4. Computer controlled cutting¶

Due 2024/02/13

How to use this document

Please refer to instructions in the week02 weblog entry

Conceive¶

-

Vinyl cutting is like a knife cutting through steak. A successful cut requires sufficient pressure and a sharp enough tool to split the meat.

-

Laser cutting is like a magnifying glass that concentrates sun light on a piece of paper in order to burn a hole in it except that the laser cutter creates its own light.

Assignments¶

Learning outcomes¶

| Have you? | Done |

|---|---|

| Demonstrate and describe parametric 2D modelling processes | Yes |

| Identify and explain processes involved in using the laser cutter | Yes |

| Develop, evaluate and construct a parametric construction kit | Yes |

| Identify and explain processes involved in using the vinyl cutter | Yes |

Checklist questions¶

| Have you? | Done |

|---|---|

| Linked to the group assignment page? | Yes |

| Explained how you created your parametric design? | Yes |

| Documented how you made your press-fit kit? | Yes |

| Documented how you made something with the vinyl cutter? | Yes |

| Included your original design files? | Yes |

| Included hero shots of your results? | Yes |

Context¶

- This week we focus on cutting in two dimensions. We cut with vinyl cutter and laser cutter.

- Syllabus FAW04

- Assessment FAW04

- Tutorial FAW04

- Video FAW04

- Review FAW04

- FabAcademy 2021 Documents

- FabAcademy Home Page

- FabLabs Home Page

Vinyl cutting¶

Comprehend (vinyl)¶

- Vinyl cutting happens when the machine drags a blade across two-dimensional material. Unlike chip and dust making such as sawing, It creates no kerf and a finished edge ready for immediate use. THEH v1, ch.6-2

- Roland CAMM-1 GS24 vinyl cutter

- Form (We used this pre-COVID)

- Function

- Performance measurments

- Silouette Cameo 4

- Form (Durability rigidity stability–DRS)

- Weight 4.7 kg

- Dimensions 57 cm x 19.5 cm x 17 cm

- Function (Efficiency repeatability accuracy–ERA)

- Work area 30.5 cm x 61 cm with a cutting mat

- Maximum cutting force 2.1 kg for carriage 1, 5 kg for carriage 2

- Form (Durability rigidity stability–DRS)

Take Caution (vinyl)¶

- Silouette Cameo 4

- Human

- Beware of loose clothing and jewelry.

- Despite the fact that the blades are well shielded, avoid cuts by handling them with care.

- Avoid moving parts when the machine is on.

- Machine

- Do not connect the machine to a non-rated power supply.

- Set up the machine with enough room around it to avoid contact with other objects; avoid areas of excessive noise and vibration; do not store the machine in direct sunlight.

- Do not lubricate the machine; do not use liquids inside the machine.

- Silouette Cameo 4 troubleshooting

- Environment

- Cutting cannot cause fires but poorly maintained power supplies can

- no fluid involved in with cutting

- no fumes involved with cutting

- From Federal Communications Commission: Cameo 4 is a Class B digital device. It may not cause harmful (radio) interference; it must accept any interference received

- Human

Calibrate and characterize (vinyl)¶

- Silouette Cameo 4 setup & calibration

- Turn on

- Load the tool

- Adjust the white rollers

- Adjust the blades

- characterize

Control (vinyl)¶

- Human-idea interface

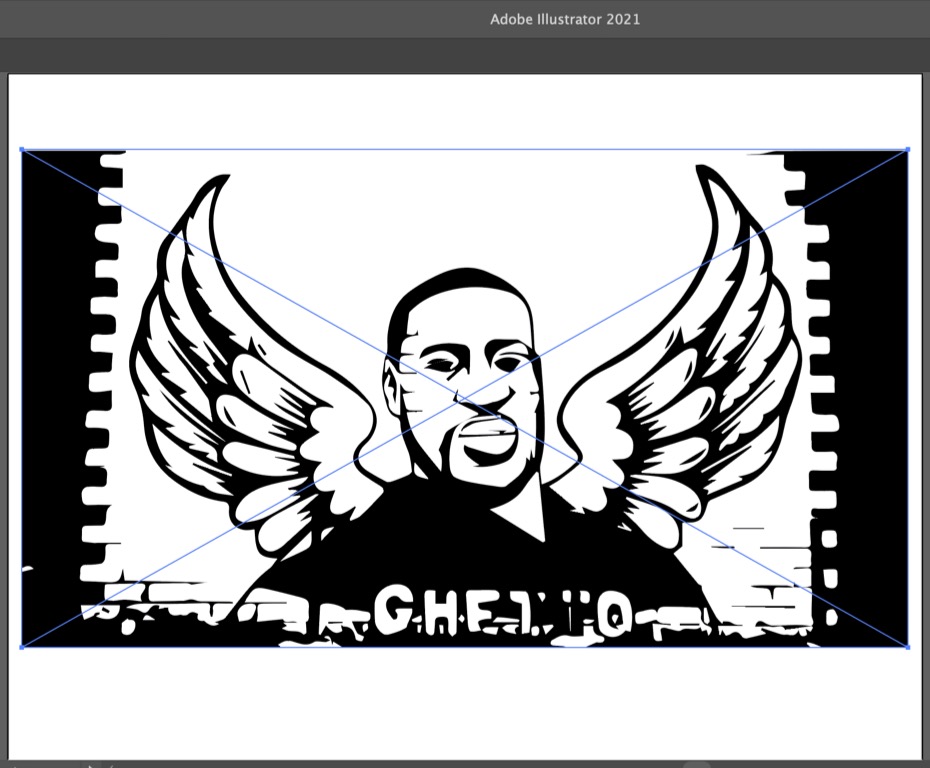

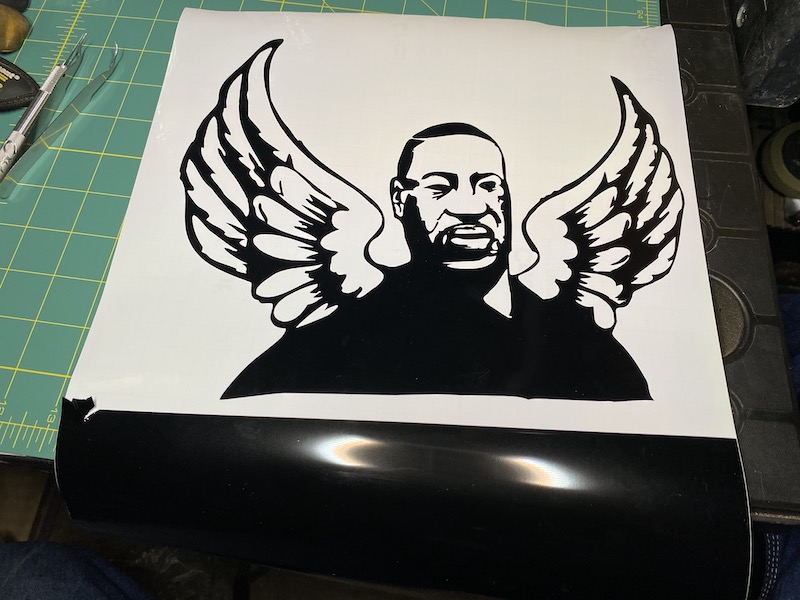

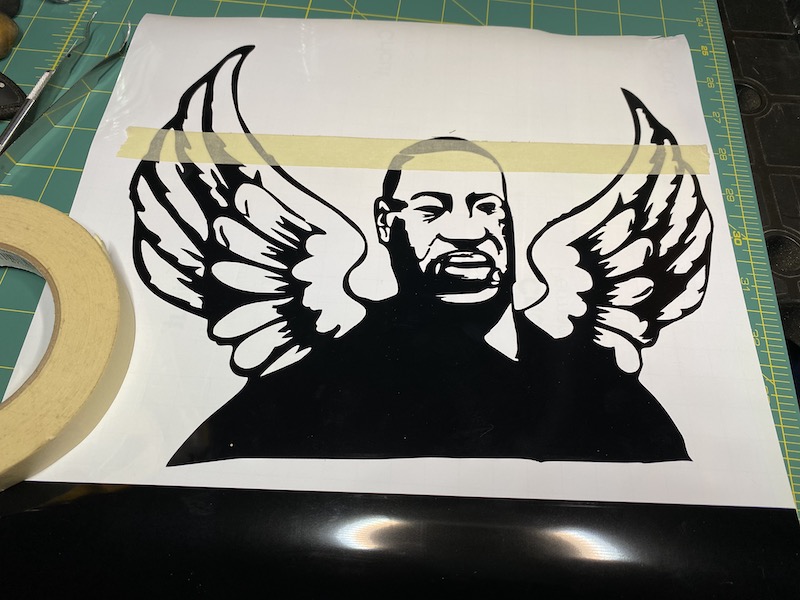

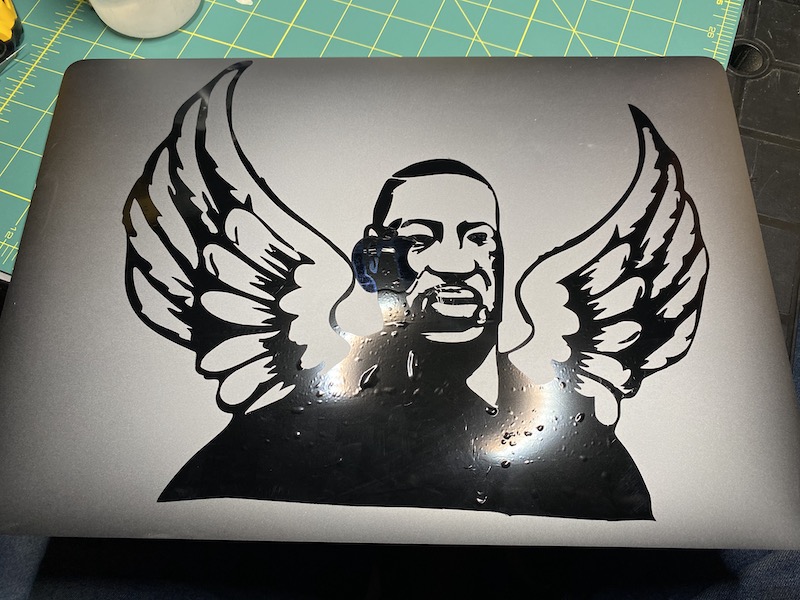

- I made an effort at this assignment before the Covid pandemic. I was dissatisfied with it. After George Floyd’s death, I was inspired to try again.

- Idea-design interface

- Initially, I planned to use Adobe Photoshop to make a black and white image then cut the black portion.

- The resulting image was pixelated. It did not produce clean outlines and was difficult to weed.

- I ended up using Adobe Illustrator instead. Using the Object>Image Trace>Make tool produced much better results.

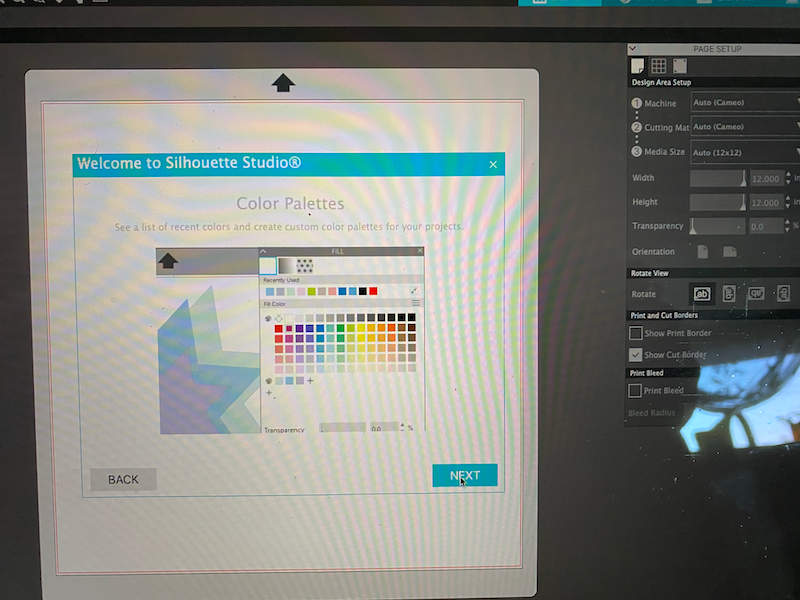

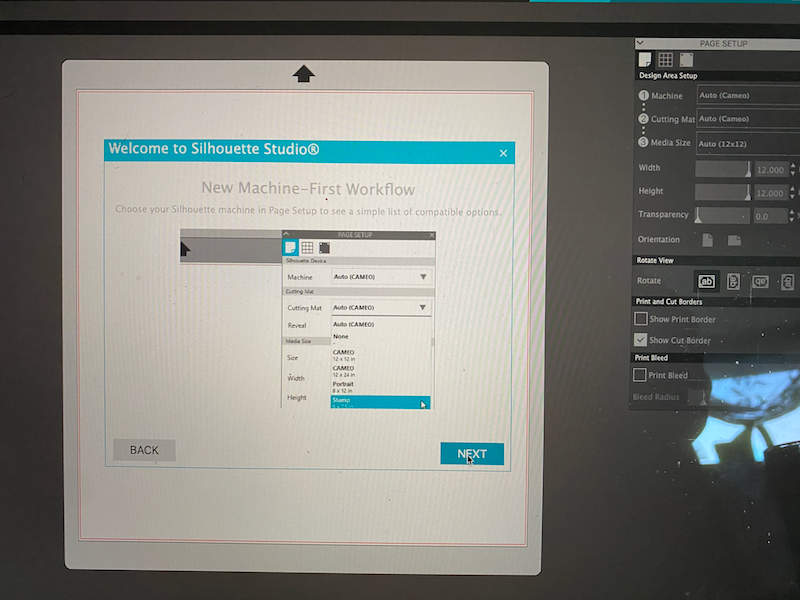

- I then exported a compatible version of the design file to the Silhouette Studio CAM software.

- Initially, I planned to use Adobe Photoshop to make a black and white image then cut the black portion.

- Design-CAM interface (DCI)

- Use Silhouette Studio to define what part of the design should be cut.

- Identify what tools the machine should use

- Identify the toolpaths the machine should take

- CAM-Controller interface (CCI)

- Controller-machine interface (CMI)

-

Machine-material interface (MMI)

-

Silouette Cameo 4

- Materials and sources

- The Cameo will cut paper, cloth, leather and other material

- I only cut vinyl

- I purchased vinyl online from US Cutter

- I purchased vinyl locally from JoAnn Fabrics

- Fixtures

- The Cameo 4 uses three techniques to present material to the machine

- Mat: place the mat on a clean, flat work surface; orient the mat so that “Silhouette is in the upper left corner; position the piece of material on the mat so that its top and left edges sit flush with the top and left sides of the grid on the mat; remove any wrinkles and air bubbles from the material; a tool such as a tile roller can help with this.

- No mat

- Roll

- I used the roll approach

- The Cameo 4 uses three techniques to present material to the machine

- Materials and sources

-

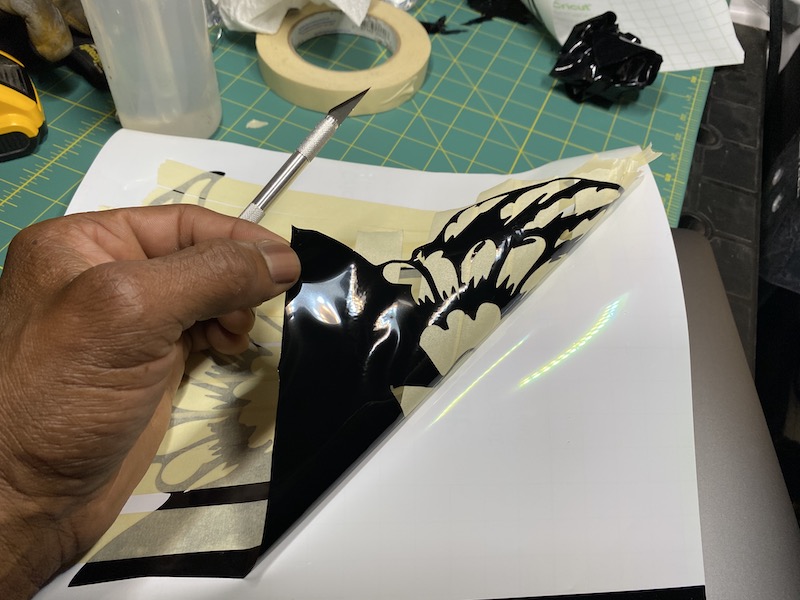

Exacto knife

- Once cut, the design must be weeded in order to separate it from the excess material.

- Once cut, the design must be weeded in order to separate it from the excess material.

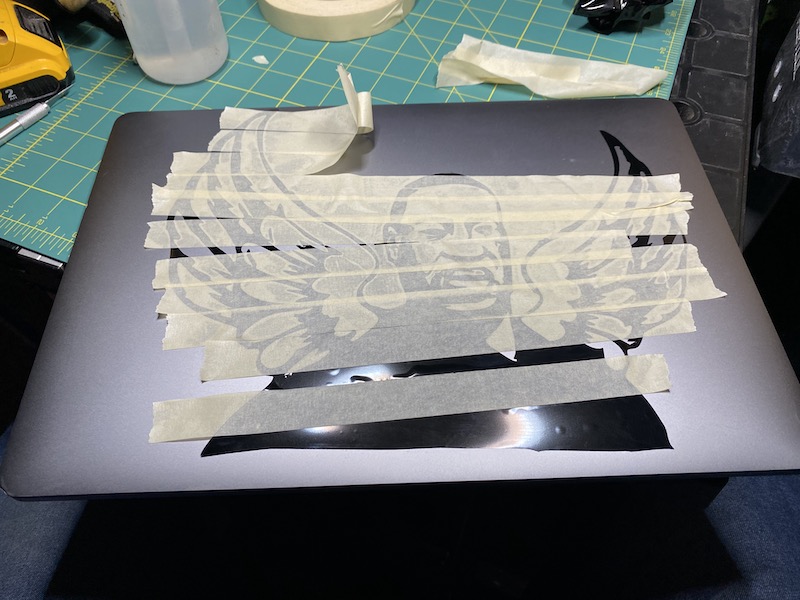

- Transfer tape

- One can transfer a weeded image to the display surface using transfer tape.

- One can transfer a weeded image to the display surface using transfer tape.

-

Laser cutting¶

Comprehend (laser)¶

- Laser cutting happens when a focused beam of light caused by electrical energy exciting electrons in a gas burns a path in material. While t does create some kerf, it also produces a finished edge. TMEH v.1,ch.14-62

- Epilog Legend 36 EXT

- Glowforge Pro laser cutter

- Form

- Weight:

- Dimensions: 965 mm x 527 mm x 210 mm

- Case: high modulus, infection-molded plastic

- Linear System: Custom extruded aluminum linear rails with belt driven v-wheel carrier

- Motion: Dual hybrid stepper Y axis; single hybrid stepper X axis

- Cooling: Closed loop self contained internal cooling.

- Air Assist: Internal air assist with no external compressor hookup required

- Recommended Operating Temperature: 60F-81F (16C-27C) Pro

- Laser: CO2 45 W operating at 10,600 nm wavelength

- Fixed Alignment: Factory calibrated optical system does not require any alignment by the user

- Sealed Optics: Enclosed optical path with cleanable and replaceable windows protects the laser optics to avoid replacement or realignment

- Peak power consumption: 800 W

- Function

- Work volume (maximum) 279 mm x 495 mm x 13 mm

- Performance measurements

- Form

Take Caution (laser)¶

- Glowforge Pro

Calibrate and characterize (Laser)¶

- Glowforge Pro setup

- Glowforge Pro calibrate camera

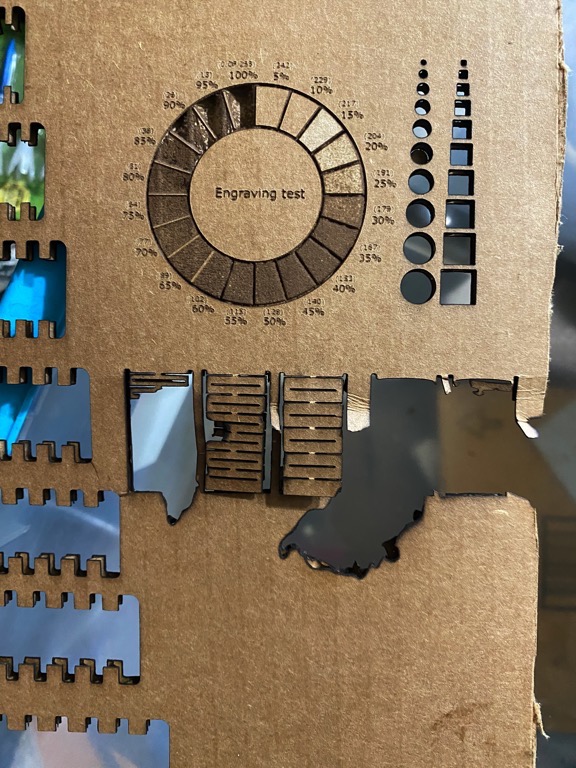

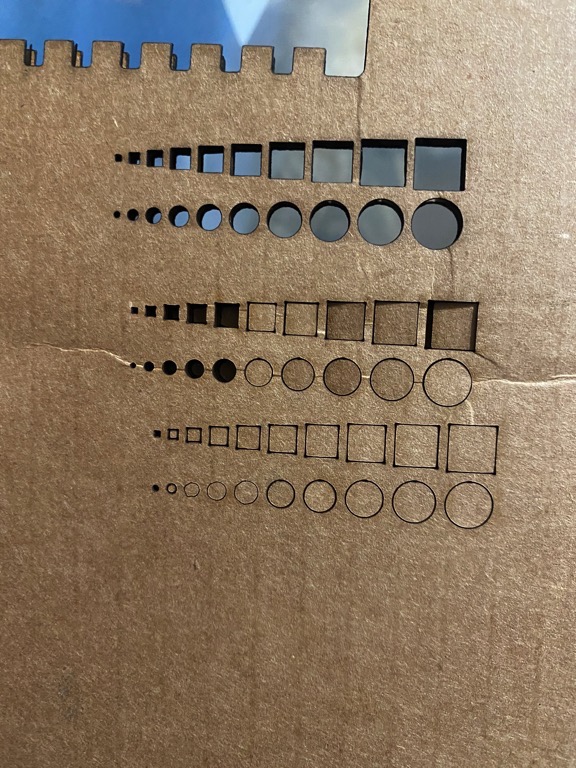

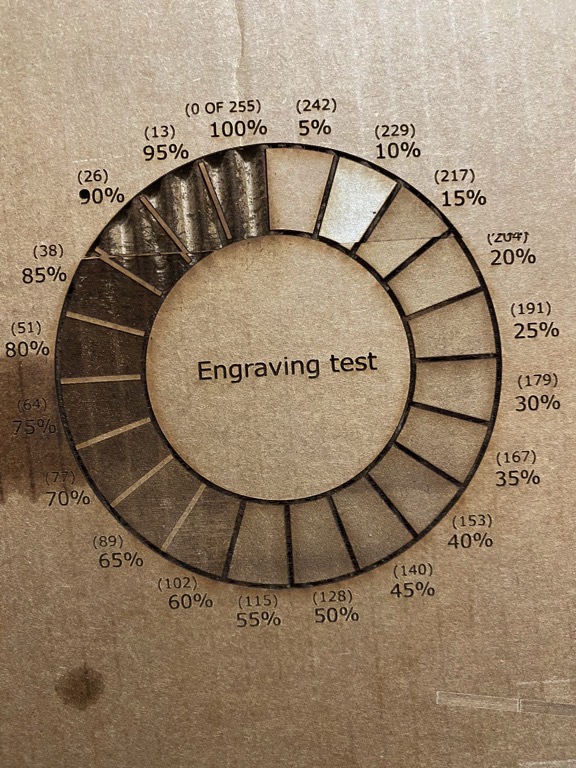

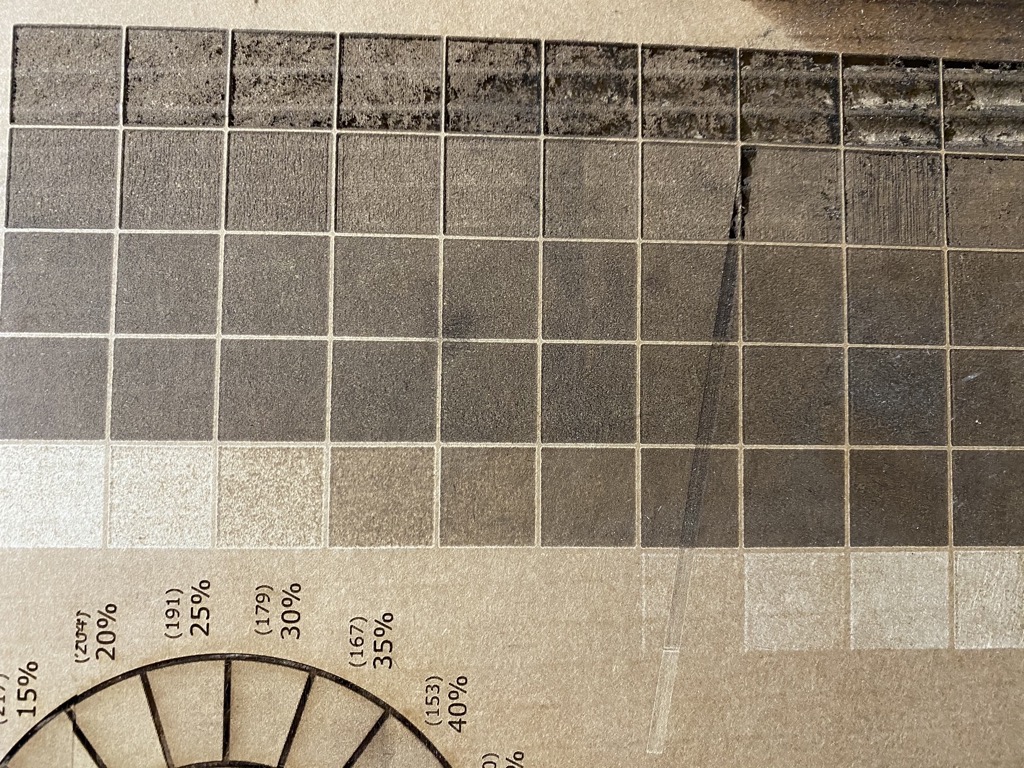

- Glowforge characterization

- Test patterns for shades

- Engrave test pattern

- Gap gauges

Control (laser)¶

- I want to make a geodesic kit. I want to connect the piece with something more than a friction piece cut to a specific angle.

- Find boackground

- search “draw geodesic dome in fusion 360.”

- Search “geodesic dome theory.”

- This Instructable and this

- EPCM white paper

- Search “icosahedron geodesic dome math.:

- Search “uniform polyhedron icosahedron.”

- Search “platonic solid.”

- Platonic solid from Wikipedia Check out icosahedron animation.

- Plato from Wikipedia espoused

- Rabbit hole!

- I wondered why Plato used geometric solids to represent the classic elements fire, water, air, earth, and wind.

- I was reminded that Plato, his teacher Socrates, and his student Aristotle were all influenced by Pythagoras.

- Representing nature with solids seems (ha) natural to me. Visualization expedites knowledge creation and concept comprehension.

- Western philosophers combined learned geometry in Africa.

- I speculate that they learned to combine geometry and logic in Africa as well.

- These two elements are necessary if not sufficient for scientific method and knowledge creation.

- Arithmetic and maths can refine understanding but can impede initial comprehension of concepts.

- I believe that geometry should be part of the trivium instead of the quadrivium. That is children should learn logic and geometry before arithmetic.

- St. Augustine also lived and studied in Africa.

- He made significant contributions to modern, Western Christianity because of his logical approach to the spiritual system.

- I believe that the ancients understood that the “African ethos” provides humans with the most efficient path to creativity.

- Wolfram Mathworld

- Design press-fit kit using Fusion 360

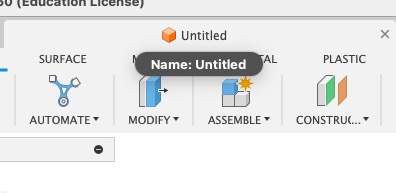

- Prepare Fusion 360 to create a design.

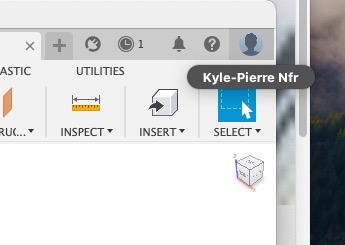

- Launch Fusion 360 and login to Autodesk account if necessary.

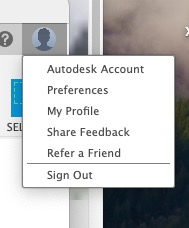

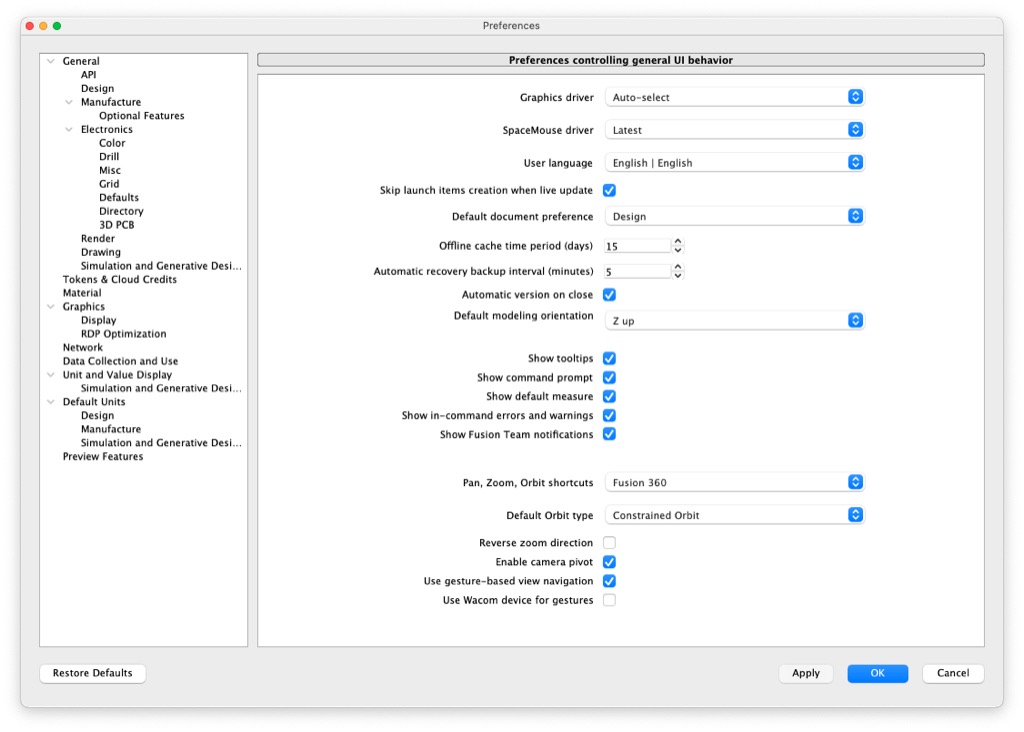

- Set Preferences under the user icon as needed.

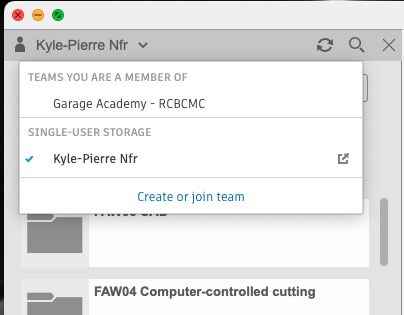

- Fusion orders folders and files according to Teams. Confirm that the correct Team is selected.

- Start design

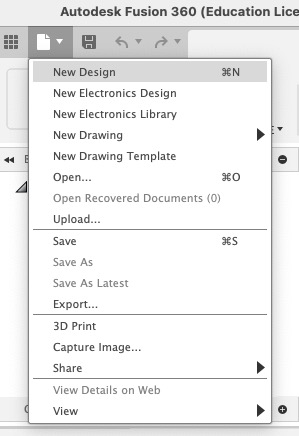

- Initialize a new design with one of the following methods:

- Fusion 360 launches with an untitled Design by default.

- Click on the plus sign tab to initialize a Design.

- Select File>New Design

- Fusion 360 launches with an untitled Design by default.

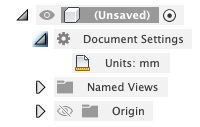

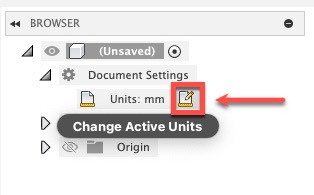

- Set the correct dimensions for the Design.

- Begin design

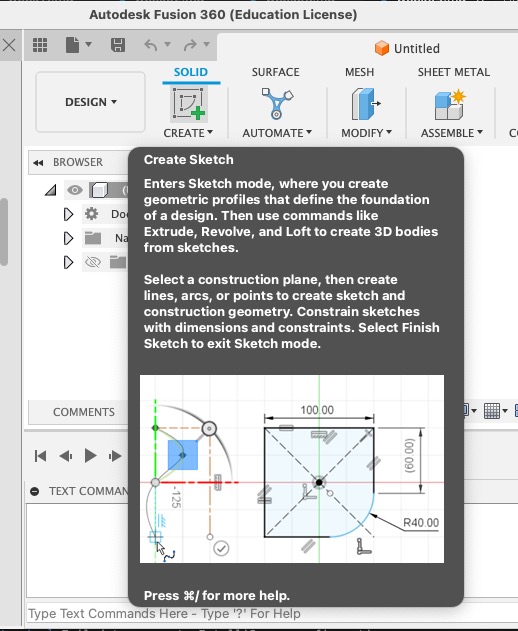

- Create>Create Sketch

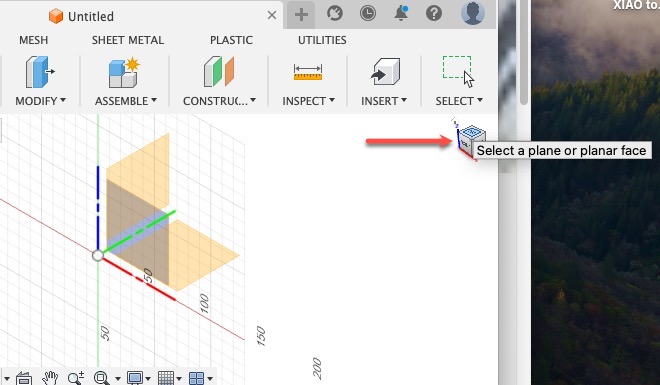

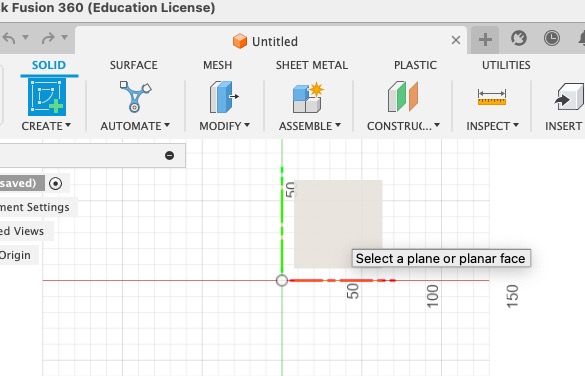

- Select plane upon which to sketch.

- We choose Top

- On the Project tree, under Origin, this corresponds to the XY plane

- Create>Create Sketch

- Initialize a new design with one of the following methods:

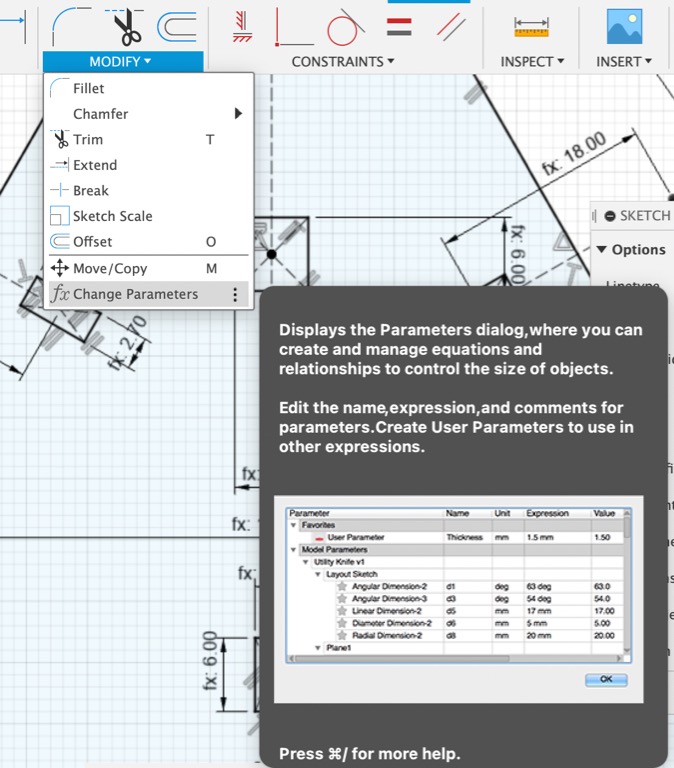

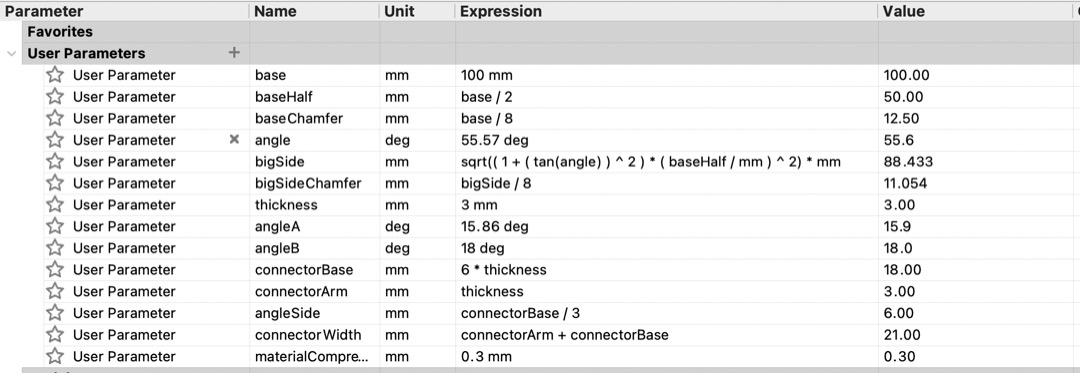

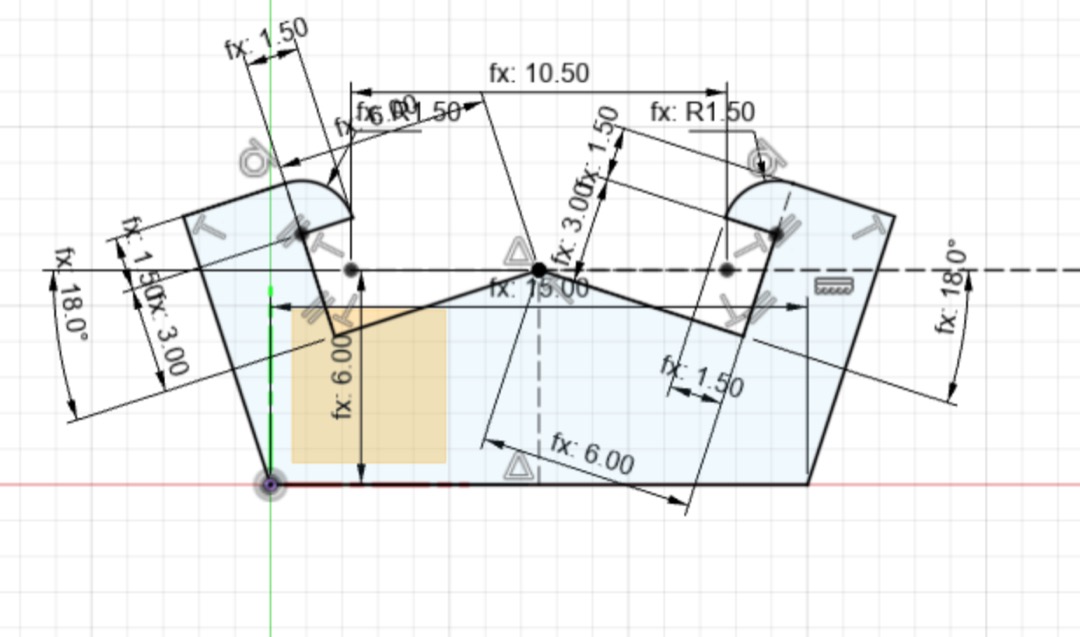

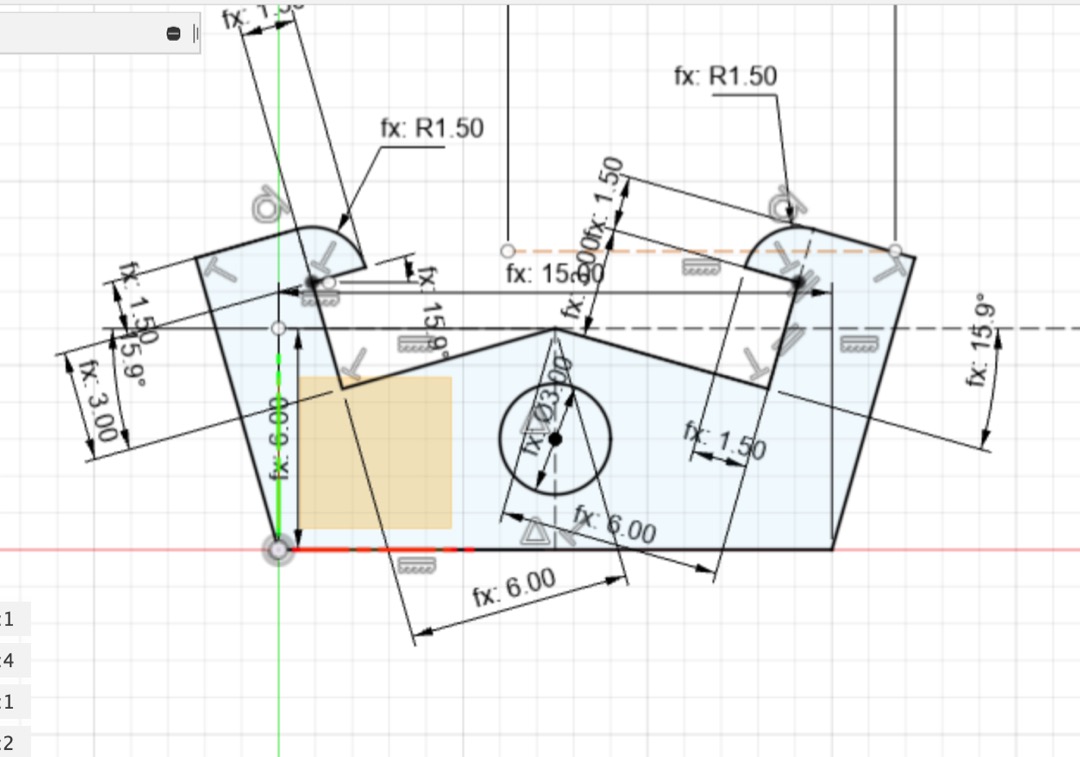

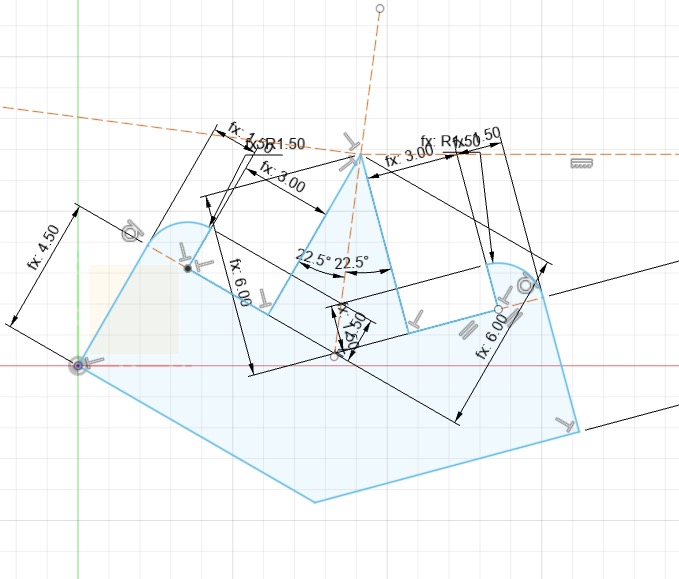

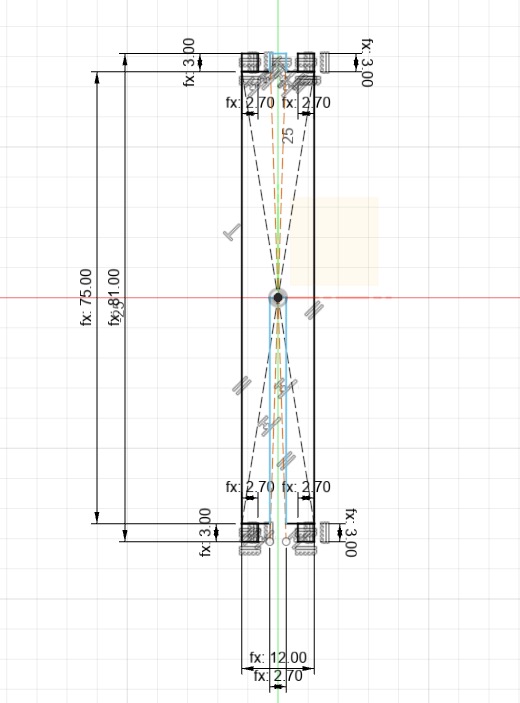

- Before sketching anything, I used Modify>Change Parameters to define some User Parameters in order to easily reuse common dimensions.

- Prepare Fusion 360 to create a design.

- Complete design

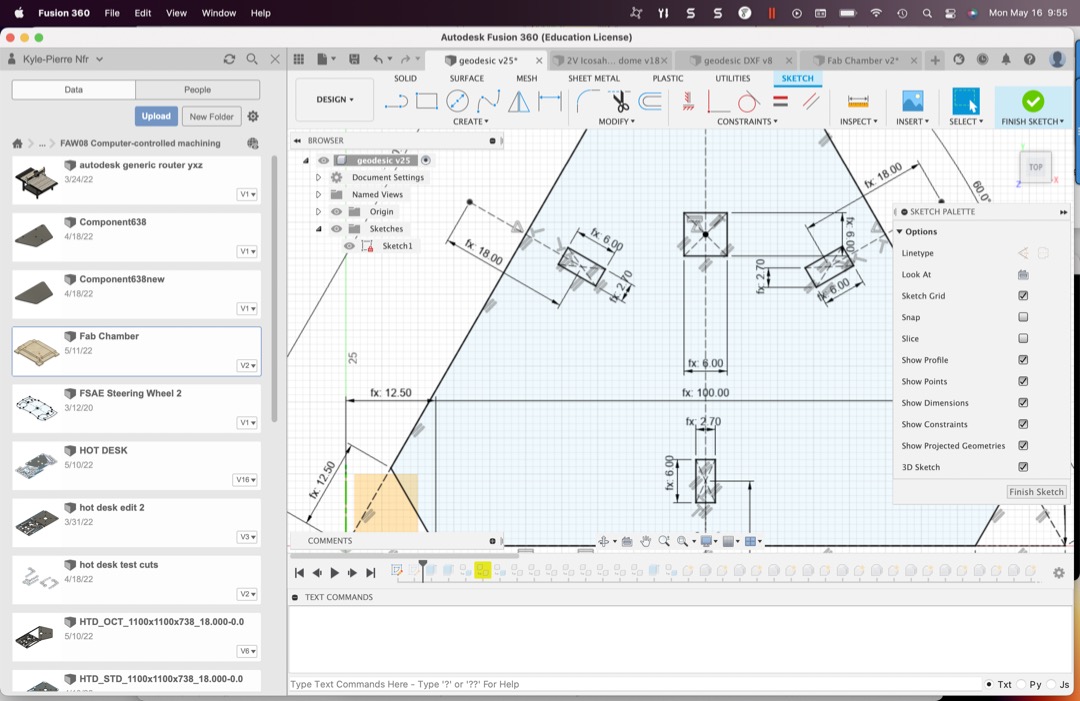

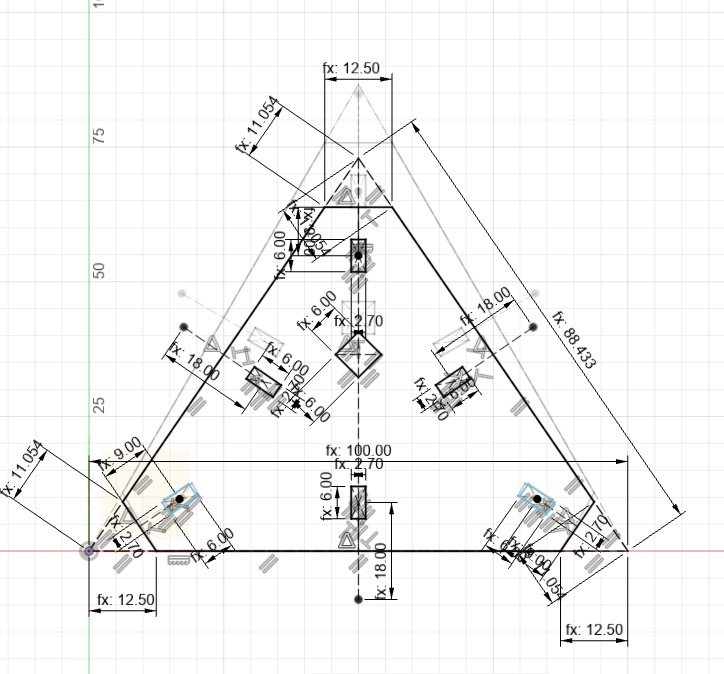

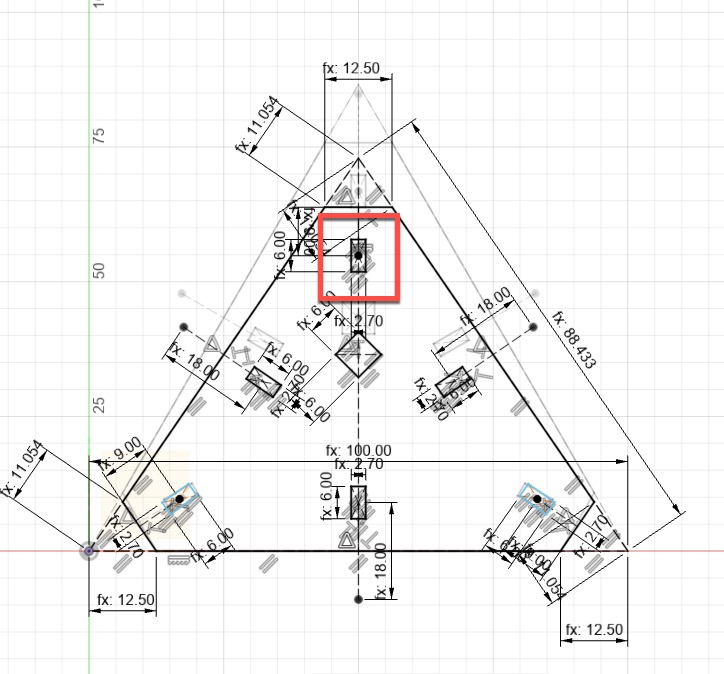

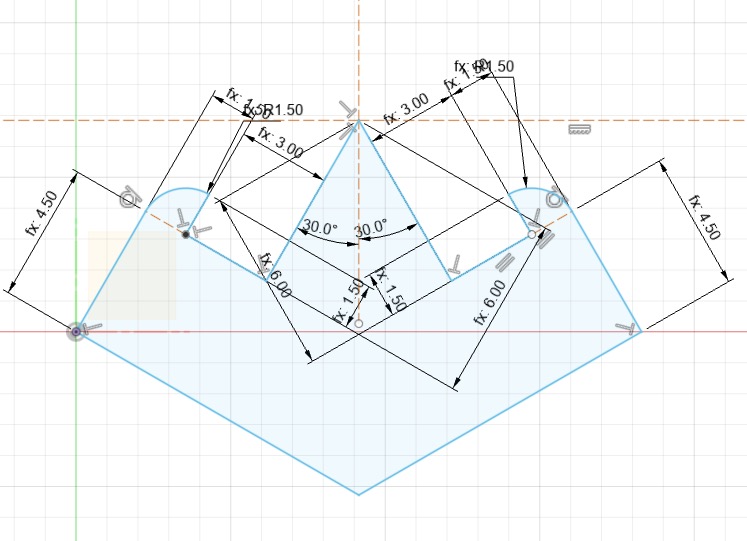

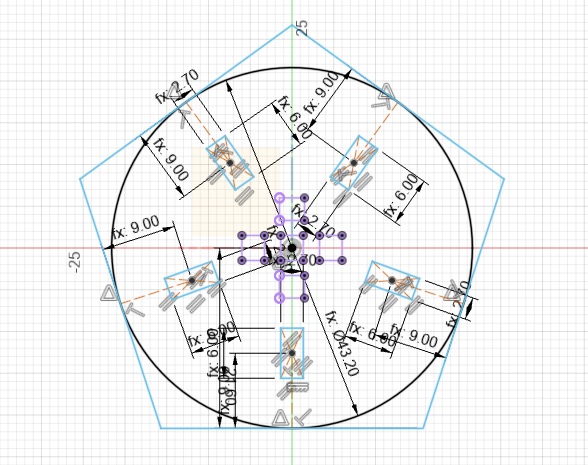

- The 2V Icosahedral 2/3 geodesic dome uses two triangles.

- I tried to make triangles with Create>inscribed>polygon of three sides but that did not work. I used line segments instead to make the basic triangles.

- I designed these connectors to account for the appropriate angles for the dome and sphere construction.

- The 2V Icosahedral 2/3 geodesic dome uses two triangles.

- Laser cut pieces

- Export design as .svg from Fusion 360.

- The Glowforge app takes dxf and svg file formats.

- For DXF, right-click on sketch of part that you want to export. then >Save as DXF.

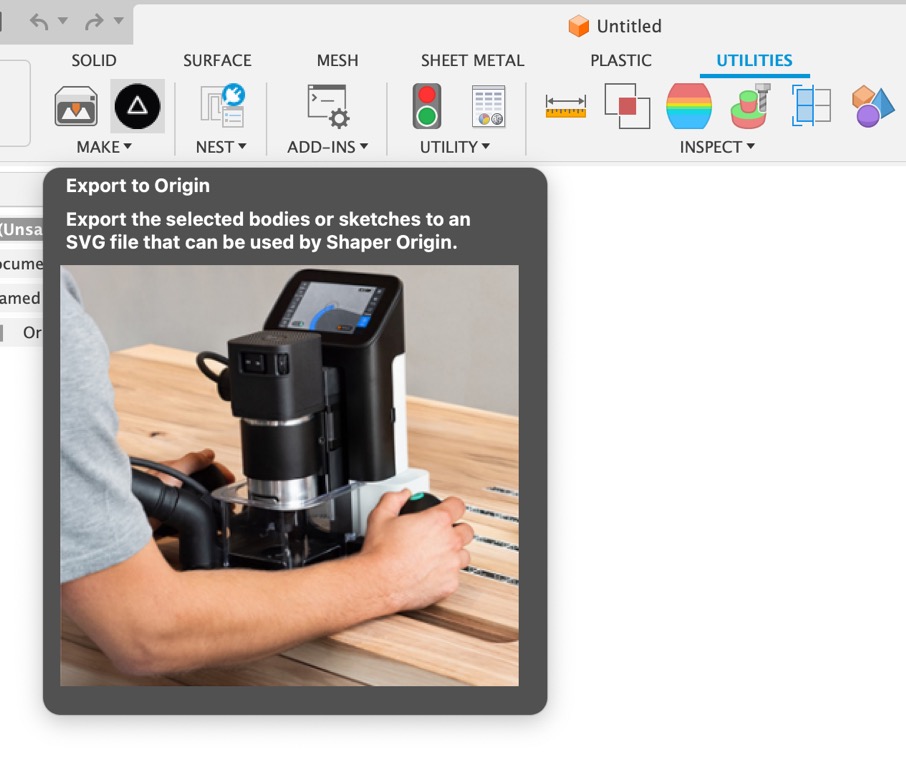

- For SVG, use Shaper Utilities Add-On

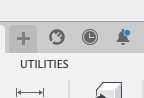

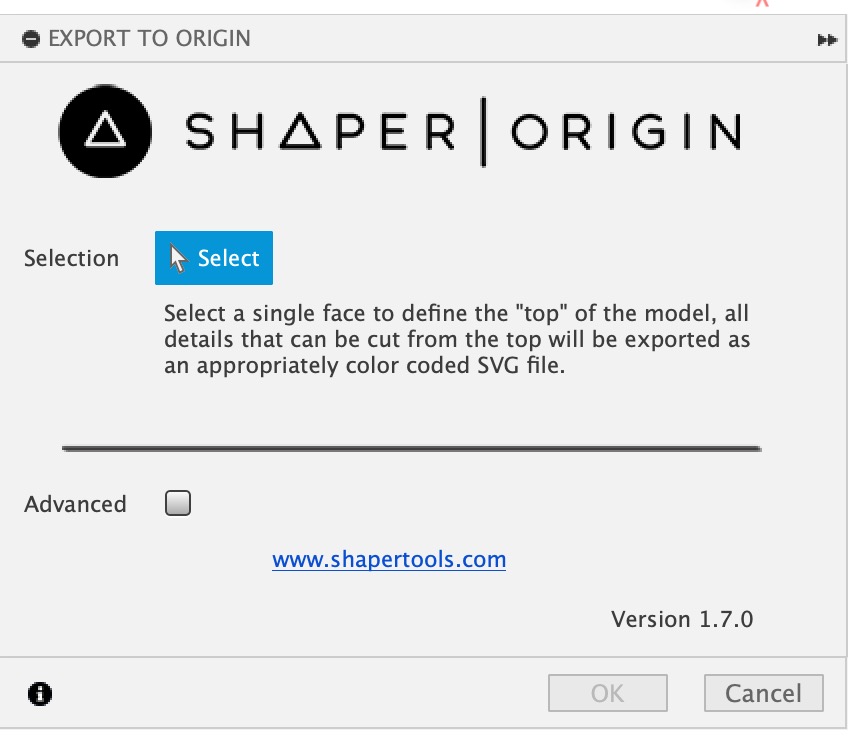

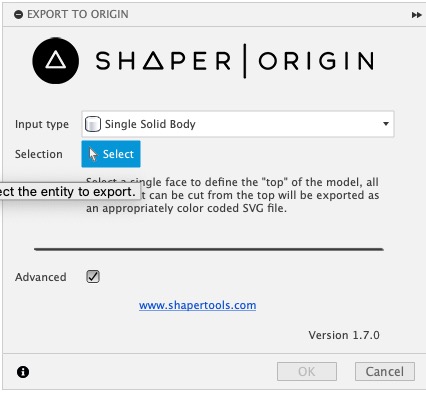

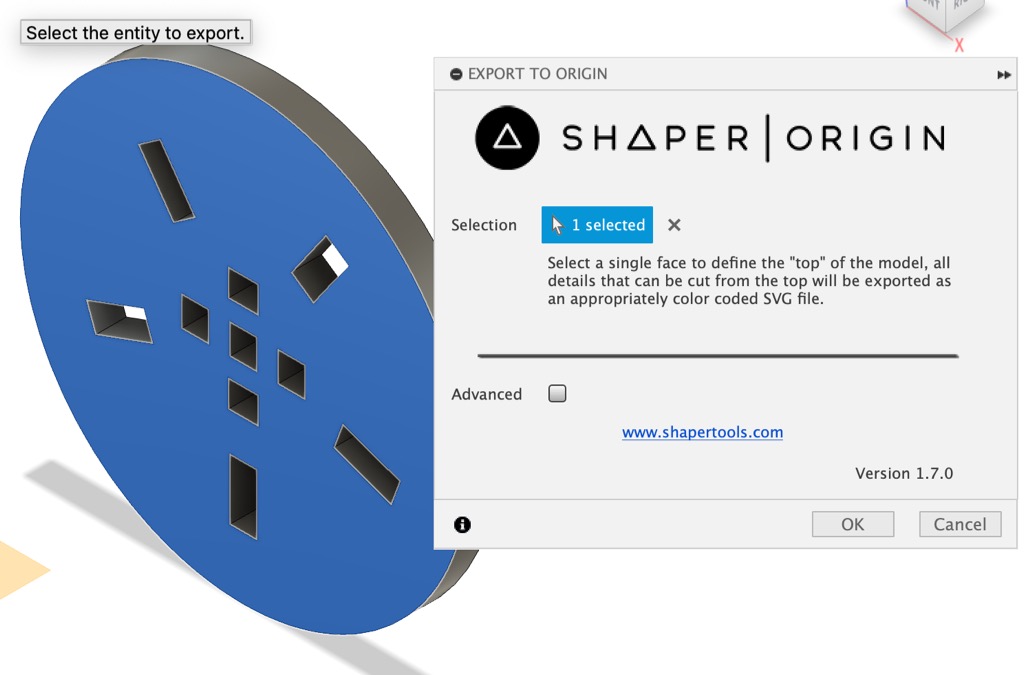

- After installing the Add-On, go to the Utilities tab and select Export-to-Origin icon.

- To Select different input types, tick the Advanced box in the popup.

- Select the body or elements that you want to export as SVG

- Click OK.

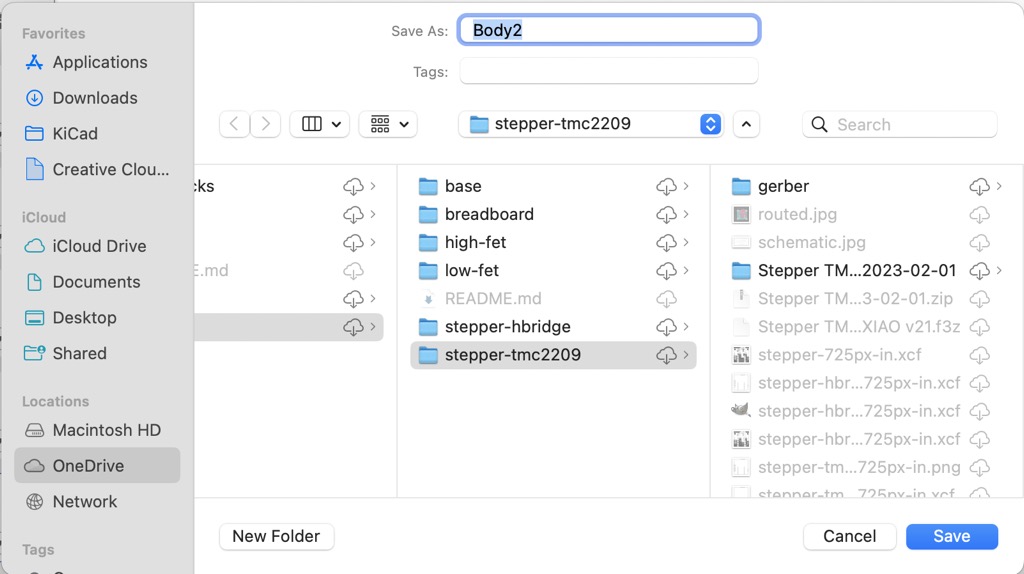

- Name and Save the SVG file.

- After installing the Add-On, go to the Utilities tab and select Export-to-Origin icon.

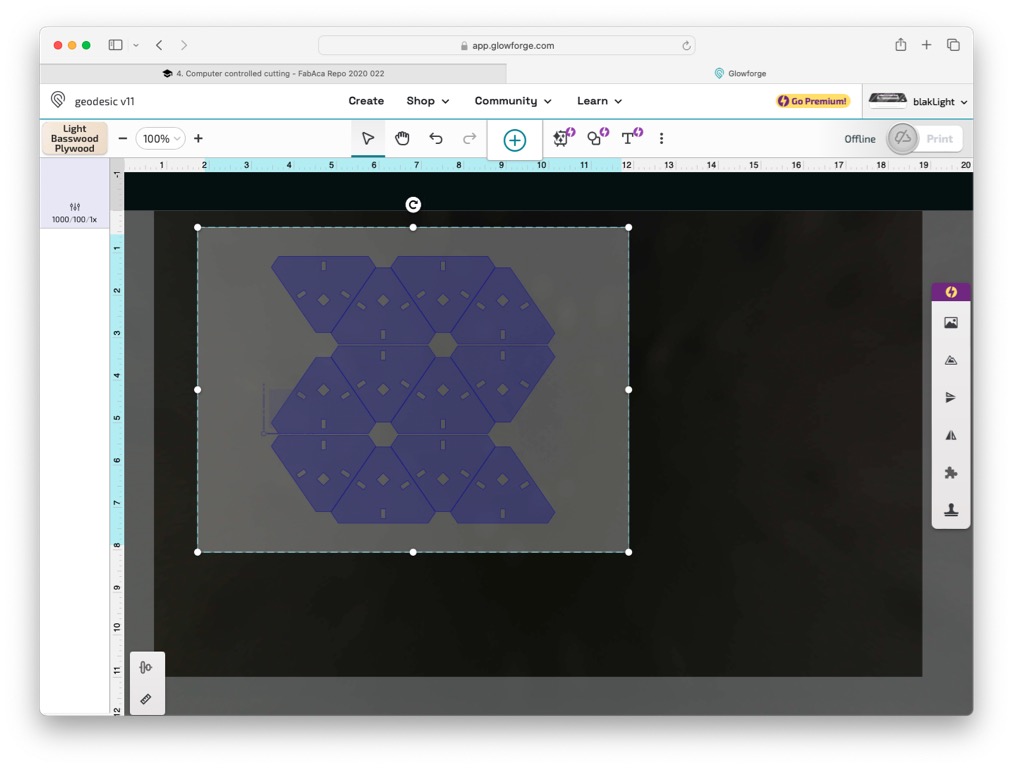

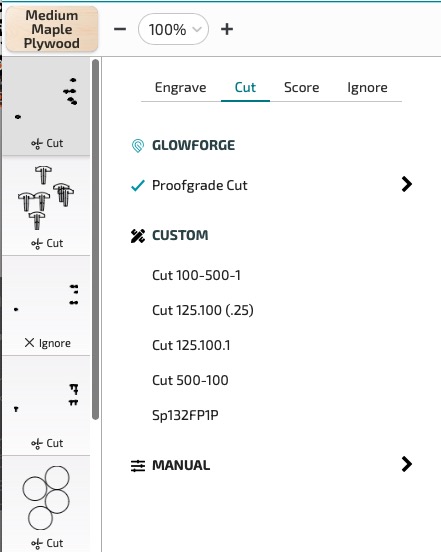

- Use Glowforge laser cutter.

- Begin a new layout in Glowforge.

- Import SVG or DXF files

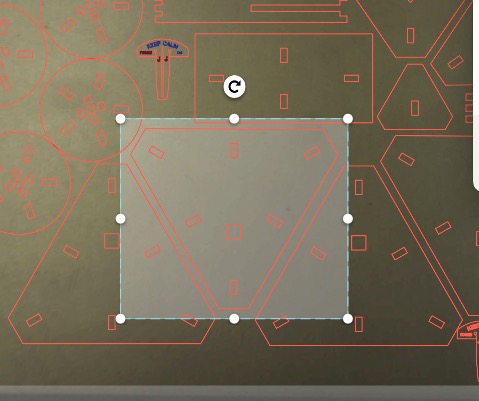

- Place the parts on the cutting area.

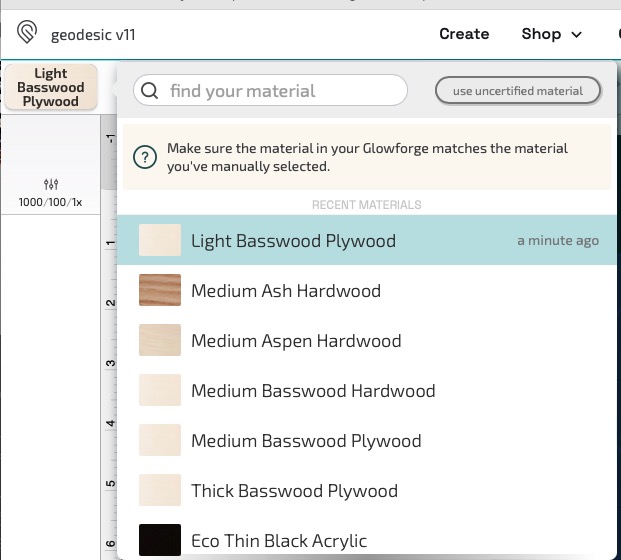

- Select material of the work-piece.

- Choose part to edit and Select cut type.

- Choose part to edit and Select cut type.

- Press print button in app to Send file to laser cutter.

- Press Print button on laser cutter to cut the parts.

- Begin a new layout in Glowforge.

- Export design as .svg from Fusion 360.

- Increase functionality of kit

- Add additional connection holes.

- Make additional connectors.

- Make different geometries

- Add additional connection holes.

- Some examples

- open flower/pin wheel

- snake

- tulip or cup

- car

Return to assignments

- open flower/pin wheel