Realization

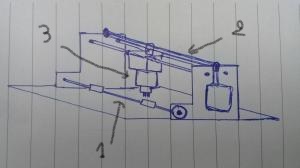

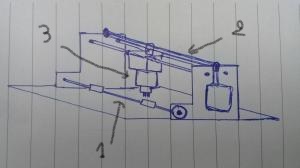

First sketch

1*: The paper feed mechanism, which must feed the paper, corresponding to the standard Braille size.

2*: The mechanism for moving the print head to specific points on a horizontal axis.

3*: The end effector, which punches holes in paper at precise points to print Braille. I decided to use one that punches six holes at the same time for faster writing.

My project incorporate

3D Design

Additive and subtractive fabrication processes

Electronics design and production

Microcontroller interfacing and programming

What will you design?

I want to make a small brailler printer that can be portable so I'm going to do the mechanical design and of course all the electrical part so that it becomes adequate to the size of the machine.

What materials and components will be used and how much it costs?

Since the lockdown, I can't find some parts on the tunisian market and I can't order them from chinese websites so I've changed many parts and I hope I could buy the old ones because it will make my machine cheaper.

What processes will be used?

3D Printing

CNC milling

PCB precision milling

Electronic production.

Lisence

My intention since the beginning of Fab Academy was to share my results with the open public, provide my discoveries and try to contribute to the community through my own learning process. For this reason, I tend to stick to a license, which allows anyone to copy and distribute the content as well adapt, remix or transform. To choose my lisence , I use the CC License Chooser a chooser of Creative commons which is very useful tool for makers and any developer in any field.it helps authors keep and manage their copyright on terms they choose.

This work is licensed under a

Creative Commons Attribution-ShareAlike 4.0 International License..