18. Wildcard week¶

In this week , we were free to pick a topic and I went for sandblasting of a 2D logo design.

Assignment¶

The main task for the week was to:

- Design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it.

The design¶

I didn’t have much time this week so decided to go with the simple option of sandblasting. Sandblasting (or abrasive blasting) is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants 1.

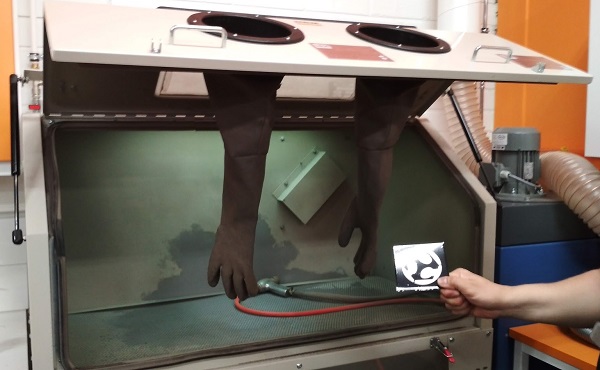

The Sandblasting cabinet available here is an SBC 420 with attached vacuum system.

To operate the machine, you first turn on the ventilation switch on the right side of the cabin, open the door, place the item to be sandblasted inside the machine, close the door, turn on the air pressure (Turn it on in the image above) and press the light switch to be able to see through the glass opening. Then, place hands inside the rubber gloves, take the sandblasting hose, step on the foot pedal gently to release more pressure if needed and blast the surface. How long you do it depends on the material, but it does not take so long. In between blasting, the item should be inspected and blasting repeated if necessary.

With Eino’s help, we first did an initial test using the Fab Academy logo. We cut the logo following the process outlined in Computer controlled cutting for operating the Vinyl cutter.

After Vinyl cutting, we attached the logo on a stainless steel piece and placed it inside the Sandblasting machine.

Below is the result right after sand blasting and after removing the superimposed sheet.

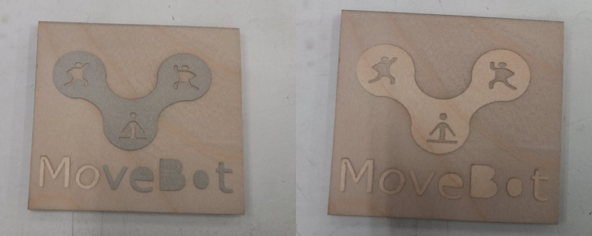

With slight modifications of the logo designed in CAD week, I vinyl cut two designs to sandblast on 3mm Acrylic and 6mm Plywood. For the latter two, I drew a 100 by 100 mm square in Inkscape and laser cut two pieces (one acrylic and one plywood) following the process in Computer controlled cutting.

Acrylic right after sand blasting and after removing the superimposed sheet.

Plywood right after sand blasting and after removing the superimposed sheet.

And all of the three side by side.

The three different materials turned out well after sandblasting, but think acrylic was the best of them, although Plywood (surprisingly) wasn’t too far behind!