Composite - Final Academy

Menu Principal:

Composite

Week11. Composites

Time flies! We are in week 11, which I had more expectations!

In early September, I started looking for "how to make a carbon fiber bike." The net is full of imformation DIY or homemade, super interesting! The searches were more fruitful or www.youtube.com www.instructables.com, I may have some links on my Pinterest boards.

Without seeking specific material I already had everything ready to make some pieces using FabLabSevilla tools.

My expectations:

Plastic greenhouses -

Double-

Filler cushions??? -

Fill food -

Vacuum pump -

A mold, fibers (glass, carbon) and epoxy resin.

After to "play" with all this, I decided to find out a little more ... and everything was complicated.

My goal was a bit ambitious, build a bike trail. I read and searched thoroughly, and to get something really light and strong, I needed much more, at the moment ... money.

Lots of money, the results are amazing, but the prices of materials scare!

Several layers of carbon fiber, kevlar, fiberglass particular, various epoxy resins such as gel coats, fast, slow, smooth ... plus an oven, sanding, polishing, precise molds ... too many things that were not available to me. I forget the project, and I've been waiting to have some materials to make small parts, this week, FabLabSevilla has met almost all of these components, and I made my first carbon fiber part!

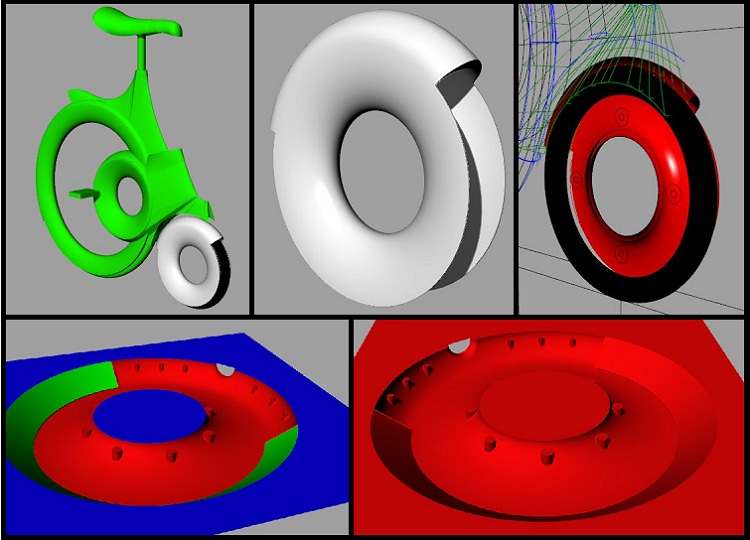

Well! I continue with the idea of making parts of the final project during the weekly homework. This week I redesigned the front wheel of my bike.

I already had a lot of work ahead for the week nine I made a 1:1 scale model of my final project. This time, I did not have a lot of carbon fiber, so I decided to do half of front fork.

I used to draw Rhino 5. First I cut the piece drawn by its half, and then I included cylinders which will place screws to attach both halves. To soften the fiber movement, I made a tapered perimeter and two flat tops.

At first, I thought to use foam to make the mold, but I worried that the vacuum pump was very strong, and dent the surface. Therefore I decided to use 30 mm MDF. The machinery is set in motion! *. stl >> *. txt and milling!

To make it, I used a 8 mm end mill, first the roughing, 4mm depth and 3 overlap, then the final lap with a 3D configuration and the same bit.

Sanding and some correction with a hobby knife. It´s ok!

How is demolded?, In a first step, I used polyvinyl alcohol, vinyl dissolved once the alcohol evaporates, the vinyl is dried and brittle. Apparently the MDF absorvió this stuff ... I was not sure it would work, so I thermoform vinyl adhesive layer in pan. On the latter, use liquid release agent.

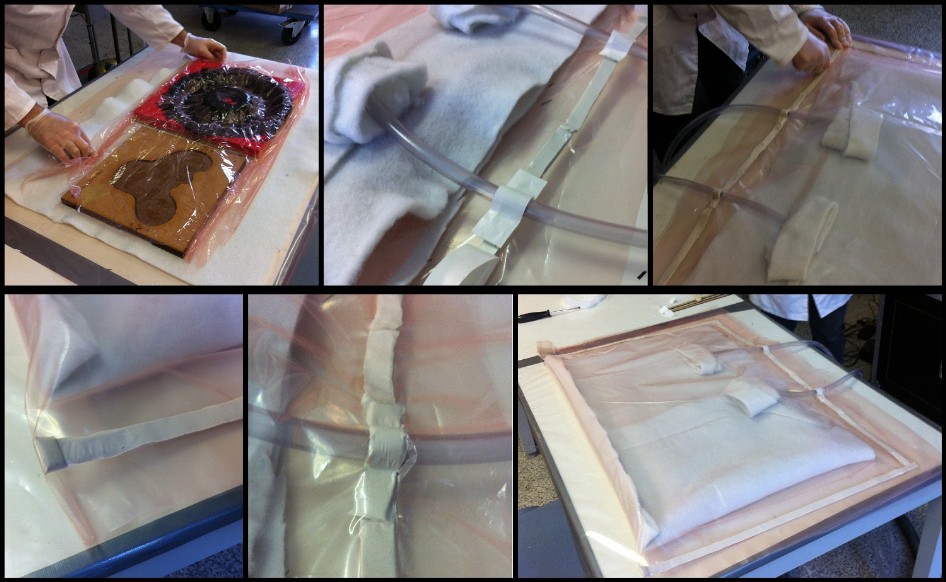

Before we start applying the resin and fiber, prepare all the materials needed to make the bag and apply the compound.

College of Engineering gave us some materials, the release agent film, mesh absorption and double-

All ready!

The epoxy resin is workable for 23 minutes. We had to be quick. We prepare several containers with the same amount of component A, so that every time we needed resin, mix 1/2 of component B.

First, a coat on the mold, after fiber. Another resin coating over the fiber, fiber again, so three times.

Now the vacuum bag, we had all the materials prepared, first, under and over the molds, the bleeding film. Between the fiber and the bleeding film we provide the vacuum film. We close by placing double-

The vacuum pump ran for hours.

Unmold! All s took off easily, but to remove the composite I had to break the vinyl, nothing serious.

The piece was not as I expected it. Very irregular, and some parts were brittle. I sanded the surface to get something softer, as is painted I'll show