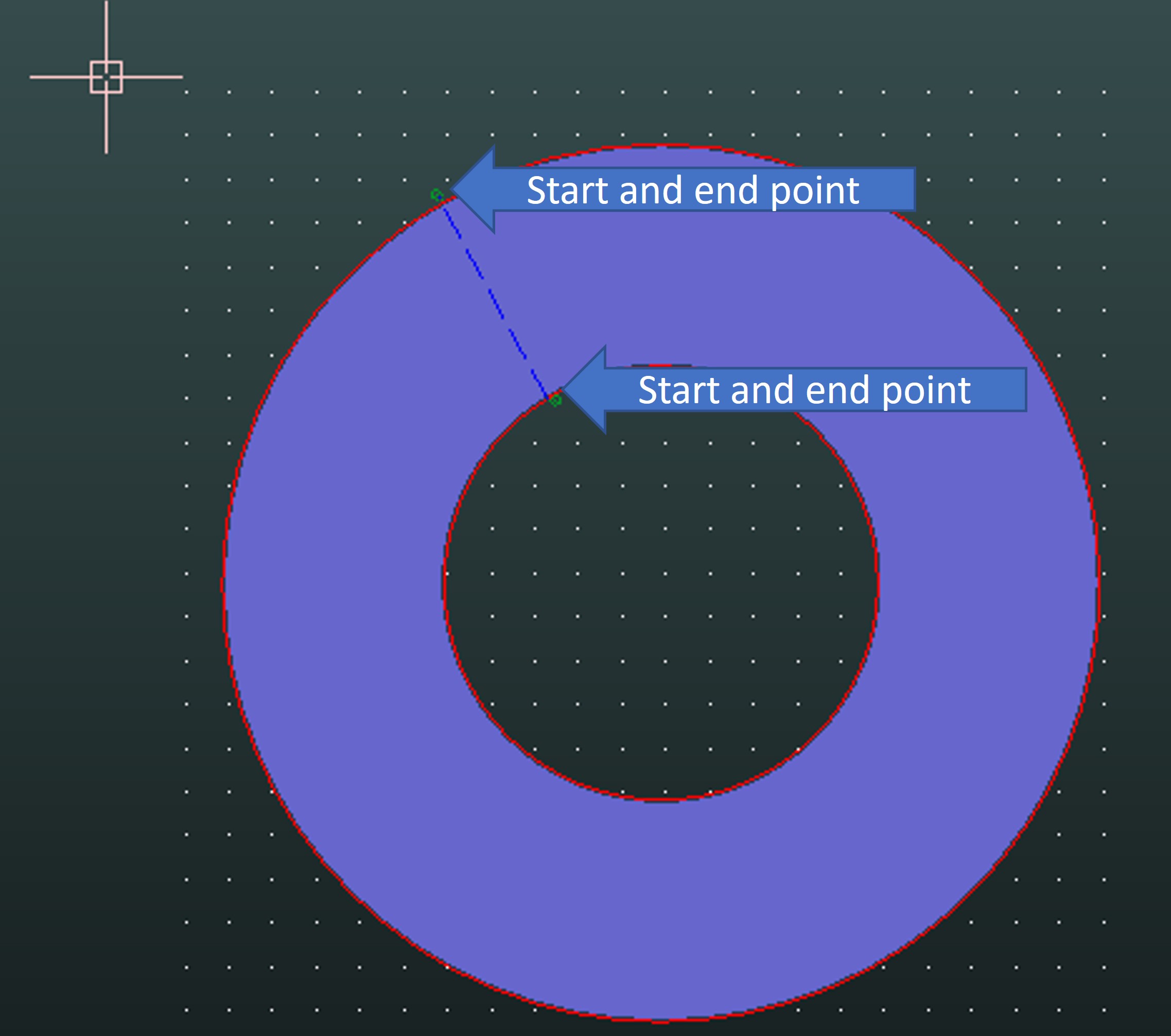

Step 13. I checked start/end poins on outside and inside.

Step 14. Then program create start/end poins onto outside and inside

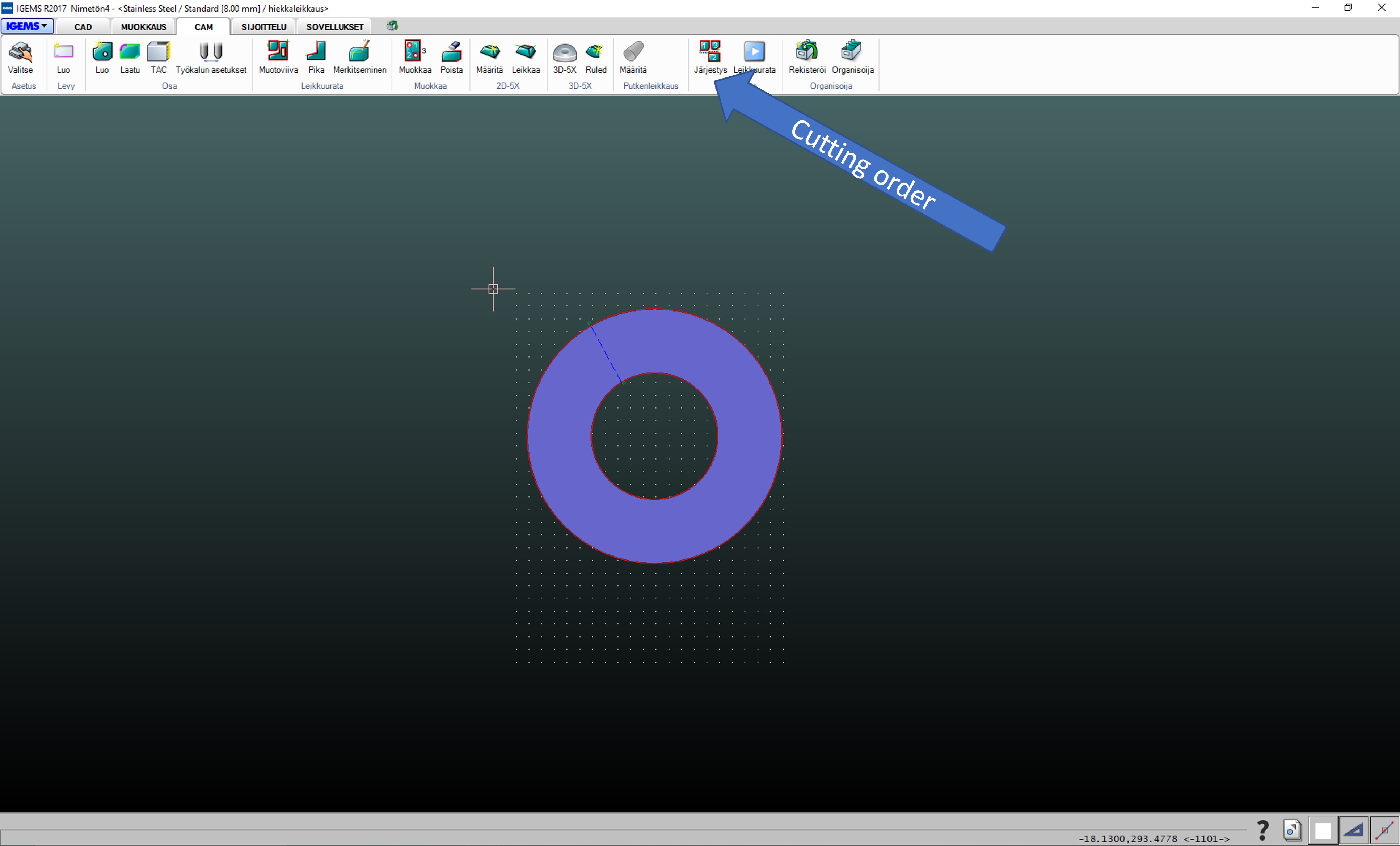

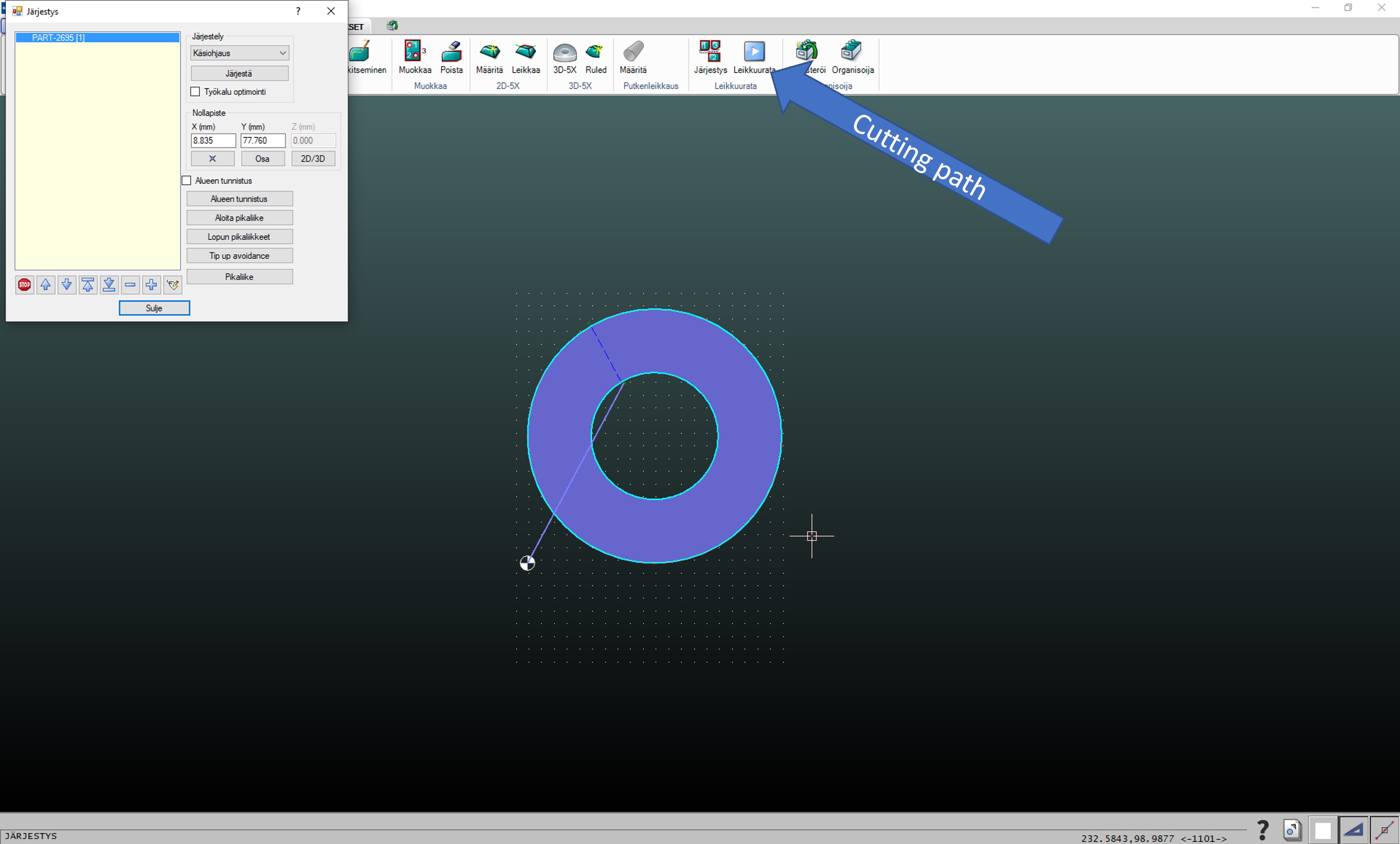

Step 15. I chose Järjestys (“Cutting order”)

Step 16. Then popped up Järjestys window. I clicked Sulje (“Close”) button

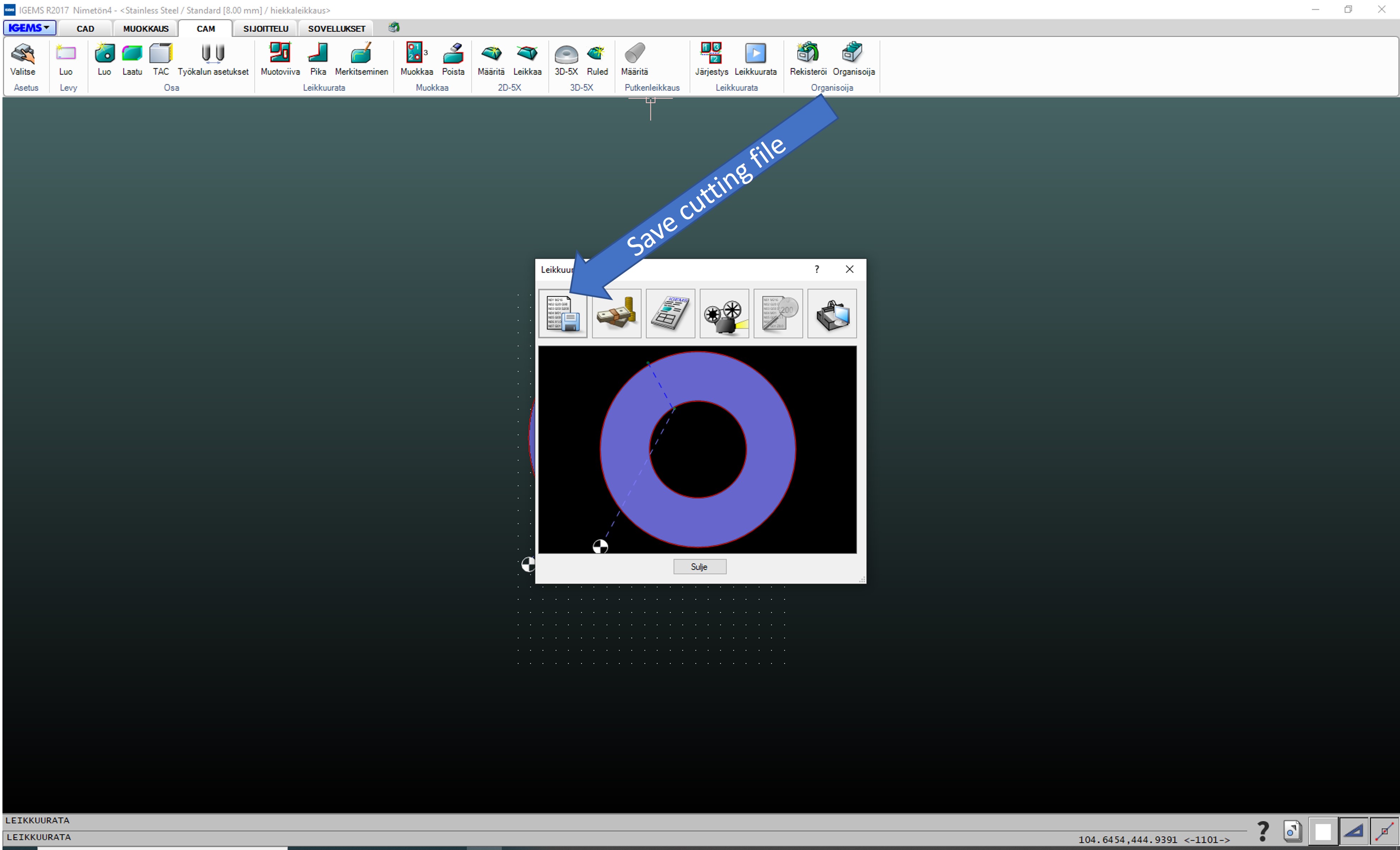

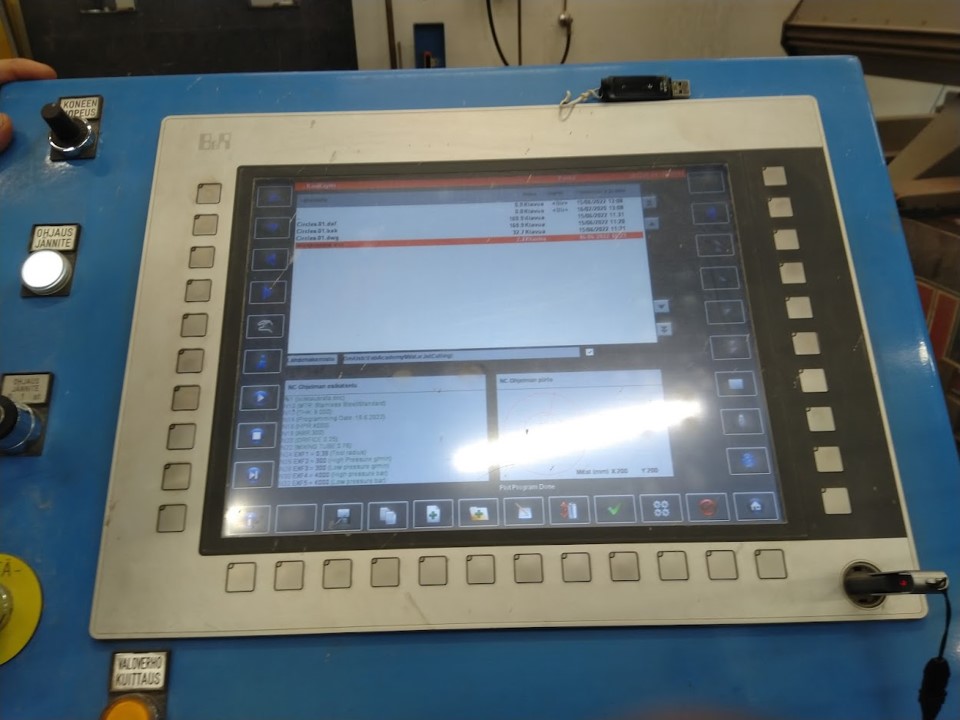

Step 17. Then popped up Leikkuu rata (“Cutting path”). I clicked Save cutting file

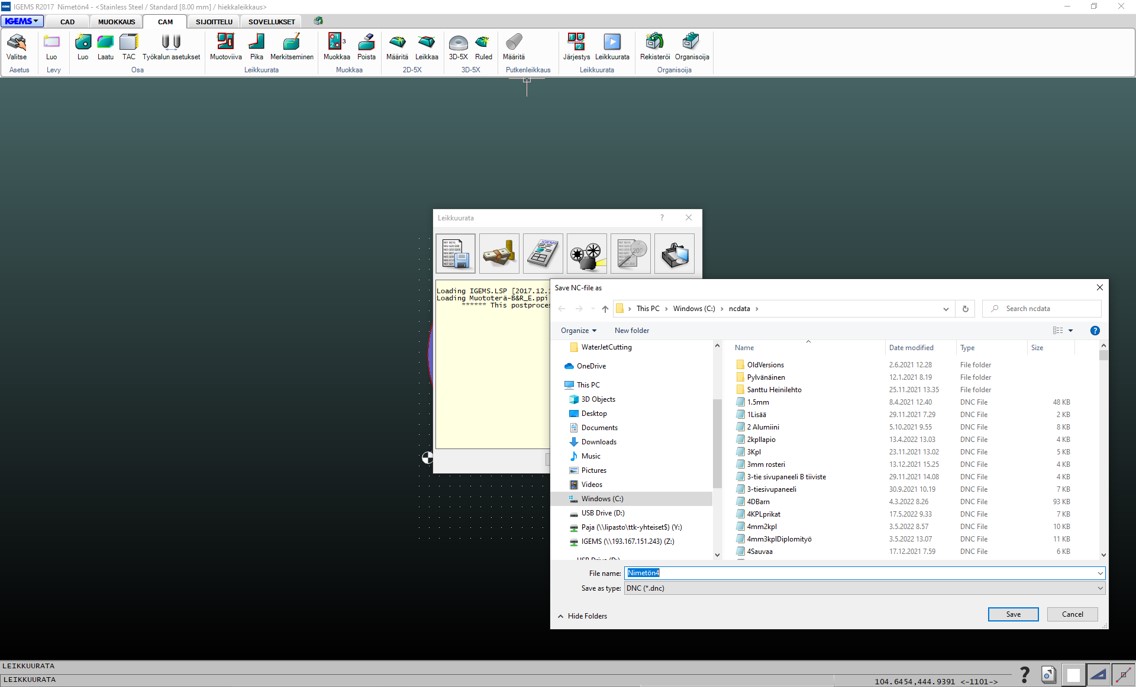

Step 18. And finally I named and saved cutting file.

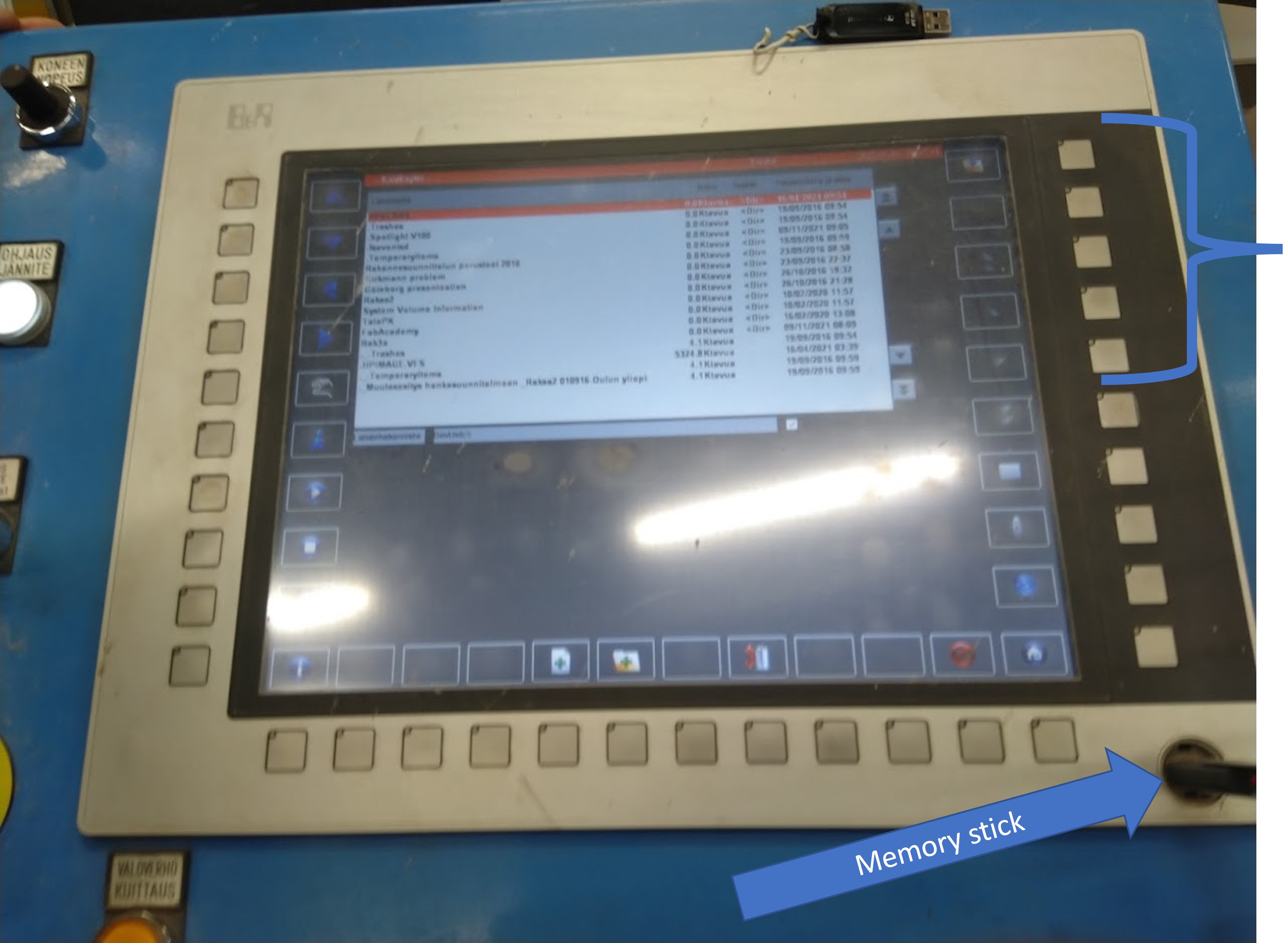

I moved file to my memory stick.

3 - Waterjet cutting¶

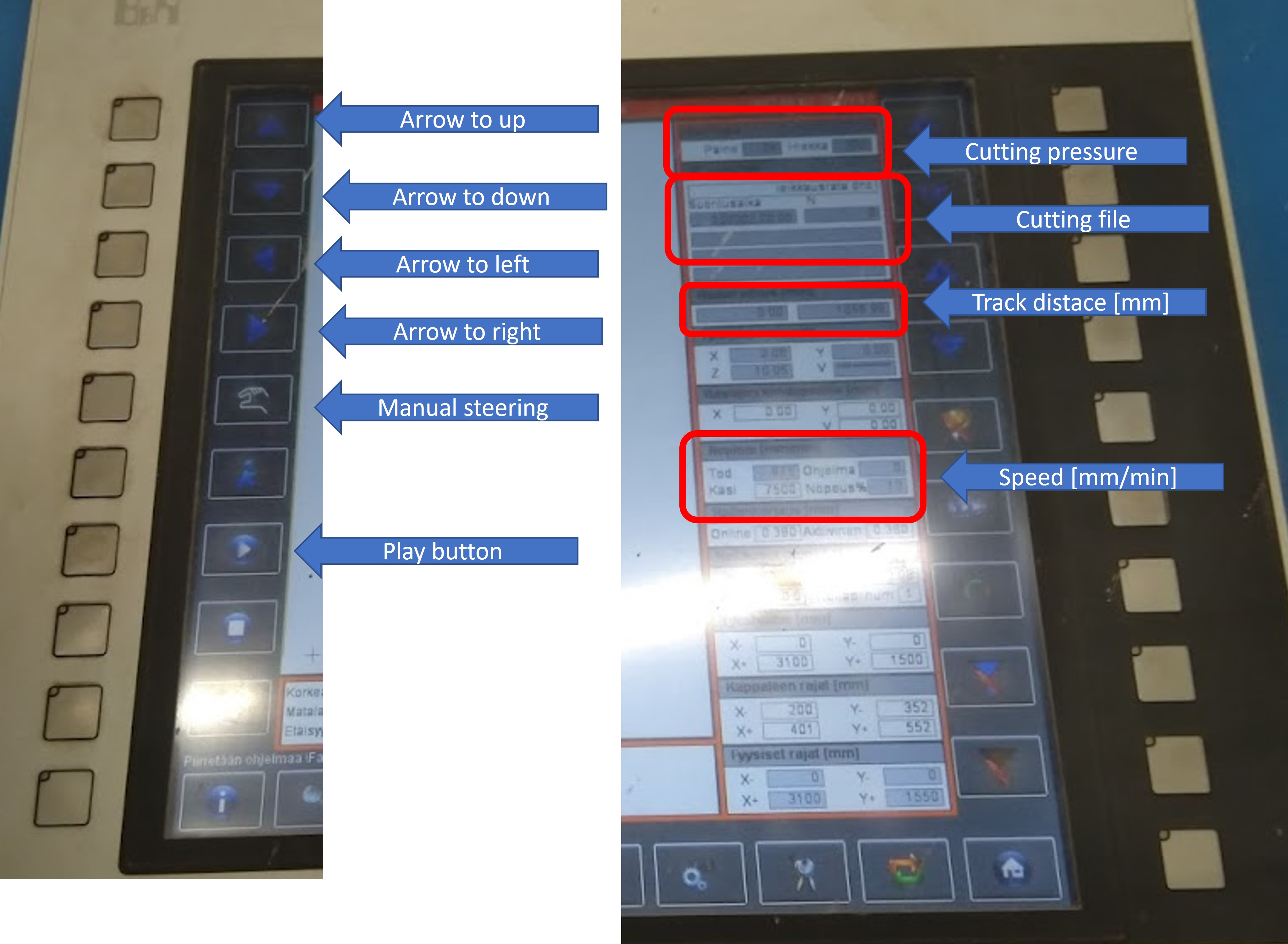

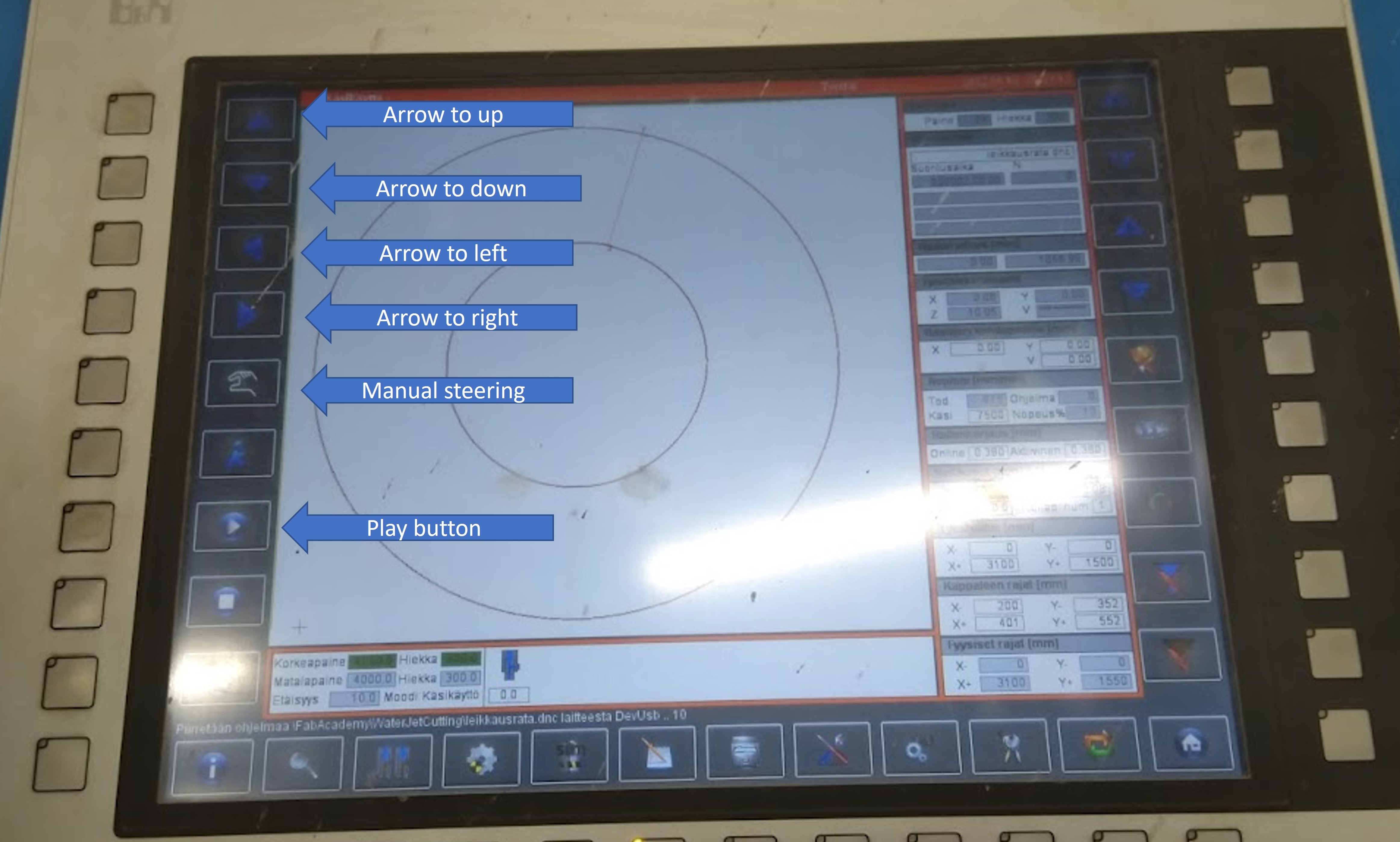

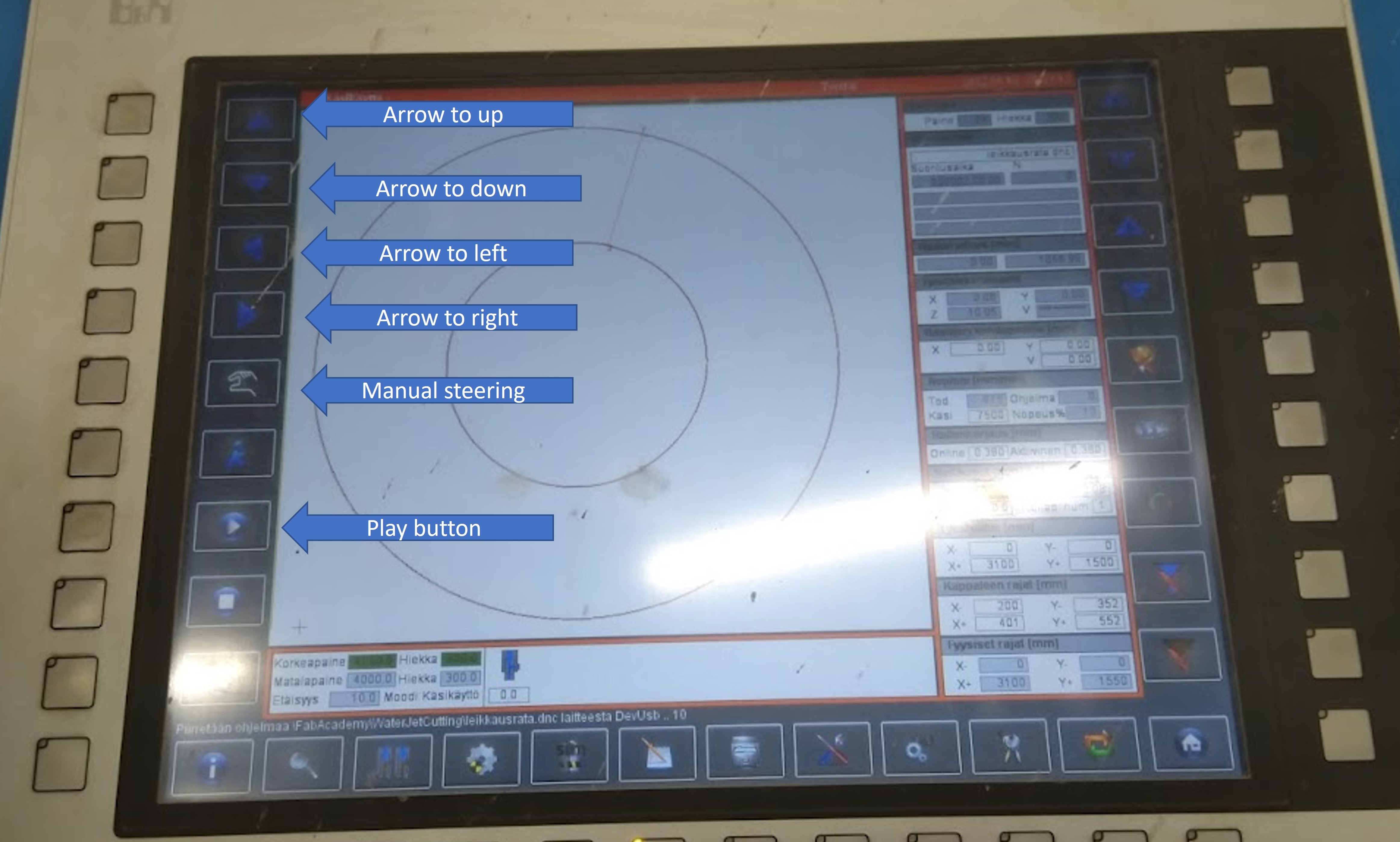

Aliko watercuter consist of Controll panel and Waterjet cutter.

Step 1. I checked that Water pressure is 3800 bar and Sand speed: 280g /min.

Step 2. I loaded cutting file.

Step 3. I set start point. I moved cutting nose with arrows buttons.

Step 4. I started cutting by clicking Play button

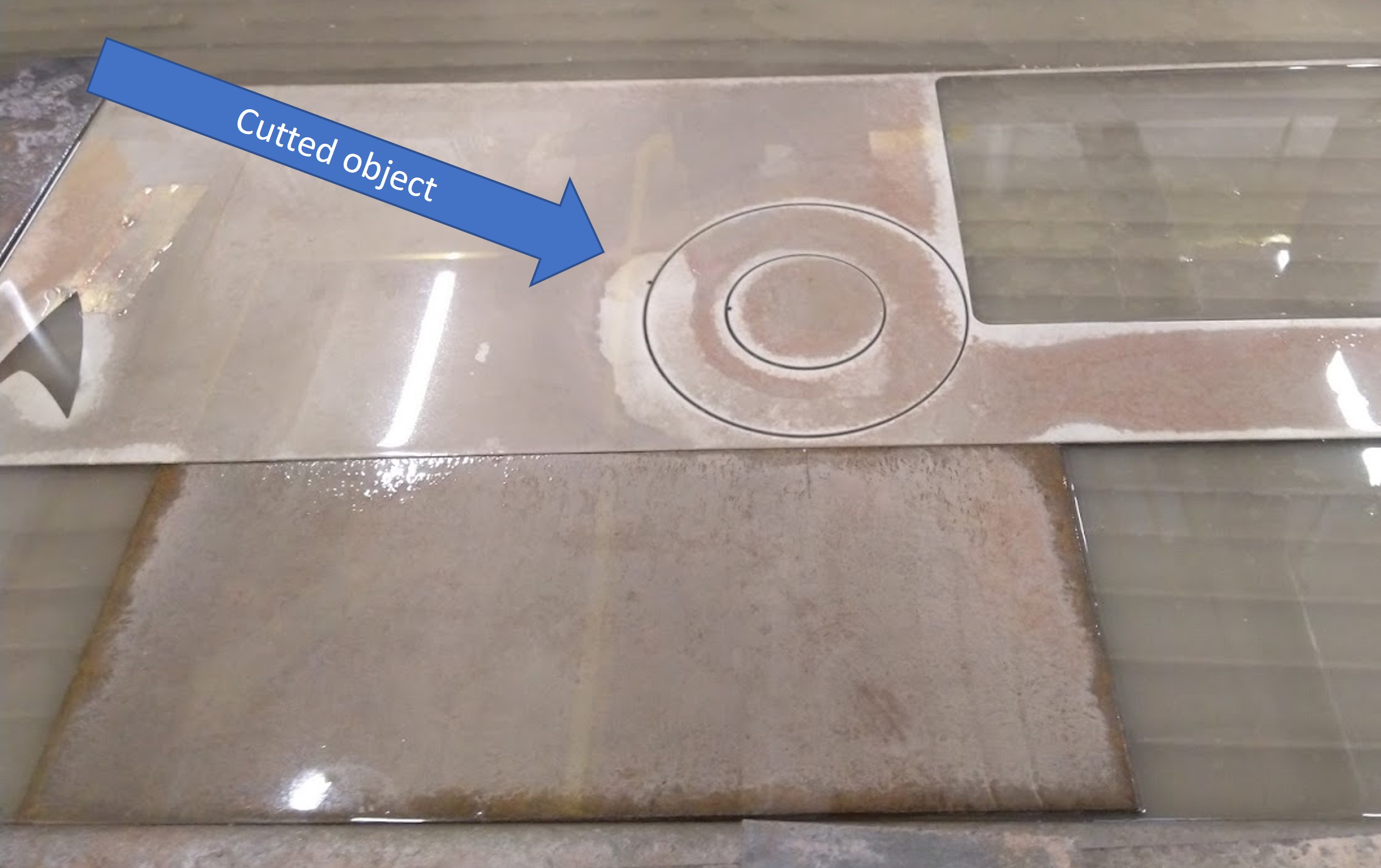

Step 5. At finally I got final cutted object.

Hero Video¶

Problem and problem-solving¶

I had some problems in use WaterCutter. It was not easy to use first time, but staff in the Machineshop helped me very well.