6. 3D Scanning and printing¶

This week was about adding direct three-dimensionality to our skillset. Up till now, we’ve been working primarily in the plane, with clever planning of joining or cutting to move into 3D space. With 3D scanning and 3D printing, we move into volume directly.

3D Scanning¶

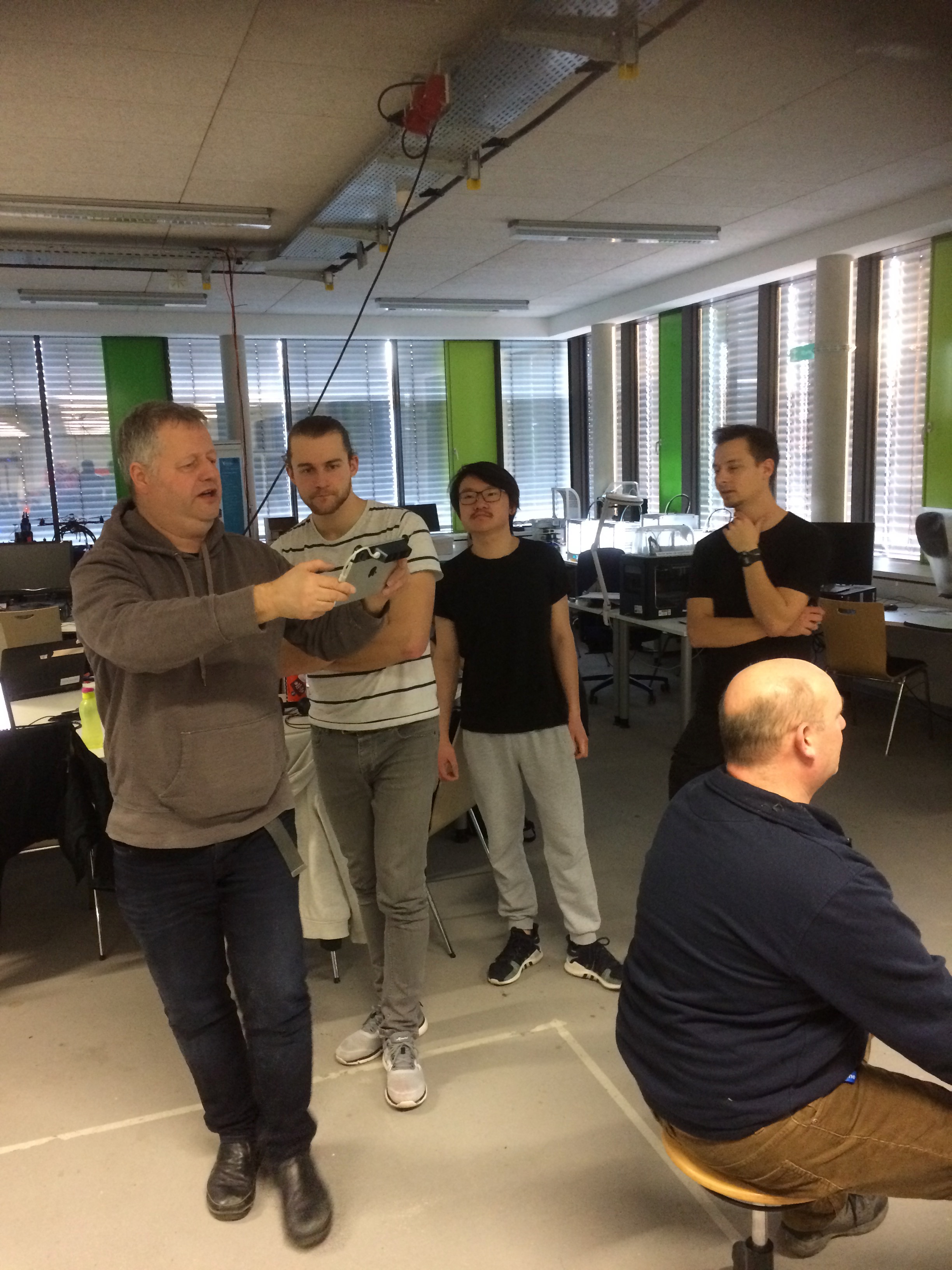

The method for scanning is simple. Modern software has come a long way since the days of yore when I had to make my own scanner using a laser pointer, linear motor and a webcam to scan a store mannequin (don’t ask). The first step in the process involves attaching a stereo camera to the back of an iPad, then starting the software. Next one selects a scene by tipping the iPad until the colour changes to red and yellow on the screen. Then it’s just a question of walking slowly around the model, rising and dipping to catch over- and underhangs, and stopping whenever the software needs to take a key frame, or loses the model. As long as the scene is relatively complex with large, slowly changing (with angle) geometries, the software can track the motion of the camera. With more difficult geometries, such as the race car frame below, the camera gets lost quickly.

This year I wanted to try a different approach. Rather than walking around the model, this time, I tried the approach of holding the camera