05. Electronics production

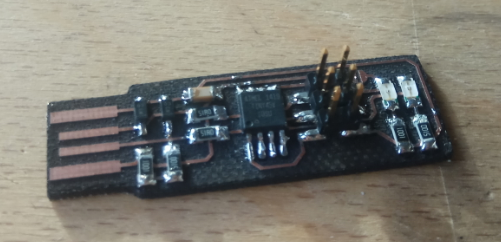

Today we are making a programmator. This will allow us to program the AVR microchips we embed on our components. AVR microchips have some flash memory that can be reprogrammed ISP - in-system programming, while they are already being used.

We will be following this tutorial

Material

The PCB we are going to use is a SMB, i.e surface mount box, which means it is 1-sided.

We can use material FR1 or FR4 that we will cut with a CO2 laser cutter.

The resistances we will solder on it have a Case-Code of 1206, which means they are 0.12” * 0.06”.

This is the smallest we can use in our lab. Anything smaller and it will be harder to make bridges over the circuit.

We had the choice bteween FR1 and FR4 FR4 is made of fiber-glass and a thin layer of copper. Fiber glass is not very elastic, so it doesn’t support drilling very well. Luckily, we will not be milling, but removing the copper with a cutting with a fiber cutter and cutting the PCB with a laser cutter

Soldering

We are going to get the components and solder them one by one on the board. We use leaded solder, not unleaded, and we start from the center.

We add lots of solder on the USB pins because the board is a bit thin.

We put some reflow for the small parts. We use a Yihua 852D soldering iron.

Programming the microchip

-

Connect the programmer to USB for power + to the Atmel ICE

-

Install the drivers and utils

sudo apt install avrdude gcc-avr avr-libc make -

Download the firmware

-

Unzip it and launch

make && make flash && make fusesThis should flash the compiled HEX code on the memory -

Disable the reset function

make rstdisbl

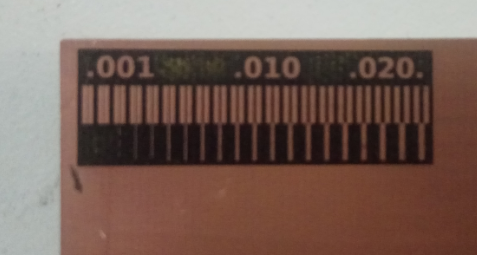

Characterization of the PCB

To see how the machine prints, we can print a tryout.

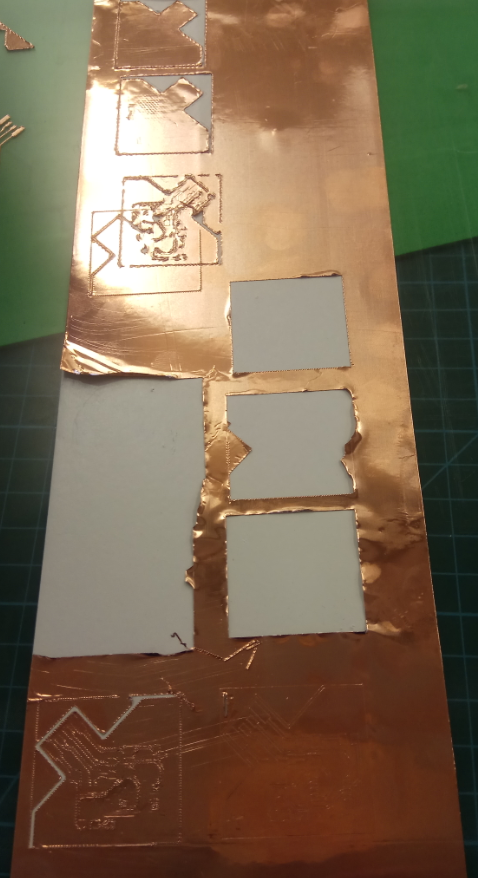

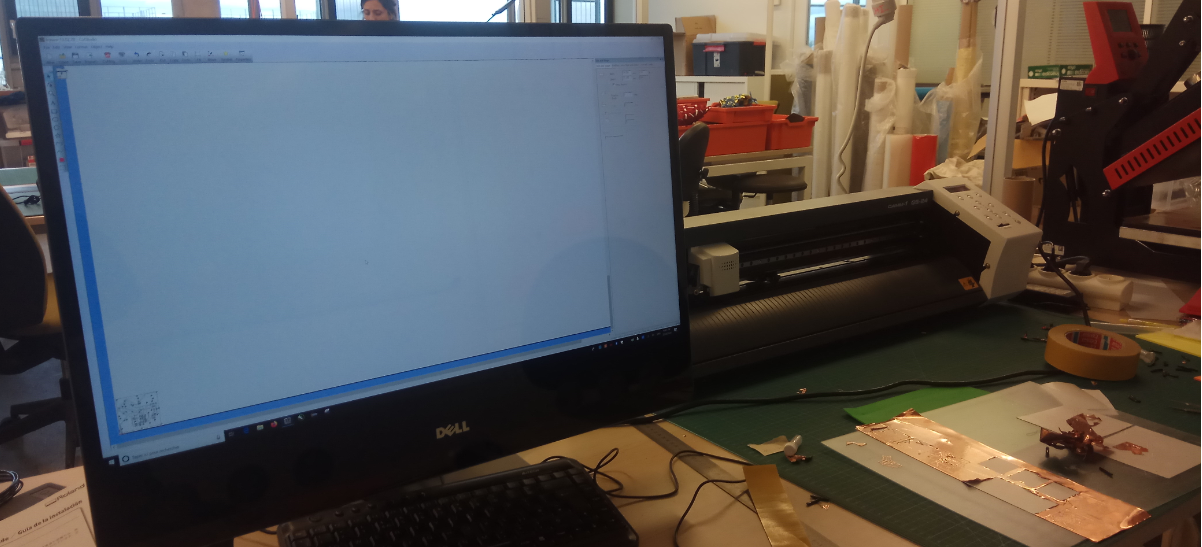

Vinyl cutter

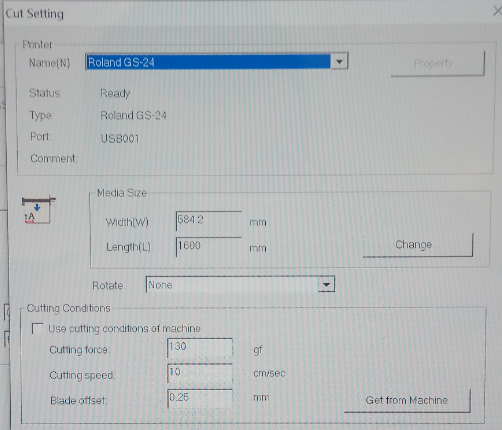

For soft materials like clothes, it can be useful to print the circuit using a vinyl cutter from a roll of sticky copper. We used the Roland GS-24

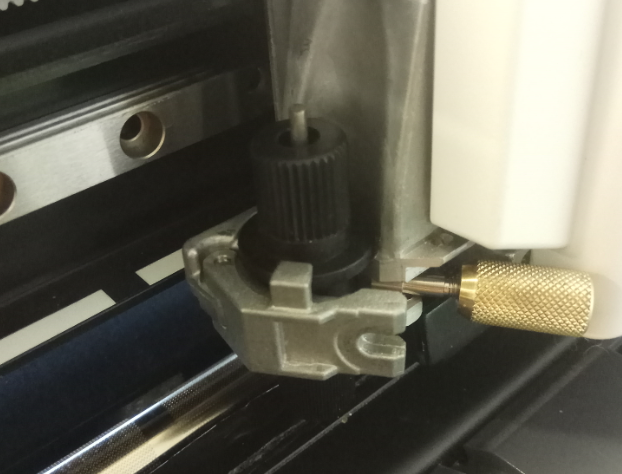

The blade was dull, we had to remove it.

And replace it

We used a strength of 130 grams and a cutting speed of 10 cm / sec. The blade offset is the position of the blade on the vertical axis. We kept it at 0.25

The end result was pretty bad.