Final Project

Final Project idea (march | 15th | 2025 ):

What does it do?

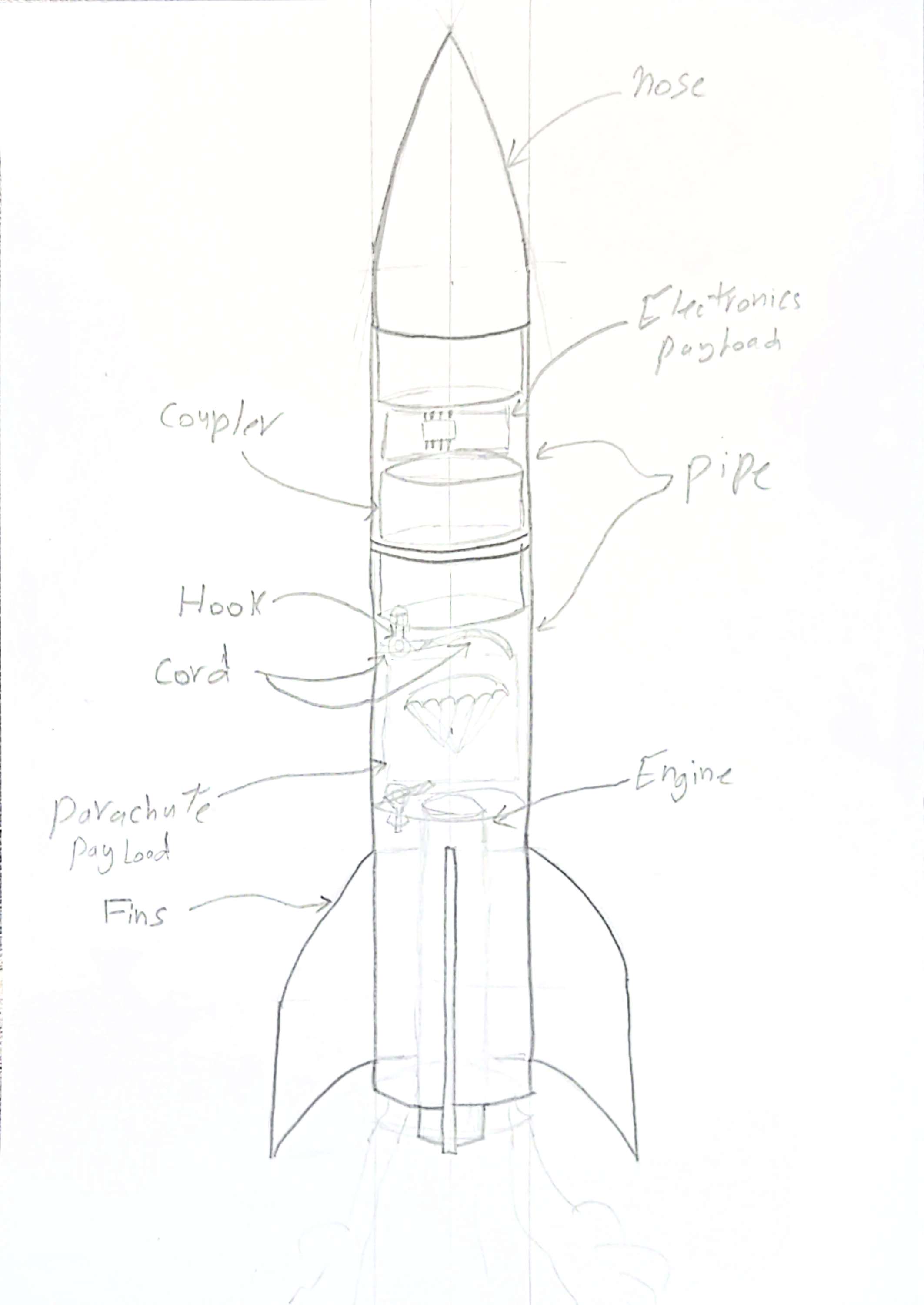

The project is a model rocket named "Al-Haitham 1", designed to launch, reach an altitude of approximately 1,000 feet, and safely return to Earth using a parachute deployment mechanism. It includes onboard electronics to measure flight altitude, temperature, and trajectory.

Who's done what beforehand?

Model rocketry has been explored by many hobbyists and educational programs such as NASA’s Student Launch Initiative and Tripoli Rocketry Association. However, combining this with digital fabrication tools and Fab Lab principles makes this project unique. Inspirations also came from OpenRocket communities and amateur rocketry forums.

What did you design?

I designed the rocket’s body structure (fuselage, fins, and nose cone), custom electronics (PCB for sensor integration), a deployment mechanism for the parachute, and a mission patch/logo. All parts were created using CAD tools, additive/subtractive processes, and embedded programming.

.png)

What sources did you use?

- Fab Academy archives

- OpenRocket simulator

- Seeed Studio documentation for RP2040 and ESP32C3

- Online communities (Hackaday, Tripoli, Arduino forums)

- MIT and NASA educational materials

- Material safety and fabrication data sheets

Where did they come from?

- Local hardware stores (materials, fasteners)

- Seeed Studio and DigiKey and Mikroelectron (electronics)

- Makerspace inventory (PLA, MDF)

- Fab Lab machines (3D printer, CNC, laser cutter)

What parts and systems were made?

- Rocket body (CAD designed and fabricated)

- Parachute deployment system (servo mechanism)

- Onboard sensor PCB (I2C communication)

- Rocket patch/logo (laser engraving)

- Embedded software for data logging and triggering

What processes were used?

- 3D printing (FDM)

- Laser cutting (for support fixtures and packaging)

- PCB design and UV printing

- Soldering and electronics assembly

- Embedded programming (Arduino, MicroPython)

- Simulation (OpenRocket)

What questions were answered?

- Can we safely and affordably fabricate a high-altitude educational rocket using digital tools?

- What materials and structural designs withstand thrust and high altitudes?

- How can microcontrollers handle sensor data and control parachute deployment effectively?

What worked? What didn't?

Worked:

- The fiberglass body, 3D printed components, and parachute system.

- Sensor integration and data acquisition.

- Simulation alignment with real performance.

Didn't:

- Some initial parachute deployment designs failed under pressure.

- The first version of the motor mount was not strong enough.

- Wi-Fi communication was unstable at altitude; fallback to onboard logging worked better.

How was it evaluated?

- Ground tests (fit, stability, electronics)

- Data review from sensors

What are the implications?

This project demonstrates that educational and functional aerospace prototypes can be built using Fab Lab tools. It opens possibilities for STEM learning, low-cost satellite deployment testing, and innovation in space education. The "Al-Haitham 1" mission bridges digital fabrication and space technology for emerging regions like Jordan.

Project idea (Jan | 29th | 2025 ):

Hi, I'm Omar, with a background in robotics, space, and engineering. I've been exploring ways to combine these fields with fabrication processes for a meaningful cause.

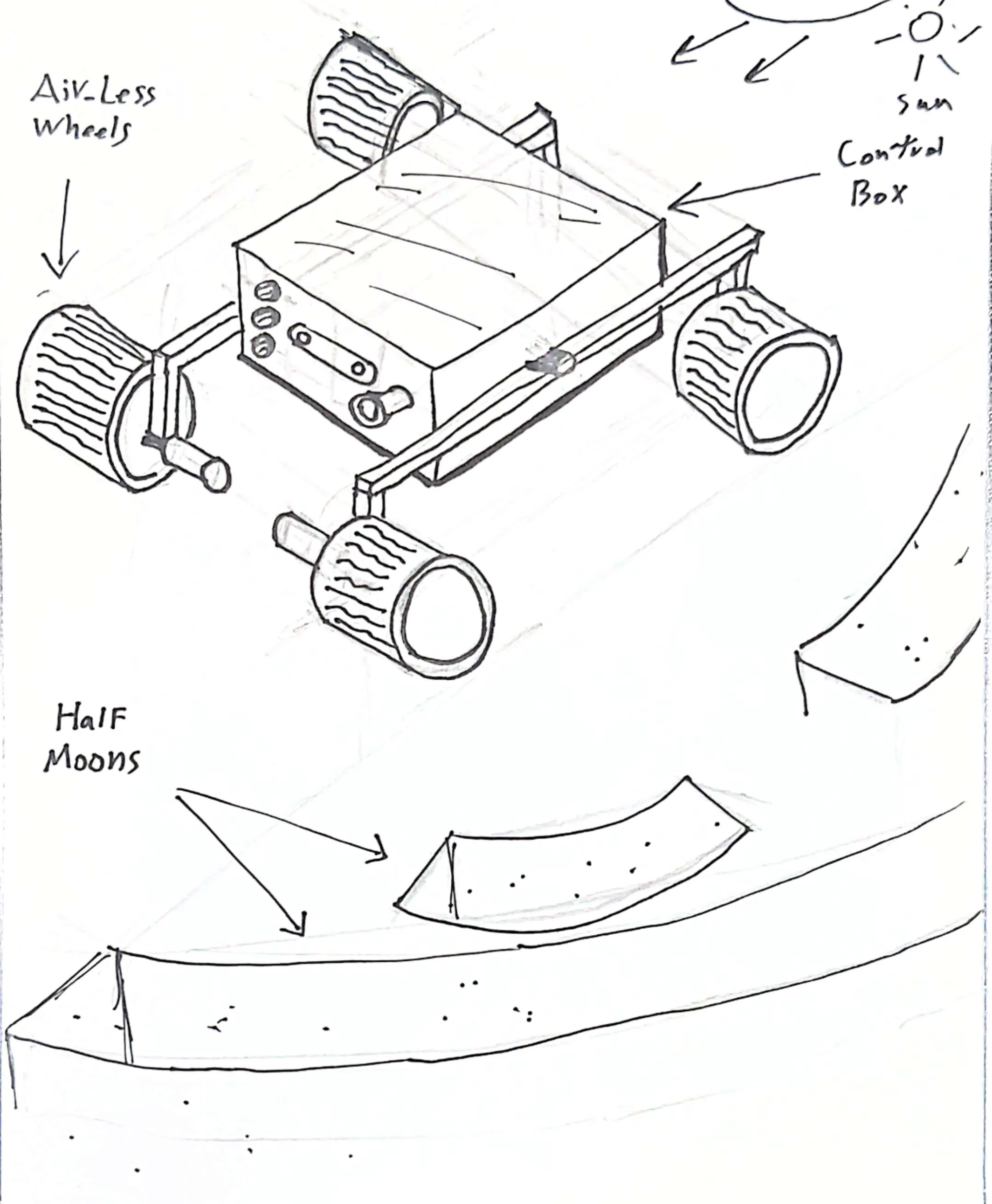

After extensive research and brainstorming, I've decided to develop a humanitarian project aimed at combating desertification. The United Nations has long sought to address this issue, and my solution involves designing a robot capable of creating half-moon patterns in deserts.

These patterns can help retain water and foster green areas over time. Instead of relying on locals to manually create these patterns, this robot will operate continuously, day and night. This innovation could significantly aid in transforming desert areas in Africa into lush, green regions.

Update 3rd/Feb:

My Local Instructor advised me to go to week 18 and answer the Assignment questions:

What will it do?

it is basically a CNC on a large scale were it will drilling a half-moon patterns to provide a solution for desertification problem worldwide

Who has done what beforehand?

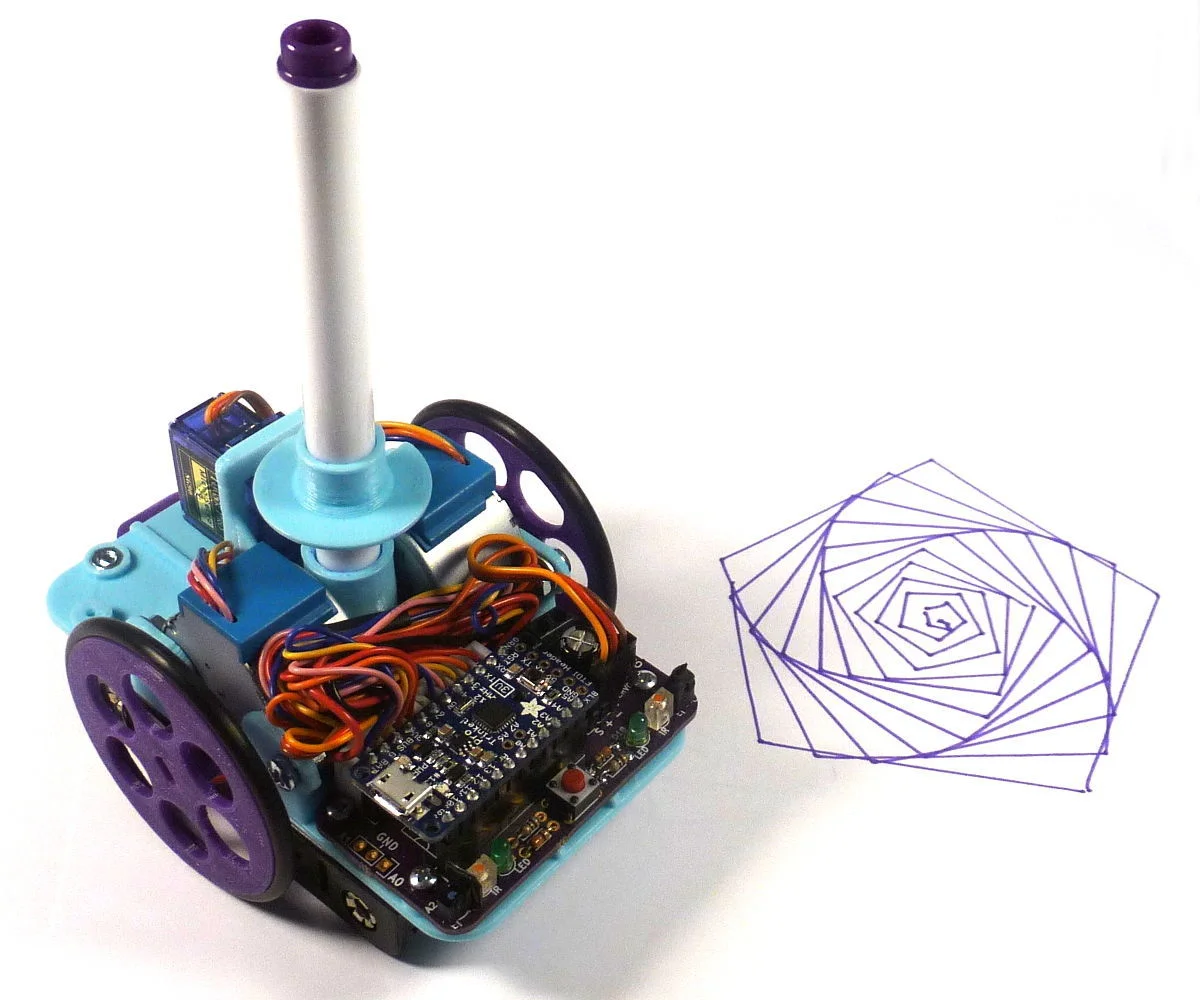

In 2014, a team from Disney in Switzerland developed a sand-drawing robot that used wheels to trace Disney characters across sandy beaches.

What will you design?

A lookalike planetary rover(Perseverance Rover) that will have a capability of drilling these patterns in desert

What materials and components will be used?

I will be using Acrylic, emergency heating foul, Microcontroller, Microcomputer, GPS, Wheel encoder, IMU, Aluminum 6061

Where will they come from?

Local hardware stores, Mikroelectron

How much will they cost?

TBC

What parts and systems will be made?

robot chassis, Power distribution board, control board, Drive board, ROS programming, AI training(reinforcement learning)

What processes will be used?

3D printing, AL milling, PCB milling

What questions need to be answered?

How to make it operate for long time? how to drill the half-moons patterns if the soil is super tough?

How will it be evaluated?

Drawing two patterns successfully without any human interaction.

Resources:

https://www.youtube.com/watch?v=ohRAL_ZgBfw&ab_channel=Christophe

https://www.instructables.com/OSTR/

https://github.com/russhughes/turtleplotbot3

https://www.youtube.com/watch?v=4N2UzxaS5dE&ab_channel=Huawei

https://www.youtube.com/watch?v=CPtaEbrO78Q&ab_channel=ducksize

https://www.youtube.com/watch?v=IPYYLbR_AJo&ab_channel=ChannelIAM-English

https://www.youtube.com/watch?v=3KZlA--rJWg&ab_channel=PABLOODYSSEUSSANDDRAWINGROBOT

https://www.youtube.com/watch?v=vSNtifE0Z2Q&ab_channel=Veritasium