Week07. Computer Controlled Machining¶

This week, we were supposed to make something big. Unfortunately we didn’t have lab access due to the covid-10 virus. Hence, I only did the design work.

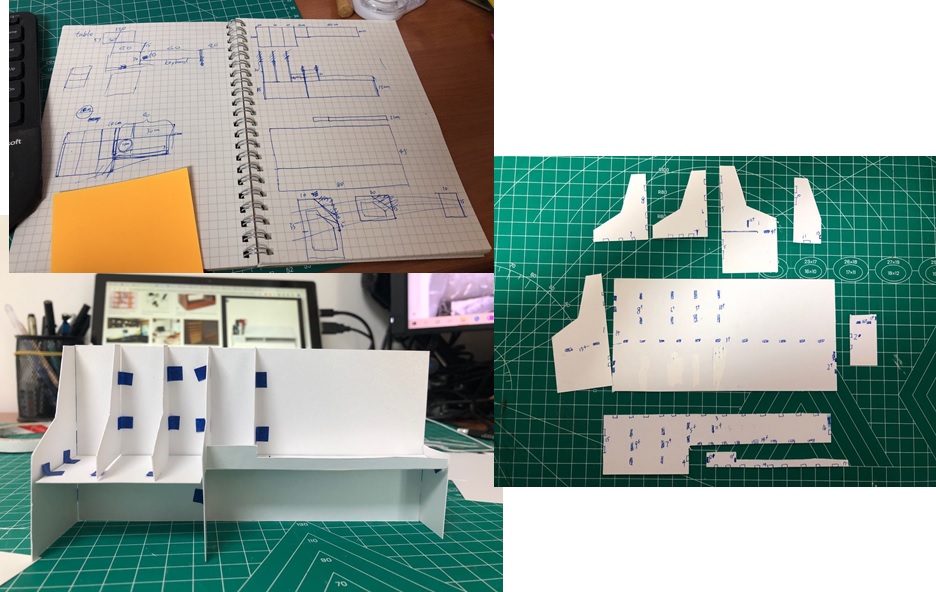

I want to build a desktop shelf for myself.

I measured the length, drew a brief design, then use card-paper to made a prototype.

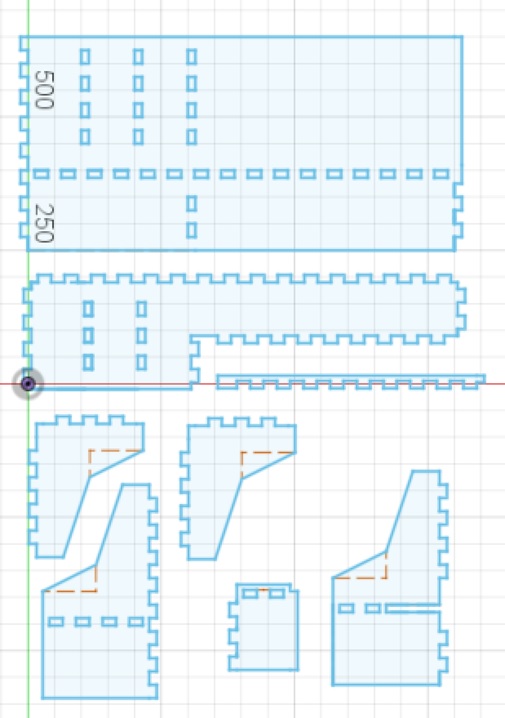

Then I dissambled the paper shelf, marked notes on the pieces, and start to use fusion360 to do the digital design.

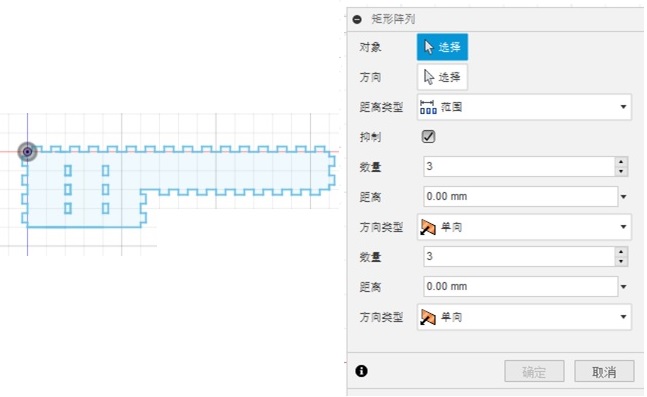

The most useful feature for sketch of this project is the pattern array.

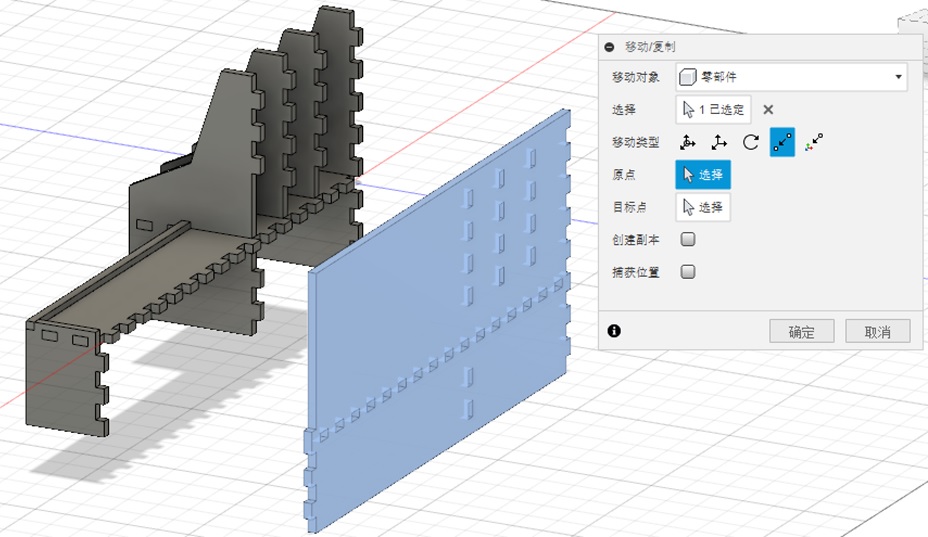

And the most useful feature when assembling components is point-to-point move.

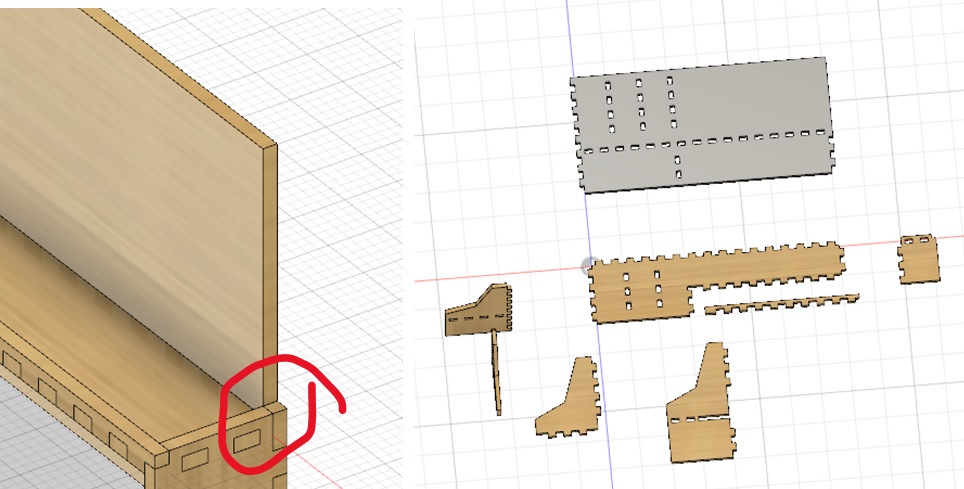

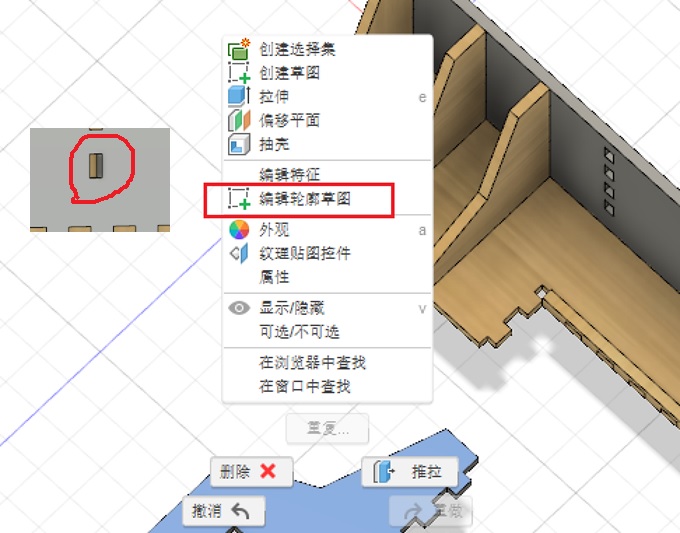

After assembled all components, I found there is one design mistake as the red-circle below indicates. I switched back to edit the sketch. Unfortunately, after finishing the edit, I found the components are decoupled, and I even could not found the previous one in timeline. I have to do the assembling work again.

Then I realize another mistake. This time I right-clicked and choose the “edit outline sketch”. After finishing edit, the component was updated automately, and all other componets were fine. So I only need to get one piece back.

Below is the result. The original design has one more partition board. I removed one as it seemed too crowdy.