1. Digital fabrication, principles and practices¶

This week I worked on defining my final project idea and started to getting used to the documentation process.

Why Fab Academy?¶

This is a Microsoft PowerPoint slide show exported to mp4 movie Initially, this file would not render. I could not figure out why. I recalled that git sometimes will not process copied and pasted text. Apparently, Markdown is the same way. I copied the Markdown image link below and replaced the previous video link. Now, the video renders.

*I further compressed the mp4 file in the iTerm2 app on a Mac using the command ffmpeg -i FAW00-DigitalFabrication.mp4 -filter:v scale=800:500 -c:a copy digiFab-800.mp4 source: https://www.ostechnix.com/20-ffmpeg-commands-beginners/

*Installed ffmpeg in iTerm2 app on Mac using Homebrew with the following command: brew install ffmpeg $(brew options ffmpeg | grep -vE ‘\s’ | grep – ‘–with-‘ | tr ‘\n’ ‘ ‘) source: https://gist.github.com/Piasy/b5dfd5c048eb69d1b91719988c0325d8#gistcomment-2571754

Assignments¶

| Have you? | Done |

|---|---|

| Group assignment: | ⬇ |

| None | N/A |

| Individual assignment: | ⬇ |

| Plan and sketch a potential final project | Yes |

| Upload it to the class archive. | Yes |

Learning outcomes¶

| Have you? | Done |

|---|---|

| Communicate an initial project proposal | Yes |

Checklist questions¶

| Have you? | Done |

|---|---|

| Sketched your final project idea(s)? | Yes |

| Described briefly what it will do and who will use it? | Yes |

| Added a page with a sketch and description of your final project idea(s)? | Yes |

Individual assignments¶

-

Plan and sketch a potential final-project.

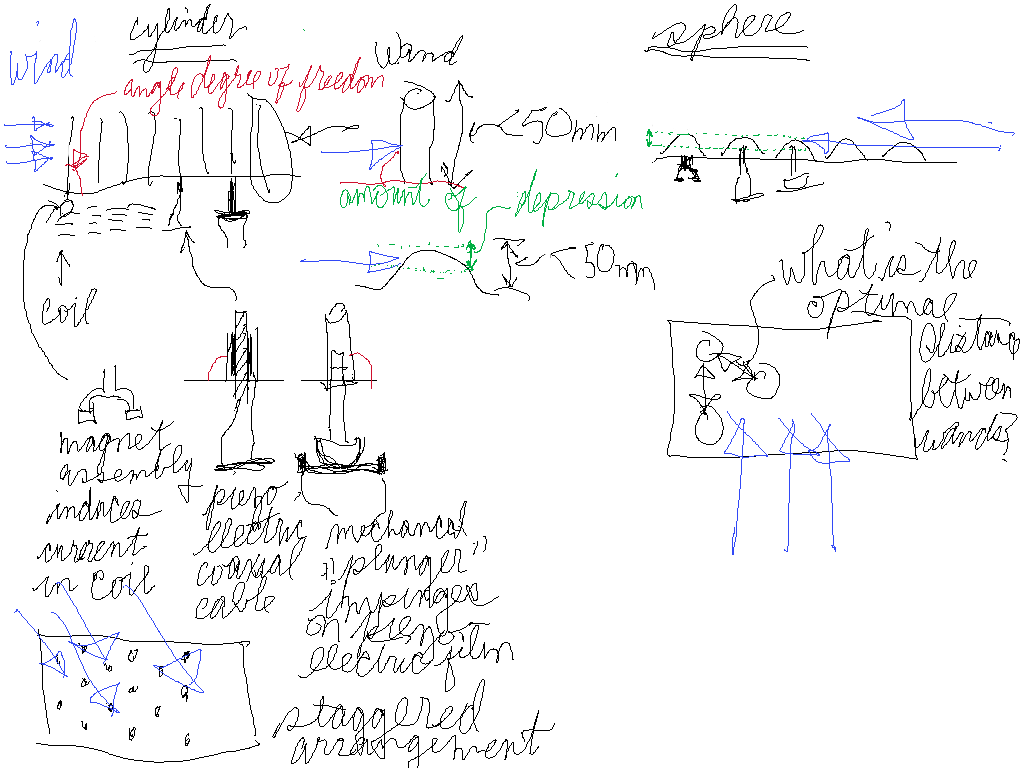

- Right now, I have three ideas for a final project. They are an autonomous golf cart & caddie, an autonomous two or four-wheel farm hand, or wind wands for harvesting energy.

The first two ideas are fairly transparent. In the first case, i could modify a Ninebot Segway to add motor control and sensors so that it could follow a player. With GPS, it could suggest clubs to use. I could fabricate a cart attachment to transport the clubs while retaining the ability to ride the Segway.

In the second case, I could automate a two-wheel tractor that I own. The idea is that it could till, thatch, aerate, seed, etc. independently. Similar to the caddie, my package would include motor control and sensors. The deck and power-take-off are pretty standard. I would spend little time modifying them. So, while personally enticing, this idea may not meet the project criteria.

In the third case, I would have to fabricate the wands, the harvesting circuitry, and the system package. If I use piezoelectric harvesting, I will use manufactured piezoelectric coaxial cable or film. I got the idea for Wind Wands some years ago after watching grass move in the wind.

-

Nfr Wind Wands

*This video illustrates the inspiration for the Nfr Wind Wand idea

Current energy-harvesting tech can not meet consumption demands. For example, urban centers consume the most energy but wind turbines are ill-suited for urban environments.Ideally, harvesting can coexist with dense, human populations and the structures that house them.

-

Constraints

- sheet form factor with limited thickness

- made from formable material

- made from transparent material

-

Challenges

- Will wands sway or vibrate?

- Will wands be cylindrical or spherical?

- Will wands use induction or piezo electricity to harvest energy?

- Will wands be omni- or uni- directional?

-

Concept drawing

-

Circuit inspiration

*This is an example of an energy harvesting circuit. source: