This week was dedicated to exploring and learning CAD tools.

While we covered a lot of possible options, the tool I'm most likely to reach for for most of our assignments and for the final project is Solidworks, both because I have experience with it, and because I should probably use the products my employer makes 😁

# Parametric CAD - Solidworks Desktop

Since I'll be away next week for the computer controlled cutting class, I figured I'd get a little head start and do some simple CAD design by starting on a simple construction kit.

More on that in next week's assignment.

# Subdivision Modeling - Solidworks xShape

Of the little time I had remaining after 3D Experience World, I decided to invest in learning a subdivision modeling tool. I feel somewhat at home with parametric modeling, at least enough that it should not be a blocker for the final project. When it comes to making more organic shapes, though, I am usually stuck fighting my very limited artistic talent or struggling with parametric surfacing, which has a steep learning curve.

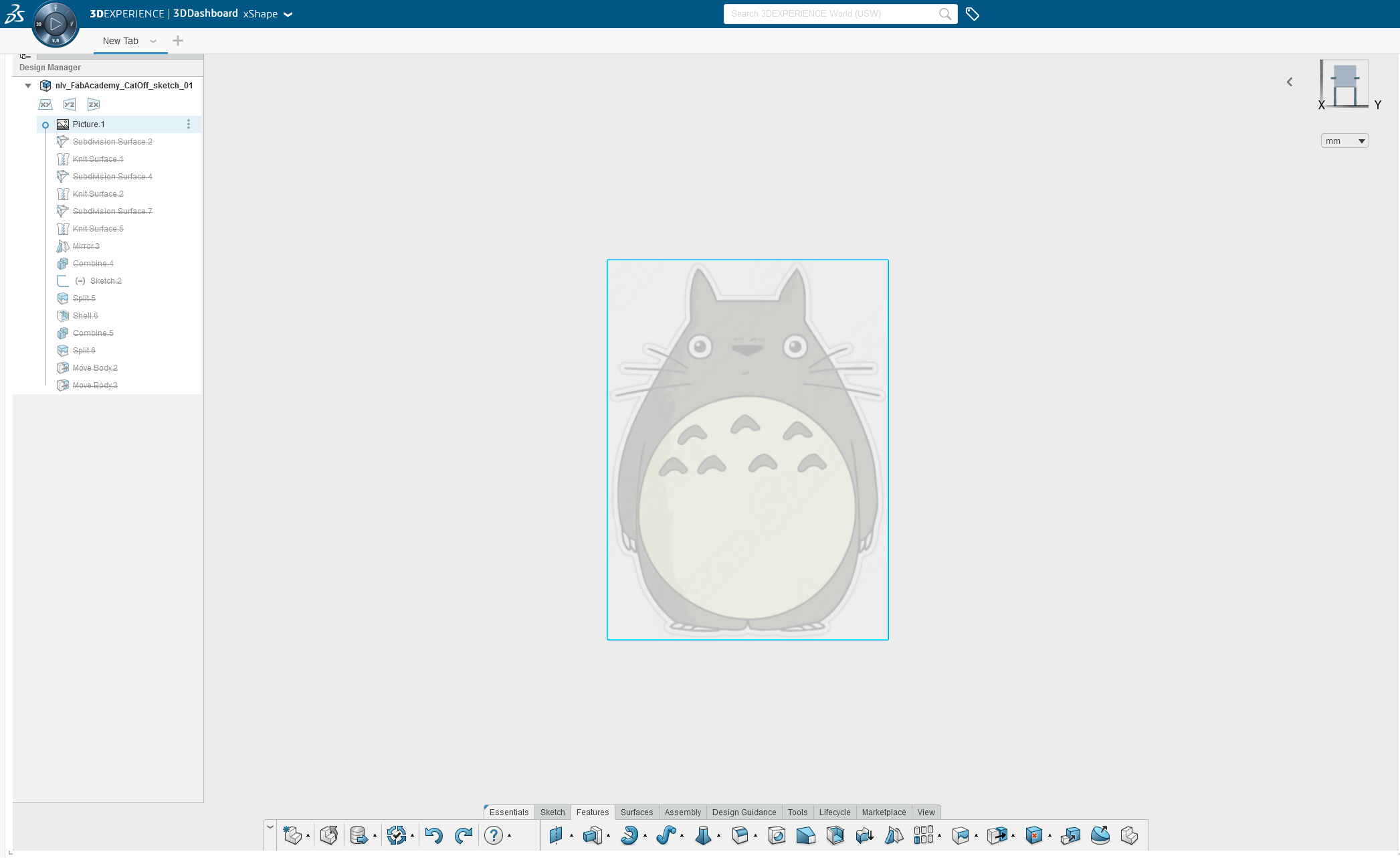

Obviously, I had to pick the option that would let me eat my own dog food, or at least my employer's, so I went with xShape, Solidworks' upcoming sub-D modeling web app.

My aim was to create a shell for my final project that would look somewhat cat like, inspired by this drawing of Totoro:

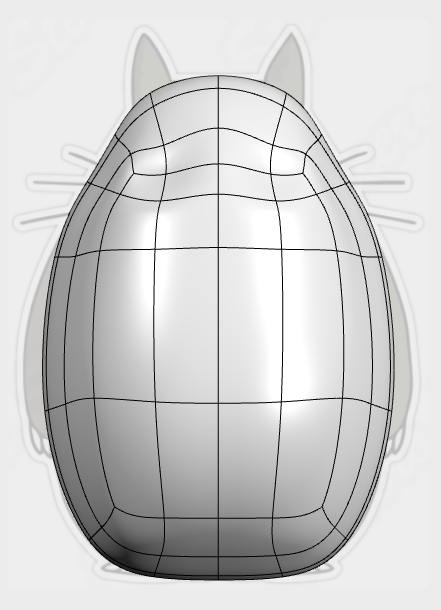

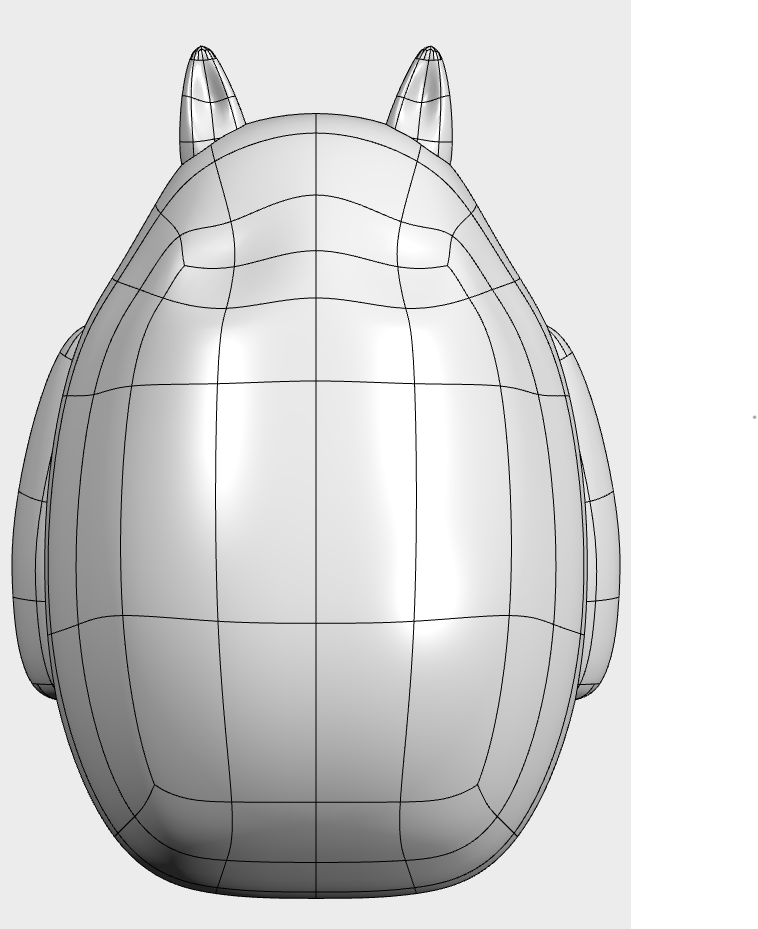

I started with a quadball and shaped it to the rough right shape (I'm not very satisfied with the result, to be honest, but I'll do another pass later when I have time available):

Then added more subdivision shapes to model the arms and ears:

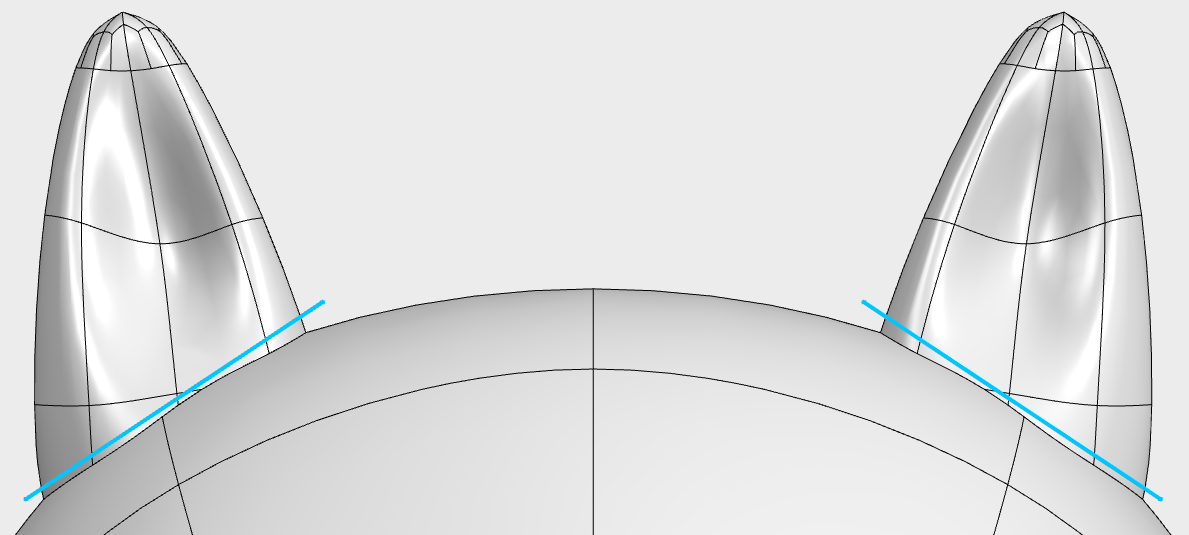

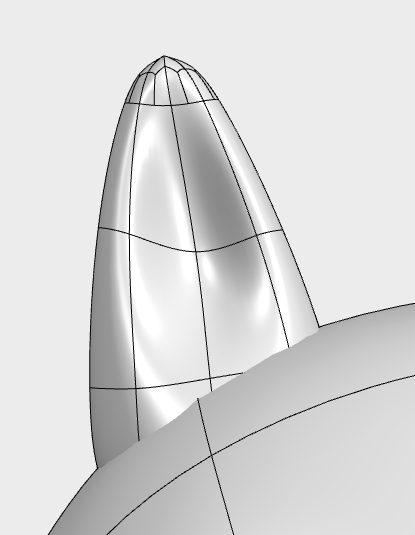

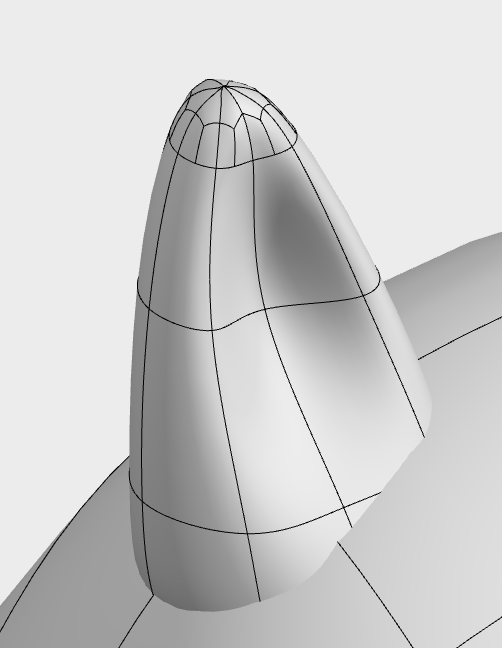

And worked on detailing the ears:

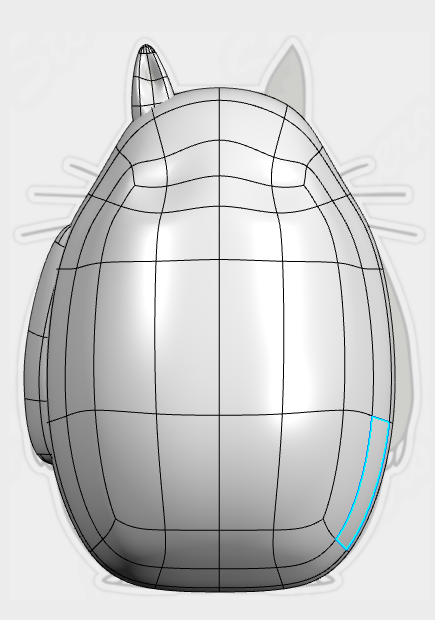

Once all of the shapes were roughed in, I switched back to xDesign for some parametric features:

- a mirror feature to create the other ear and arm

- a combine feature to merge all the bodies into a single solid

- a shell feature to hollow out the solid for future 3D printing (and to fit the actual project inside, obviously!)

- a cut feature to separate the two halves of the shell

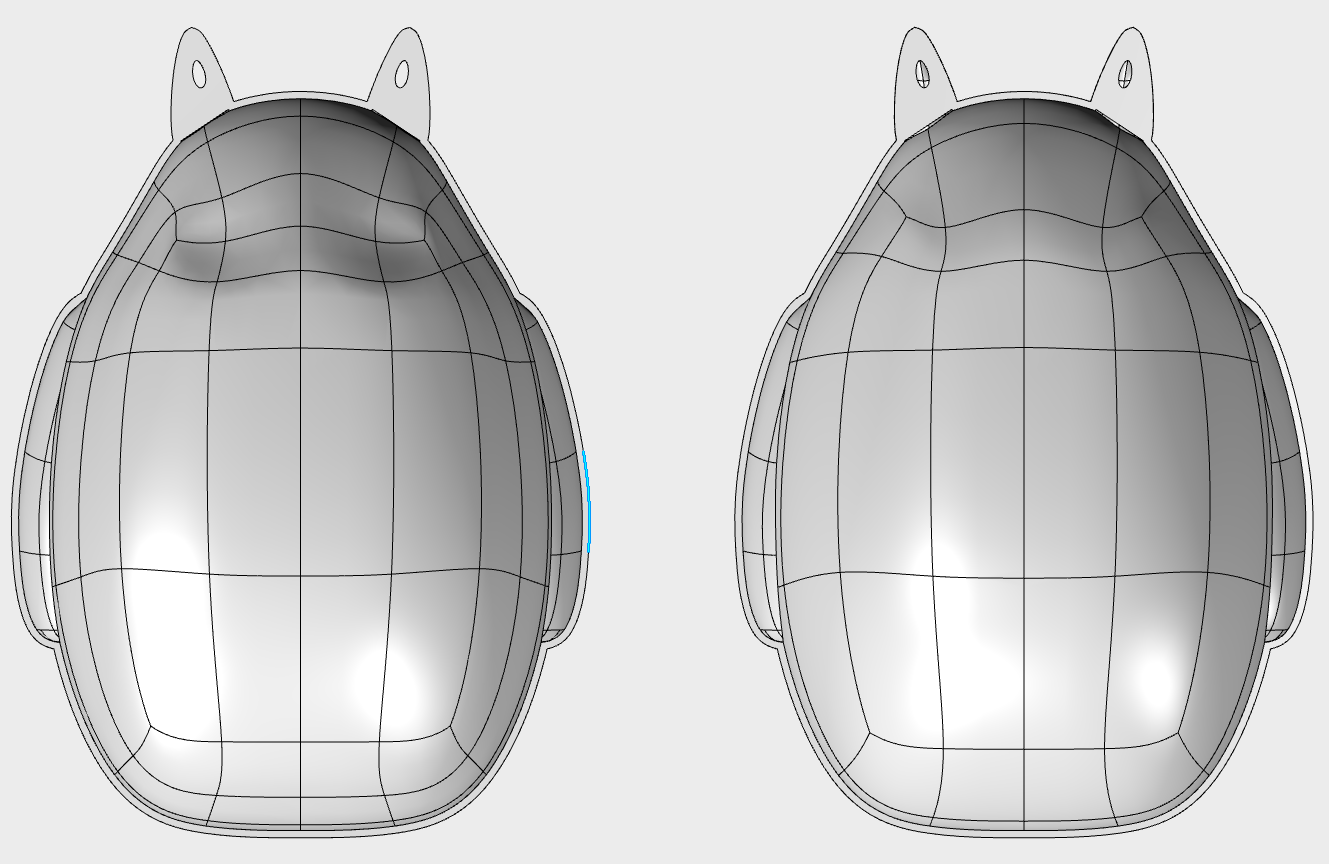

One interesting issue I ran into during this process was with the shell feature. The geometry of the ears on this model is such that the operation would fail unless the walls of the shell were made incredibly thin, which would be fragile and difficult to manufacture.

The solution I ended up going with was to split the ears off after merging all the bodies together, as close to their base as possible. I then shelled the rest of the body and merged it back with the ears. This means they will be fully solid (if printed at 100% infill), but that seems acceptable and should make it easier to fabricate.

Here's a view of the sketch used to split the ears off: