7. Computer controlled machining

This week we design and build something big (It can be furniture, models, sculptures, etc.) We learned to use CNC machine, we desing a prototype in CAD software, we use a preprocessor software in order to generate the cut trajectories and adjust cut velocities and revolutions. we supported the MDF of 15 mm tickness on the Router CNC and we were cutting with a tool of 1/4" inch a model of Zeppelin of 1.4m of large

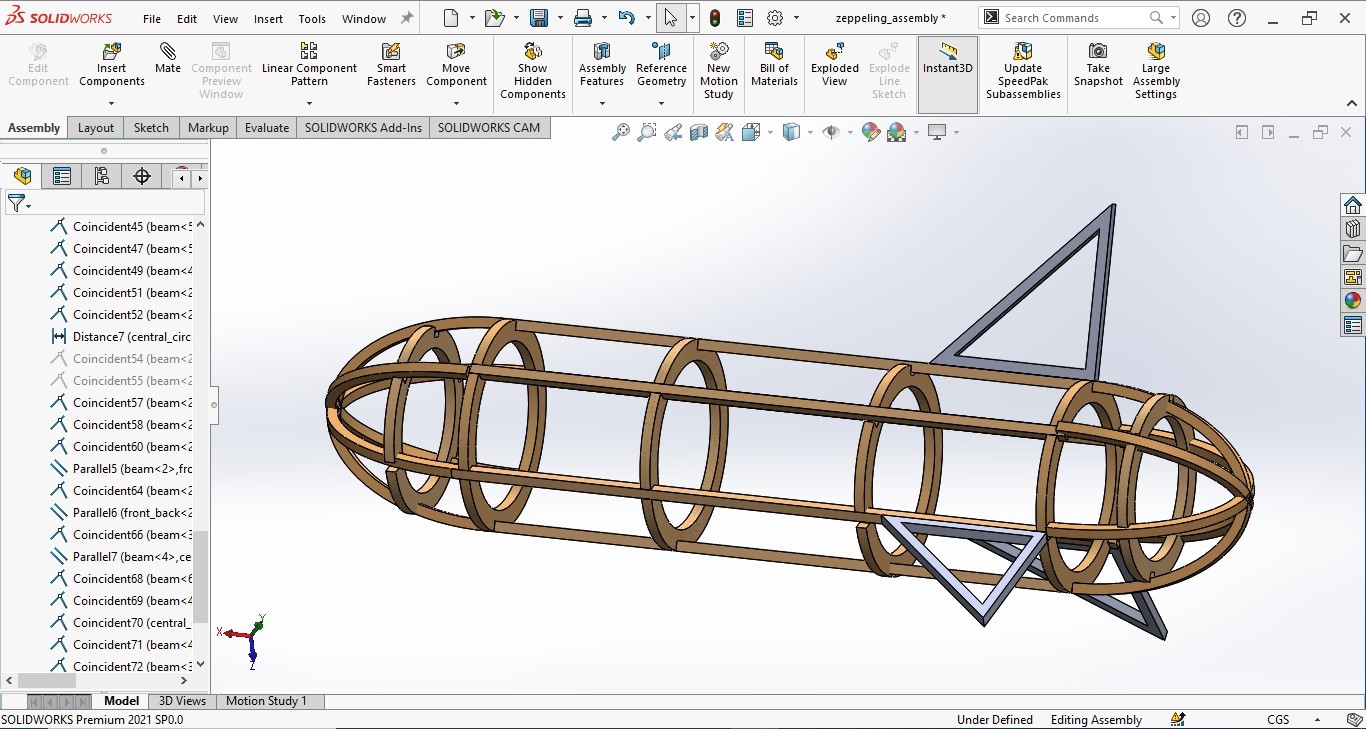

CAD design

We use our Zeppelin CAD desing and scale it in order to obtain a big model, the Zeppelin model is with 1.4 meters length and 0.3 meters width.

The Zeppelin scaled is show in this figure

Vcarve Pro software

VCarve Pro brings the third dimension under your control with the ability to import and toolpath a single 3D model. With unlimited job and toolpath size, true shape nesting & job set-up sheets

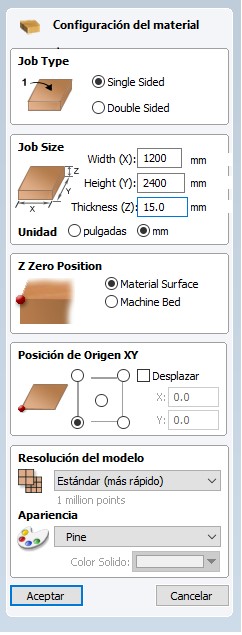

First of all we open the software Vcarve Pro

We configure the material, in our case it is a MDF sheet,

also configure the zero tool, and the zero

position

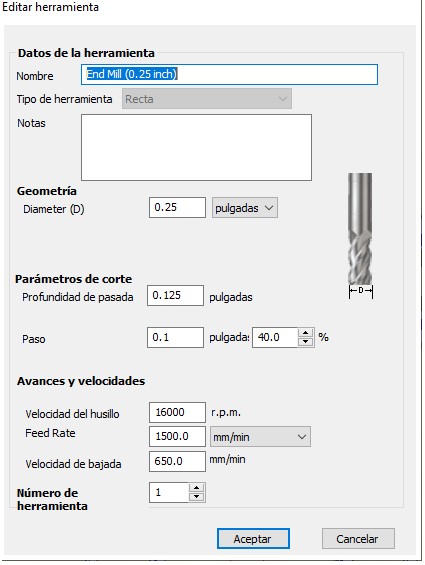

We configure the tool, it name is End Mill, with diameter

of 0.25 inch, also configure the cut

parameters,

and cut veocities and feed rate

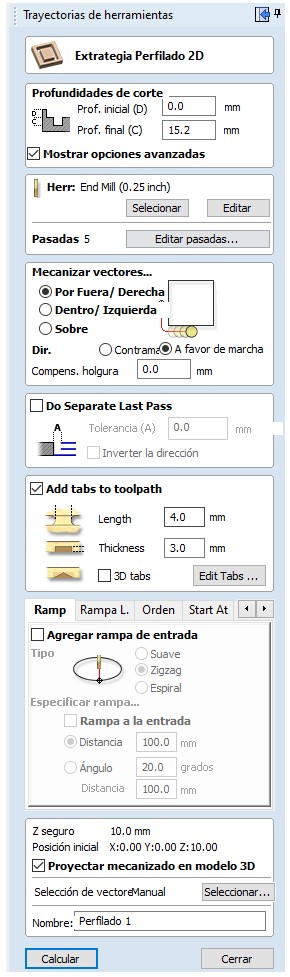

We configure the toolpath and tabs

We open our model files .dxf and they are inserted

on the main window, we select the toolpath and tabs

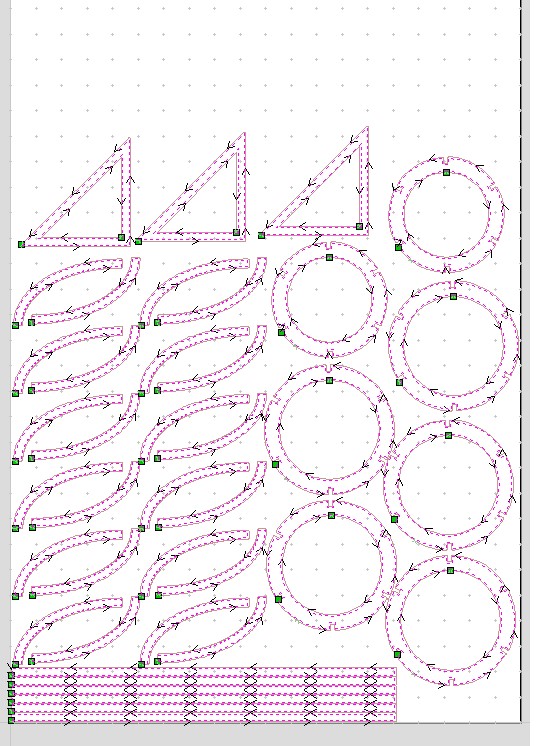

as is depicted in this figure we can observe the

resulting toolpaths with directions

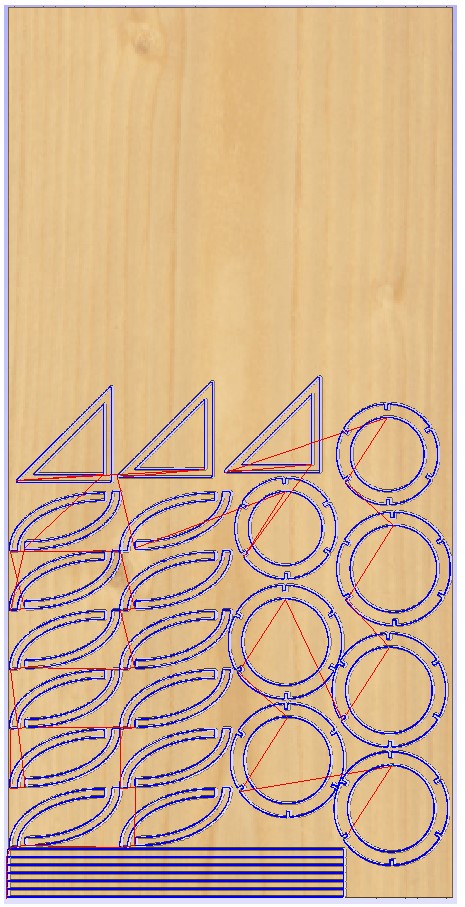

A simulation of cut process is show in this figure

Router CNC cutting process

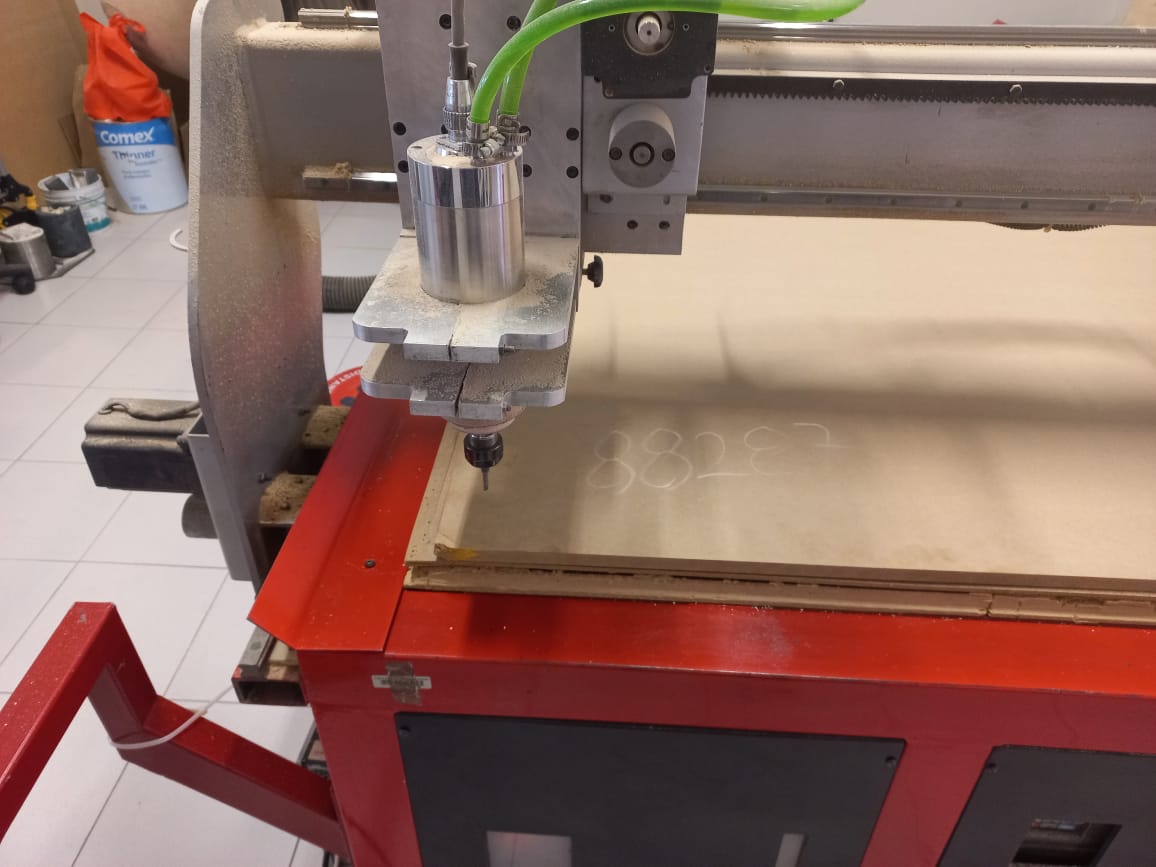

We use a CNC router ASIMA, the first step is to fix the MDF sheet with nails

We fixed the MDF sheet of 1.2m width 2.4m large

and 1.5mm thickness with nails on the CNC Router

We make sure that it is well fixed

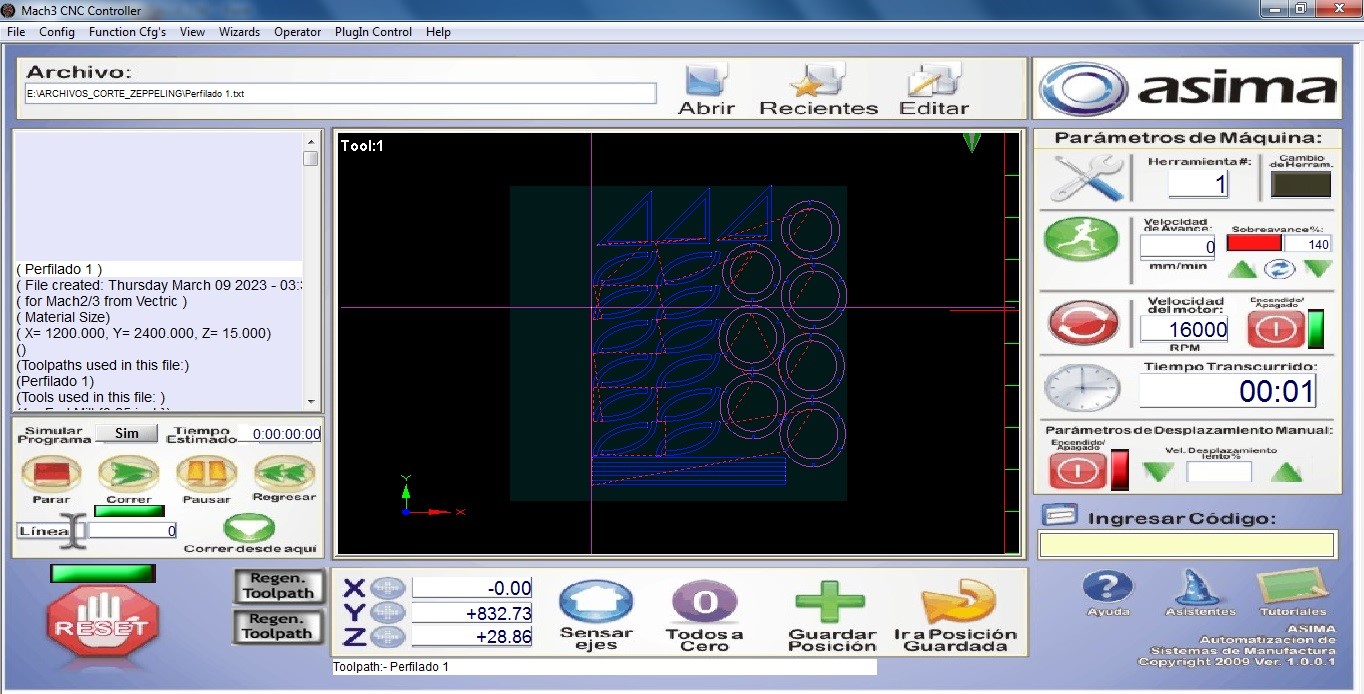

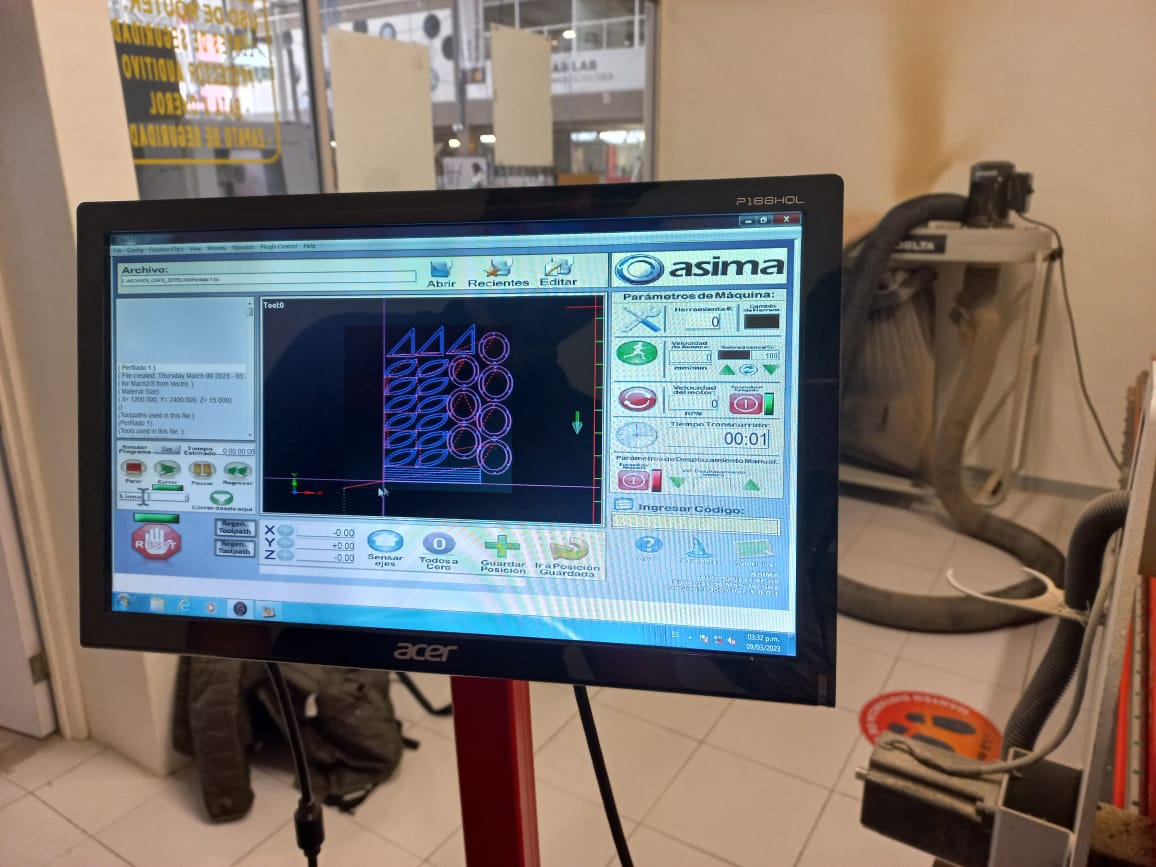

We open Mach3 CNC controller software and open our file .nc

We move the machine to the zero tool, and the zero position

We configure the zero tool, and the zero position on Mach3 software

VIDEO CNC ROUTER CUTTING

We start the cut proccess as is shown in this video

Final model ensambled

We ensambled the Zeppelin model but due to its large size we had to use wooden dowels to hold it. Final Zeppelin ensamble with diffetent views are presented in the following figures.