Project (rev.)¶

Due 2021/26/05

Conceive¶

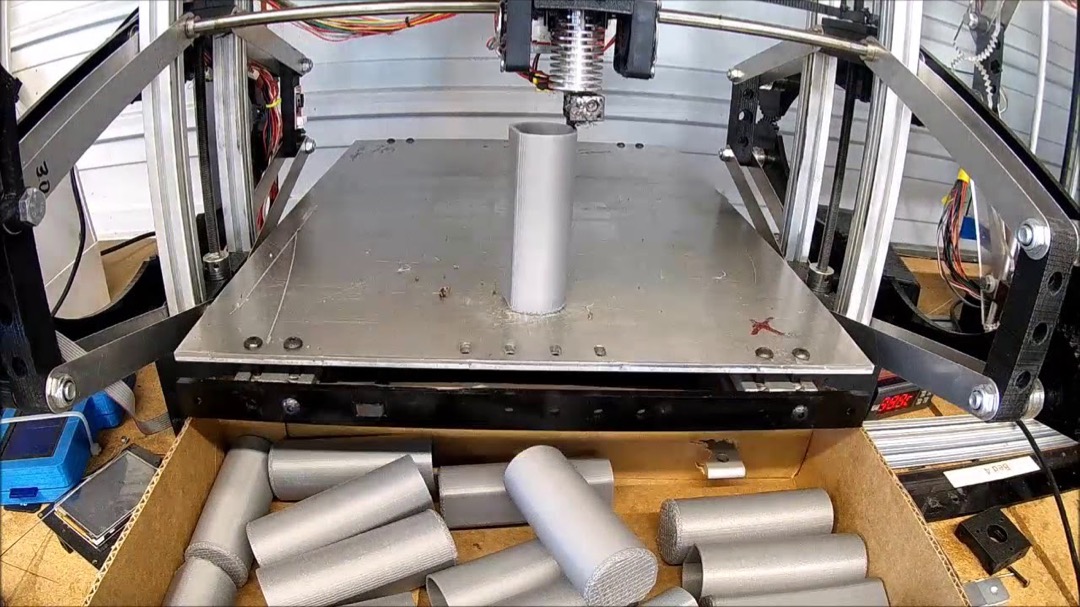

- This week we I propose a print factory using automation.

- In digital fabrication, humans tell machines what to do. Whereas, in digial automation the machine decides what to do.

Learning outcomes¶

- What does it do?

- Who’s done what beforehand?

- What did you design?

- What materials and components were used?

- [Where did they come from?]

- [How much did they cost?]

- [What parts and systems were made?]

- [What processes were used?]

- [What questions were answered?]

- [What worked? What didn’t?]

- [How was it evaluated?]

- [What are the implications?]

How to use this document¶

Please refer to instructions in the week02 weblog entry

Context¶

- Syllabus Final

- Assessment Final

- Video Final

- FabAcademy 2021 Documents

- FabAcademy Home Page

- FabLabs Home Page

Comprehend¶

- Print automation happens when the printing system determines when and how it runs jobs.

- I found several different attempts to automate print removal from the build area:

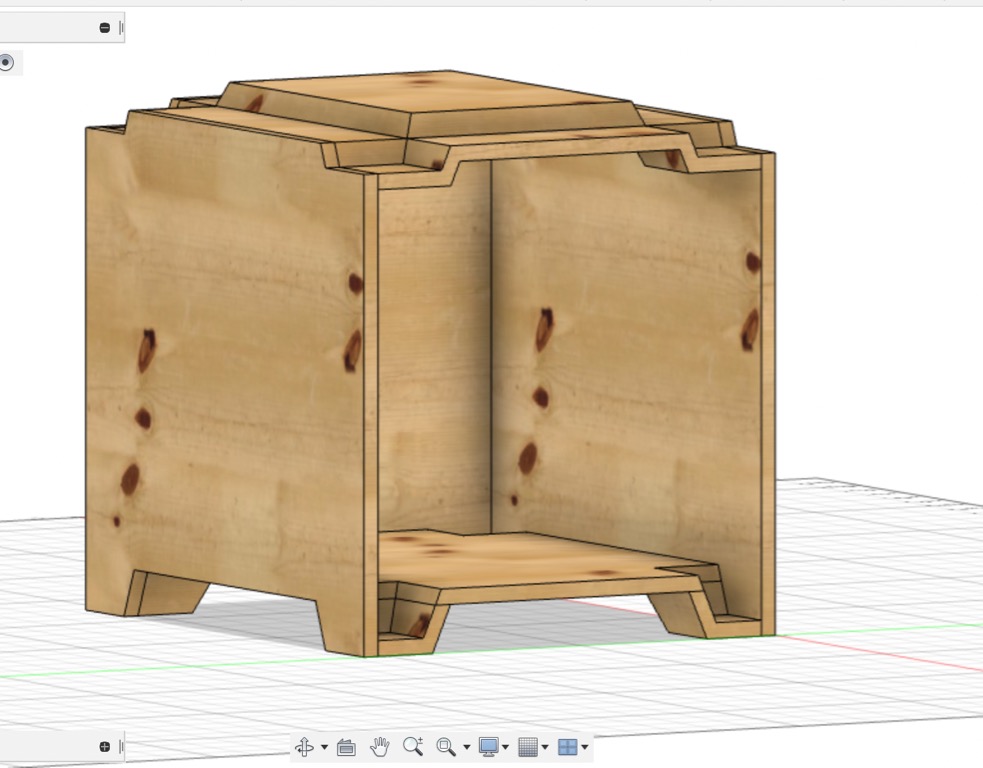

- This Kickstarter project OpenCreators uses build plates and a conveyor to remove prints.

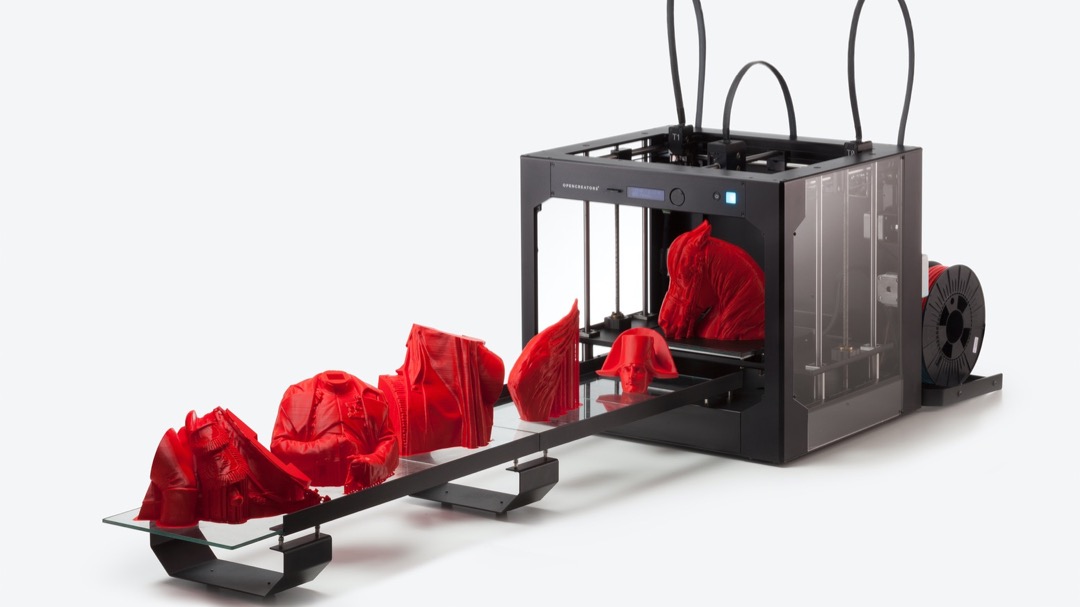

- This YouTuber uses a stainless-steel conveyor belt to remove finished parts.

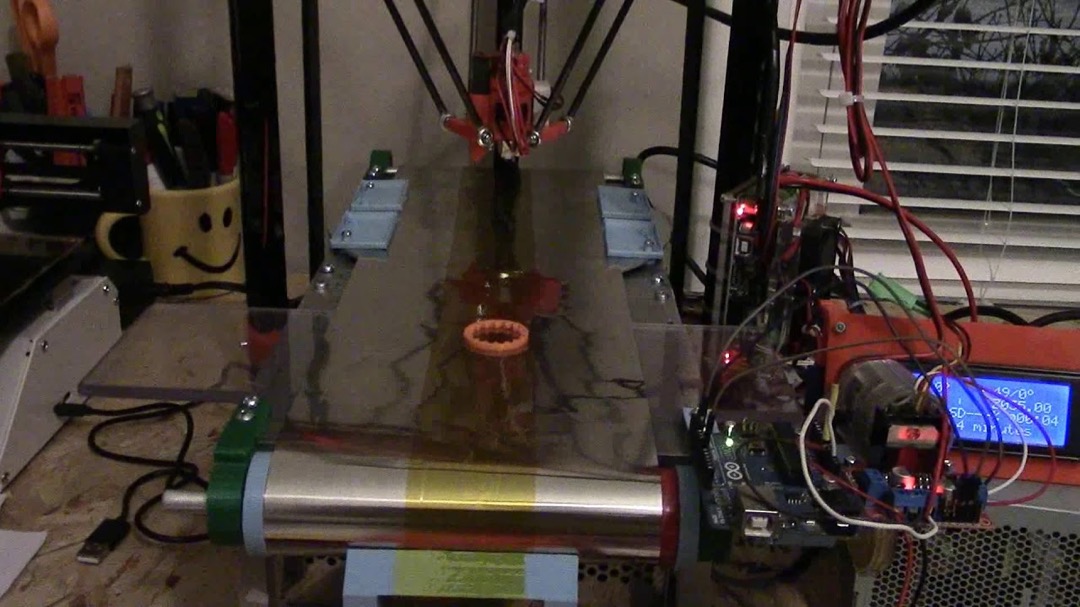

- This one uses the x-axis of the printer to eject prints.

- Voodoo Manufacturing uses a robot arm from Universal Robotics to insert build plates to printers and place completed prints on a conveyor belt.

- This Kickstarter project OpenCreators uses build plates and a conveyor to remove prints.

- While all of the solutions mentioned above improve productivity on one machine, only one scaled to multiple machines. Because of cost, that solution is not immediately accessible to the first-order FabLab.

- On the other hand, I found several examples of print farms that used Prusa printers. These robust machines offer very consistent prints and possess long duty cycles. However, these systems offer little in way of automated printing to make unattended printing possible.

- I would like to combine the qualities of unattended printing to the durable rep-rap-based Prusa. I would also like to enclose the printer to improve print quality so the FabLab can offer on-demand printing to the public at reasonable prices.

- I have the following expectations for this system:

- This system is conceived as an on-demand printing farm.

- I would like the machines to print continuously.

- I would like multiple machines to coordinate print jobs with one another.

- I want the system to distribute jobs based on print height, print material, and print footprint

- It should monitor filament

- How much is left

- What type

- Moisture content

- It should monitor print quality

- It should monitor printer health.

-

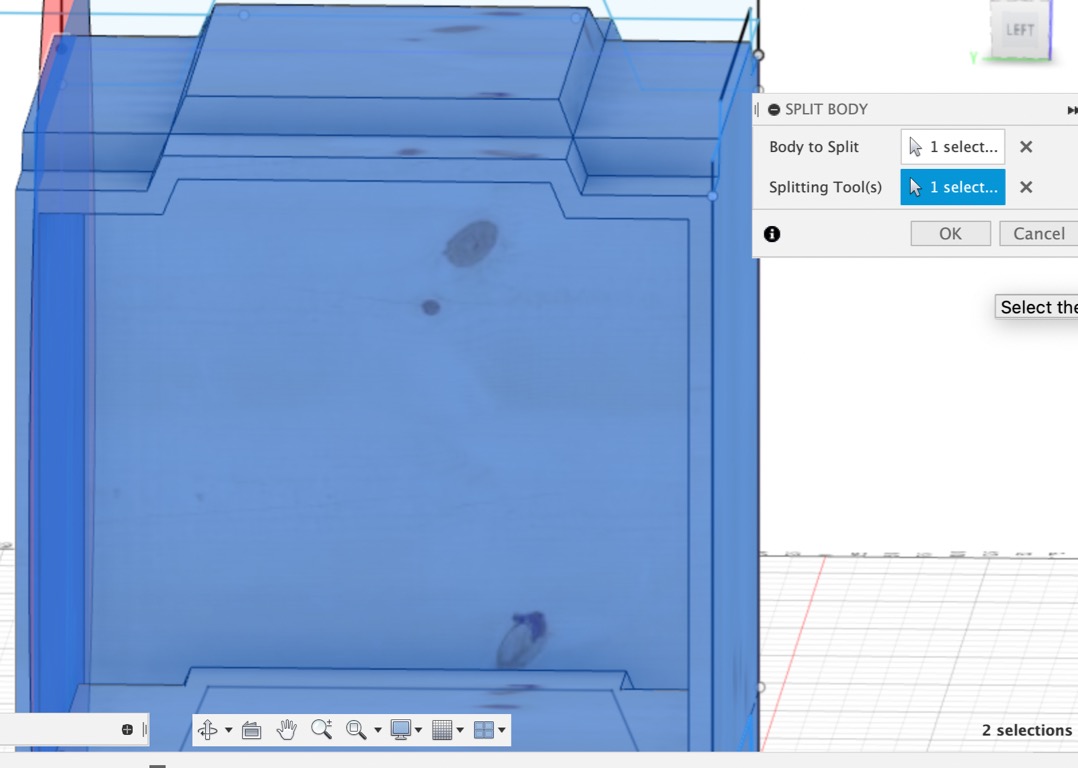

Based on these requirements, I propose a design with the following components. Fab Factory Chambers to facilitate Fab-Lab production and suppress the the effects of by-products on the environment. This is an integrated framework building on applications such as Octoprint (Octopi). It manages print-job distribution,temperature, fumes, and chamber integrity. Stretch goals include safety switches, bad-print monitoring.

- Print break that breaks prints from build plate by coming down across the plate similar to a train-crossing gate. I will use a sensor to make sure the “crossing” is unobstructed. (2 days)

- Octoprint provides remote management of printers. (2 day estimate)

- Task manager to distribute jobs to unused space on machines preparing to print. (3 day estimate)

- UARM open-source robot arm to remove prints from bed. (4 day estimate)

- Printer enclosure (3 day estimate)

- Improve prints by managing print environment.

- Reduce fumes in the workspace.

- User interface (2 day estimate)

Take Care¶

Control¶

- Make print break.

- possible materials

- servo

- controller

- sensor

Tips, Tricks, & References¶

- VC.One at Stackoverflow helped me find the embed iframe code under the Youtube share button

- Change mkdocs theme to Material using instructions from Readme>Quick

- Use the command gimp -b from the terminal to batch process images.

- Add an header reference to a section on a Mkdocs page using the following: [refer to this sec close bracket open parenthesis #heading) where close bracket==] and open parenthesis==( with no space between this will display “refer to this sec” as a link. when clicked, the browser will go to the section of the current page witht the name “heading.”

- “rm -r mydir” to recursively remove a directory (folder) in *nix.

- Add highlighting to Mkdocs by adding “-pymdownsx.mark” to the markdown_extensions section of mkdocs.yml file in the root directory of your repository and adding two = before and after the word that you want to highlight. By adding two = on both sides of a passage, you can highlight several words at once. More information here

- windows terminal runs cmd, Powershell, Ubuntu, etc. Tutorial available here box plexiglass ports for external filtration fan leds panic button hall fume door heater multi material