12. molding and casting¶

This week I worked on defining my final project idea and started to getting used to the documentation process.

designing the mother object.¶

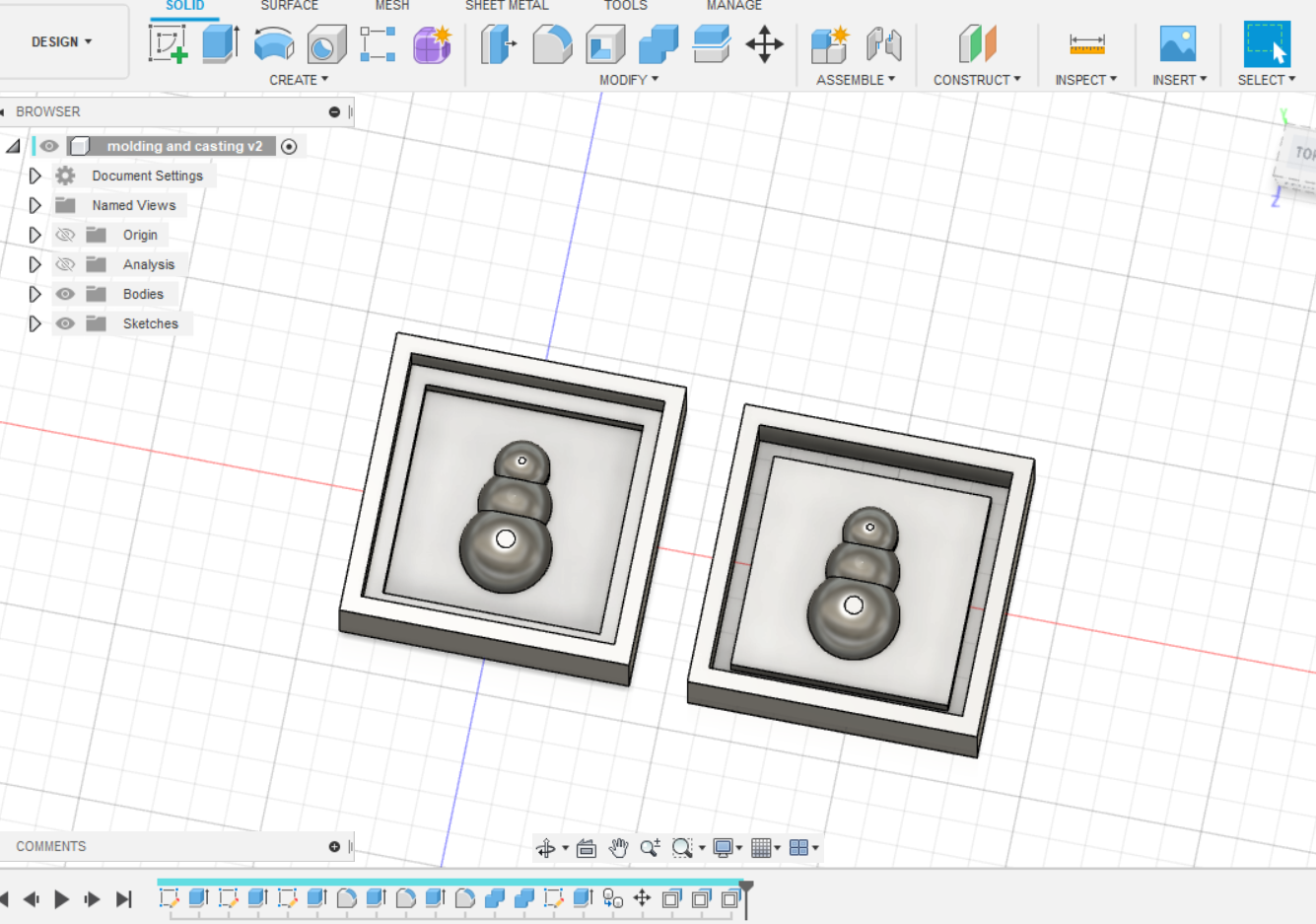

I designed the object in fusion360 , I started from a drawing i made in inkscape.

I imported the .SVG file in fusion.

I made a couple of extrudes so that it is in different levels.

I exported the drawing as STL so i can mill it.

Making the cnc file.¶

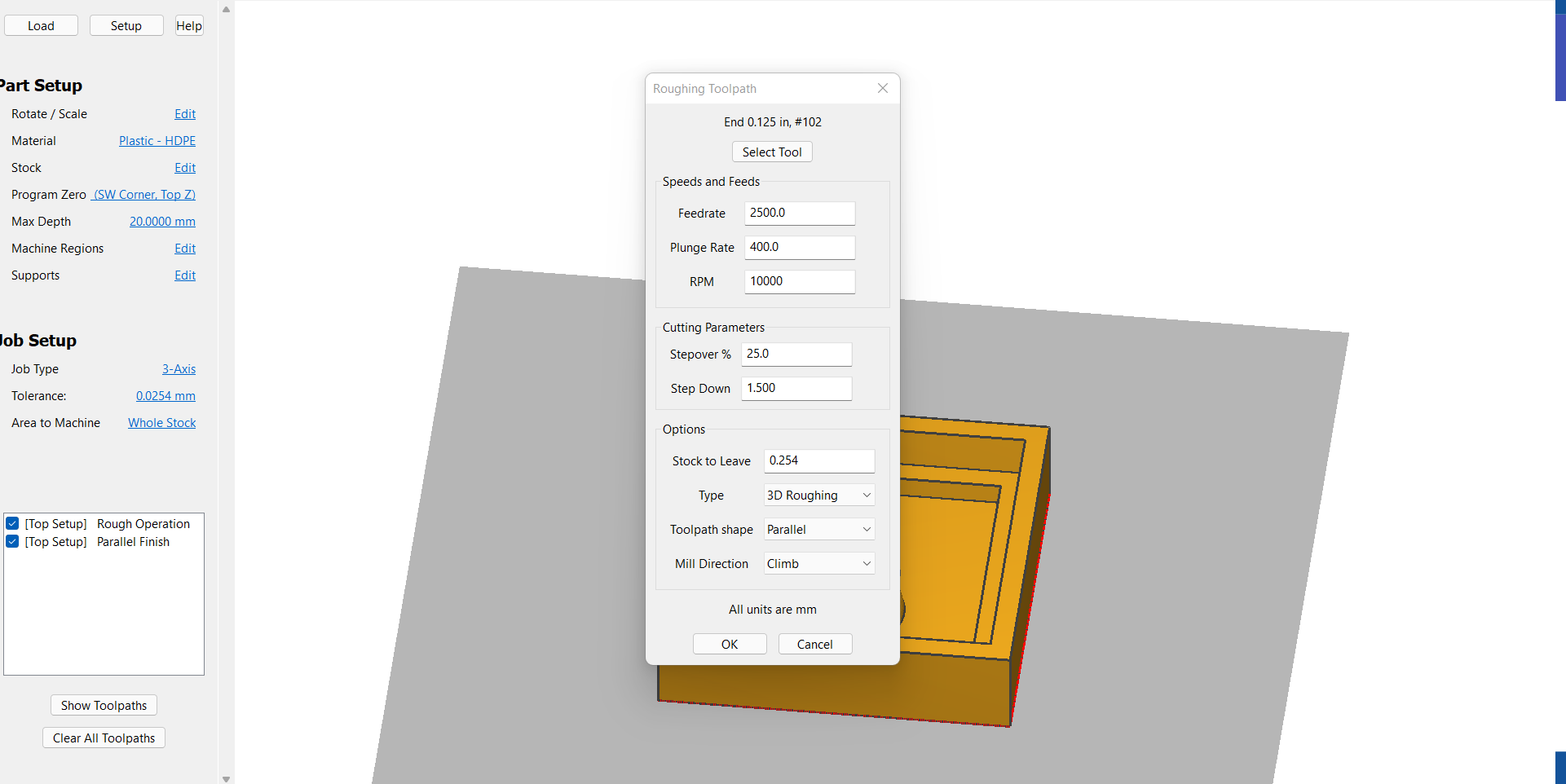

To make the toolpaths I used meshcam. With this software it is possible to import .STL and make toolpaths.

First import the .stl in the program

First i defined the stock. I used HDPE

Now I made the toolpaths.

For this i needed 2 toolpaths. One is a pocket and the other one is the contour.

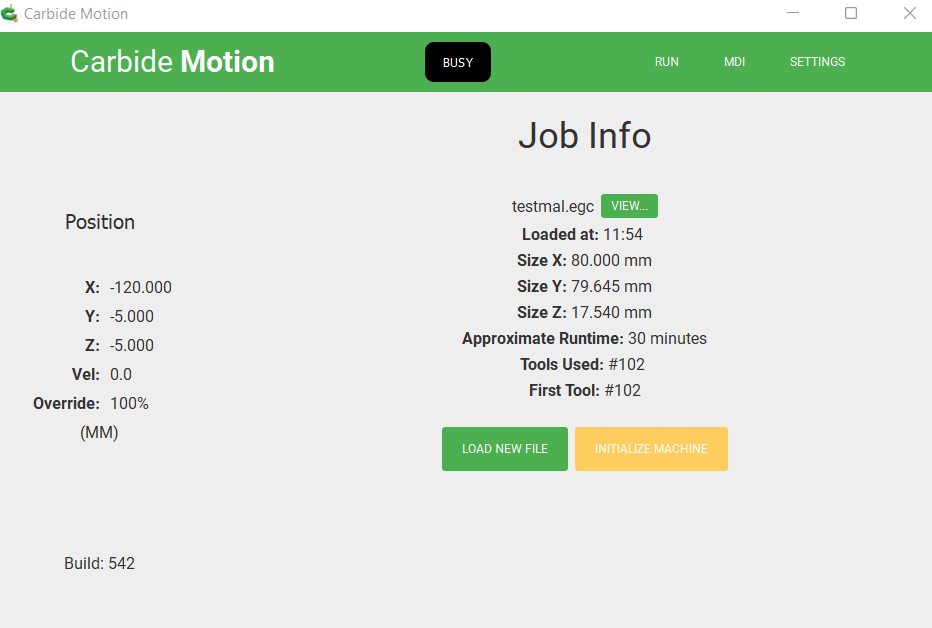

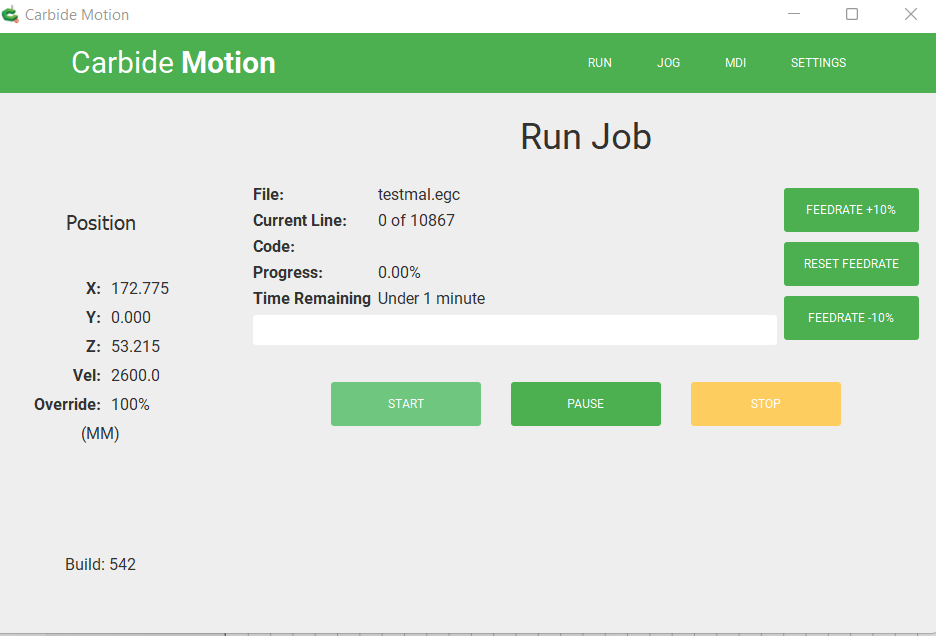

I saved the Gcode and send it to the machine

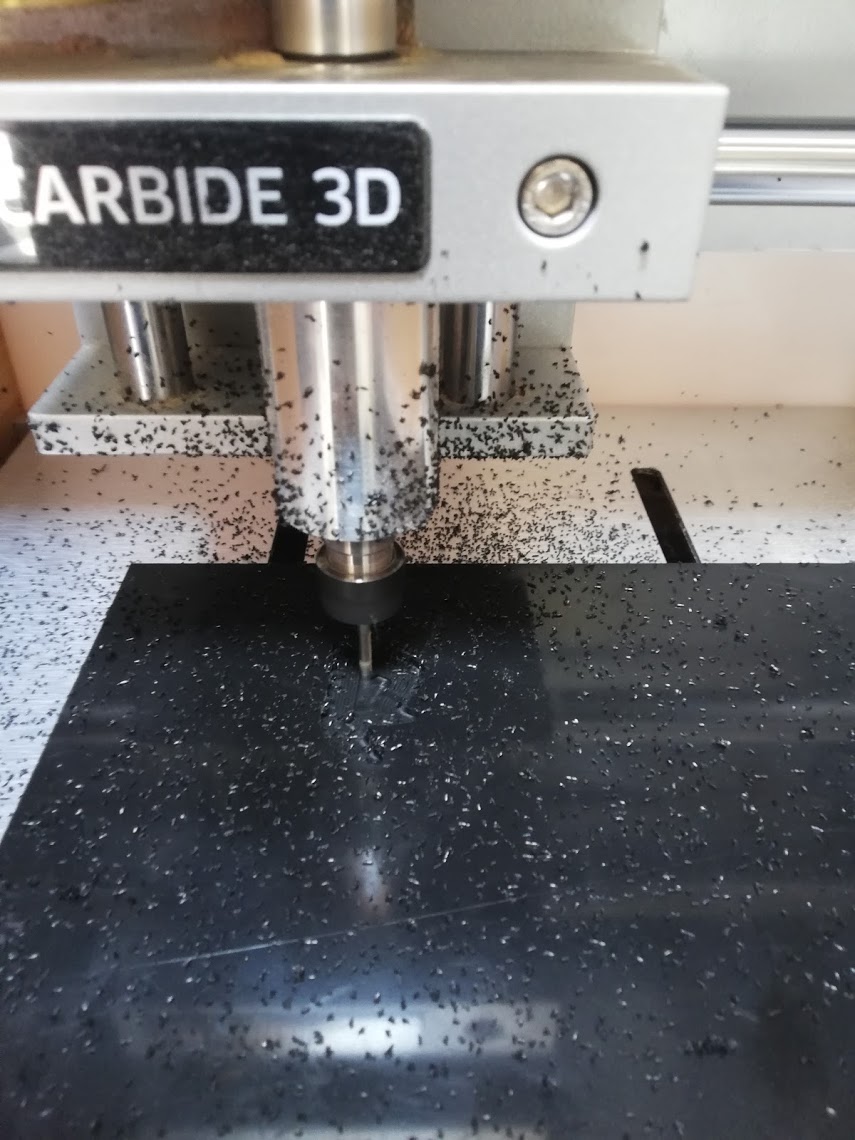

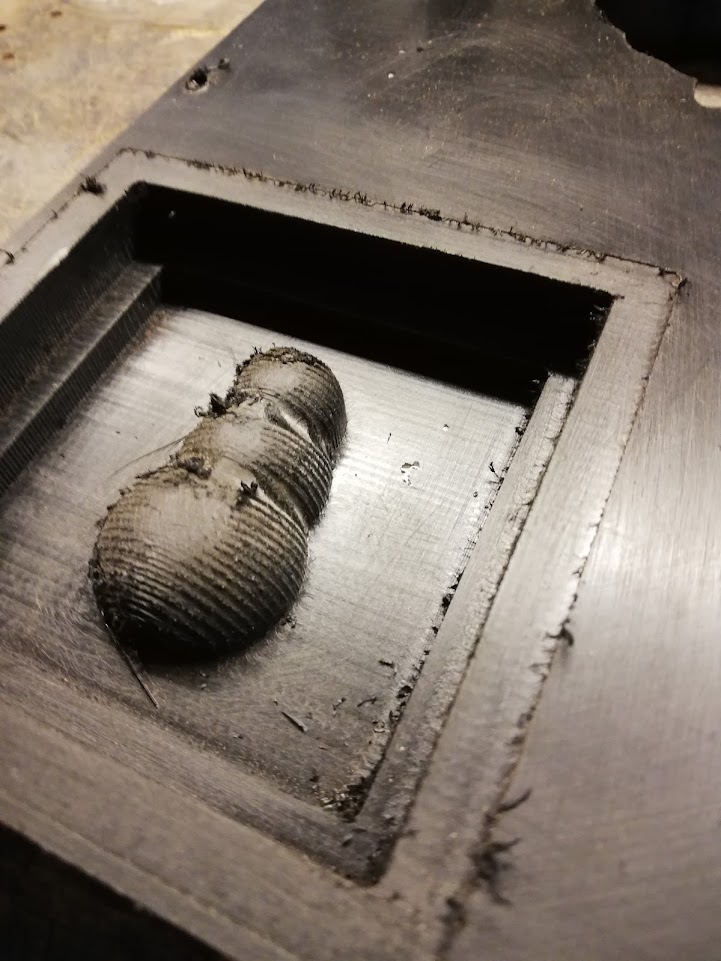

Milling¶

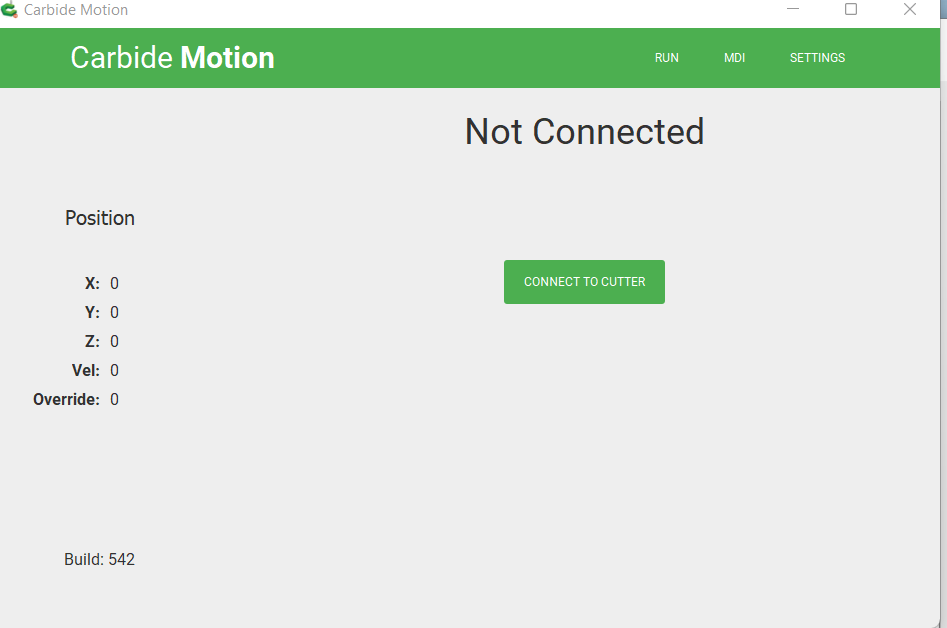

I milled the shape on the Nomad 883.

casting¶

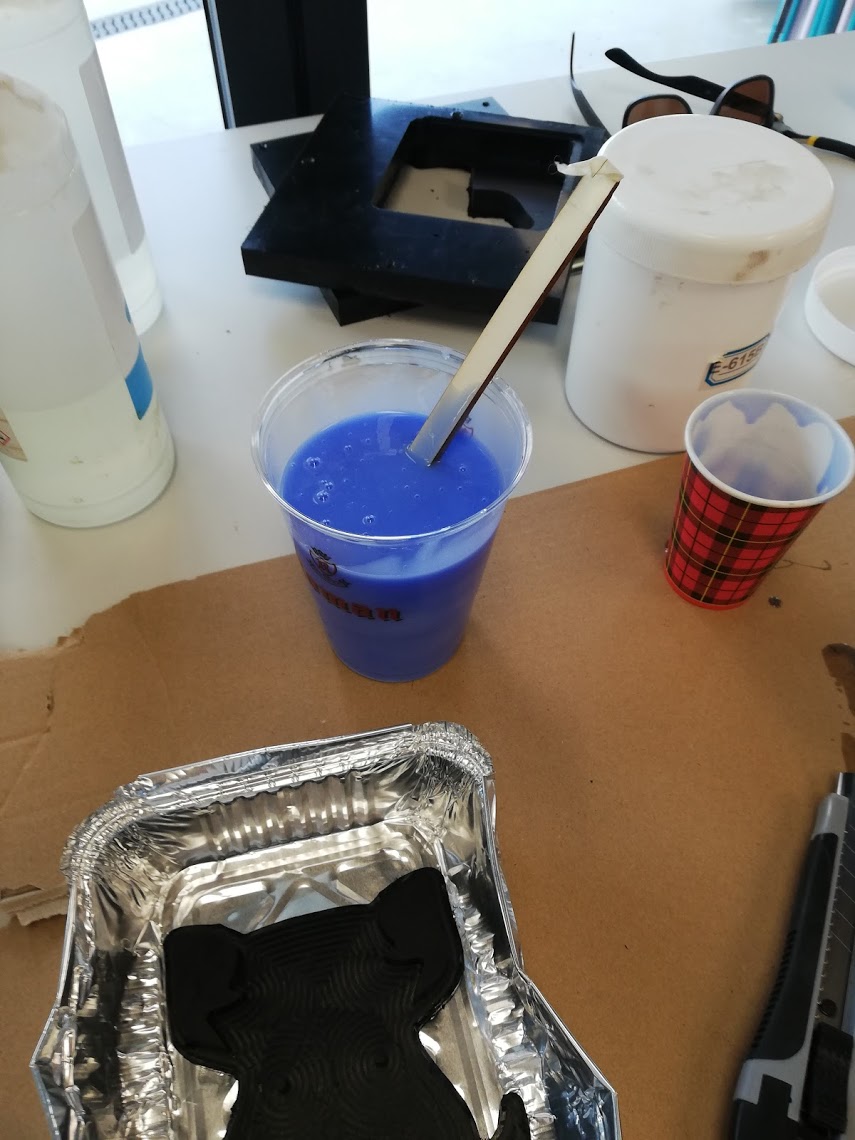

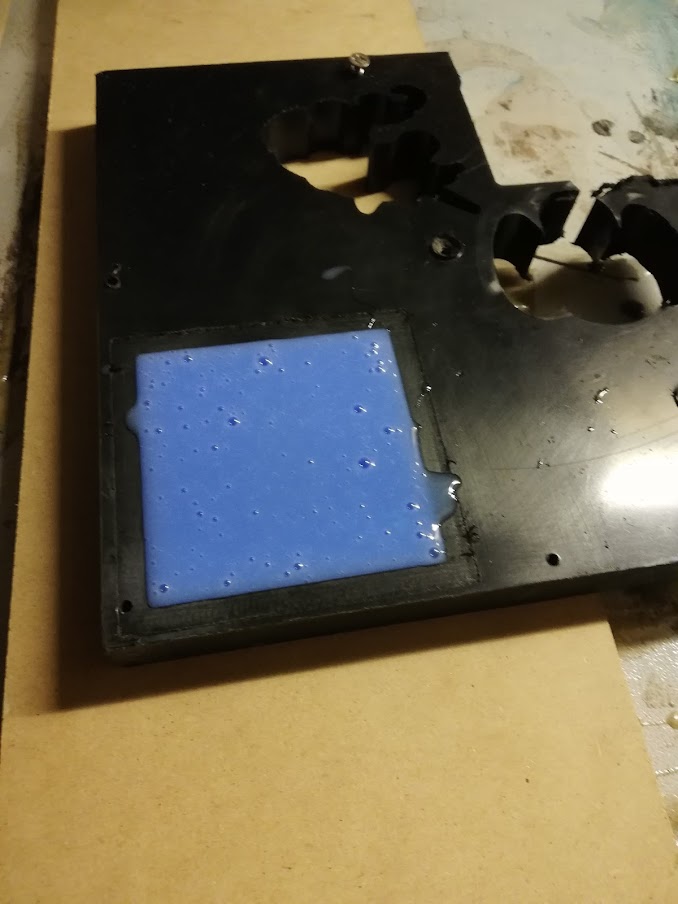

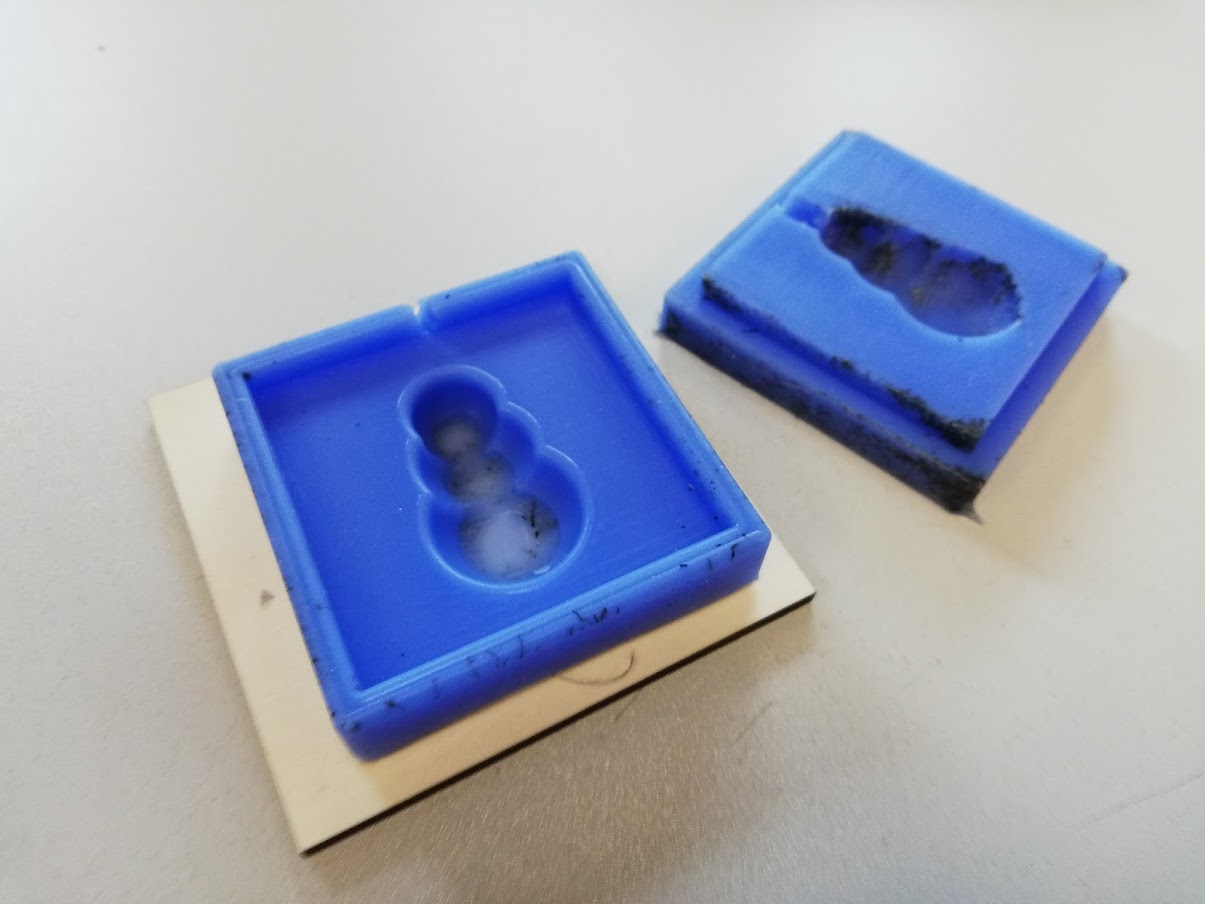

I use the object to make a silicon mold so i can recast the mother object in different materials. The sillicone has a ratio of 100 - 60. it is a very flexible silicone so it a good one for molding complex objects. But it is not so strong.

When the silicon was hard i was able to get the mother object out of the mold. The first matererial i will test is epoxy. I have put some LEDs in the eyes before is filled the mold with epoxy.

second silicon mold.¶

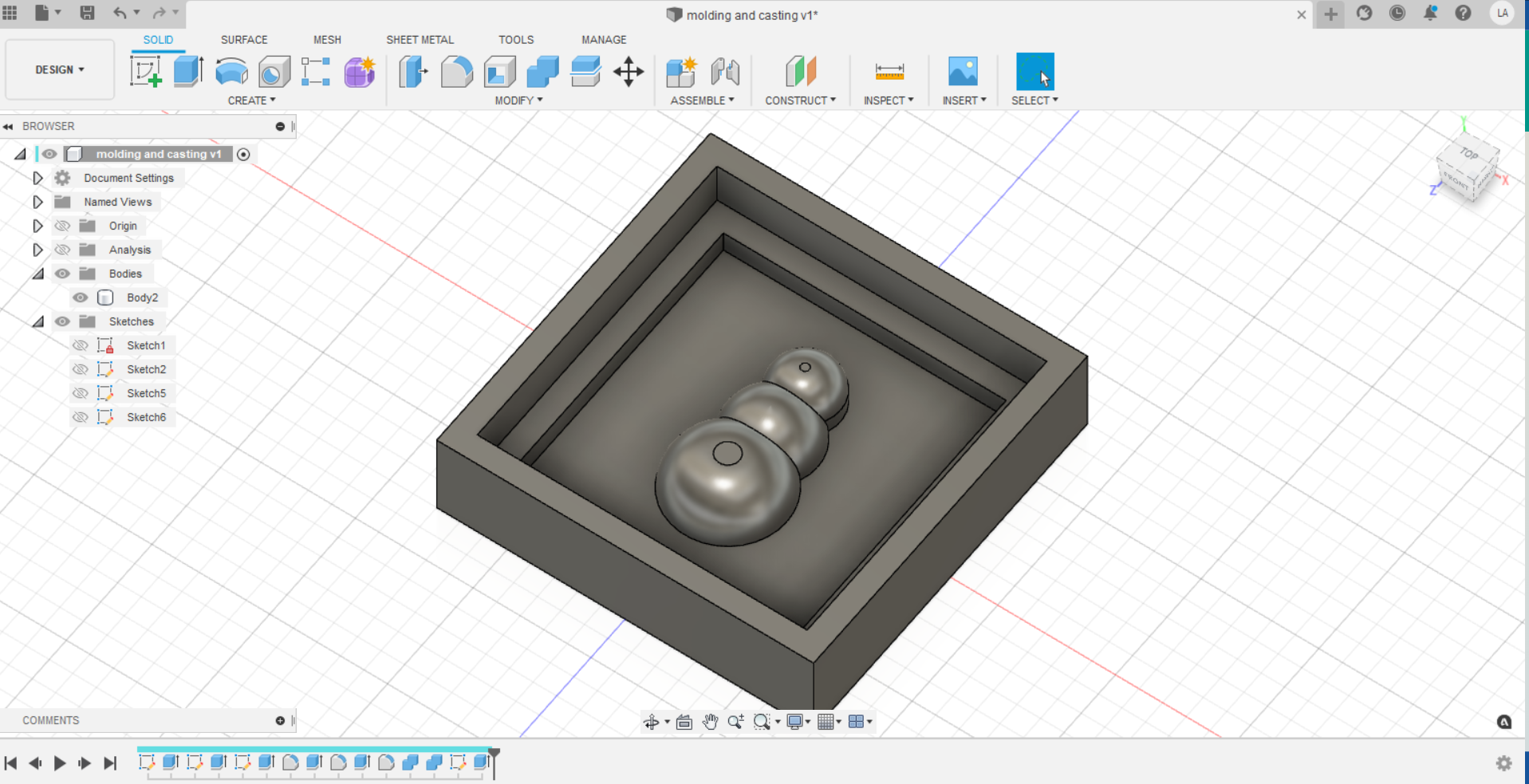

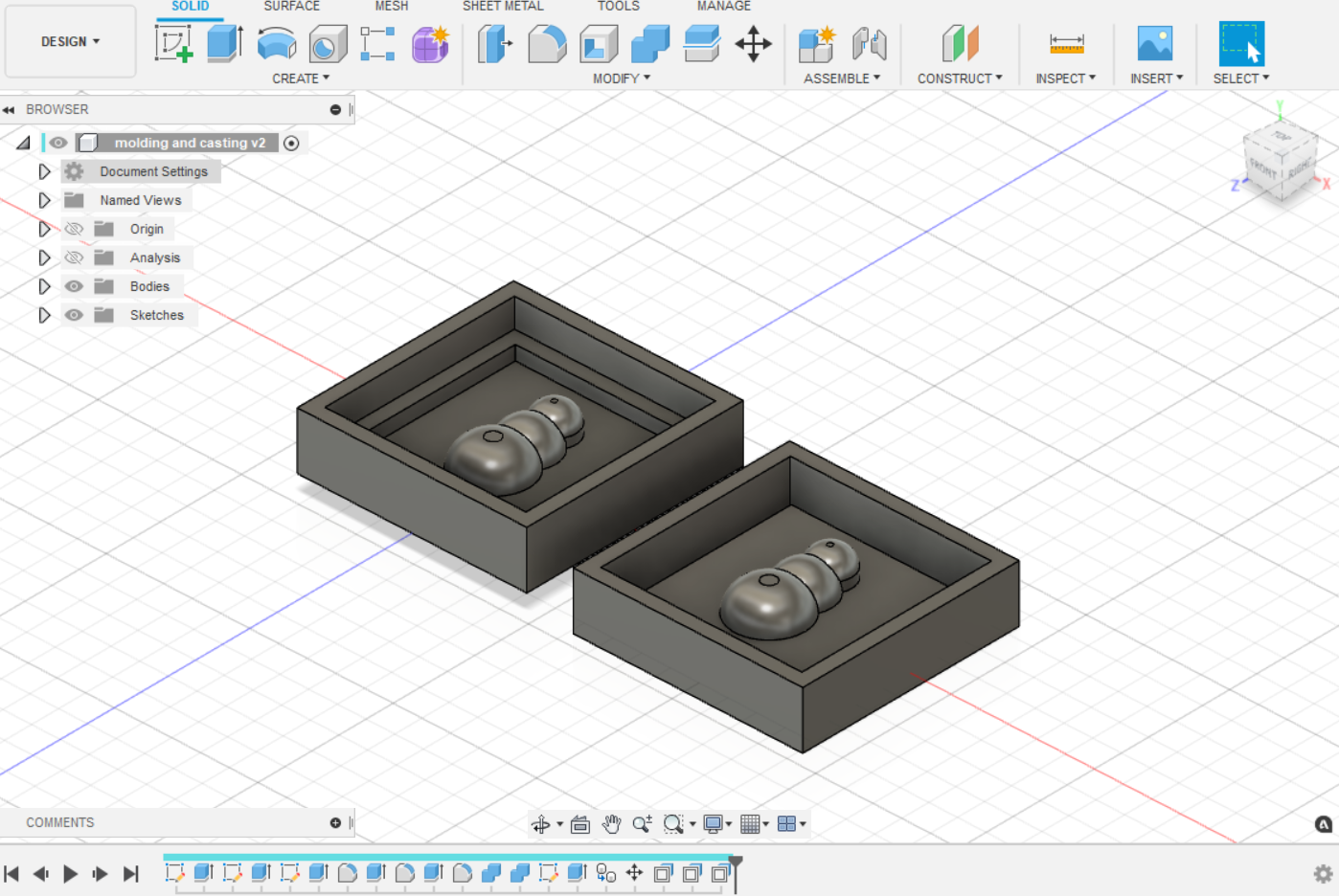

For my second try I wanted to make a two piece mold for a little snowmen. I started with the first part of the mold in fusion360

I made the toolpaths with the following settings. I started with a rough cut first and then I did a smooth finish.

Defining the starting possition with the jog function.

Press start.

While the machine is cutting I drew the second part of the mold.

After the milling was done i filled them with the silicone, discribtion off the silicone in the group assigment.

The silicone has a 1:1 ratio.

It cured during the night.

vacuum casting¶

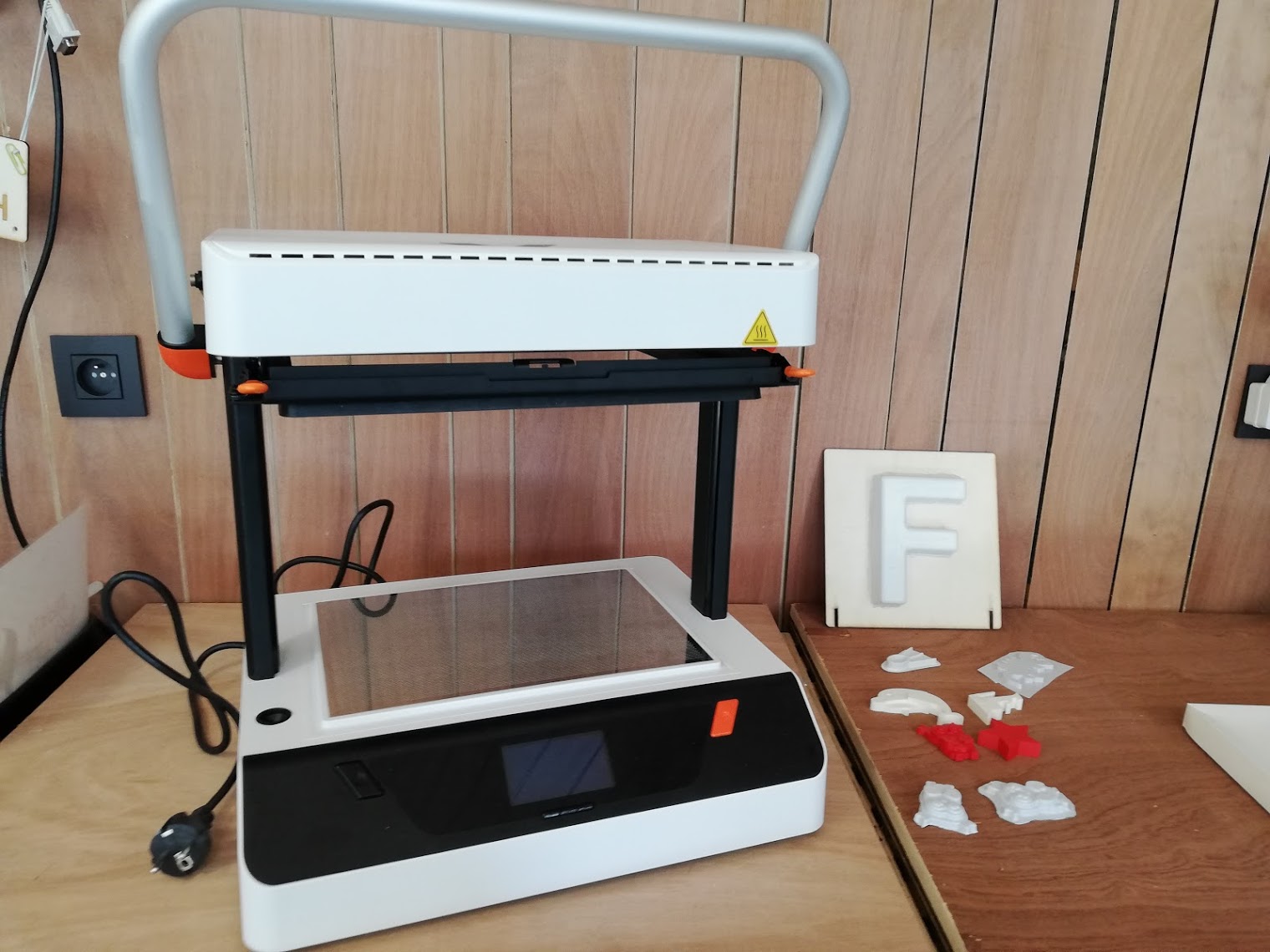

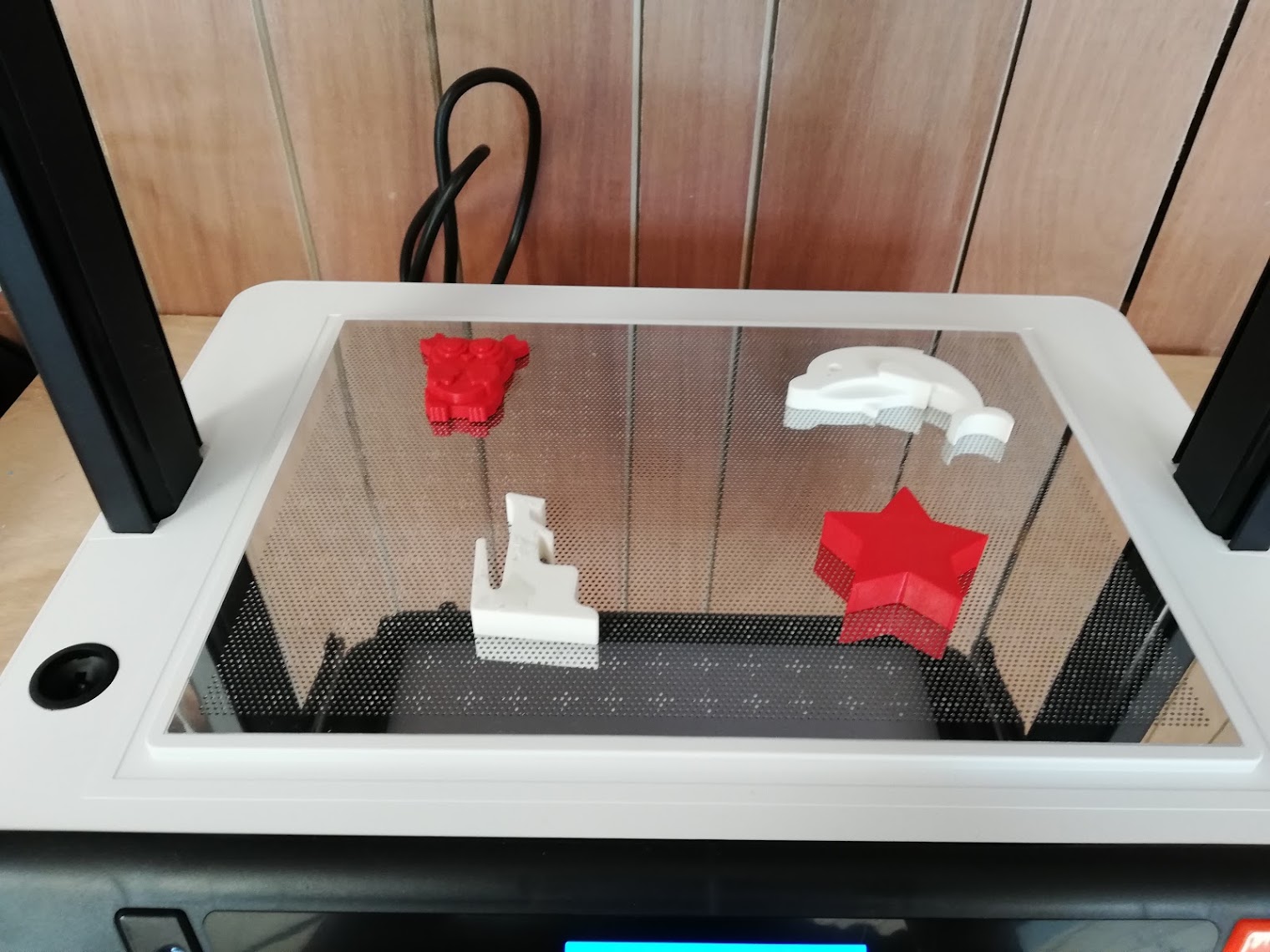

One of the workshops I do a lot with children in the lab is using a vaccuum vormer to make things. We mainly use 3D printed objects as motherobject.

tool for little girl with a muscle disease¶

This girl has a muscle disease, her hand closes automaticly. Her doctor spoke to me and asked if i could make something to help her. The tool she needed is something that keeps her hand open. we first started with molding clay. From the clay model i made a silcon mold to recast it in epoxy.

### link the the group assigment