Rules and guidelines are only reminders but Safety glasses and hearing protection are a must. Every person must know lab safety manual, machine manual, and be trained by appropriate person before using the cnc.

As we know the CNC router to be a precise, powerful and expensive piece of machinery. Each use must be approved by supervisor, below are the safety indication for the devices in the pictures above

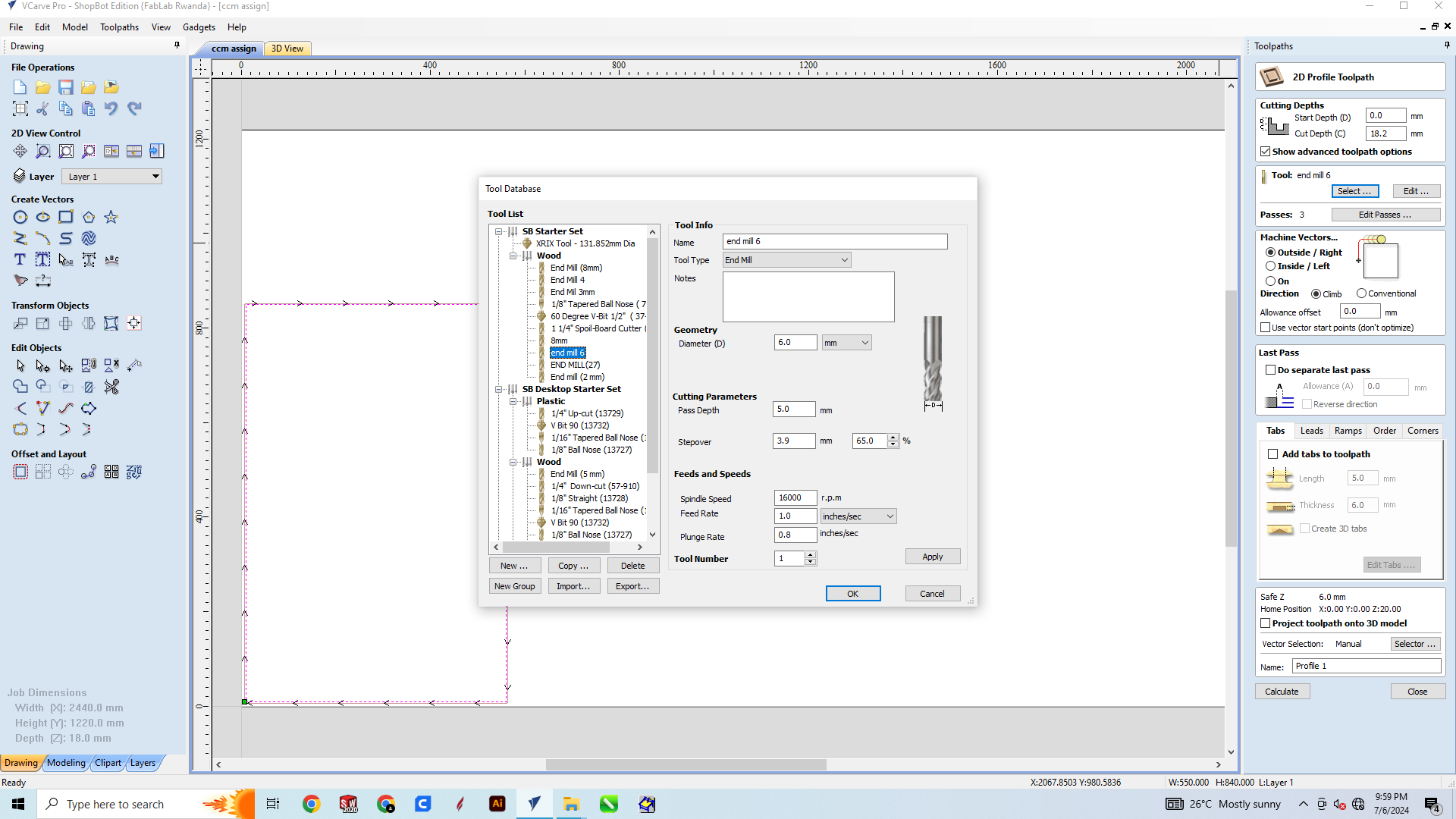

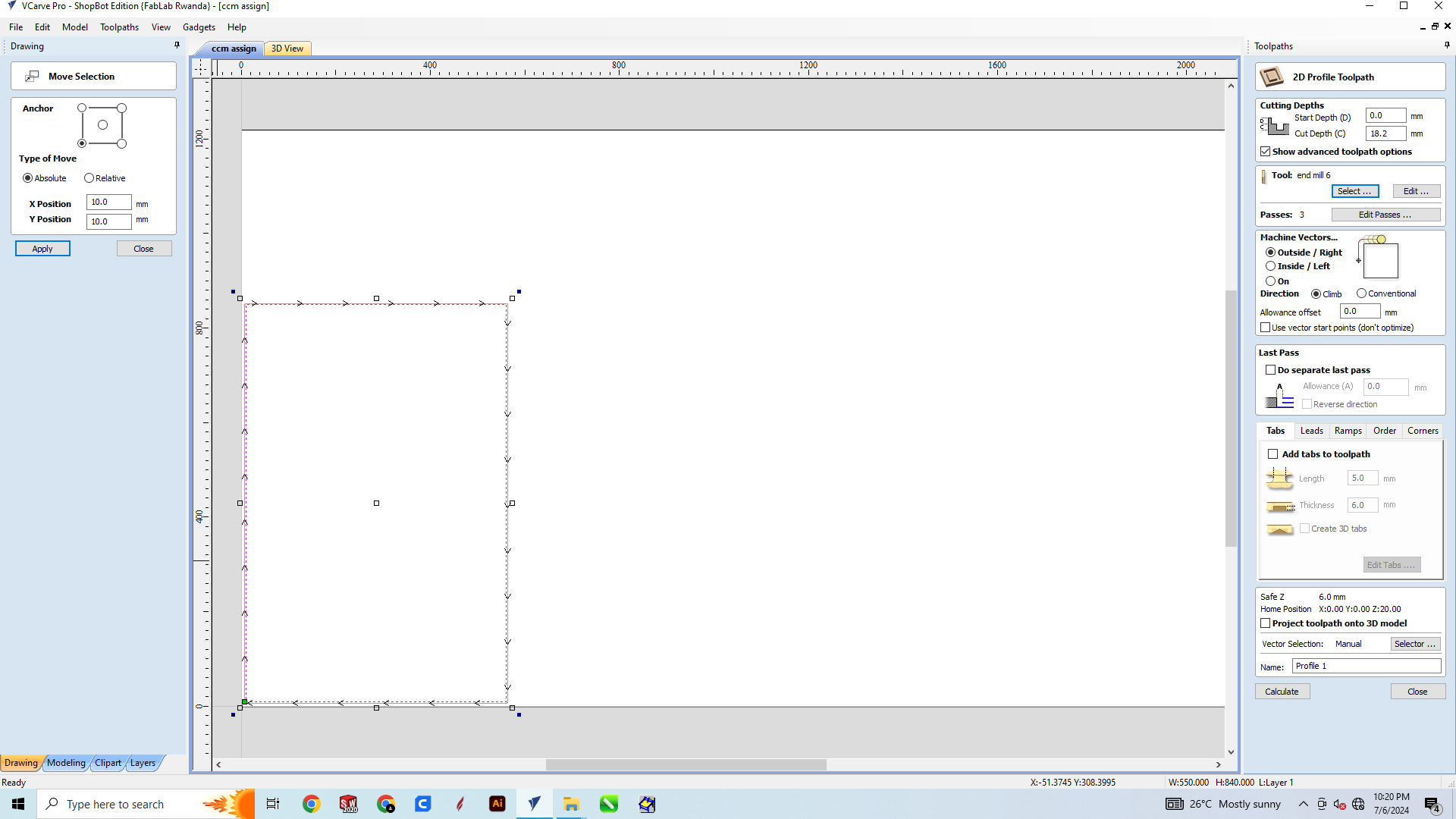

For our lab machine test runout i was able to realize that for the mdf material with a thickness of 18mm, a rectangular shape with a size of 840MMx550MM was cut and this actual size wasn't equal to the design size exactly, there was a difference in size of 2MM on both sizesi got this results having set the parameters for the toolpaths the following.

So as you can see by calculating the toolpath then due to the tool being set to cut the outside of the part to give us the actual size equal to the design sizes it wasn't done to the Absolute perfection by 2MM more to the design sizes. As for the design sizes the for the cut out compared to what the actual cutout sizes were there was a difference of 6MM more than the design size.

We learned that the output of the machine becomes different depending on how you set the toolpath, what part of the material you need from the piece thats been cut whether if its the cutout or the inside part. THe feeds and speeds depend on the on what kind of material you use and how thick it is. Aligning files on the workspace is done using a feature in the commands called Move Selection, feeds is set depending on the type of material we using; so we have the plunge rate is set between 0.6inches/sec-1.2Inches/sec while the feedrate is set between 0.8inches/sec-1.8inches/sec whereas speed is set to 16000rpm and is affected by the tool diameter and it is also affected by the stepover the lower this stepover the longer it takes for the work to fininsh. We set ours to 65%. We worked with MDF materail but i'm also familiar with acrylic. As for the number of passes while calculating the toolpath,it is set according to the type of material, the tool diameter, the feeds and speed.