Week 5 - 3D Scanning and Printing

This week focused on understanding 3D printing design rules, material characteristics, and how to optimize angles to avoid "spaghetti" effects in unsupported structures. Through hands-on testing and creative projects, I explored the capabilities and limitations of both 3D printing with PLA and resin printing technologies.

Tasks

-

Group Assignment:

- Test the design rules for the 3D printers

- Documentation of work on group work page and reflection on individual page of characteristics of the printers

-

Individual Assignment:

- Design and 3D print an object that could not be easily made subtractively

- 3D scan an object

Process explanation

Group Assignment

I collaborated with Lauri Hallman and Shahmeer Adnan Rana to test three printers in our Fab Lab:

Printer Capability Analysis

| Feature | FDM (PLA) | SLA (Resin) |

|---|---|---|

| Max Unsupported Overhang | 6mm | Unlimited* |

| Minimum Wall Thickness | 0.4mm | 0.2mm |

| Surface Finish | Visible layer lines | Optically smooth |

| Post-Processing | Sanding required | Washing/Curing |

Individual Assignment

Fusion 360 Design Process

Concept & Non-Subtractive Features

I designed a phone holder with integrated cable management, focusing on features that are impossible to create with subtractive manufacturing:

- Design was rotated 90% to reduce print time, and minmize support

- 3mm hollow cable channels

- Full support mode and a 100% infill

The curved arms grip the phone through internal overhangs, while the hollow channels prevent cable clutter – both features that milling machines cannot produce without disassembly.

Technical Specifications

| Dimension | Value | Rationale |

|---|---|---|

| Base Thickness | 5mm | Prevent warping during printing |

| Wall Thickness | 0.5mm | Balance between strength and material use |

| Overhang Angle | 60° | Avoid supports on grip surfaces |

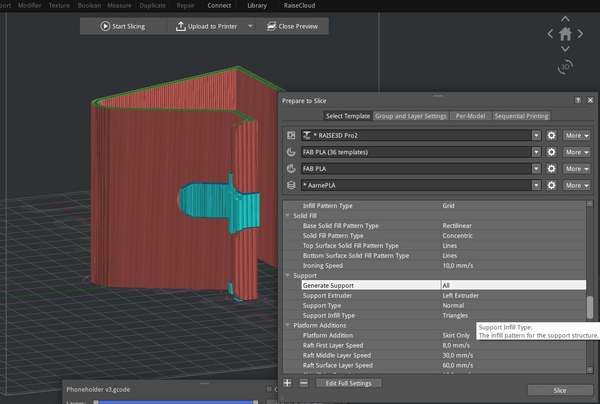

Slicing Strategy

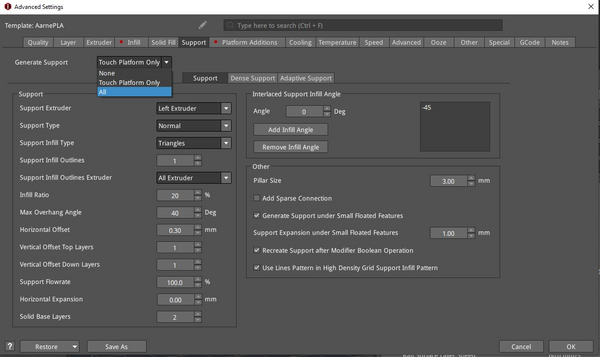

Critical Settings (IdeaMaker)

- Layer Height 0.2mm

- Infill 15%

- Supports All (Auto)

Printing Execution

Initial layer using 215°C nozzle/60°C bed

Hour 2: Support performance check

Post-processing with needle-nose pliers

Print Statistics

| Metric | Value | Tolerance |

|---|---|---|

| Total Time | 6h 30m | ±15m |

| Material Used | FAB PLA |

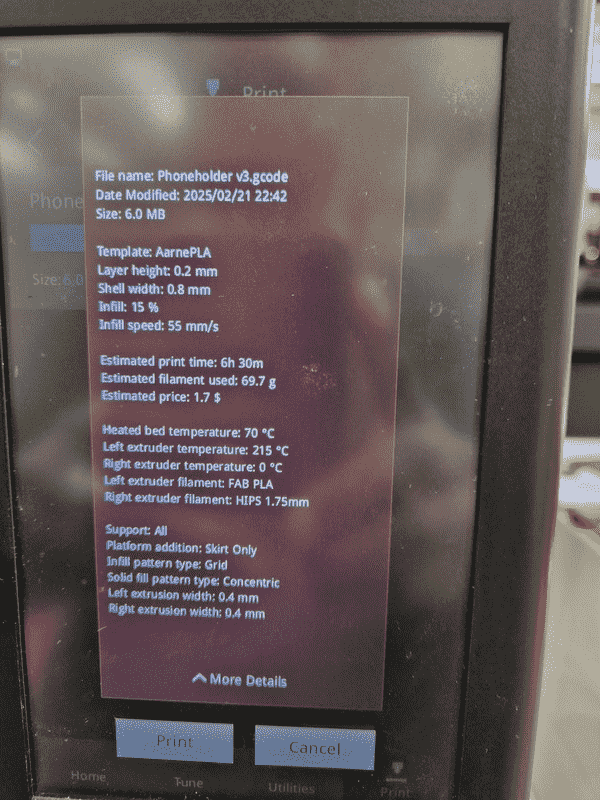

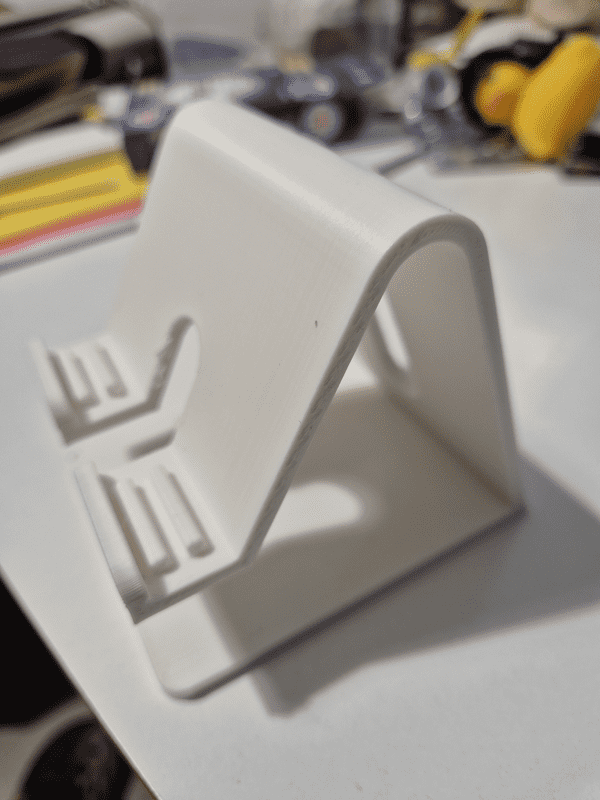

Final Result & Hero Shot

- All cables fit through 3mm channels

- No visible layer separation on curved surfaces

- Supports removed cleanly from hidden areas

Vase Scanning Workflow

Scanning Process

- Surface preparation should be done especially for transparent materials

- 6-angle turntable capture

- Mesh alignment in software

Before/After Cleanup

Resin Print Result

Resources Utilized

- Software: Fusion 360, IdeaMaker

- Hardware: Creality Ender 3, Creality Ender 3 Pro,

- Materials: Fab PLA+, Resin

Reflection

Summary

This week revealed the delicate balance between design ambition and 3D printing realities. While additive manufacturing enables unprecedented geometric freedom, each technology has its constraints - from FDM's support requirements to resin's post-processing needs. The scanning process emphasized that capturing reality requires both technical precision and artistic interpretation during mesh cleanup.

Main Difficulties

- Phone holder design: I would need to redesign the phone holder to hold the phone vertically better.

- Scan Artifacts: Addressed through multi-angle captures, and patiently slowly capturing.

- Resin Curing: Improved with UV station calibration

Main Learnings

- FDM requires ≥60° overhang angles for clean prints

- Resin safety protocols (gloves, ventilation)

- 0.4mm minimum wall thickness for structural integrity