System integration

Summary

This section outlines how the mechanical, electrical, and software components of the rocket are integrated into a cohesive and functional final product. The goal is to ensure that every subsystem is properly connected, securely packaged, and contributes to a professional, finished prototype.

Work Process Detail

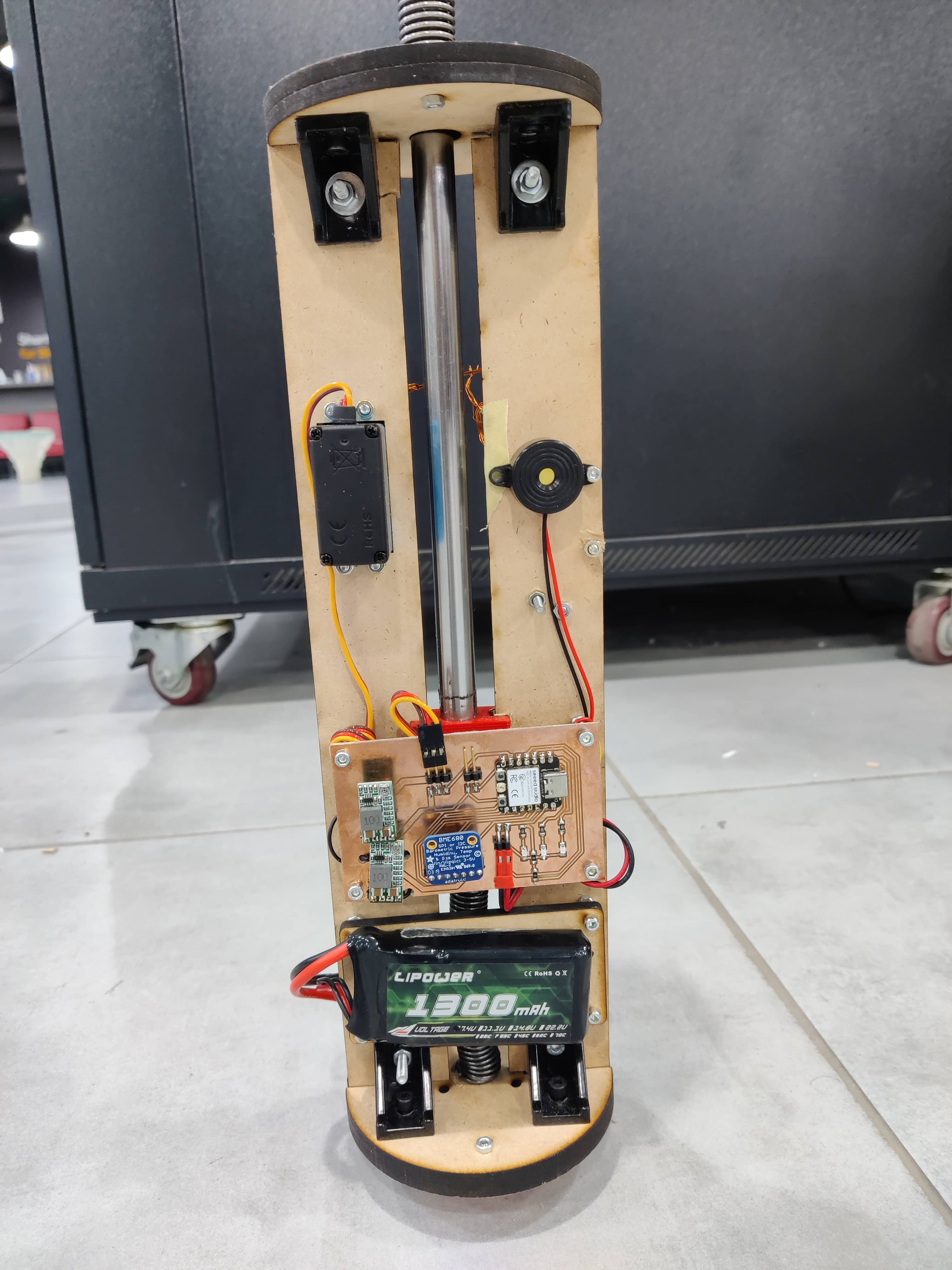

🛠️ Mechanical Integration

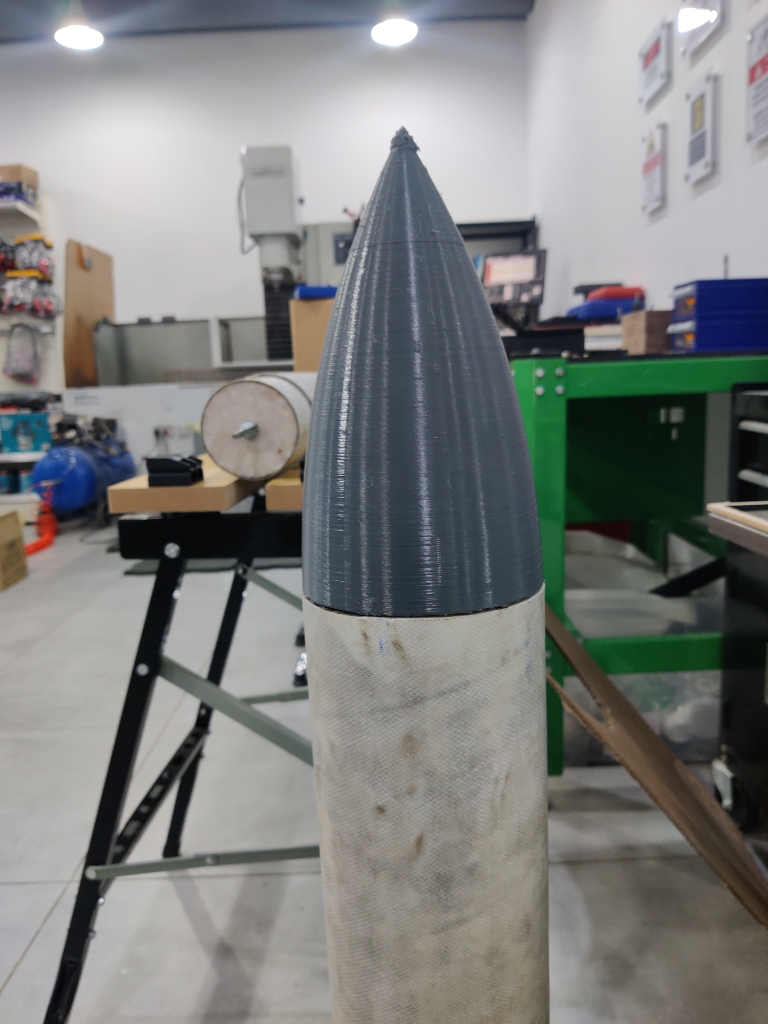

- Airframe Finishing

- Body tubes joined with precise couplers

- Integration of fiber glass to reinforced parts

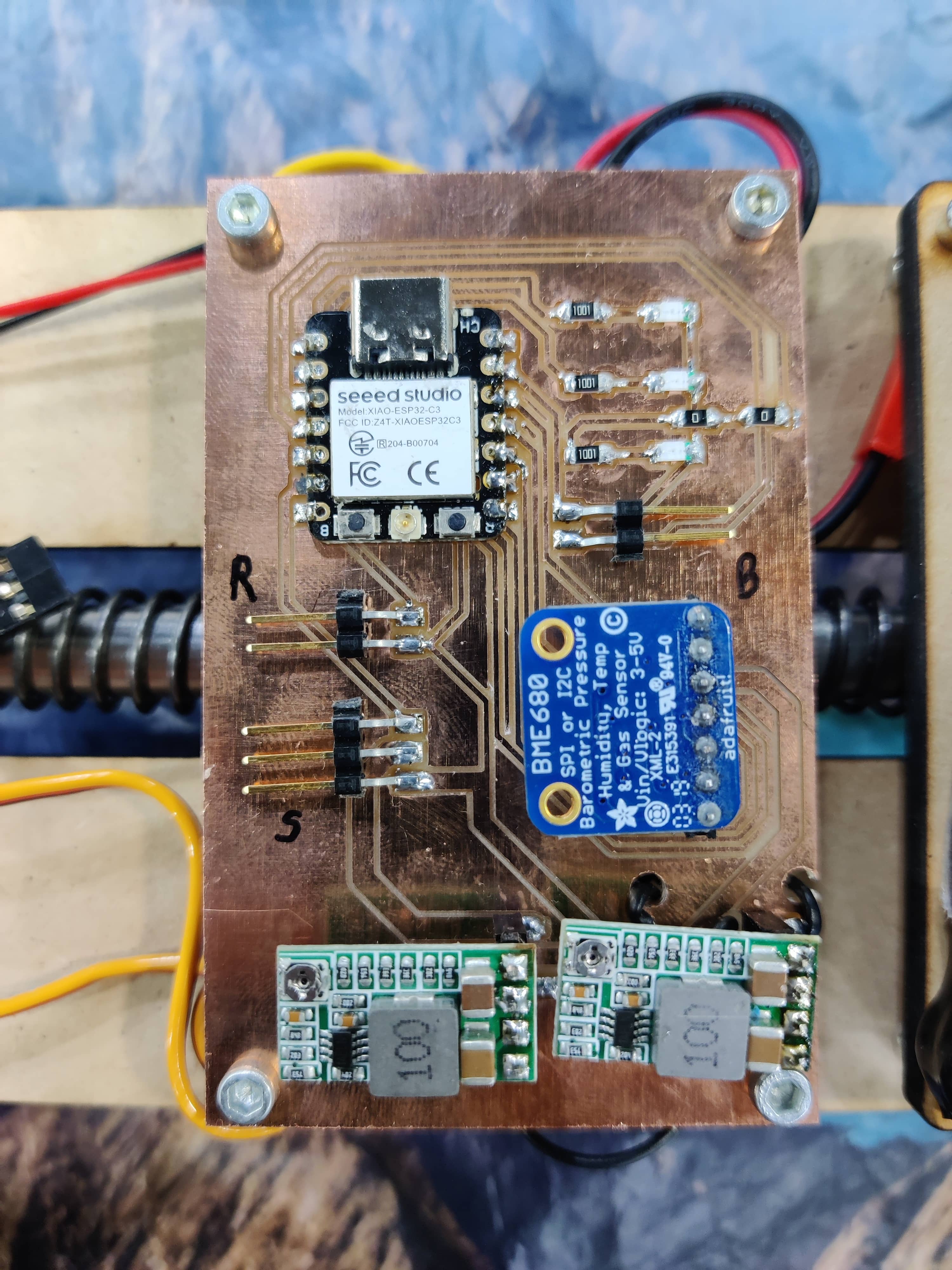

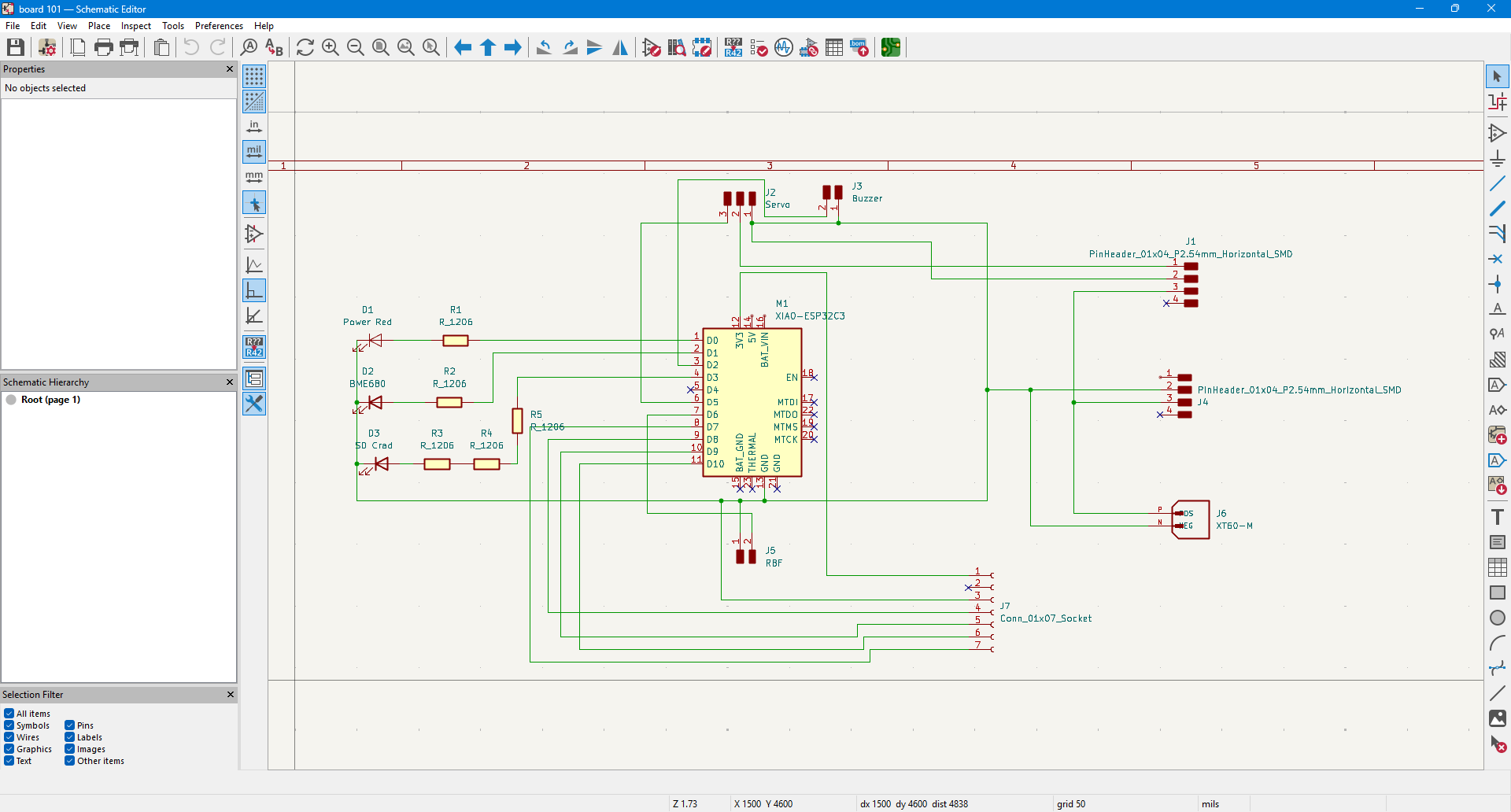

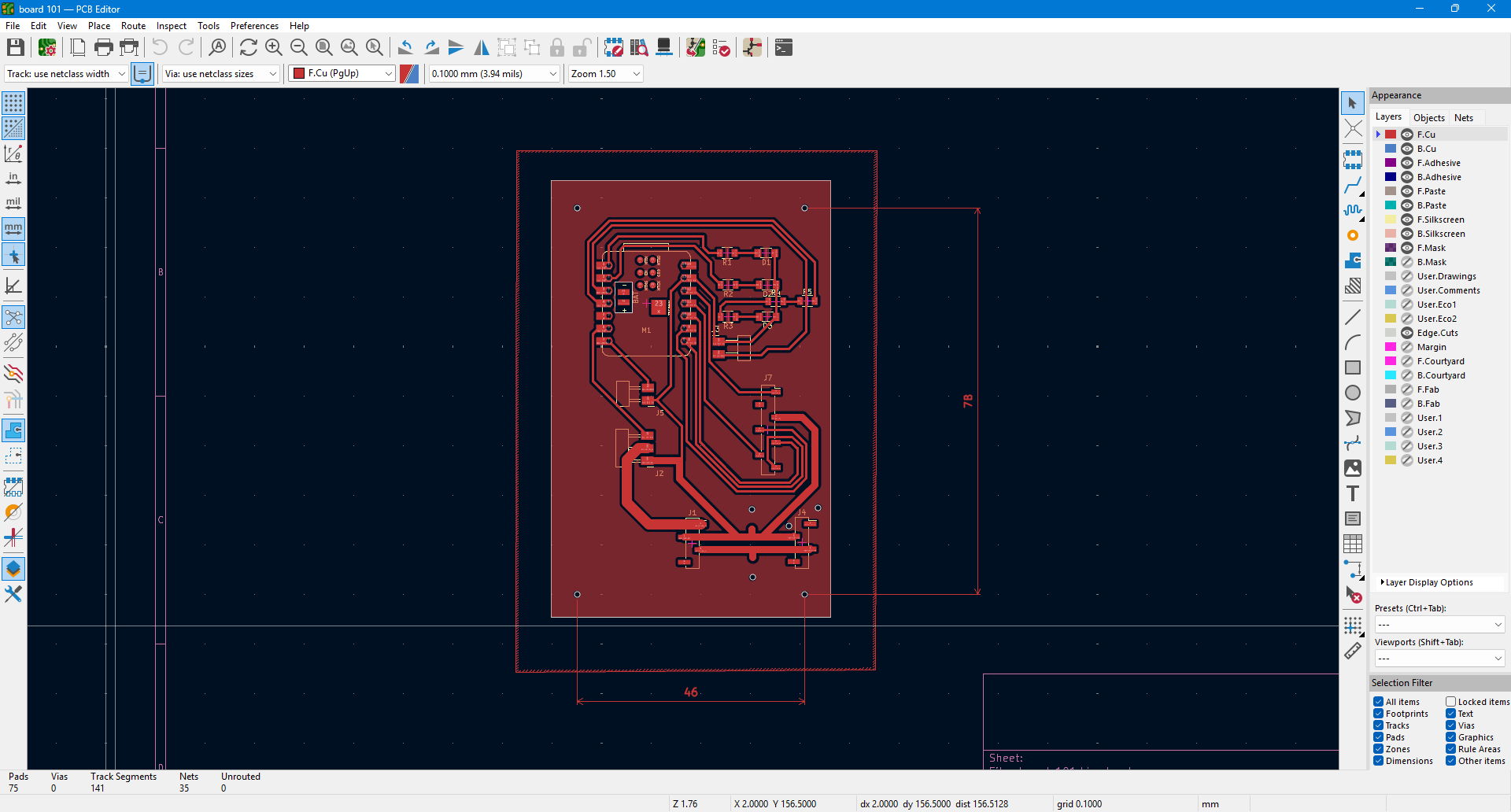

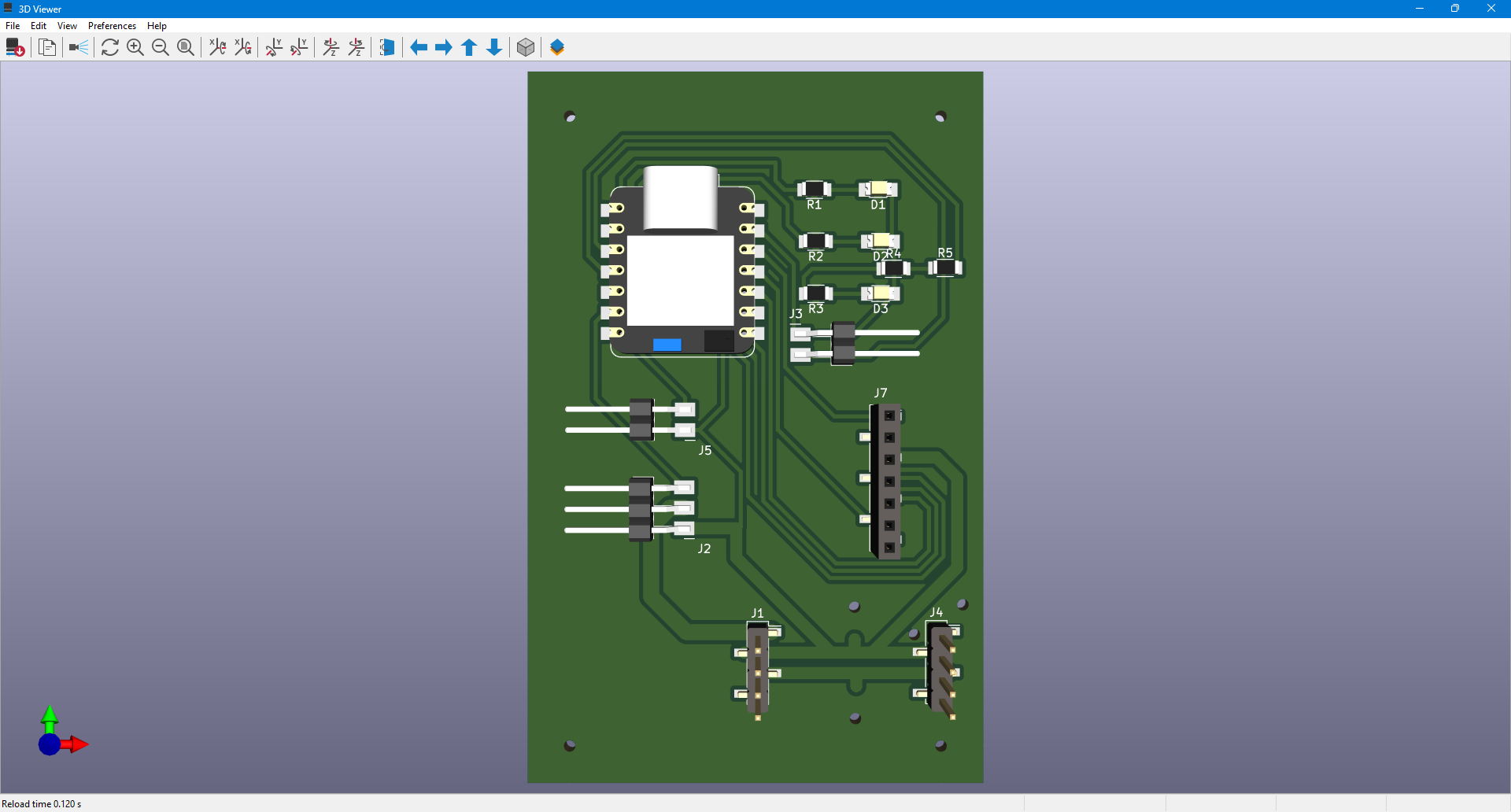

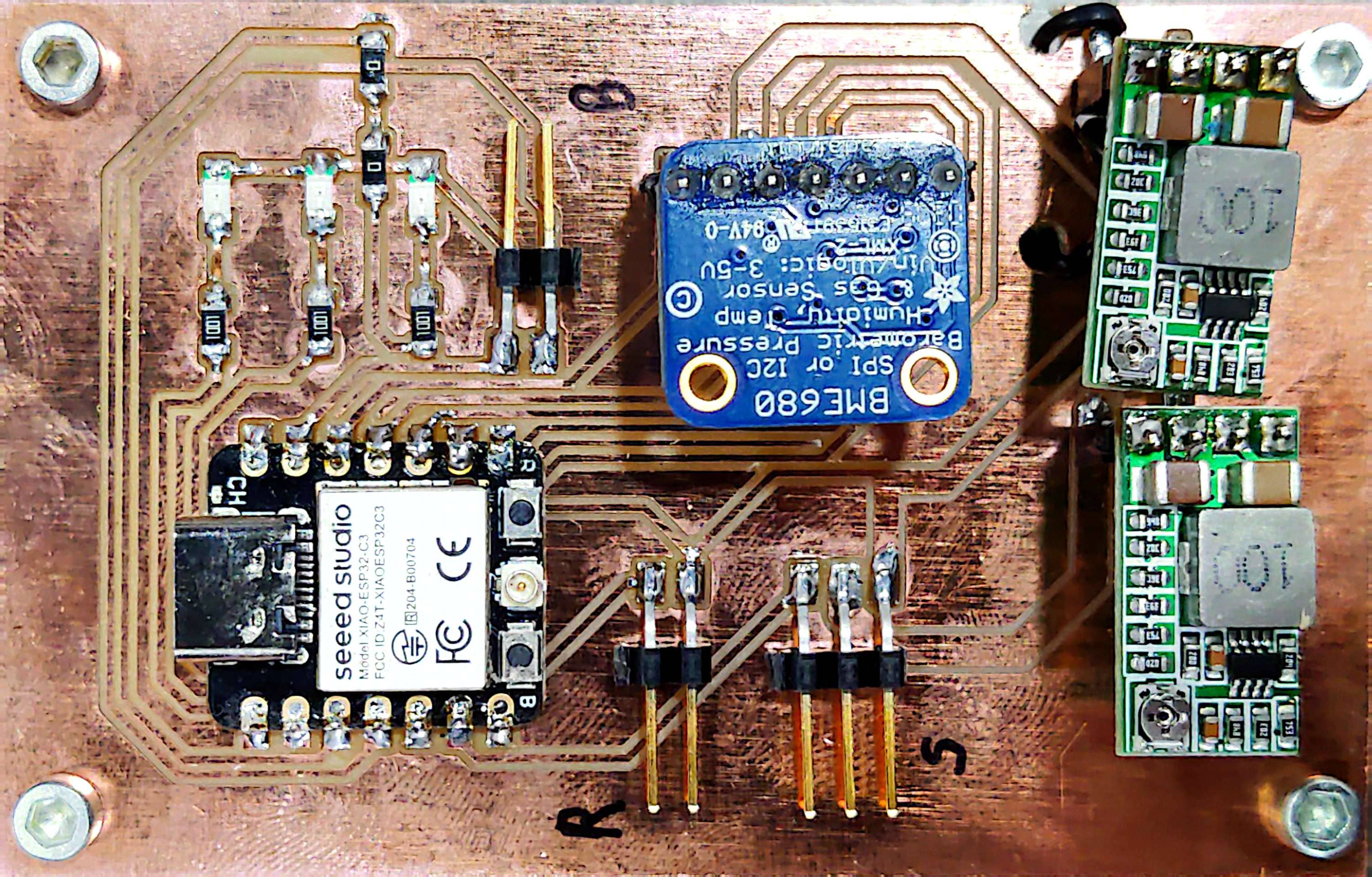

🔌 Electrical Integration

- Power Supply

💻 Software Integration

- Flight Sequence

System Logic:

1. Initialization (

setup()function)- Serial communication starts for debugging.

- Pin configuration is set:

RBF_PIN(Remove Before Flight pin) is input.

BUZZER_PINis output.

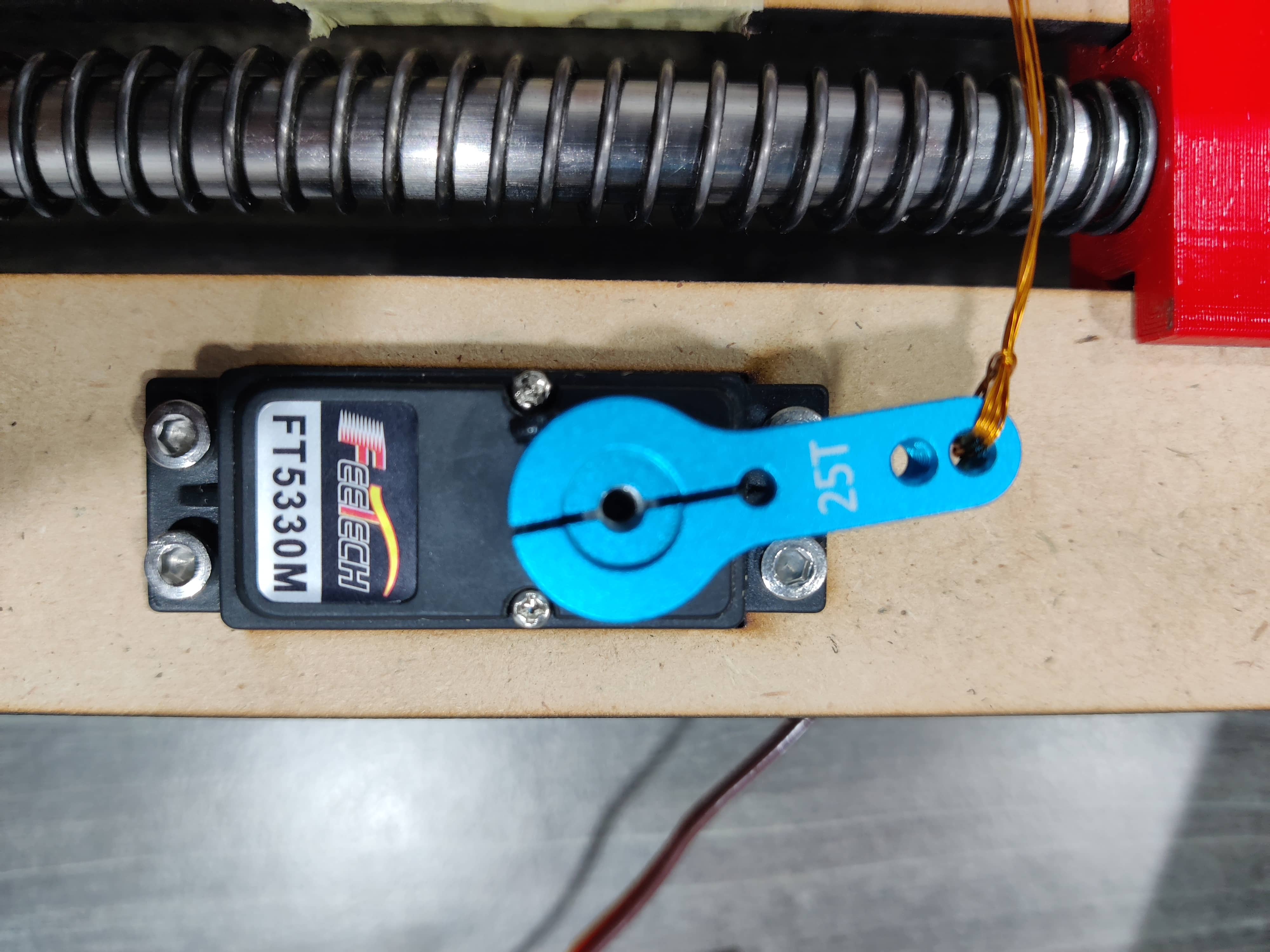

- Servo is attached and set to 180° (arming position).

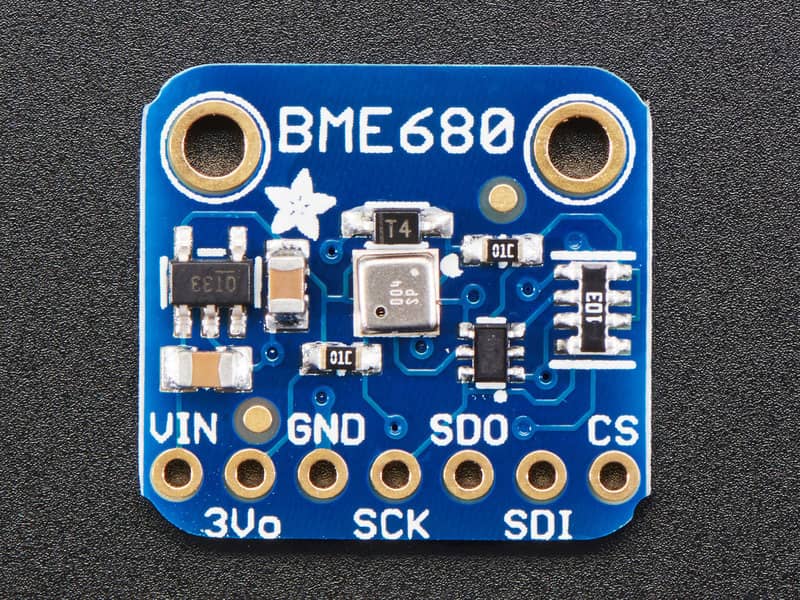

- BME680 barometric sensor is initialized and configured for accurate altitude readings.

2. Waiting for Launch Preparation (

loop()function)RBF logic:

- The system waits until the

RBF_PIN(Remove Before Flight pin) is pulled LOW (i.e., shorted or pulled to GND).

- Once detected:

- The current time is recorded in

rbfRemovedTime.

- The buzzer beeps once to confirm the system is armed and entering delay.

- The current time is recorded in

3. 2-Minute Arming Delay

- After RBF is removed, the system waits 2 minutes (120,000 ms).

- During this time, nothing else happens—this is your safety delay before launch.

4. System Starts After 2 Minutes

- After 2 minutes, the system:

- Beeps again

- Prints altitude to Serial Monitor for testing

5. Real-Time Flight Logging

- On every loop:

- The BME680 reads pressure.

- Altitude is calculated using the standard barometric formula.

- Altitude is printed on the serial monitor.

6. Apogee Detection (Key Logic)

- The code checks if the rocket is still gaining altitude.

- If altitude keeps increasing, it keeps updating

apogeeAltitudeandapogeeTime.

- Once altitude stops increasing for more than 2 seconds:

- Apogee is confirmed.

- Servo is activated → rotates from 180° to 0°, releasing the parachute.

deployed = trueis set.

7. Landing Detection

After deployment:

- The code monitors the altitude readings:

- If the altitude is stable (±0.2 m) for over 5 seconds,

- It assumes the rocket has landed.

- The buzzer is triggered to continuously beep so you can find the rocket on the ground.

What the System Does (Full Timeline):

- Power ON → System waits for RBF pin to be pulled

- RBF pulled → 1 beep → 2-minute wait

- After 2 minutes → 2nd beep

- Rocket launches → Altitude increases

- Apogee detected (altitude stops increasing for 2 seconds) → Servo activates → parachute deploys

- Altitude stabilizes after landing → Continuous buzzer sound helps you locate it

📦 Packaging & Professional Finish

Learning Outcome

- Understood the principles of system-level thinking

- Practiced multidisciplinary integration (software + electronics + mechanical)

- Developed a product that mimics a real-world aerospace system

- Enhanced reliability and maintainability through modular and organized design