5. 3D Scanning and printing

This week we used different 3D printing machines and materials in order to compare its main features and functionality. we also identify features that could be used in our final proyect.

Mario Ramirez Neria - Fab Academy

This week we used different 3D printing machines and materials in order to compare its main features and functionality. we also identify features that could be used in our final proyect.

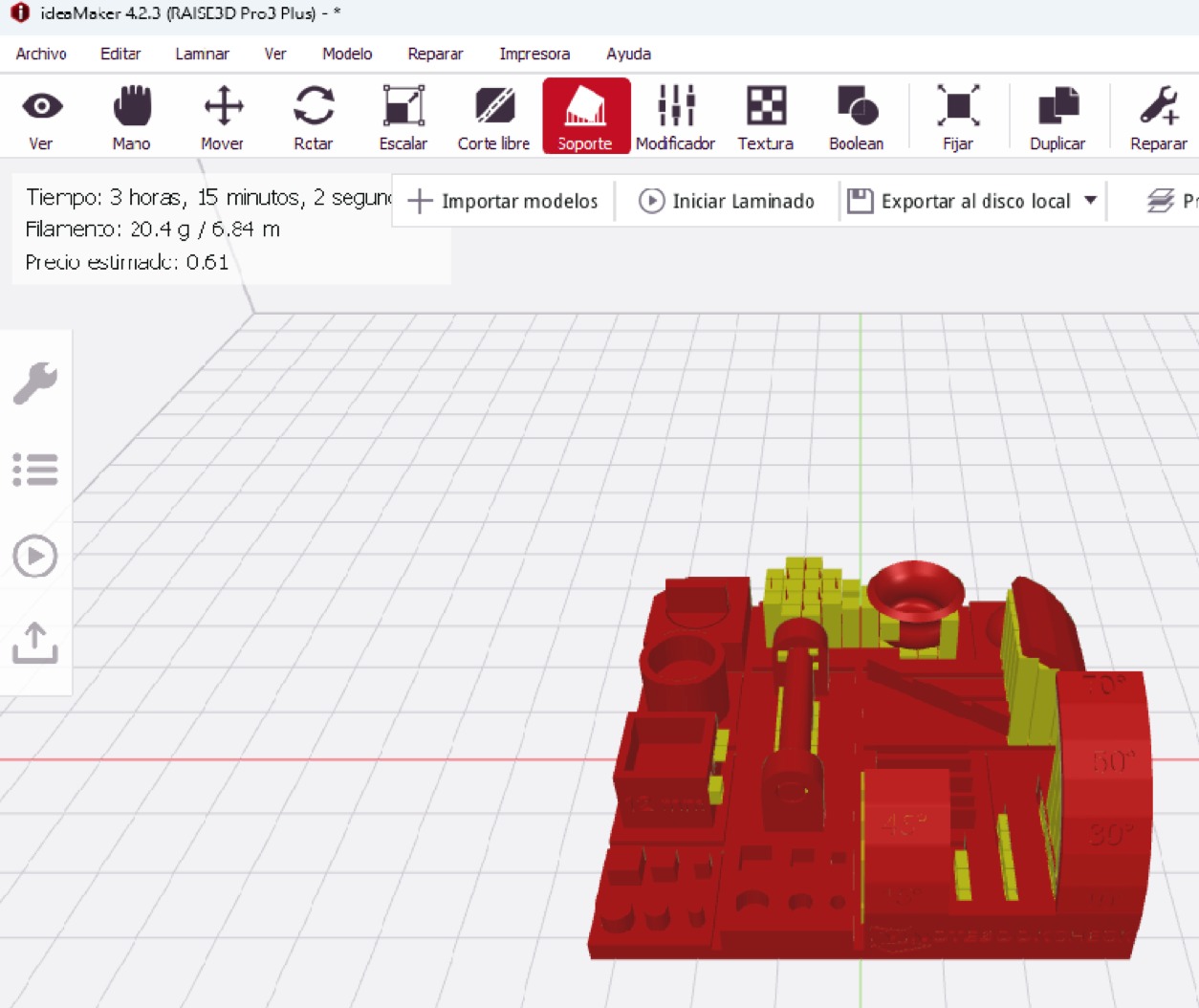

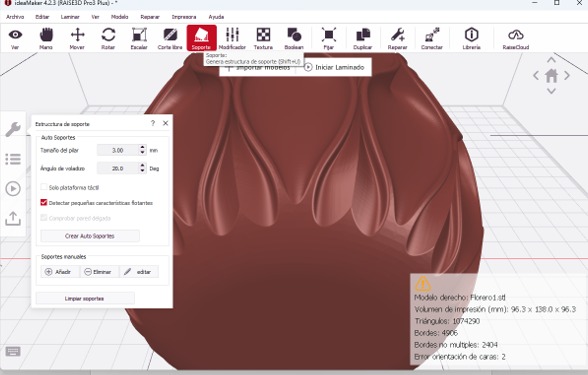

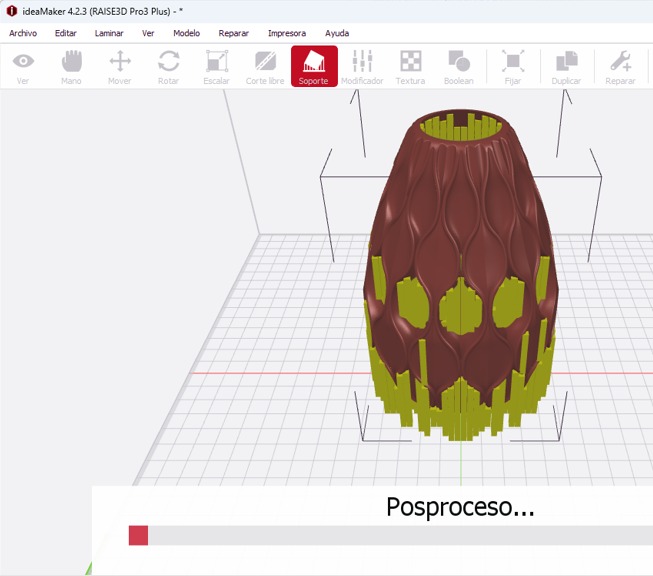

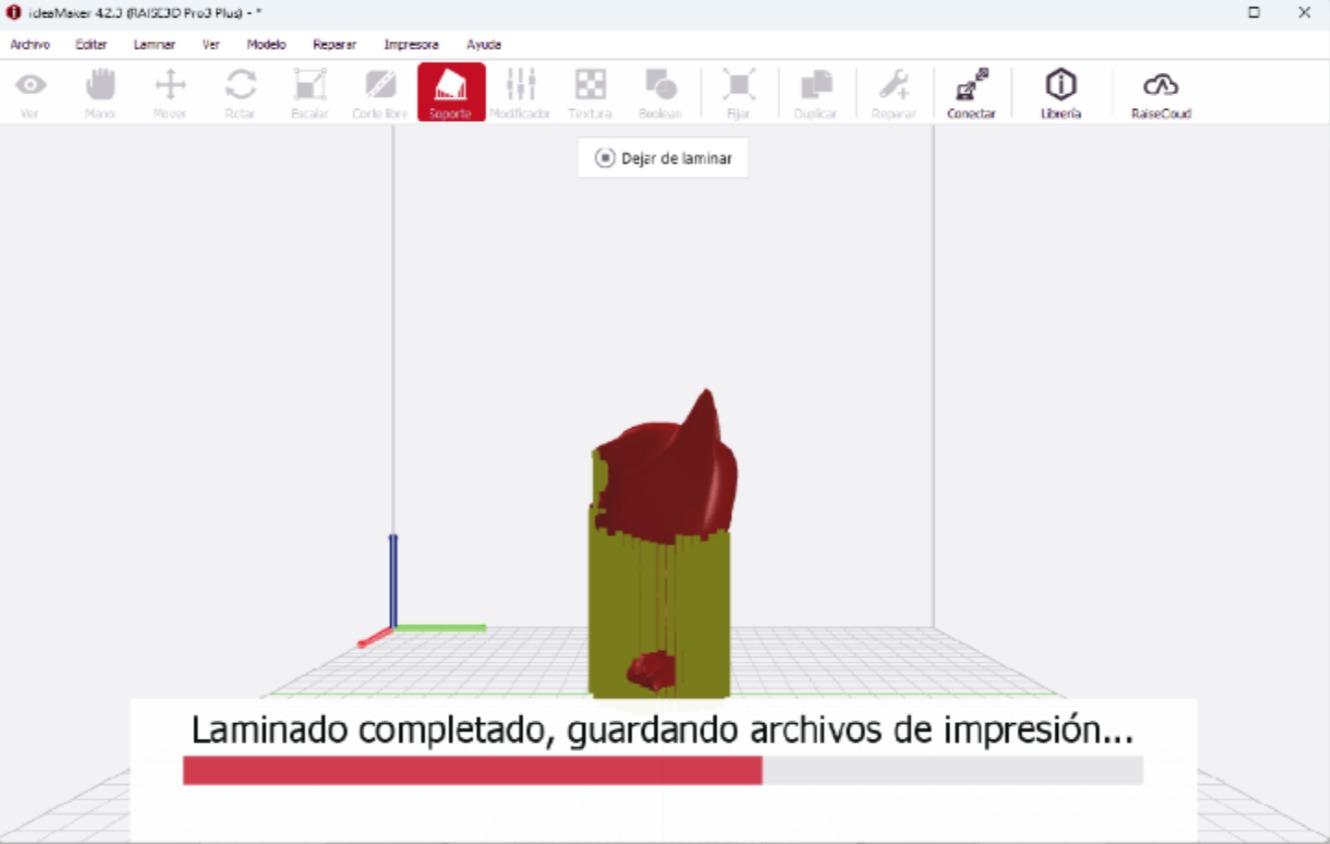

We use ideaMaker for the stl format, here added support

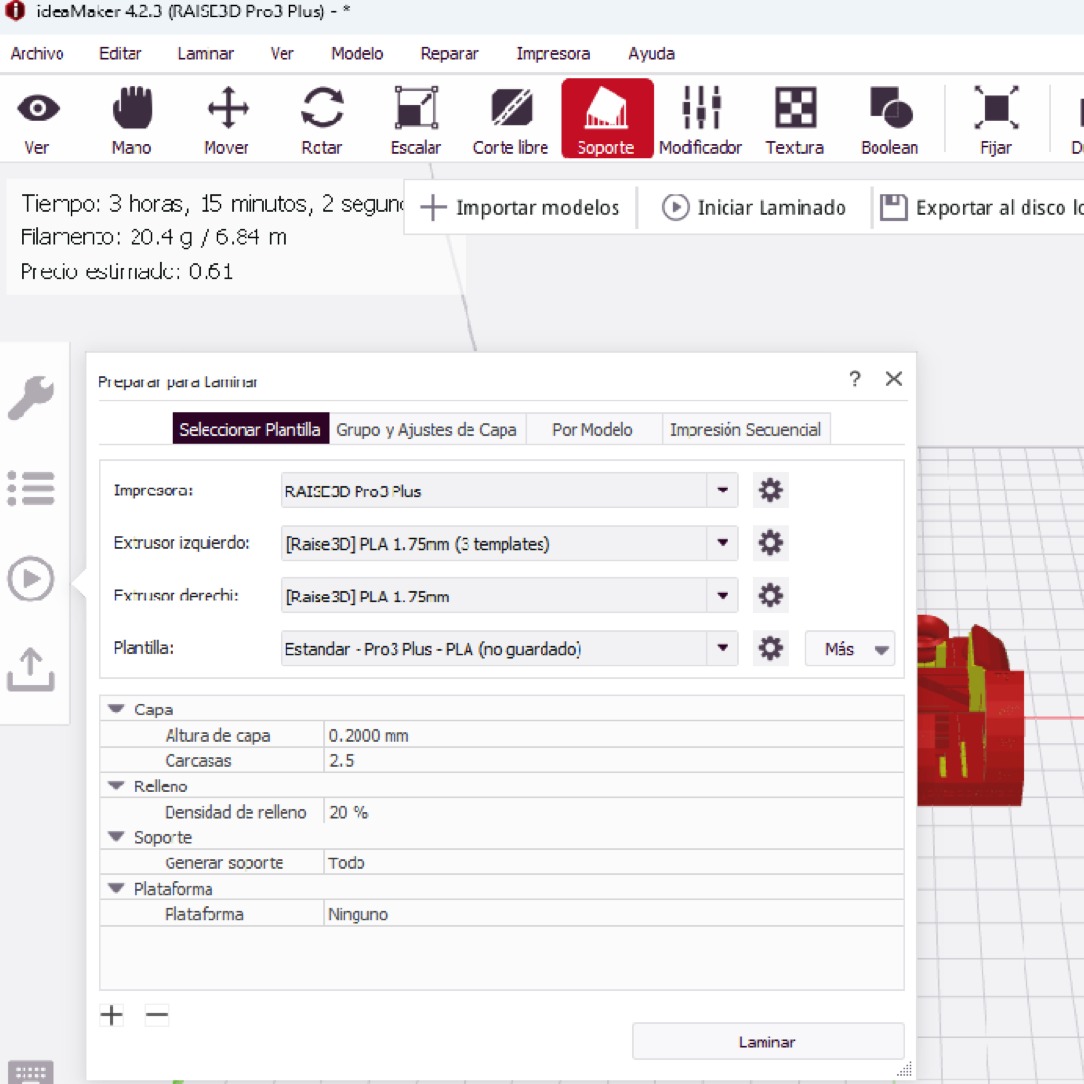

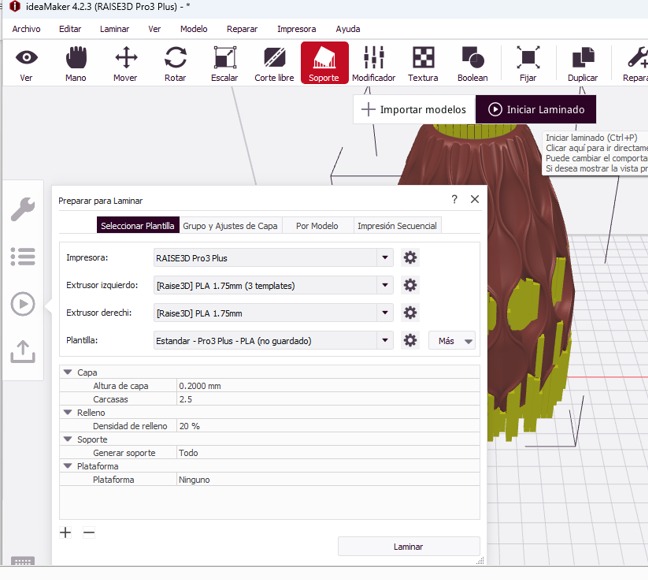

Select extruder and print quality before laminating

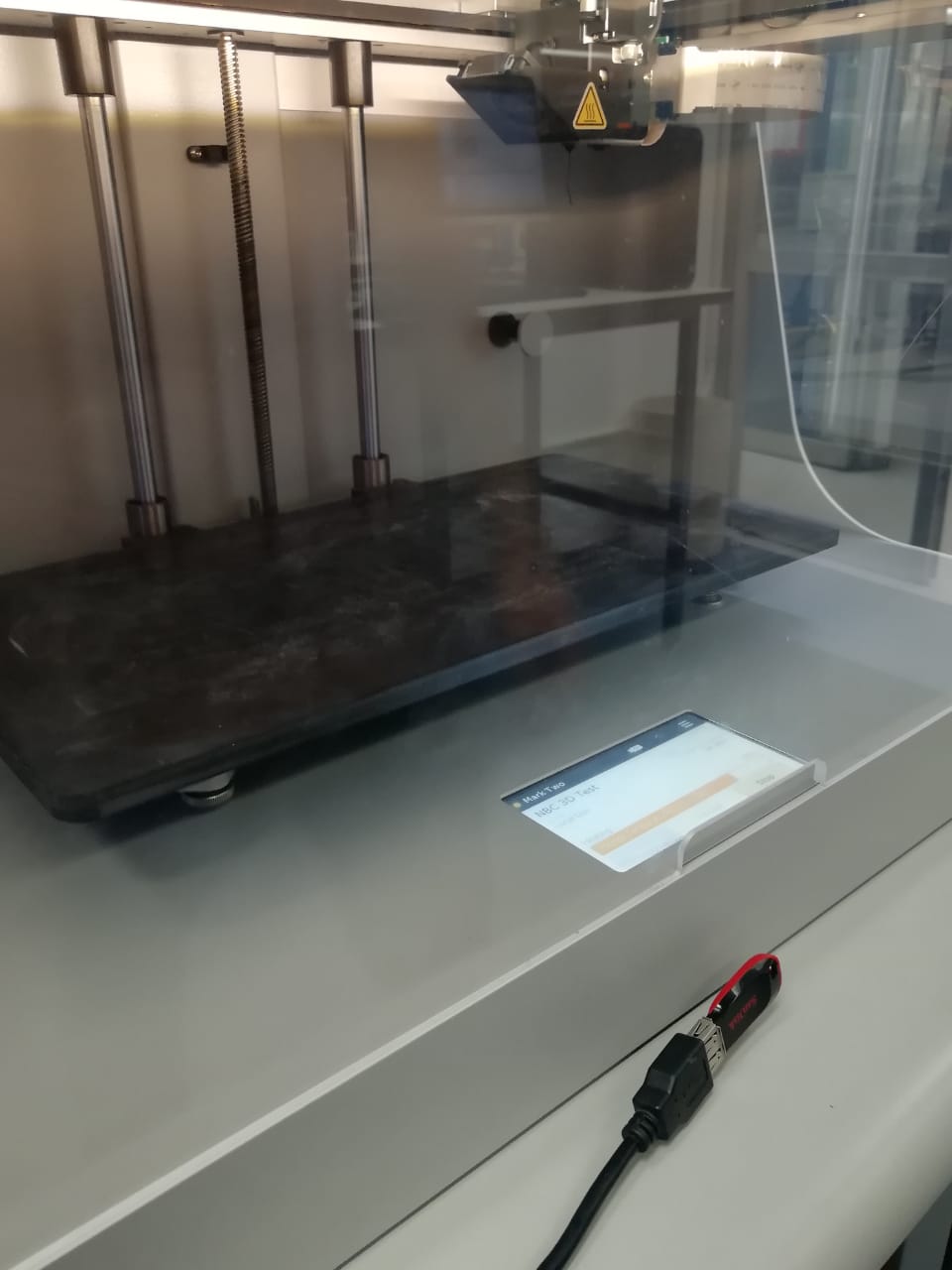

ONYX printer Markforgerd

Load the file

Processing data and extrusion time

We see that the file is already progressing

and we can let the printer work

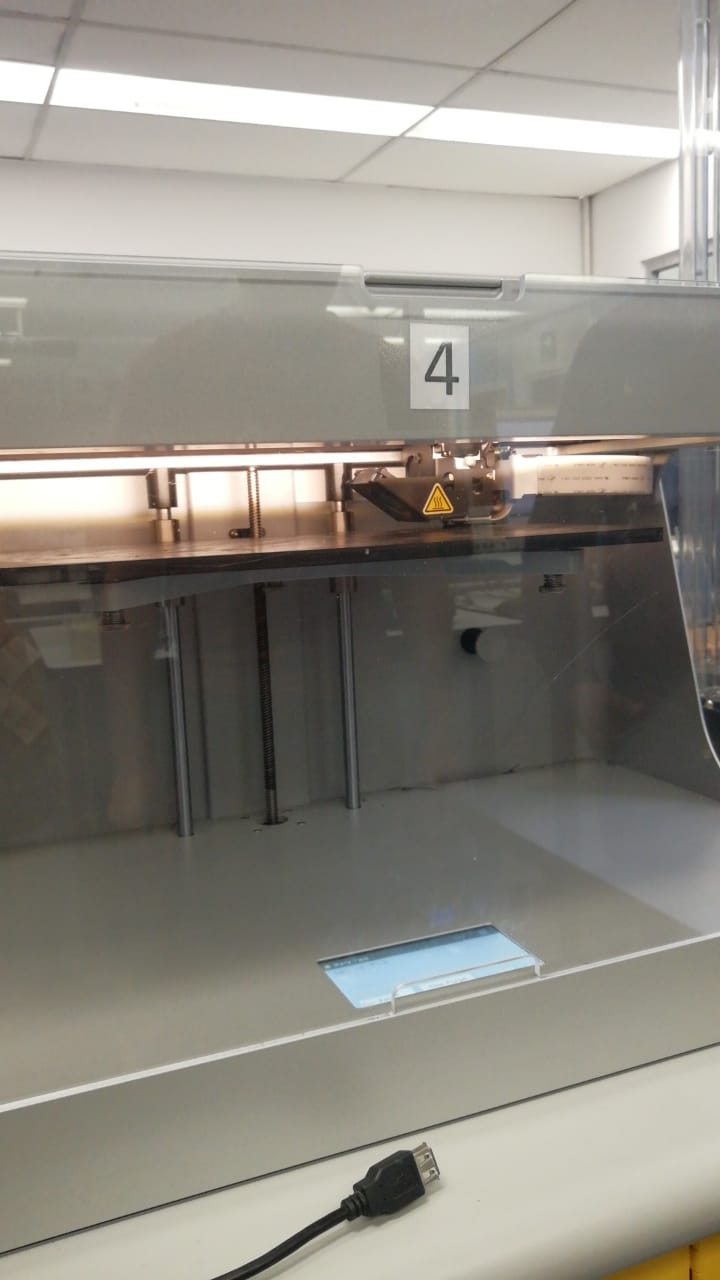

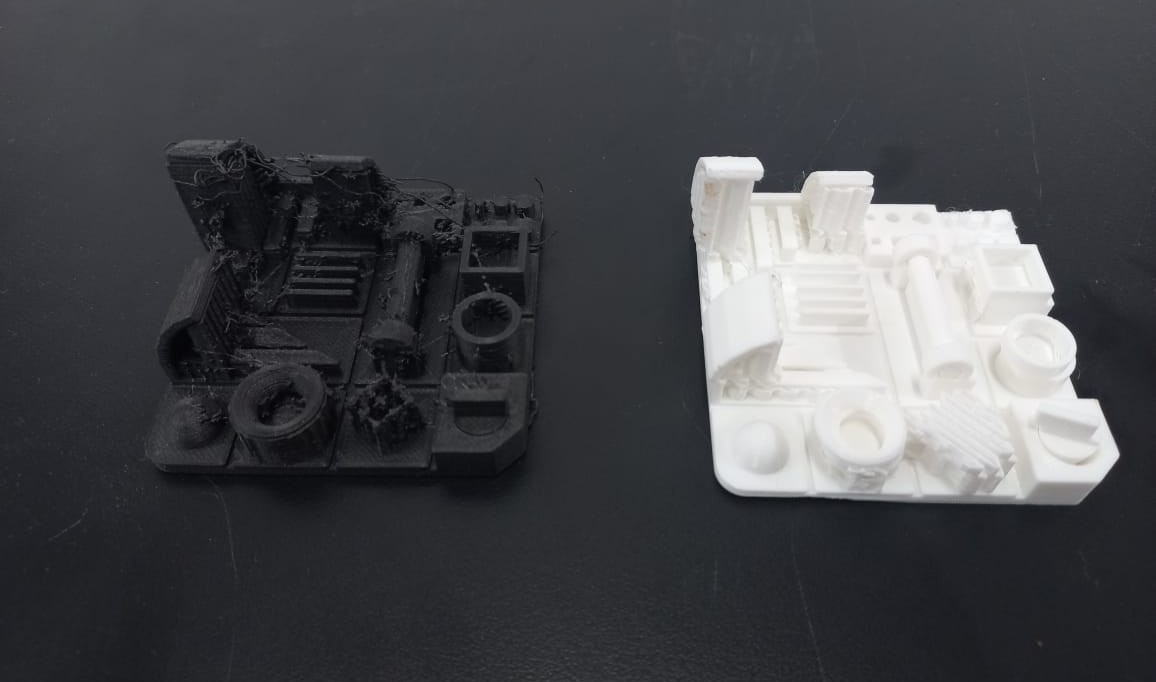

Raise3D Pro 3 plus, this is also used for

the printing the white piece

Results with Onyx and raise 3D

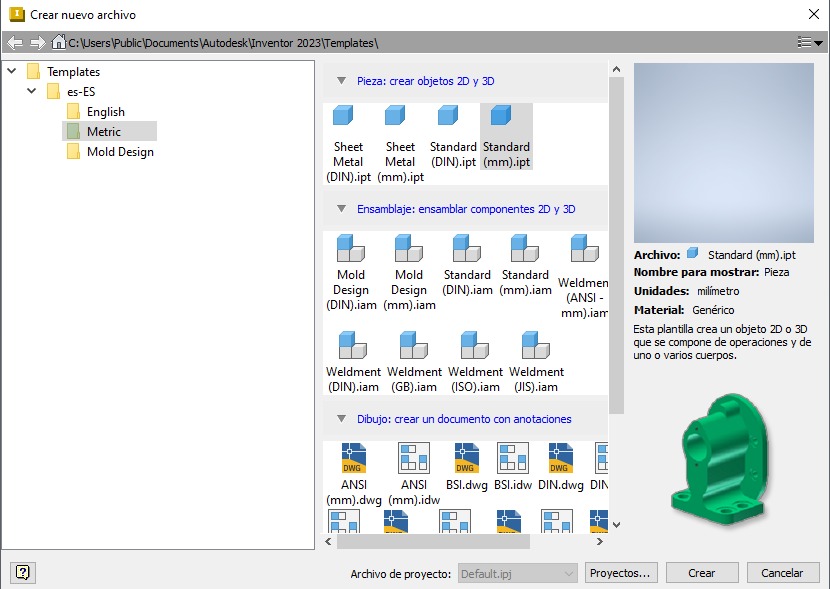

Autodesk Inventor Professional 2023 is the software that

was used for this design process.

We select the option: "New" in the upper left, and in the option

we choose: "Standard(mm).ipt", the we

click on create.

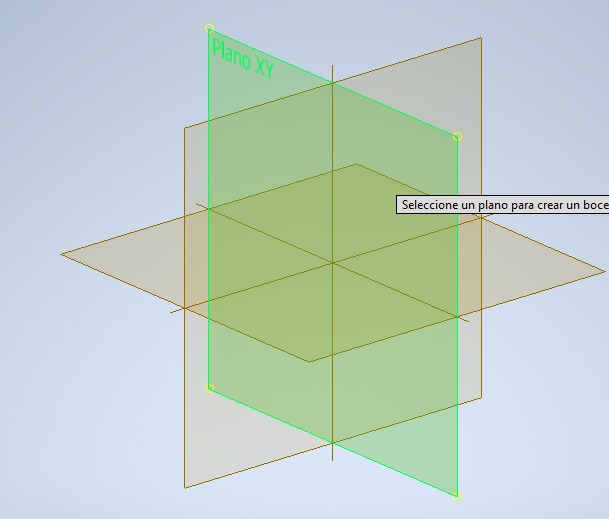

Create a new 2D sketch. We choose the XY plane.

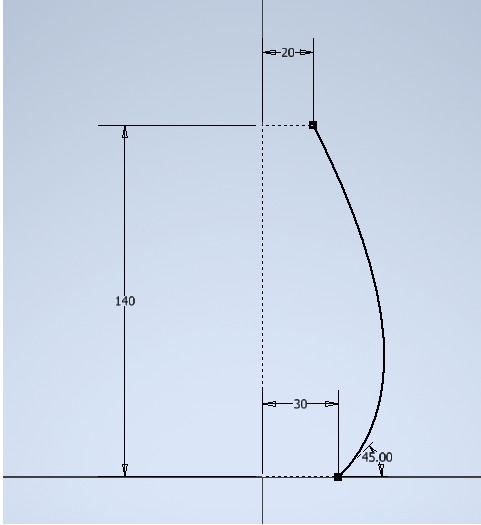

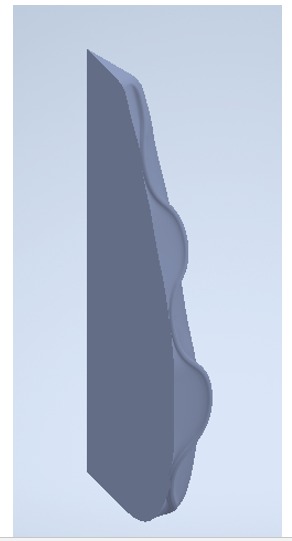

Initial sketch. Here is the base figure of the expected design.

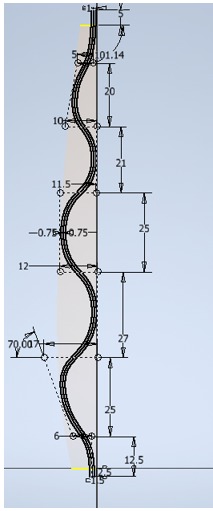

Sketch to make the snake-line pattern.

For this, the symmetery was used,

first we have a mirror of the first design,

then with the surface we make

rule adjustments,

we remove the faces thah we do not used

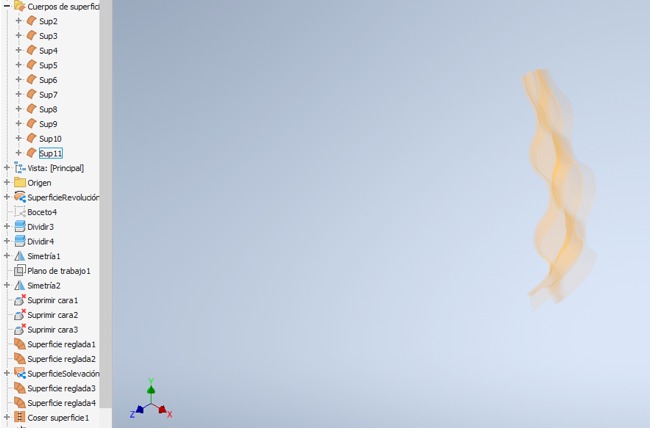

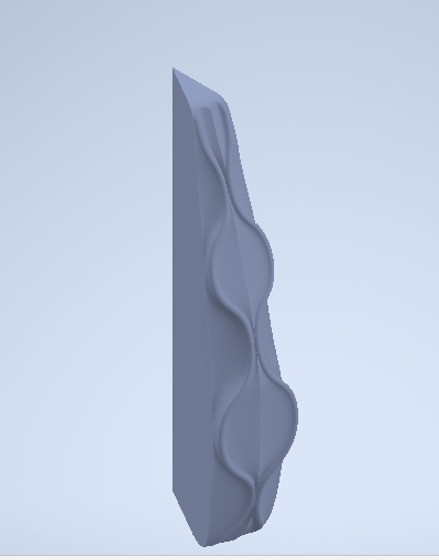

Sketch extrusion.

Symmetry of the extrusion

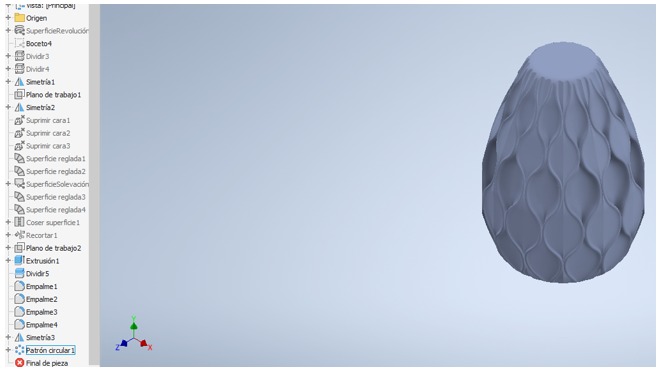

We created a circular pattern of 12 repetitions

to be able to otain the cylindrical shape.

Here a new sketch was created on the top face

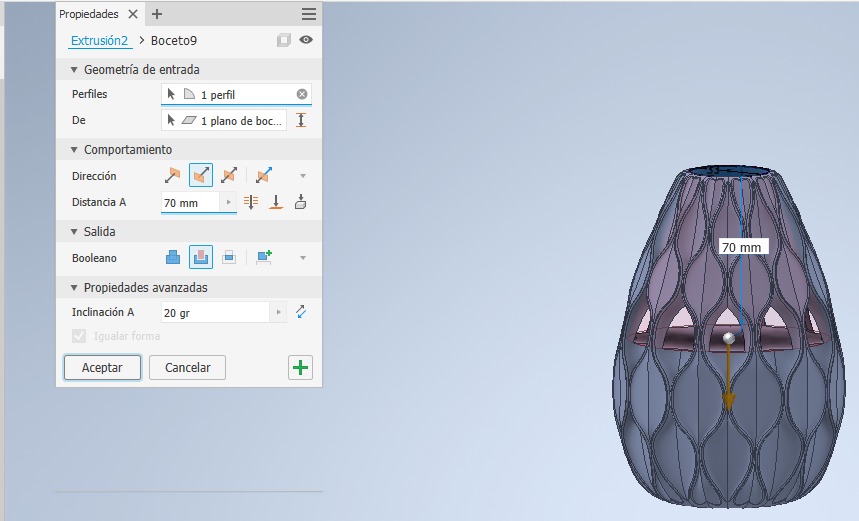

We created a 33mm diameter circle a 70mm extrusion

with 20

degrees to follow the geometry

Once we have the 3D part modeled, it is exported in .stl format so that it can be read by the ideaMaker software.

This is a software:

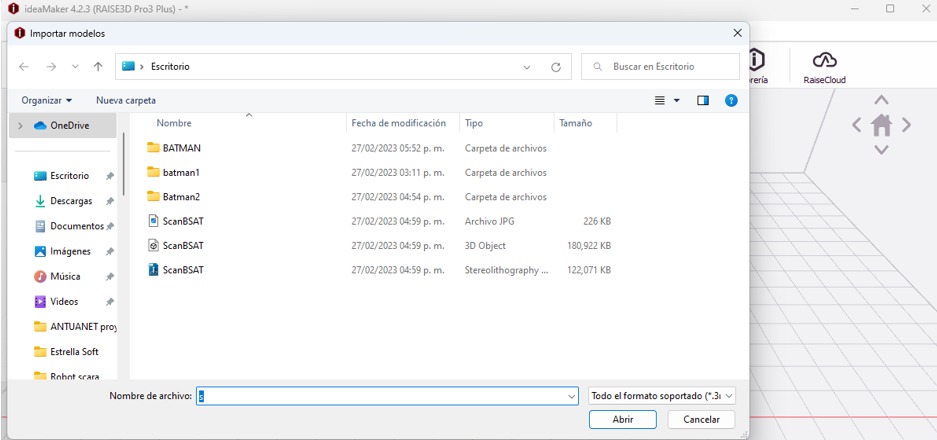

First we select the file in stl format

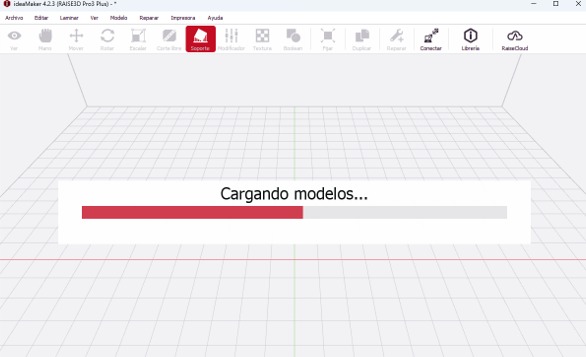

We hope the model is loaded

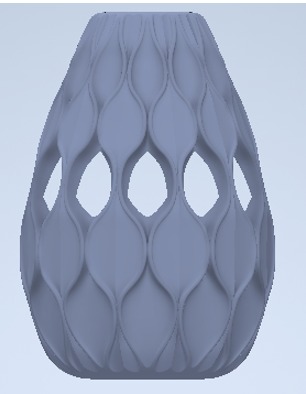

Preview of the 3D model.

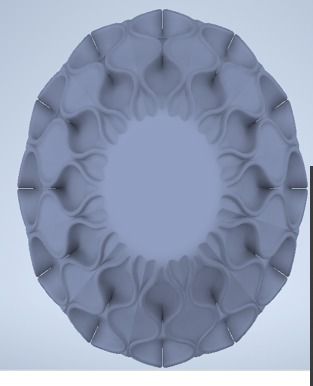

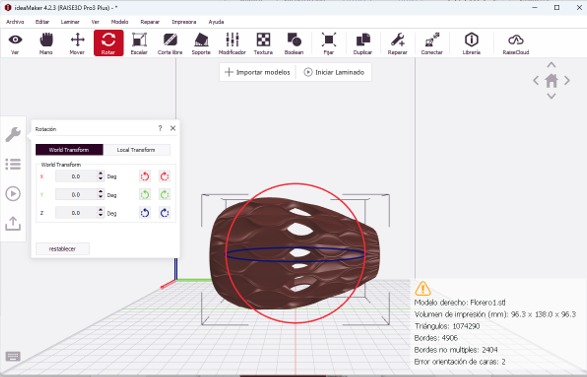

We rotate the piece 90 degrees to have a better

of the piece to create the support and optimize the

use of the material.

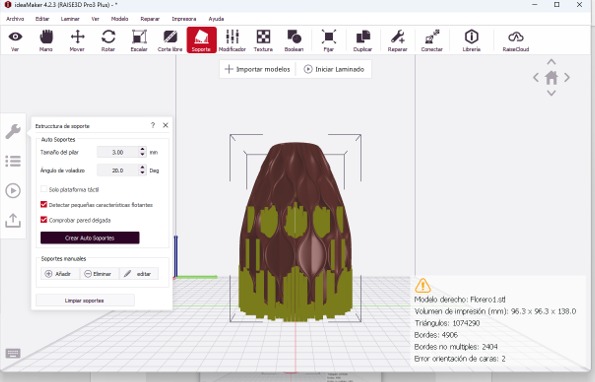

Add the support, this support is generated

autmatically by the software

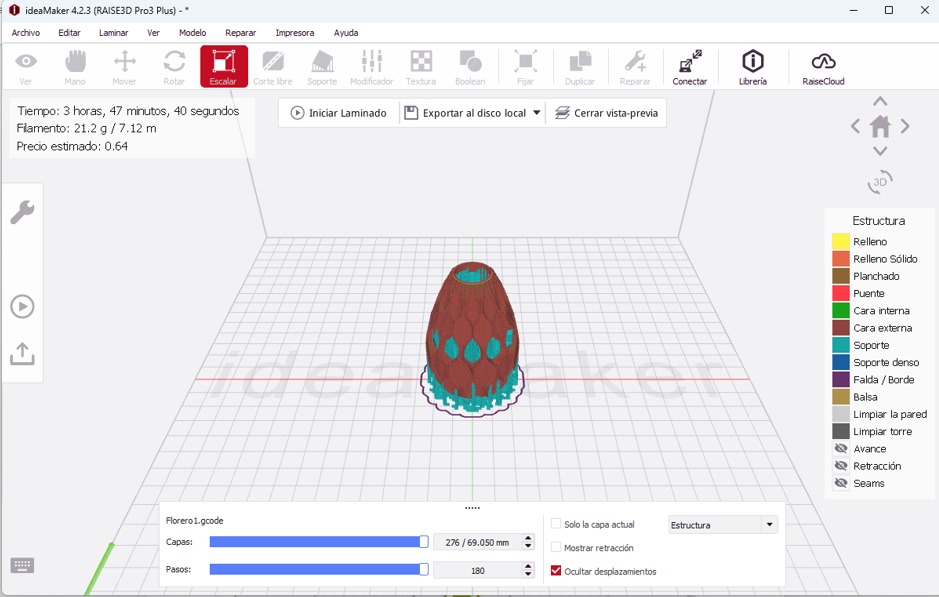

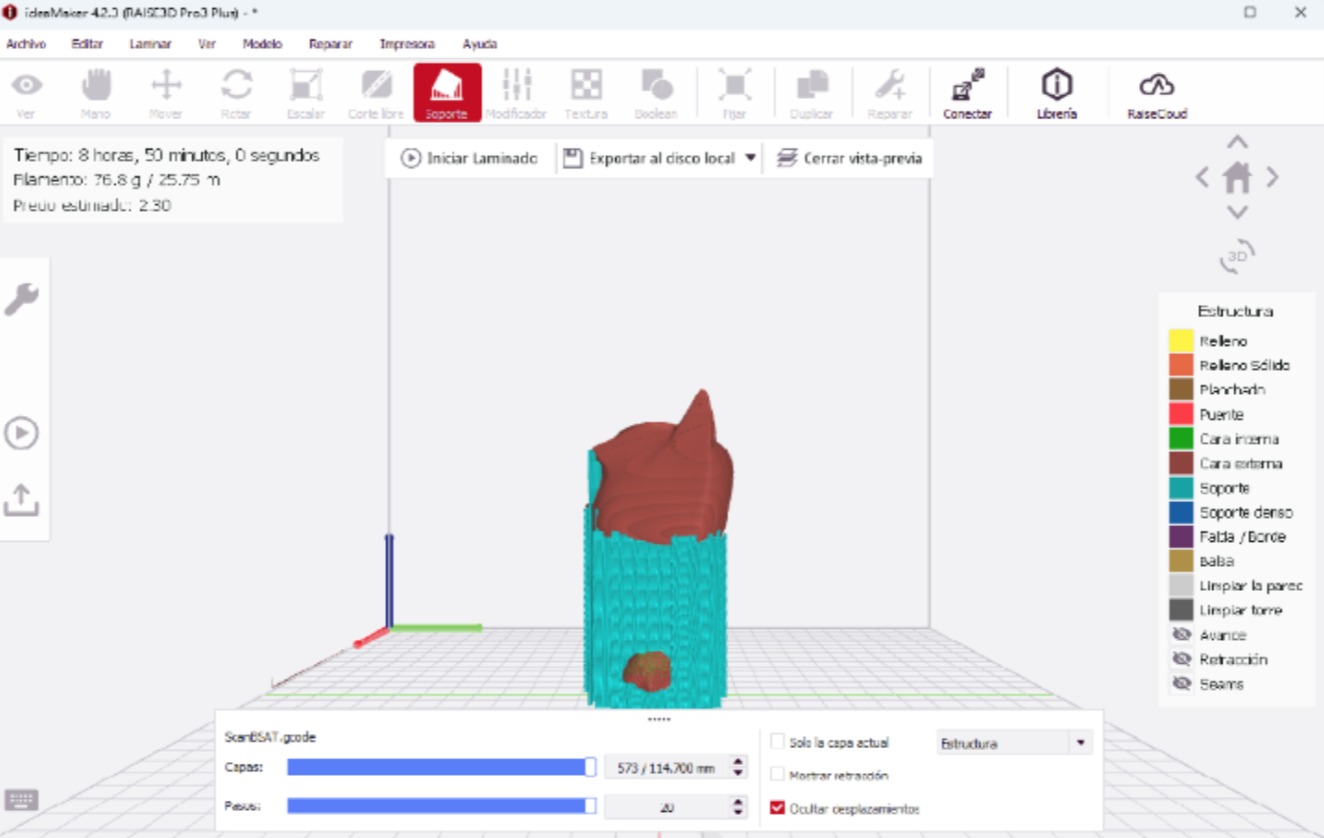

In this part, the print quality and speed are

and the rigth or left extruder is also chosen.

This is a procees

Here we can view the correct form. This is the preview

/

These are the results after 3d printing.

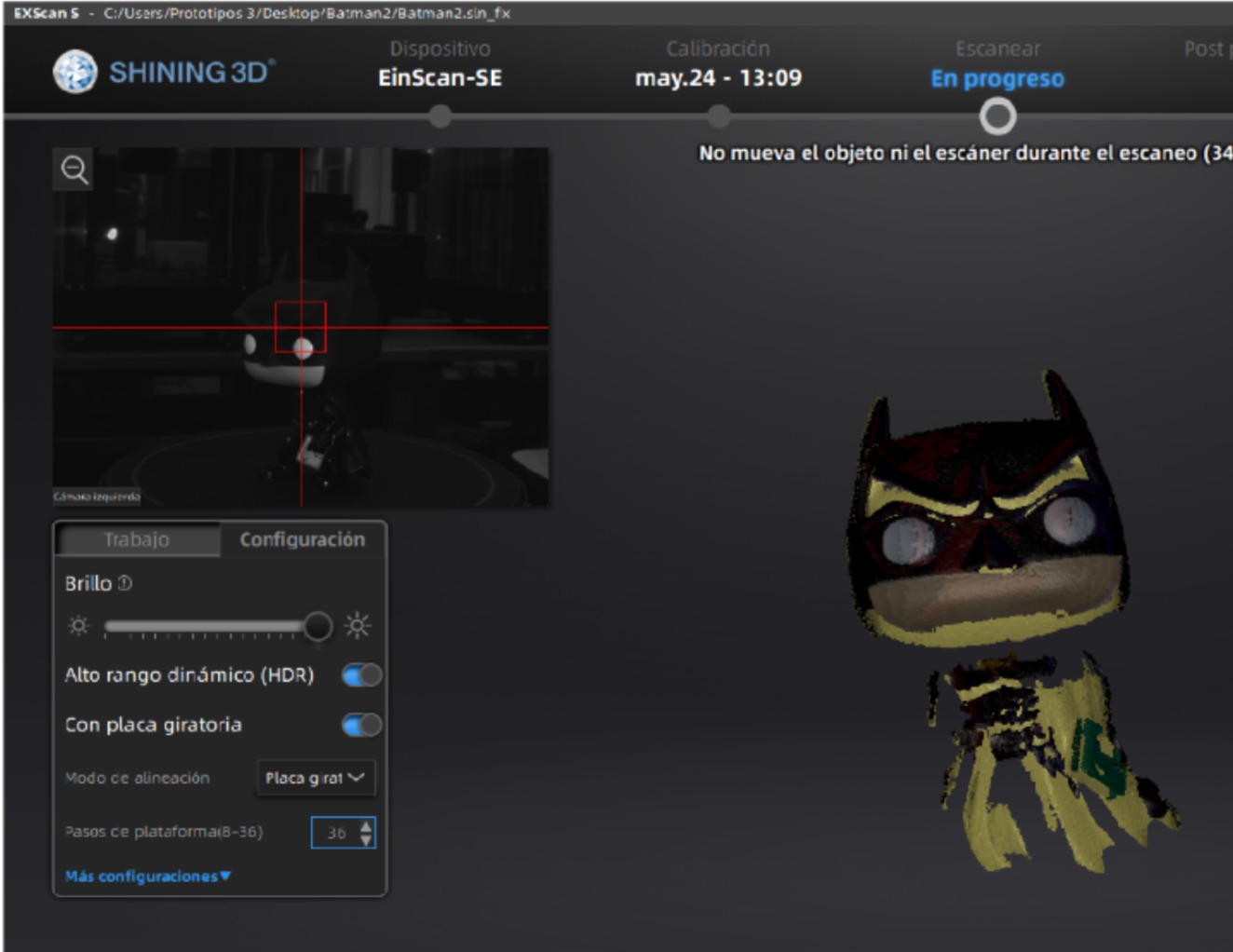

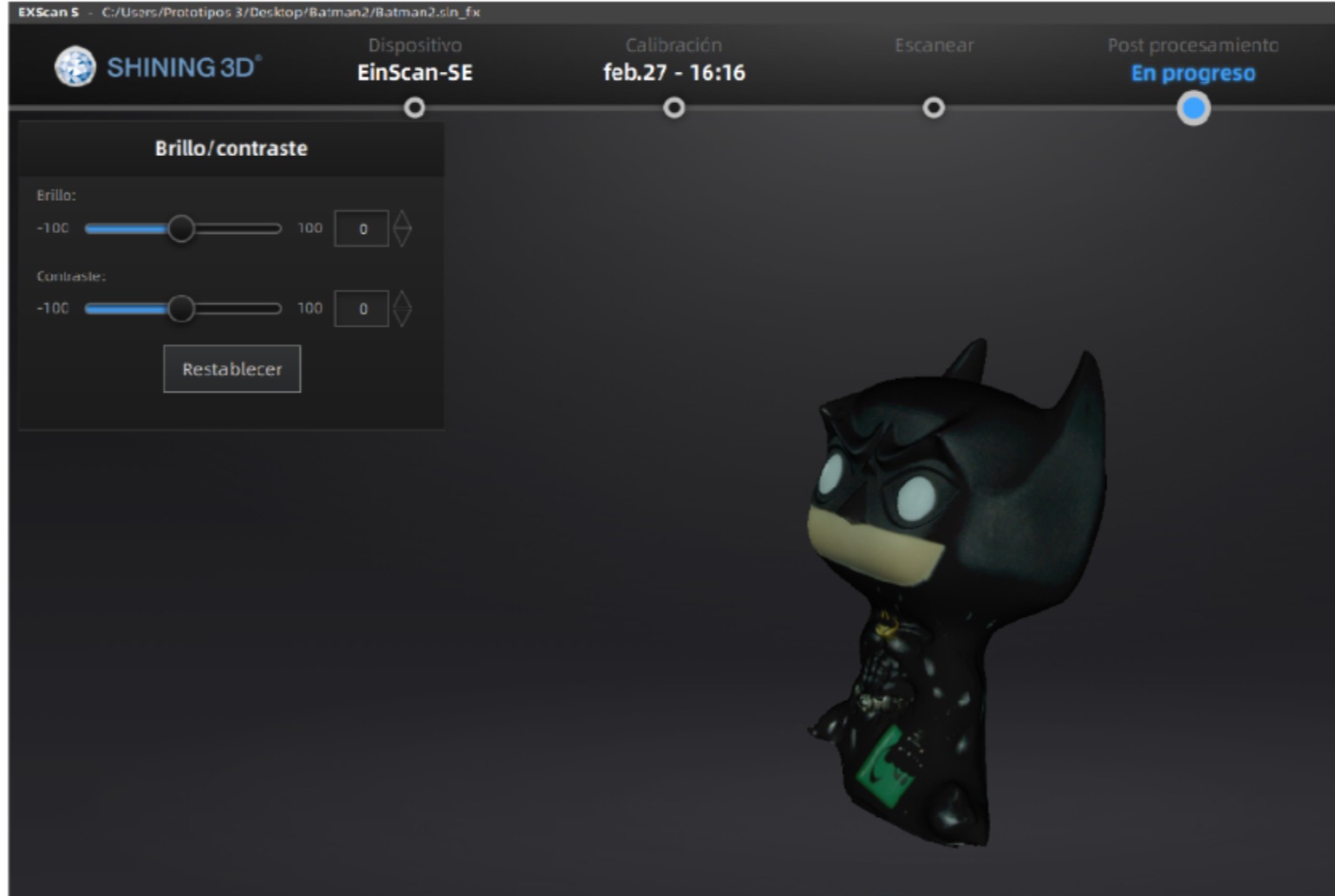

In this section, first a random 3D figure was scanned, the in the corresponding software it was formated and exported in stl format so that the following software(ideaMaker) can help us to give us the gcode already with it's characteristics for printing

This is the Batman printing process:

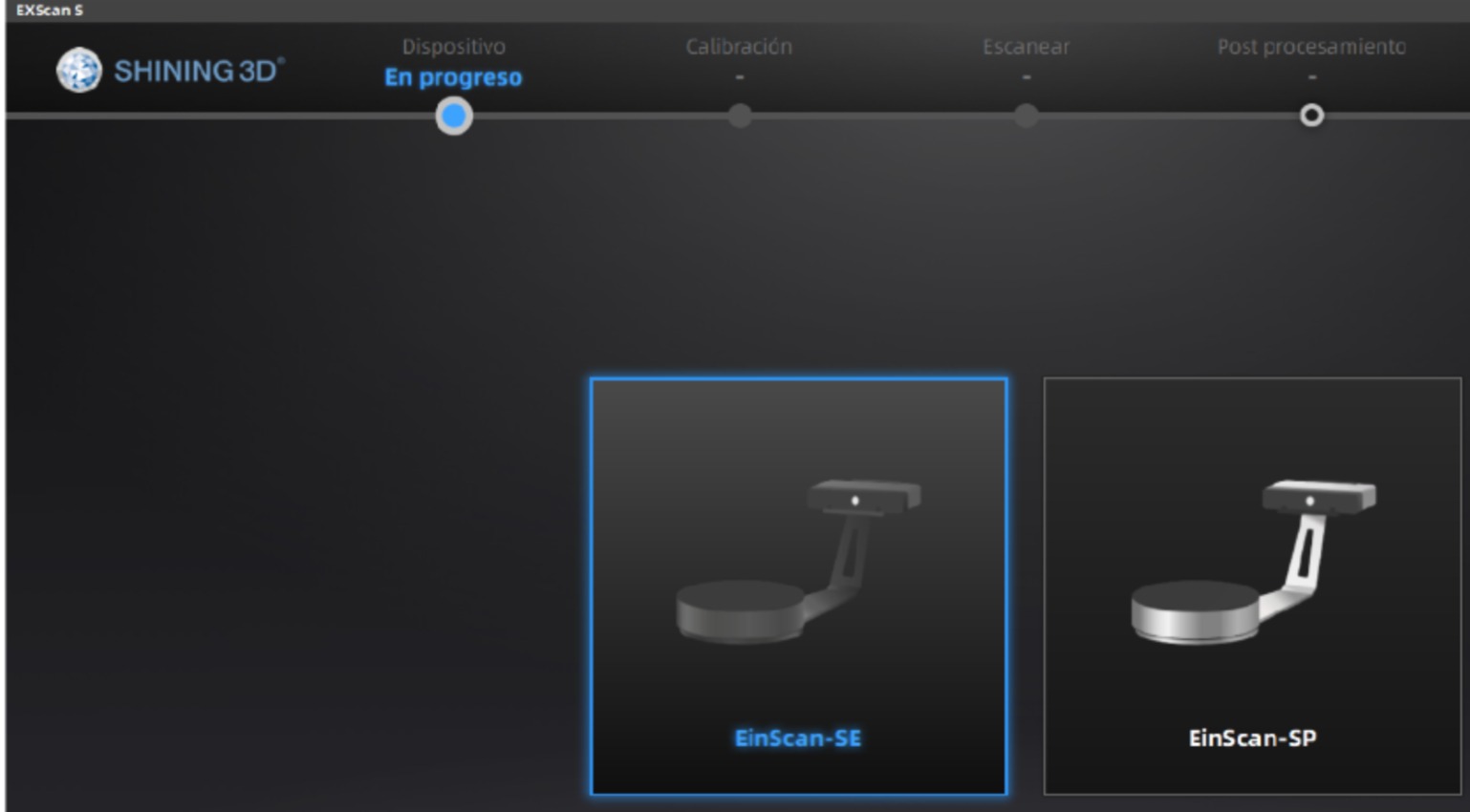

Starting the EXScan S

Select EinSacn-SE

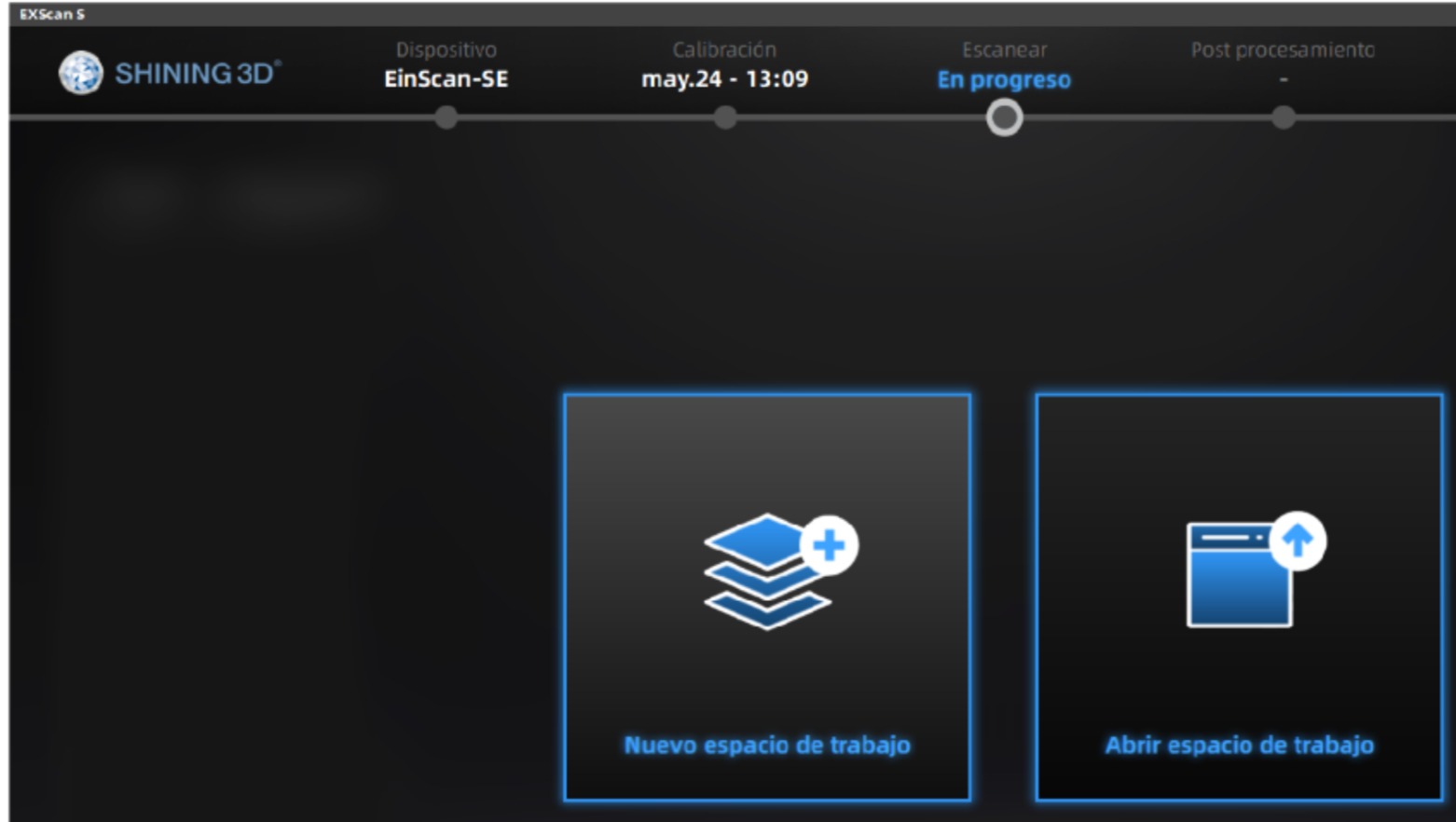

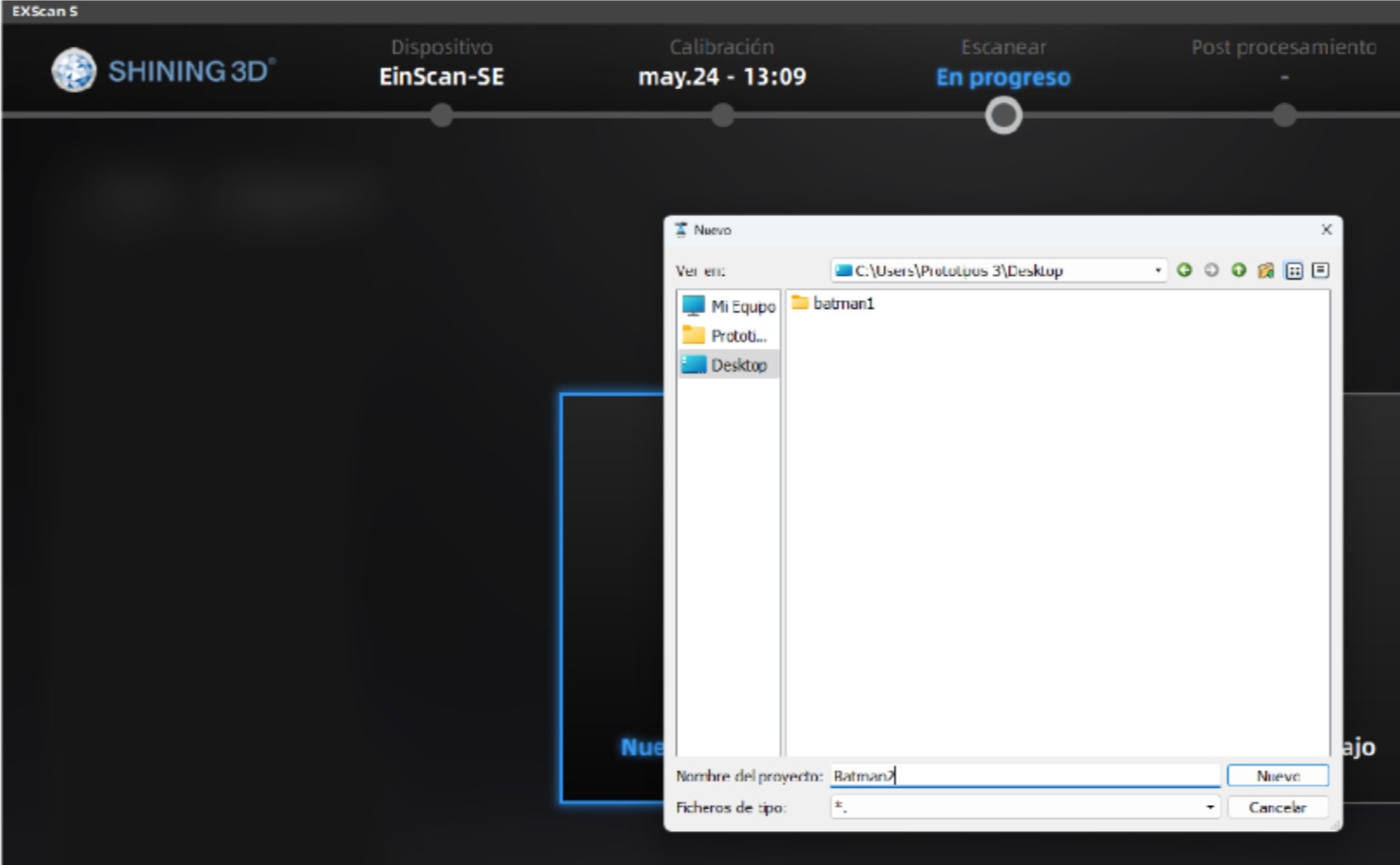

Select a new workspace

Create a folder on the PC to save the scanning information,

then create the new file

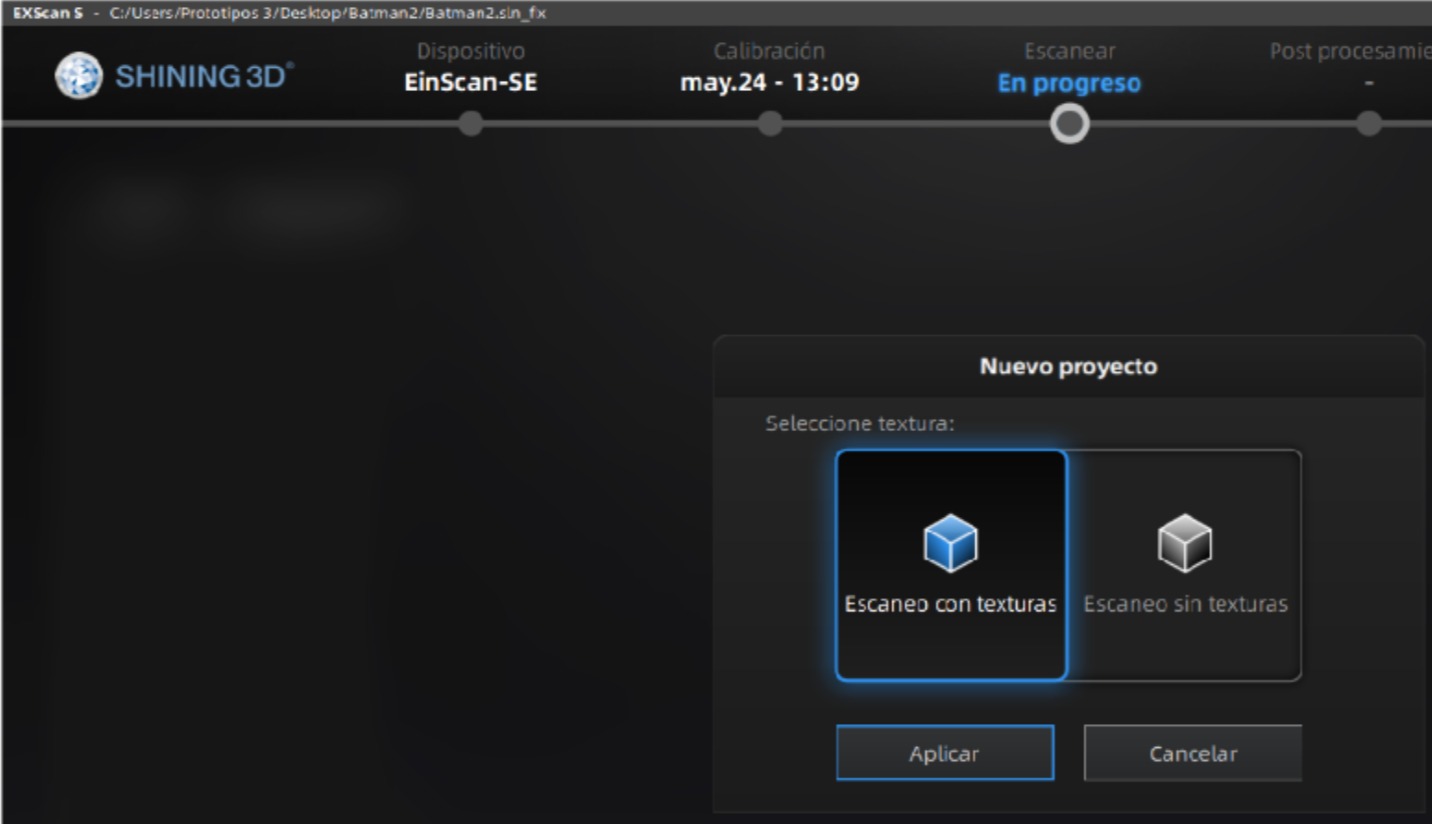

Select textured scanning

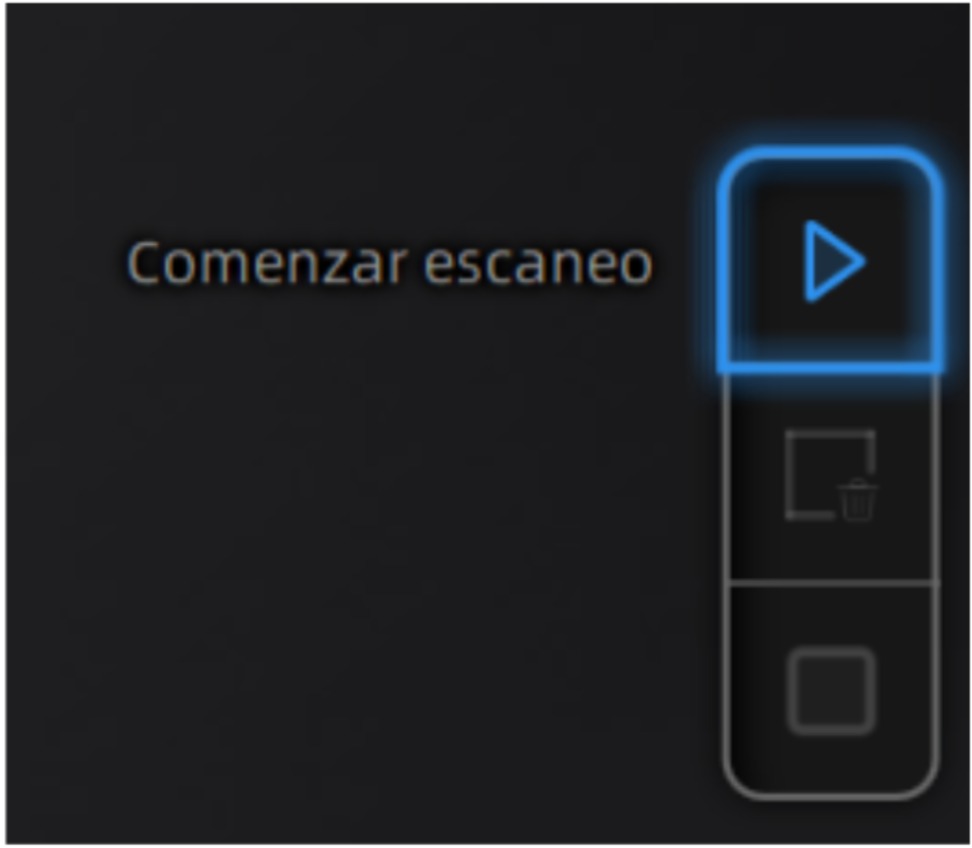

put the part on the base of the scanner

Start Scanning

Wait for you to upload the information

Here, Start scanning

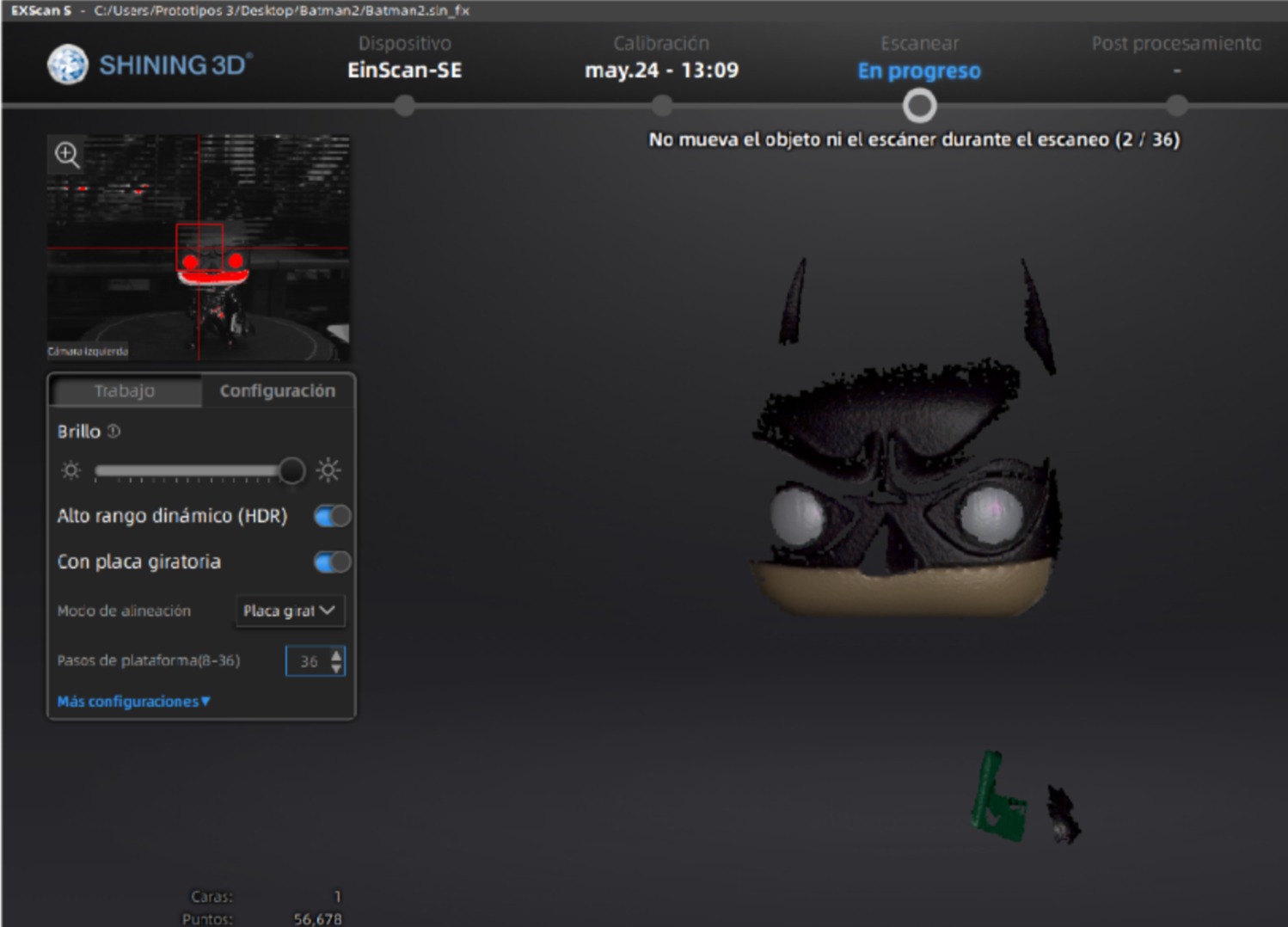

Scanning

Scanning

Scanning

Scanning 2/36

Scanning 14/36

Finally the piece is completed

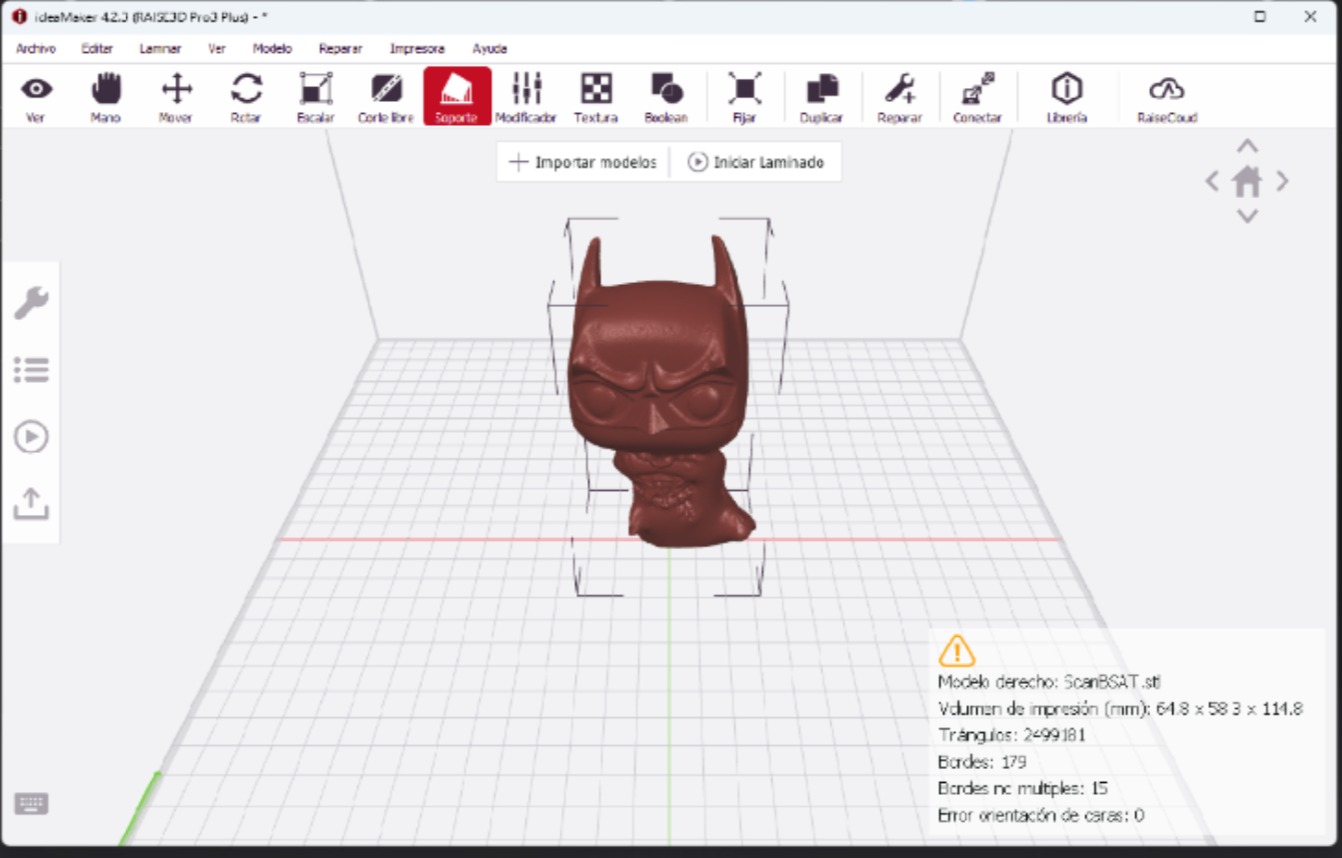

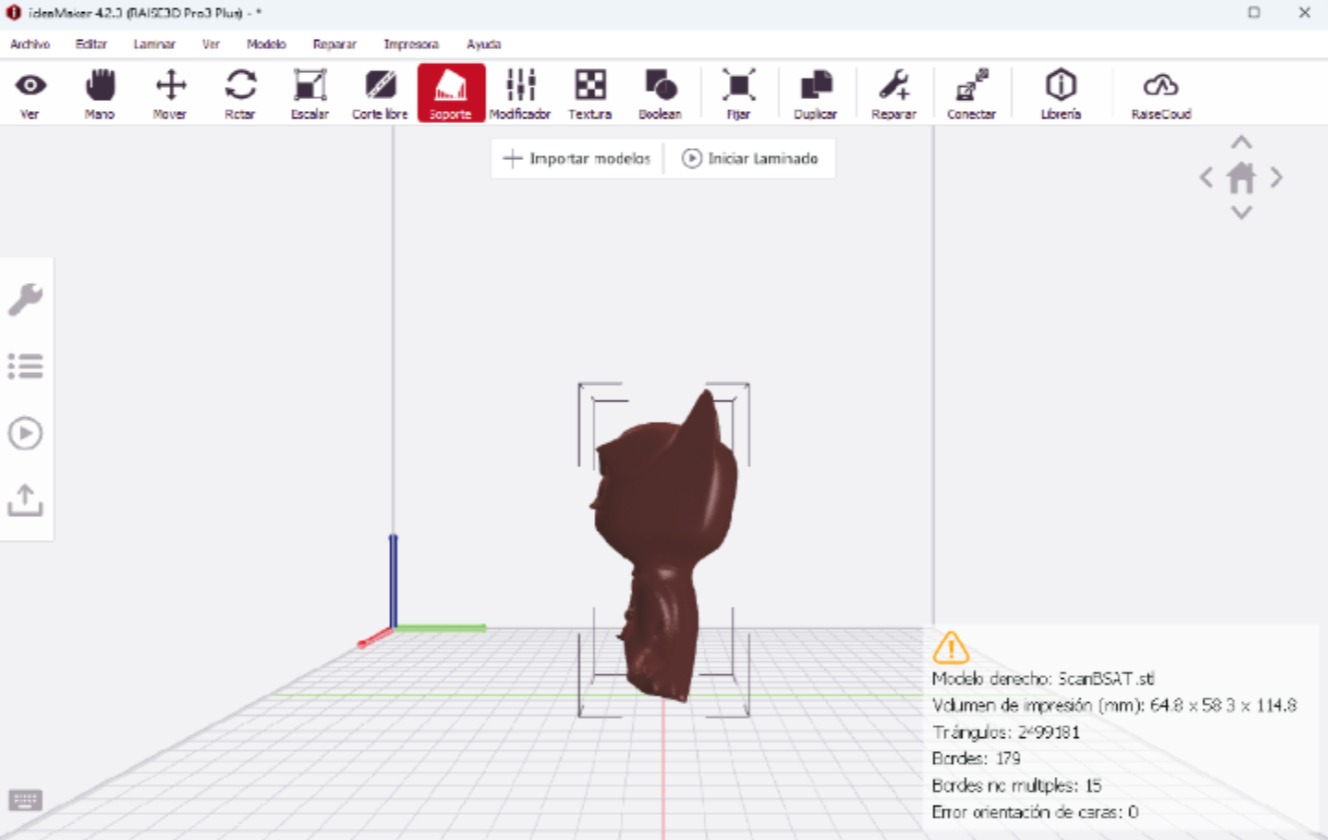

In ideaMaker software load the file in stl format

Possess the figure in (0,0,0) respective (x,y,z)

Generate self-support and start laminating

Preview how the part will look o the printer

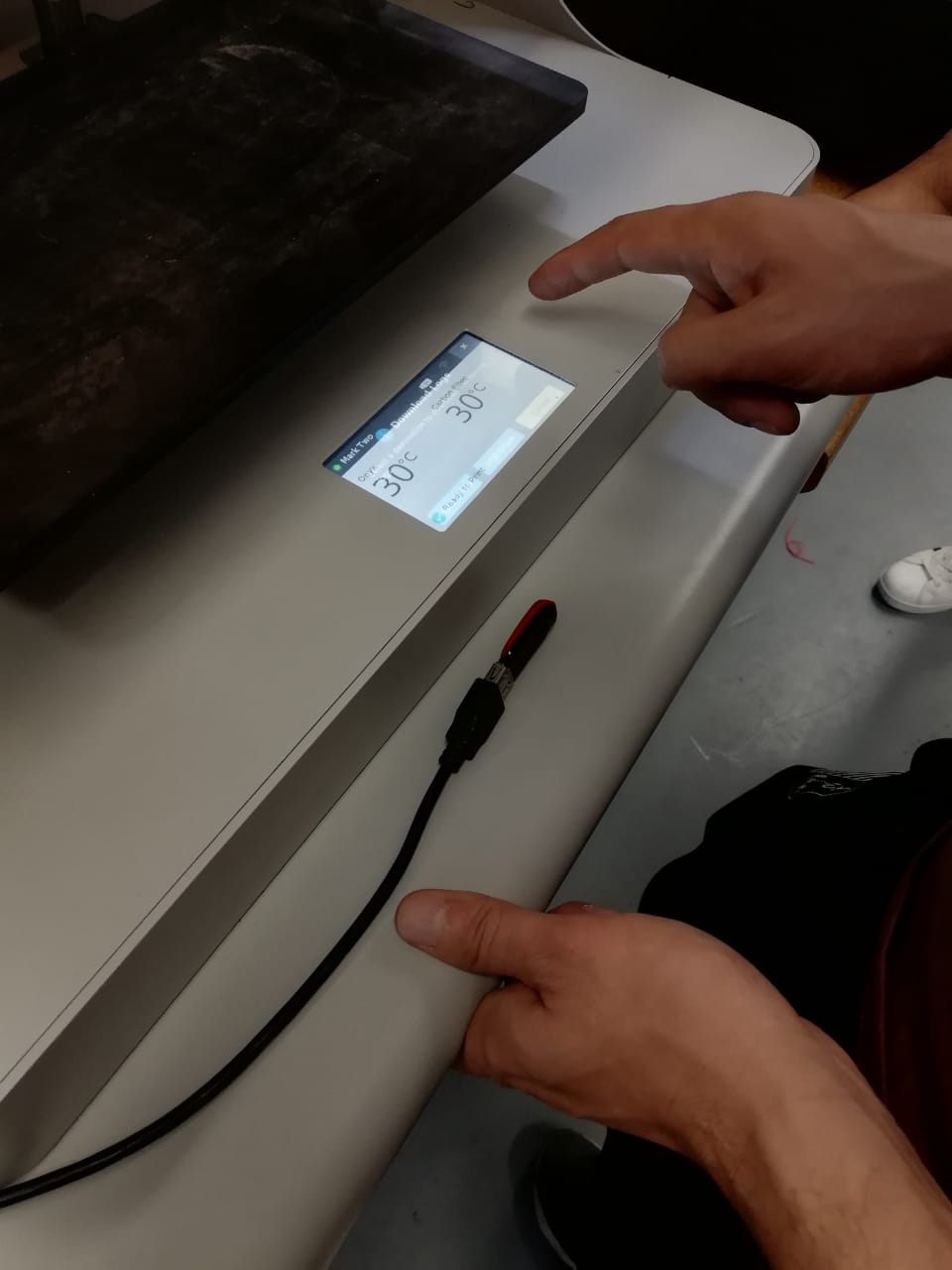

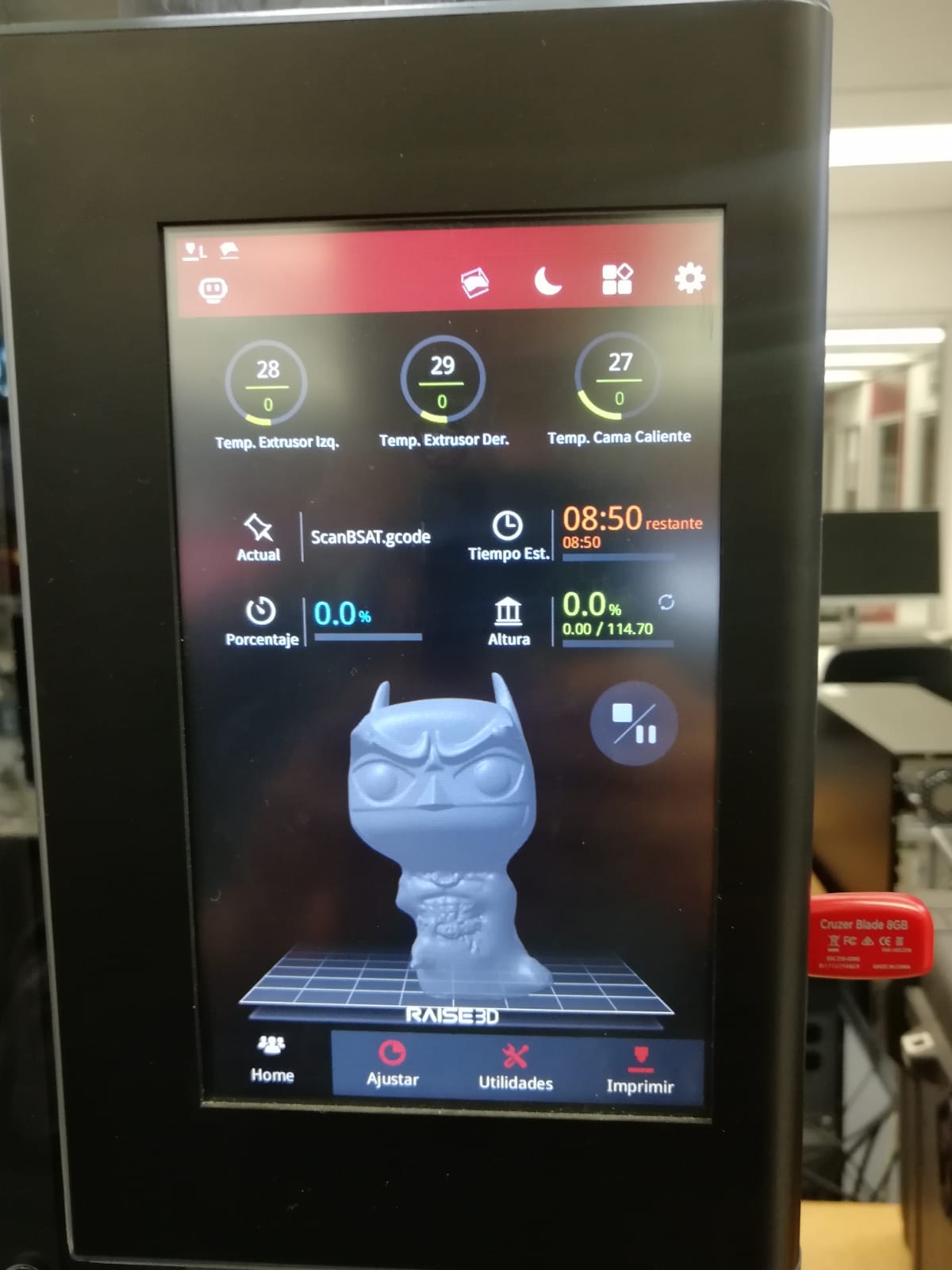

Turn on the printer

Place the USB thah contains the file,

on the screen we choose USB storage

We choose the file we want

We start printing, on the screen we will

see the details of the piece

Tis is the result