4. Computer controlled cutting¶

This time we will work with the Laser Cutter and Vinyl Cutter machines… How interesting… new projects to be carried out… Always learning new things…

Group Assignment¶

Working first with the laser cutter and then with the vinyl cutter…

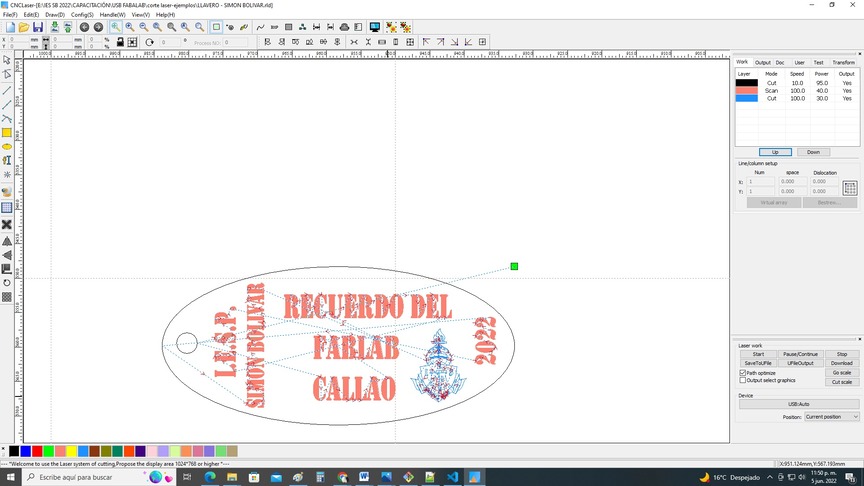

Fab Lab del IES “SIMÓN BOLÍVAR”

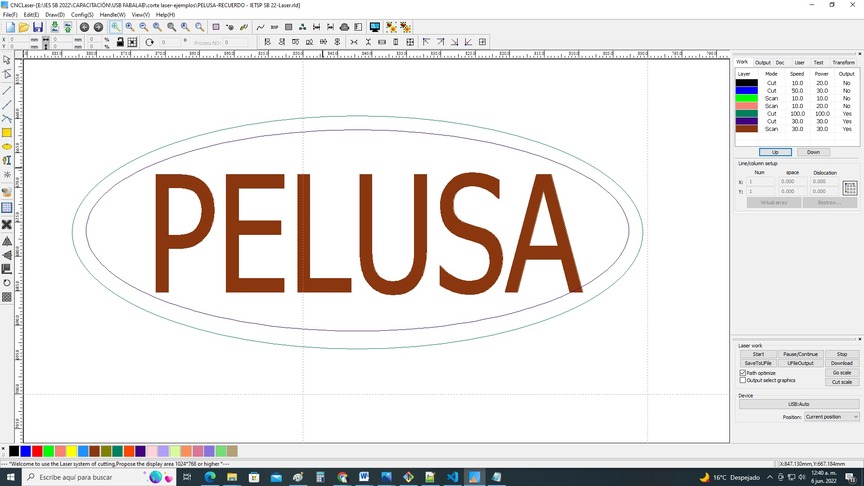

The software to be used in the laser cutter is CNCLaser and you can download it (information at the end)

Getting to know the laser cutter: https://megalaser.com.ar/descargas

Knowing the technical characteristics of the laser cutter…

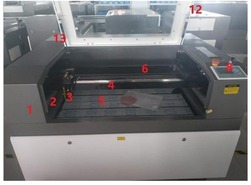

Structure of the machine

The front view of the machine is as shown in the figure below: ① Main unit(material collector included) ② Y-axis movement mechanism ③ Laser head ④ Crossbeam of the machine ⑤ Work table (beehive or strip sole) ⑥ X axis movement mechanism ⑦ Foot wheel and foot caster ⑧ Dashboard ⑨ Emergency stop ⑩ Laser switch ⑪ Ammeter (power indicator) ⑫ Laser output (Each left and right) ⑬ Top cover of the machine

14 Machine cover main power cable 15 Exhaust blower connector 16 Laser tube cover 17 Water pipe and air pipe joint 18 Main power supply switch

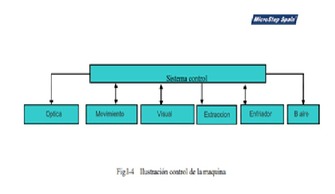

Machine control illustration

Composition of movement mechanisms Movements in plane The mechanism of movement of the plane is composed of the mechanisms of movement of the X axis and Y axis in vertical relationship, as shown in the figure below:

① X-axis motor ② X axis beam and guide rail

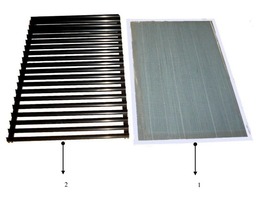

Work platform The working platforms of LG/LC series laser machines are mainly of ruffle or strap sole. Some types of machines with higher absorption requirements are equipped with a vacuum absorption platform. The ruffle sole is mainly used for the placement of soft materials such as fabric or leather, while the strap sole is mainly for the hard materials like organic glass or thick plank.or leathe,

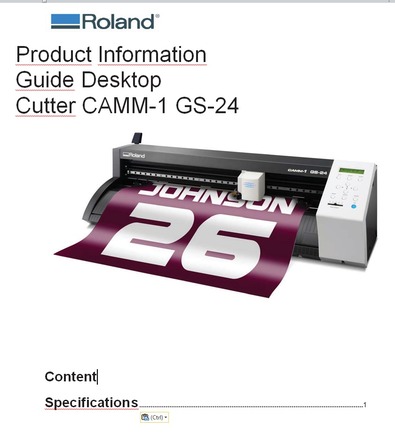

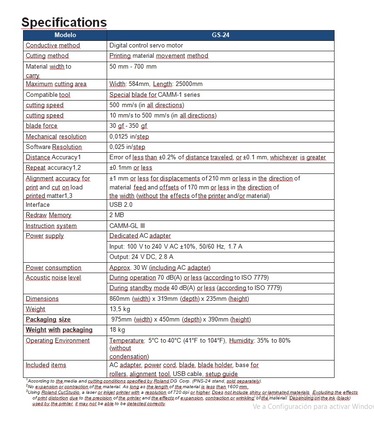

Knowing the technical characteristics of the vinyl cutter…

Individual Assignment¶

Practicing with the laser cutter…

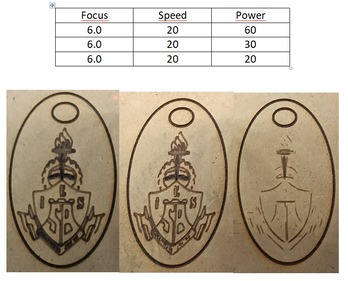

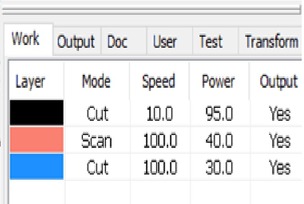

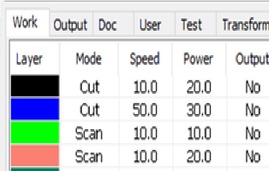

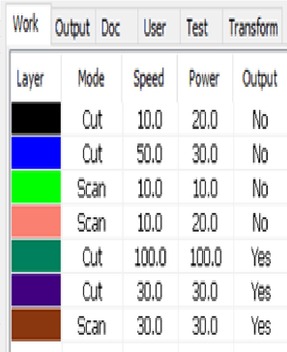

Recommended parameters for Acrylic 3mm

Recommended parameters for 3mm cardboard

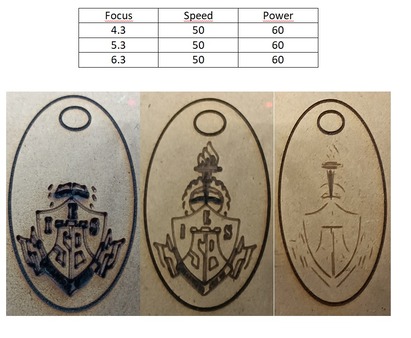

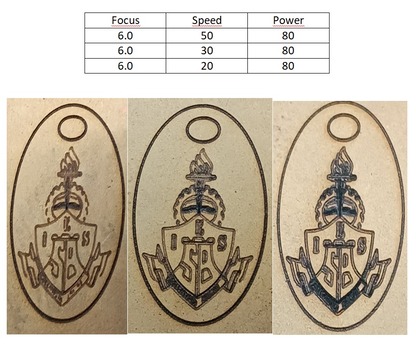

Recommended parameters for 3mm leather

What shouldn’t happen…

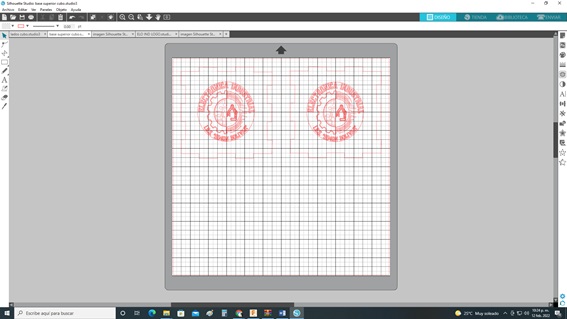

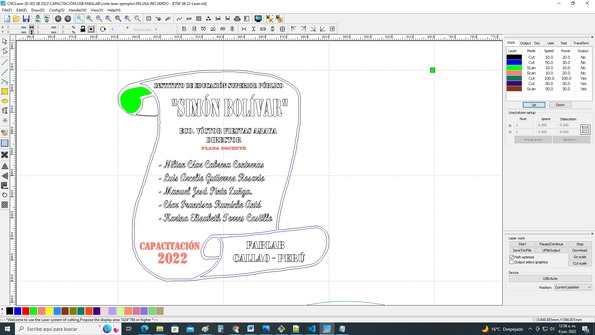

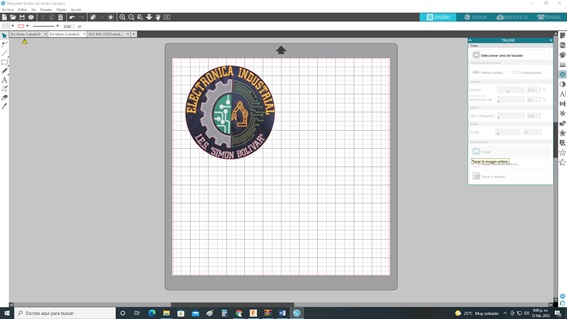

Project to cut a cube with the Industrial Electronics study program logo. The design of the vectorized logo was worked with Silhouette Studio.

Silhouette Studio

Useful links¶

- Silhouette Studio Silhouette Studio is software for hobby plotters.

Silhouette Studio: Support video

-

RDWorksV8Setup CNCLáser software.

-

Software for vinyl: CutStudio download CutStudio software.

The following process was carried out¶

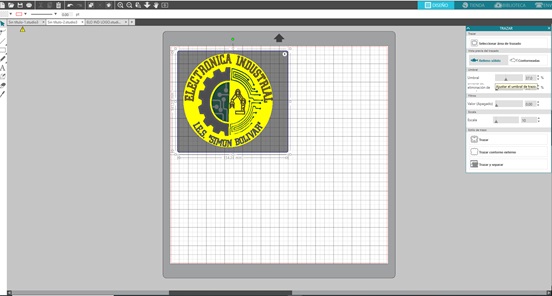

Insert an image to plot

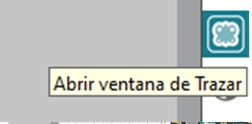

Select plot window

Select the area to plot

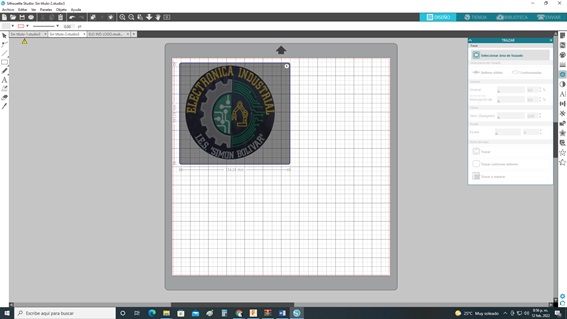

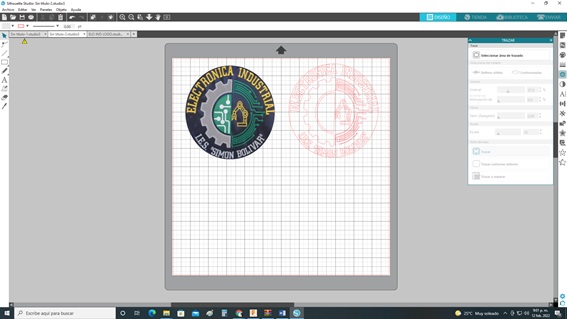

Adjust threshold for cutoff

Click on draw

Insert an image to plot

The selected area is outlined in red

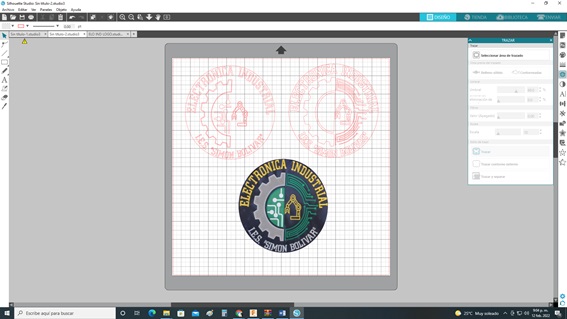

Then click on the image and move

I carried out the same procedure for an area that had not left the circuit design part of the Industrial Electronics study program logo of the IES “Simón Bolívar del Callao.

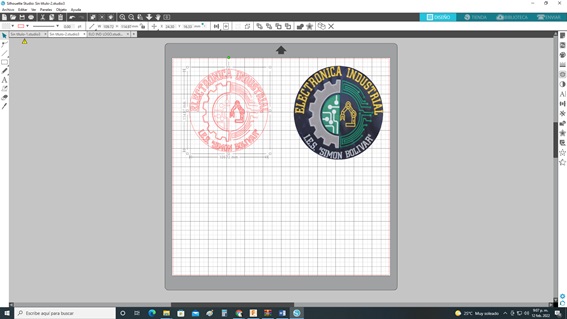

After grouping the two logos

just a picture

Save to a hard drive.

With the duplicate option, the sides of the cube were completed

base and top