Assignment 8: Computer Controlled Machining

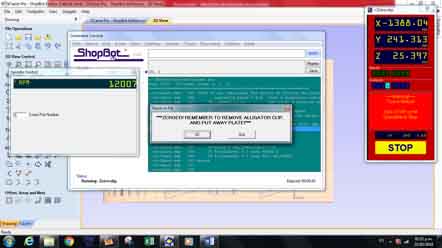

I have fun doing this assignment. It was my first prototype of my final project. So, with the help of Victor, the man in charge, of the Shopbot I took over the milling process. One thing that happen was the vacuum system take two wood pieces, so we need to stop the machine for a while in order to extract them. After that in aproximately one hour and fifteen minutes, the milling process was finished. After, I used the vacuum cleaner to extract all the dust from the board, then with a carpenter tool start to bring out the pieces from the board. That took me around thirty minutes more. Then I wrapped every single piece in plastic wrap and headed to my car for lunch at 4:30 pm. Here I share some images of the process.

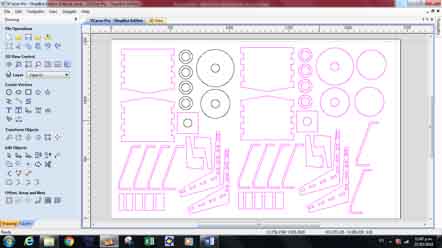

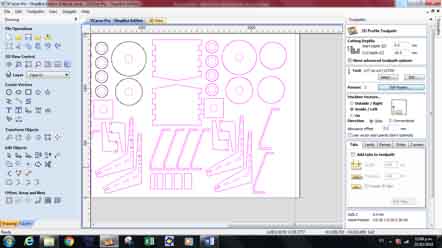

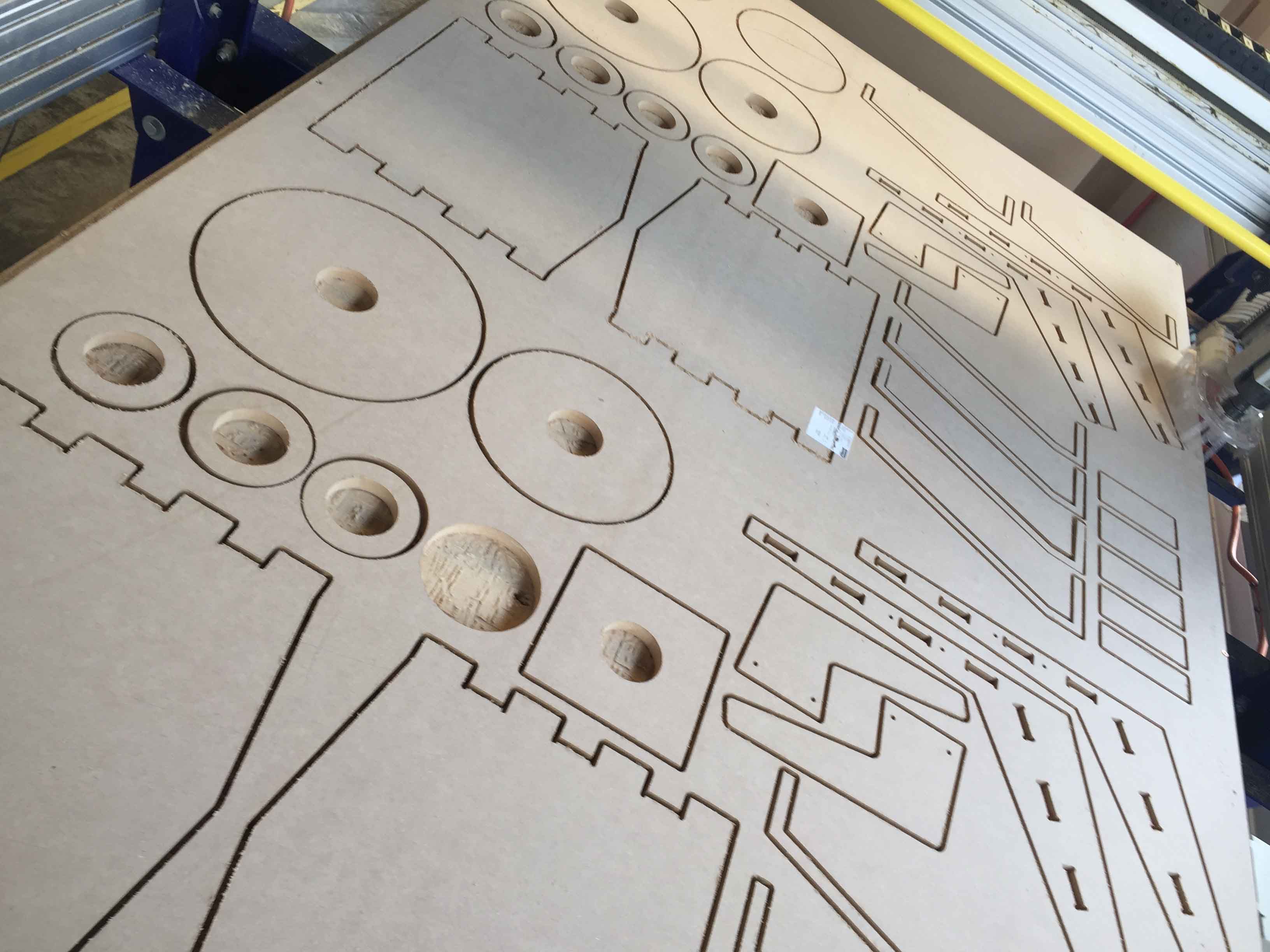

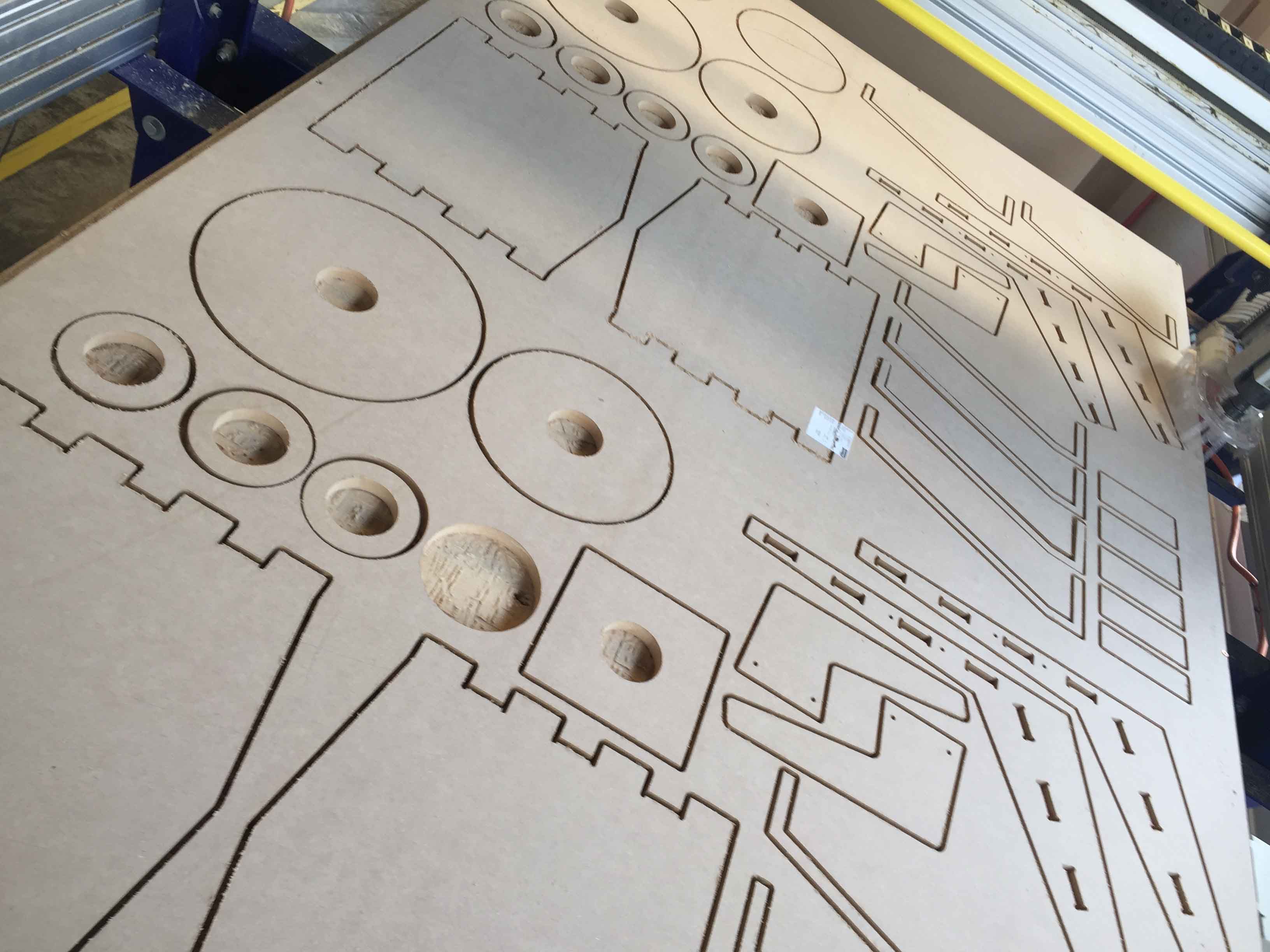

After importing the file into the VCarve Shopbot program machine and configurating elements, depths, number of pass, taps,

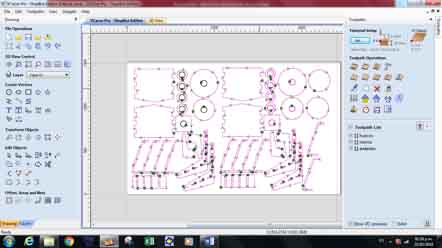

putting the axis in place, I was ready to milling cut.

Now I was ready for cleaning the plywood with the vaccuum cleaner and using a carpenter tool for extracting the pieces.

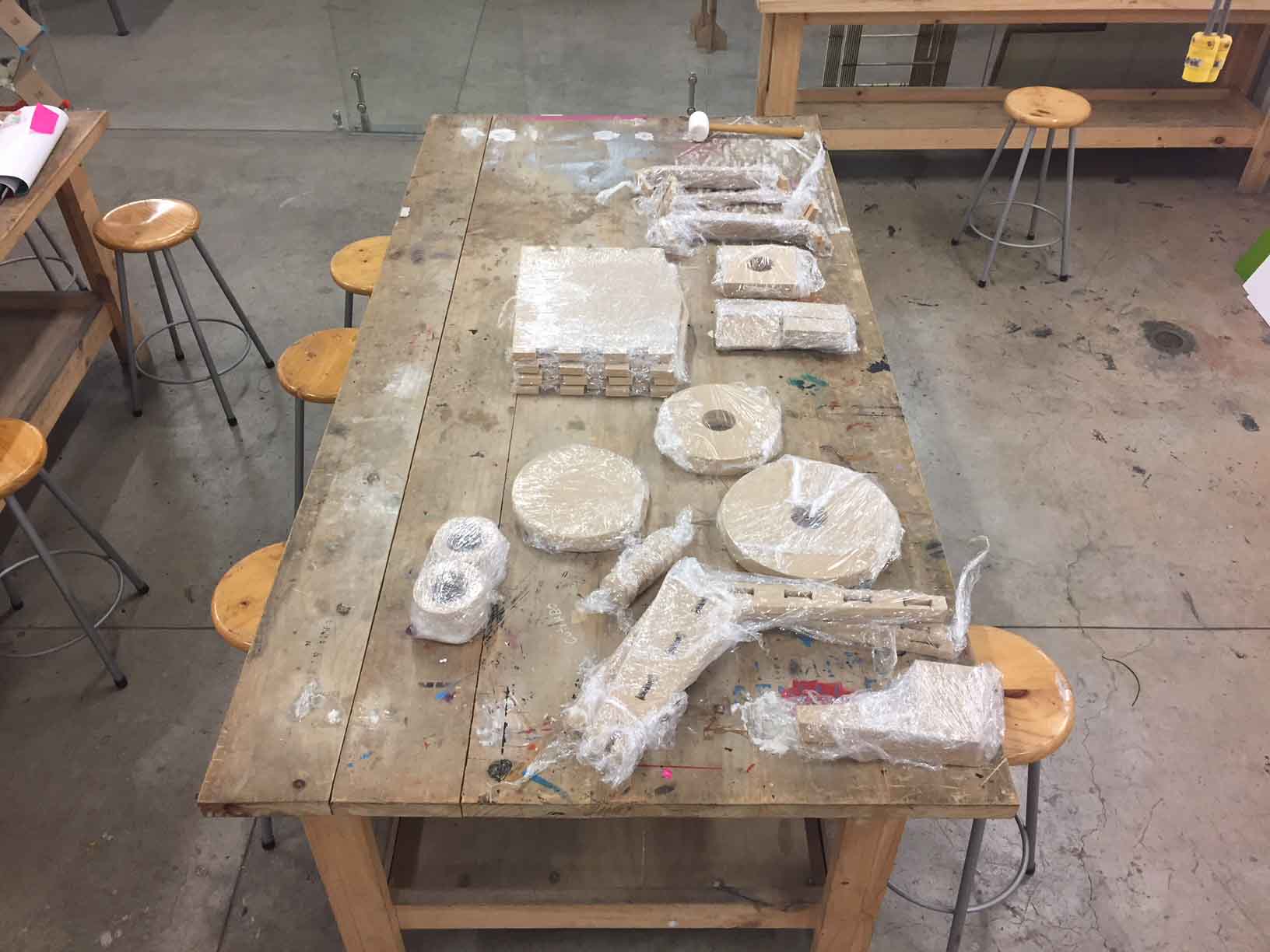

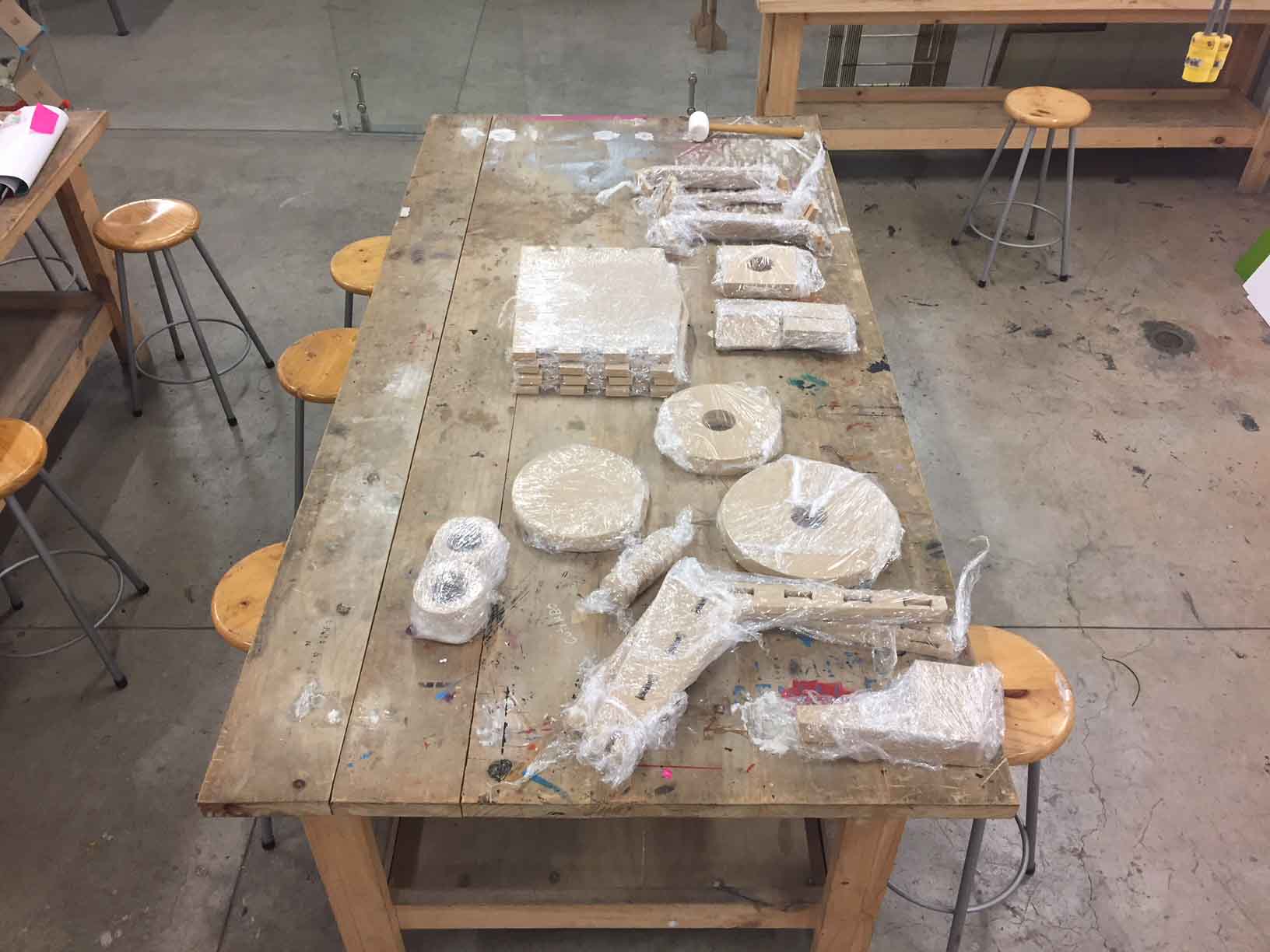

So, I wrapped in plastic all the elements of the chair to build them later in UCAL FabLab. Here some pics of the first prototype,

which I need to fix the press fit because the holes where to tight, so I have to use a machine saw in order to open it a little bit.