Nature is circular, learn from her

Last year in Toulouse I met Alysia Garmulewicz during a workshop on biomatrial. Her platform materiom contributes to find new material more circular and respectful of the environnement. Nature is full of composite materials, but the difference is that betwen each element the bond is weak. When the natural composite is no longer used like a leaf who dies, it fall on the floor and the weak link break and each simple bloc is released and can be used by other. Nowaday scientists all around the world have created a lot of materials, but most of them use stong link between each elements. Then to recycle them we need alot of energy to reforme it or redetach all these elements that compose the material.

Creating a material from scratch

For this wildcard week I create 2 biomaterials from the plateform materiom and create something with it. I begin by creating 2 samples to see more what I can do with it. The plateforme does not explain the physical property of the material so I don't know if I can make a bloc with it or only tin sheet. The recepies that they are giving use element that are usually in big amount world wild, it will maybe not be in the same form but they will be available and respectful of the environnement. I will make the eggshell biocomposite and the Coffee/agar - alginate. These are the two composites I will recreate and I will choose 1 to create something after. I suspect that I could lasercut the material, mold it in something thinner that 10mm and that it would be fragile.My challenge of this week:

- Find all the ingredients

- Do samples test of them

- Do a object with it

How to

1-Creating the eggshell biocomposite sample

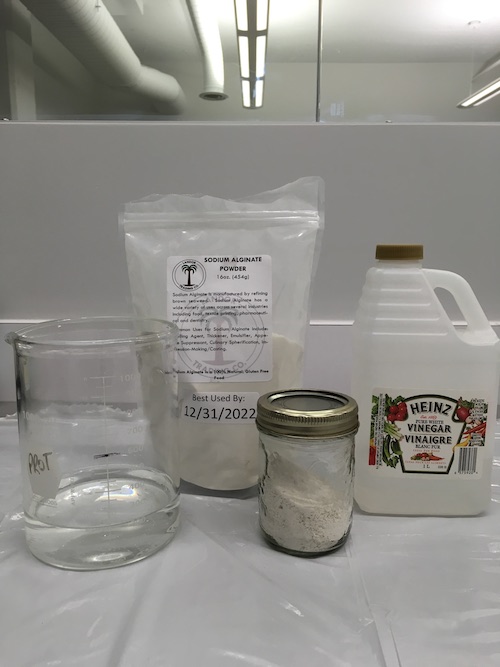

I need for ingredients:

- 4 grams - Alginate

- 5-10ml - Vinegar

- 15 grams - Eggshell

- 200ml - Water

In the lab we already have the vinegar and the water, but not the alginate and the egg. My family have a big brunch on sunday so guess where I found 12 eggs. The sample need only 15 grams, but I knew that maybe I need it more after the sample. The alginate can be sell on powder on a kind of paste to do casting with children. I think that powder is more polyvalent and can be mix easier ...but that is a guess. I didn't find only alginate so I order sodiom alginate and pray that it makes no difference.

Ready to go!

- Creating a powder from the eggshell. Like suggested in the recipe, I boil all the eggshell during 5 or 10 minutes and I put them on a pan that I put in the oven at 250fahrenheit. I wait that averything dry. After I break them in a coffee grinder and press on until the chips are very small. I'm not able to obtain a constain texture. It always do 3 type of grain; fine powder, similar to sand and small pieces.

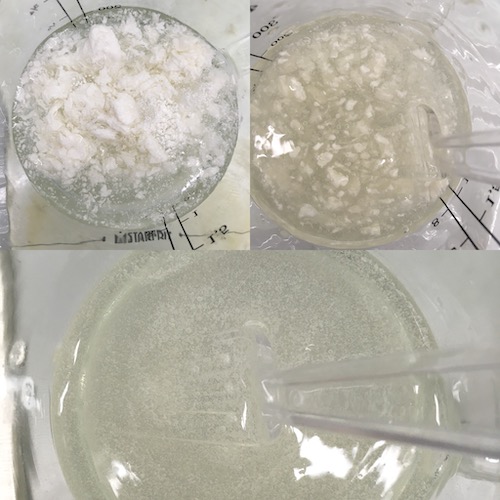

- I put in one shot my 4grams of alginate into the 200ml of water and stir. Oops the texture is not so great so I stir more. It was better but not good, so I stir more and more and more. I let it sit to stir later and magicaly everything hydrated and it is a uniform gelly mixte. I let it sit for 24hrs. After few hours the alginate powder is already hydrated to his maximum, but a lot of air bubble is traped inside. I think we could probably use a vaccum in a seal bagg to speed the extraction of air bubble but I didn't do it.

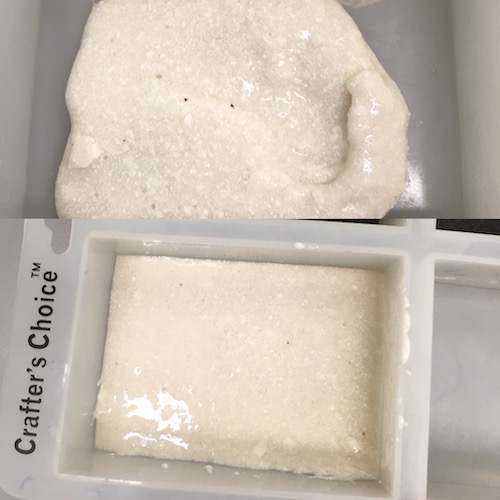

- The next day, I mix 32g of this alginate hydrated with 20g of eggshell powder. It is supposed to be 20grams of alginate and 15 grams of eggshell but I lost count and our balance is not the sharpest, so consider that it was around 32g of alginate and around 20g of eggshell

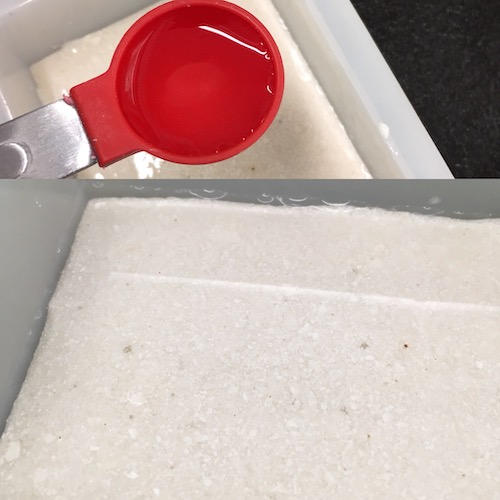

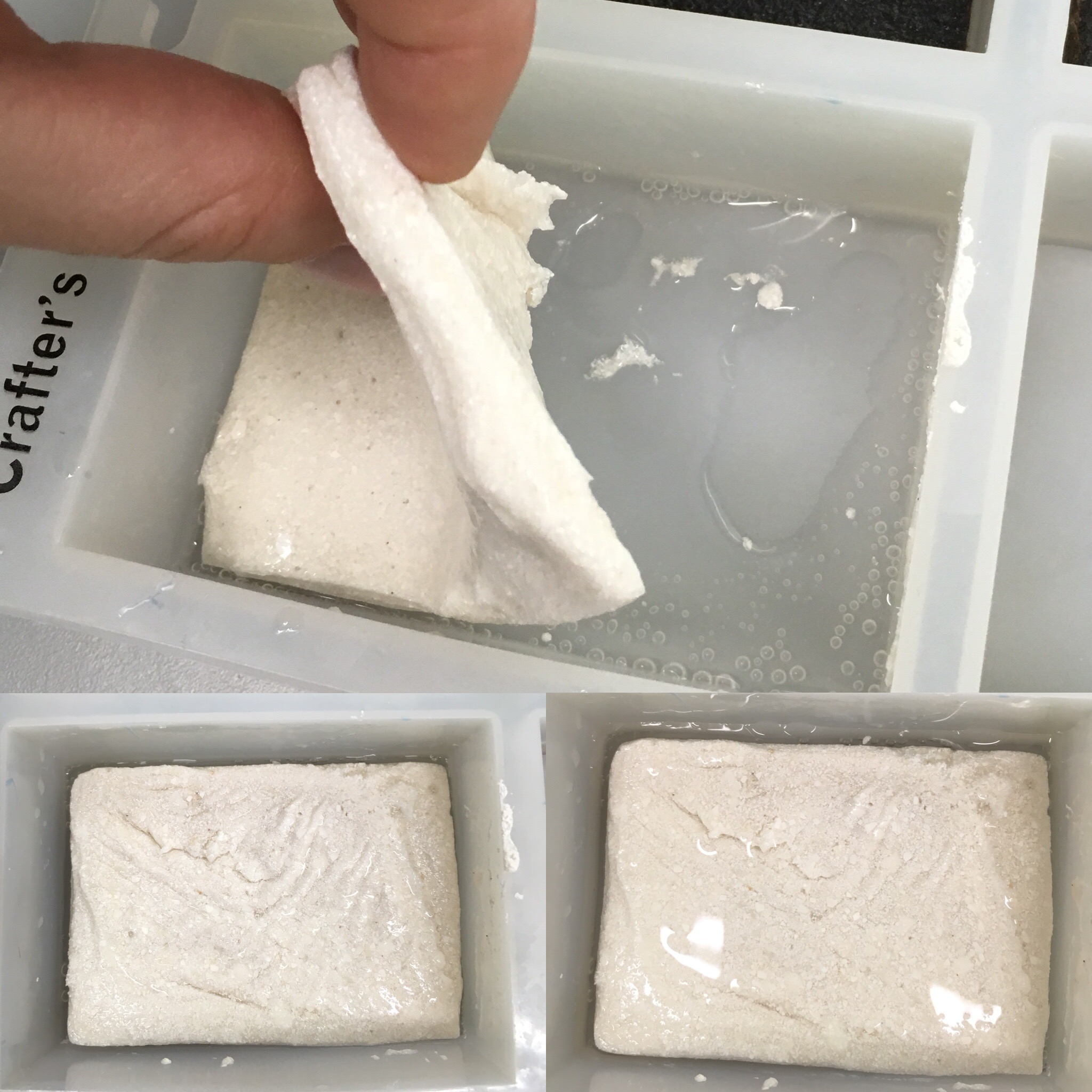

- Put the mixture in the samples mold, shake it again and when everything look perfect, poor 5ml of vinegar on top of it to make it react for 15 min.

- Add another 10ml of vinegar and manipulate the mold to try to make

Here the picture of the material on materiom

The ingredient I use (water, alginate, eggshell powder, vinegar)

Boiled the egg for at least 5 minutes and put it in the oven

Broke the eggshell in the coffee grinder until it's powder.

I was not able to have uniform grain we have fine powder, medium size like sand and a little bit bigger.

The different state of mixing alginate (after 1minute, after 10 minutes of stiring and after 30 minutes waiting)

Mix the 20grams of alginate hydrated...oups I use 32g so instead of using 15grams of eggshell powder, I use 20g.

The texture is really thick. avoid air bubble when mixing. I also shake it like a silicon mold to force the air bubble out. My theory of leaving the alginate for 24hr is to let the air bubble out.

Add 5ml of vinegar on top of the material, it become stronger instently. After 15 minutes manipulates the mold to force the vinegar to go under.

When you will turn it on the other side, it's still soft so becarefull to keep the shape of it. Add again vinegar to react.

I try to poor directly the vinegar into the mixture and after put it in the mold, but has you see, the result was no good.

2-Creating the coffe/agar - alginate sample

I need for ingredients:

- 15ml - Agar agar

- 5ml - Glycerol

- 250ml - Water

- 5ml - Alginate

- 0.5 cups - Coffee grounds used

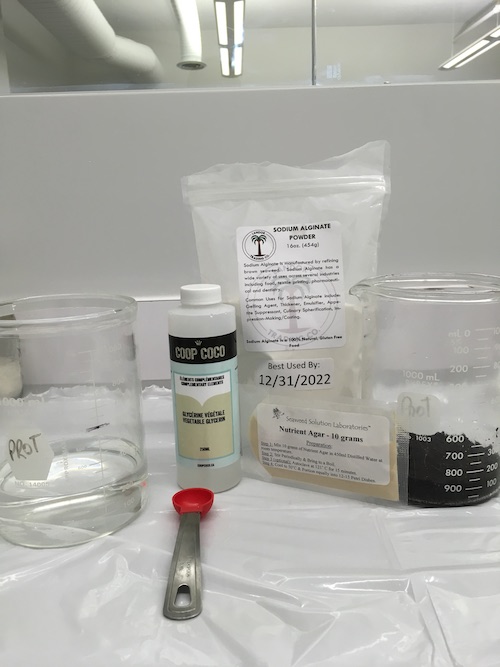

In the lab we already have the agar agar and the water (obviously) and the Glycerol. Be careful here, the glycerol, glycerin or glycerine are all the same. The glycerol refere usually to a pure concentration and the glycerin or glycerine refer normaly to a commercial name so the concentration is around 90 to 99%. I use some vegetal glycerin from coco. The alginate I ordered it like I said before. For the coffee ground I take used expresso ground from my coffee machine.

Ready to go!

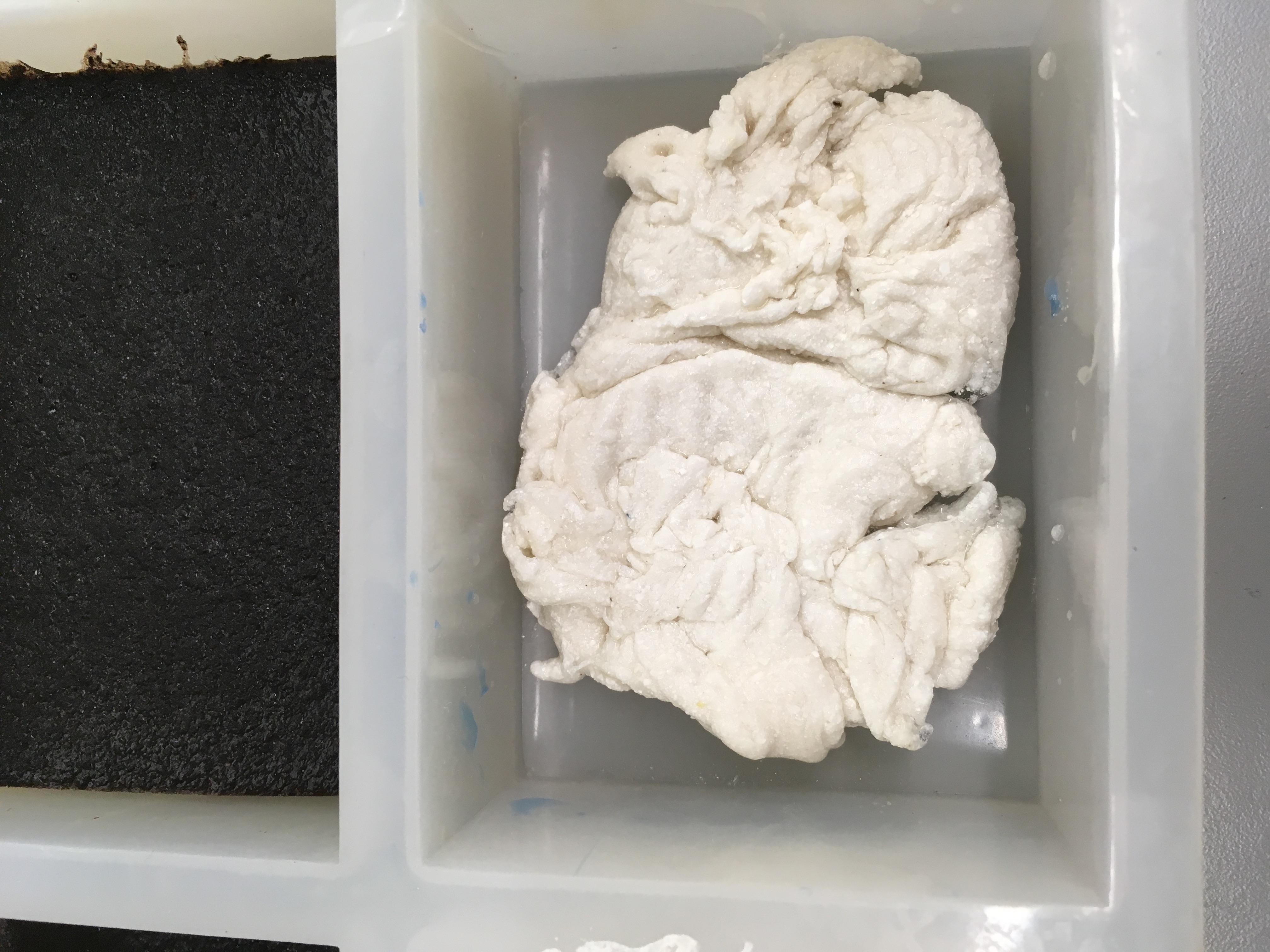

- Mix all the ingredient together and stir. Based on my previous experience with the alginate, I try this time to incorporate slowly the powder in water...but there are no differents in it do the same aglomeration, you just have to stir.

- In the plateform they said : Heat everything until it thickens and bubbles begin. but at the lab we have no stove, we have induction plate and the only container that work on it was full of old melted wax. I decide to fill it with water and put my glass container in it. I put it at the maximum so the water was boiling. The mixture heat slowly and began to be ticker like peanut butter. Unfortunatly it never create the bubbles, but I took the risk.

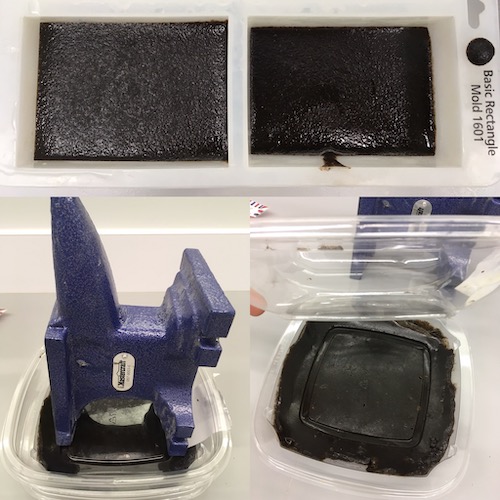

- Pooring in simple rectangle mold, I made a little brick and a little sheet around 1cm thick. I have alot of mixture left so I take plastic container from the recycle bin and I try to squiz the mixture bettween and put a weight on it. Will it dry...no idea, it seems liquid enought that it would take few days to dry.

- Big suprise! it dry very fast, I just had to take lunch and it already began to be solid.

- After 2 days it's still not dry and I began to see some little fury mold on it. Also the retraction of the material is incredibly important. What can I do with that kind of material. cast it will make very poor result even if I streach the shape. Another problem is that the exterior dries faster than the inside witch is normal but the consequences is that the outside of the material try to shrink but not at the same speed has the inside. The consequence of this phenomenon forces the material to bend and than if the material is not straight anymore, then it's difficult to work with it in the laser on with the CNC.

- If you can not cast it, modify it in the laser of with the cnc what can you do with it? Let's think about that for a day.

The ingredients I used (water, vegetal glycerine, alginate, agar, coffee)

Mix everything and heat it. That was my installation because on the induction plate we must use metal and the only plate was fool of machinable wax.

When it's thicker, poor in a mold

3-Create something with it

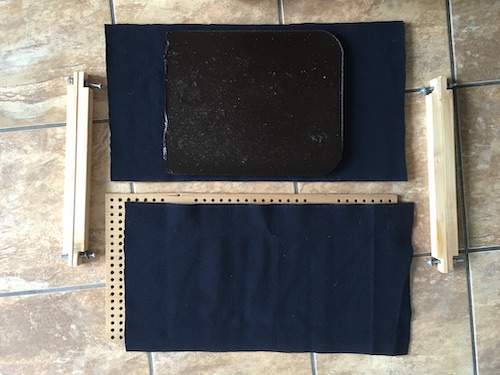

- I think about that previous problem and decide to make a drying press. I found crazy that many biomaterial are availale, but we can not do something great with them because they are unstable. I will make a drying press to for the material to stay straight and a regular thickness.

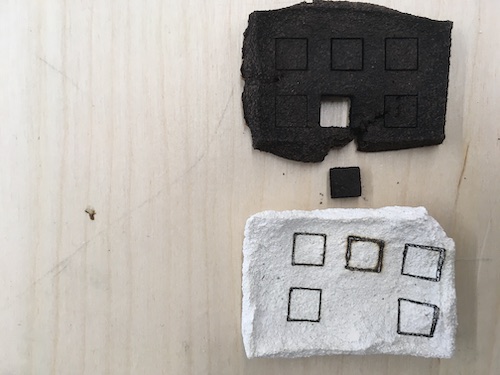

- Before everything, make a really man made prototype of what could be the solution. I drill holes in 2 pieces of wood and put a felt bettween both of them. The felt absob a bit of the water and disperse it in the total of the material so technicly the outside of the material will dry in the same time has the middle. The felt could also help to redistribute the force apply on both wood pieces. I try without a felt and the material is easy mark.

- To choose my felt I went in a warehouse of textile and I found alot of felt...but acrylic felt. If I wanted to put everything in the oven to let it dry, it need to resist at the heat like wool for exemple. I choose first few 100% wool felt, but the lady who was helping me made a flame test to prove that these 100% felt was in reality not 100% felt. (There are a big problem here if someone is interested)

- I decide to go with a felt of 80% wool and 20% nylon...At leat I know the plastic in. I verify the melting point of fusion of the nylon and decide to try to put my oven to 190 deg. Everything was perfect, noting burn, no smell was alerting me and experience worked, the coffee material dry like a charme and was straigt.

- When everything was dry, I try to laser cut them with different parameter. The eggshell material just burn and the coffe material cut well. So I decide to make a big dryer to do some bigger sheet.

- This drypress will go in a oven that is use for food so I iliminate all plywood and stay with massive wood. I take a pine with 0% of umidity. I is one of the more stable wood.

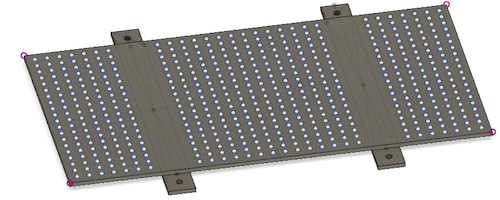

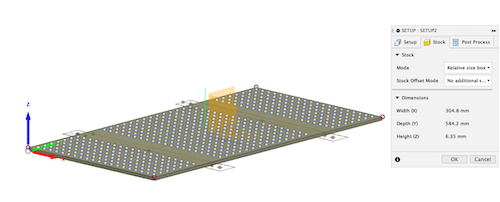

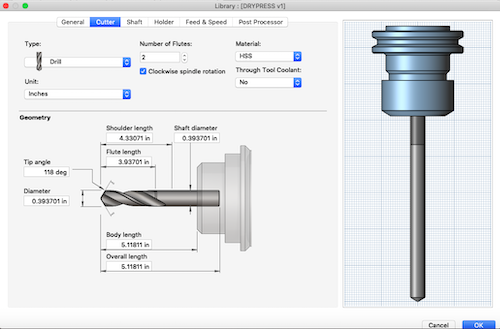

- I create a 3d model of the drypress and CNC it.

- I made a big batch of coffe material and dry it in the oven at 200F during 5 hours.

Drying test, small scale

Laser cutting test on both material

Modelise the drypress and doing my cnc path on fusion 360

CNC production

Creating a coffe ground sheet biomaterial

The moral of this story

Biomaterial is very interesting, but using them is complicated. I wanted to try to create some for a long time ago and I now a tones of questions come to me about all the property and how to work with them. I think that working with them means also to change the ways we design things and the ways we modify them. It was very suprising the retraction coeficient the coffe material reduce. Also, the eggshell material can open a door on new kind of mold that can helps coagulate the material. I think I will have a very interesting year after the fabacademy. Files

Contact

Annie Ferlatte

ferlatte.annie@gmail.com

Montreal, QC, Canada