CHECK LIST

Complete your final project, tracking your progress:

what tasks have been completed, and what tasks remain?

what's working? what's not?

what questions need to be resolved?

what will happen when?

what have you learned?

My Project

Develop a sustainable bus stop that allows to create a green

area on the roof, to create a habitat for insects and to help eliminate suspended particles of contamination

to see the final result enter the following link.

Final Project

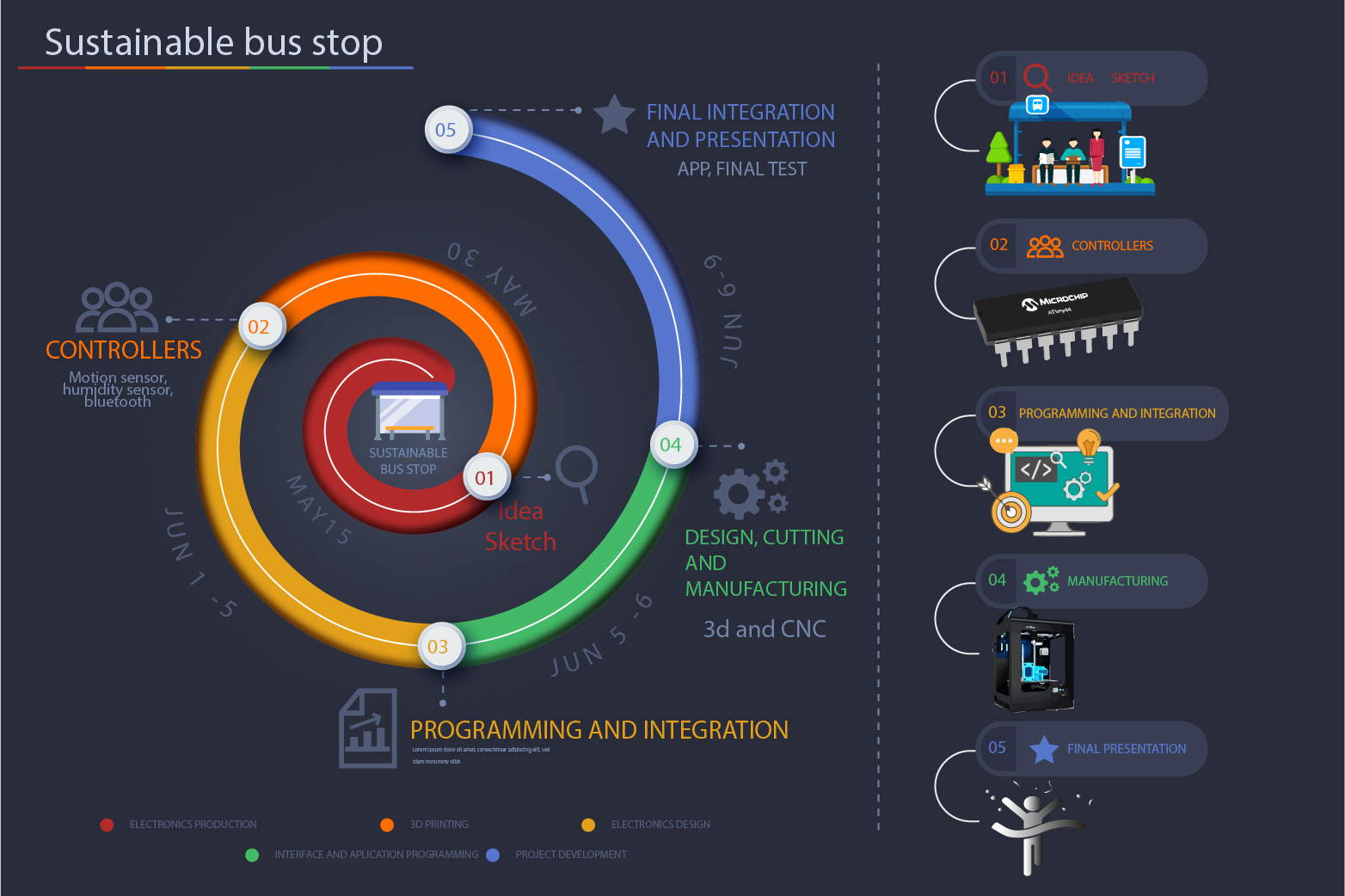

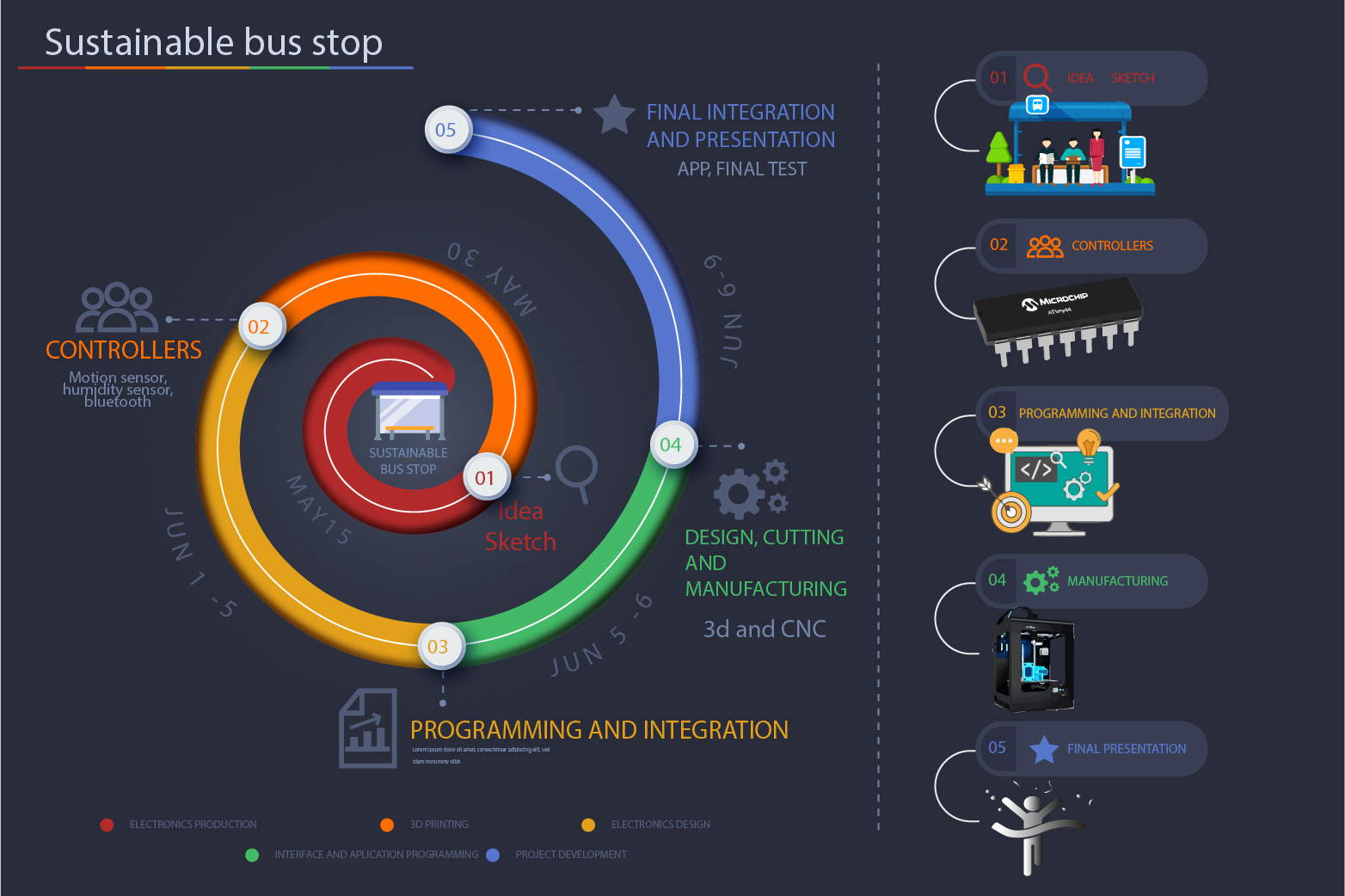

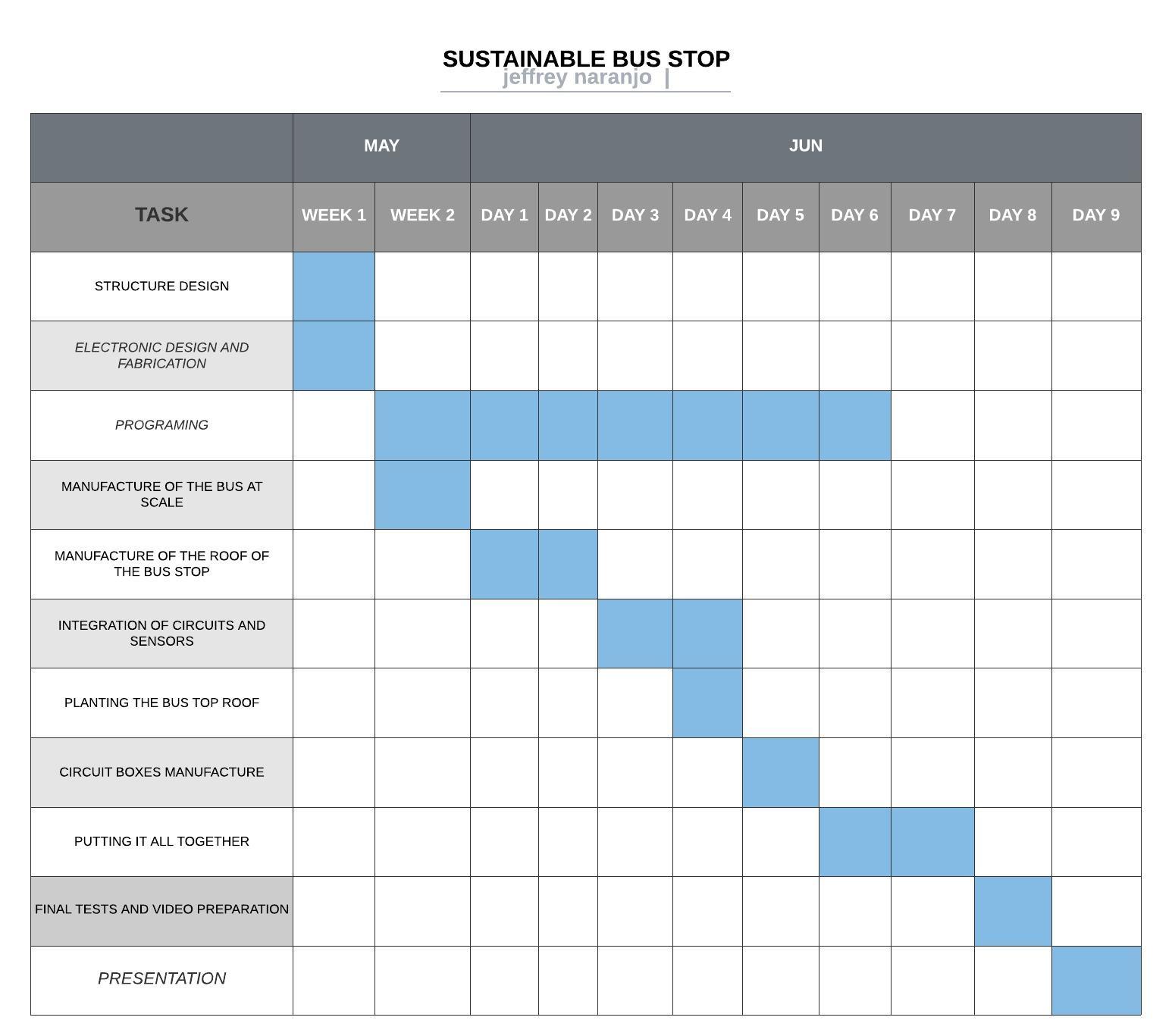

FINAL SCHEDULE

For the development of the final project I make a spiral diagram for the development of the activities to finish in the established times

Complete your final project, tracking your progress:

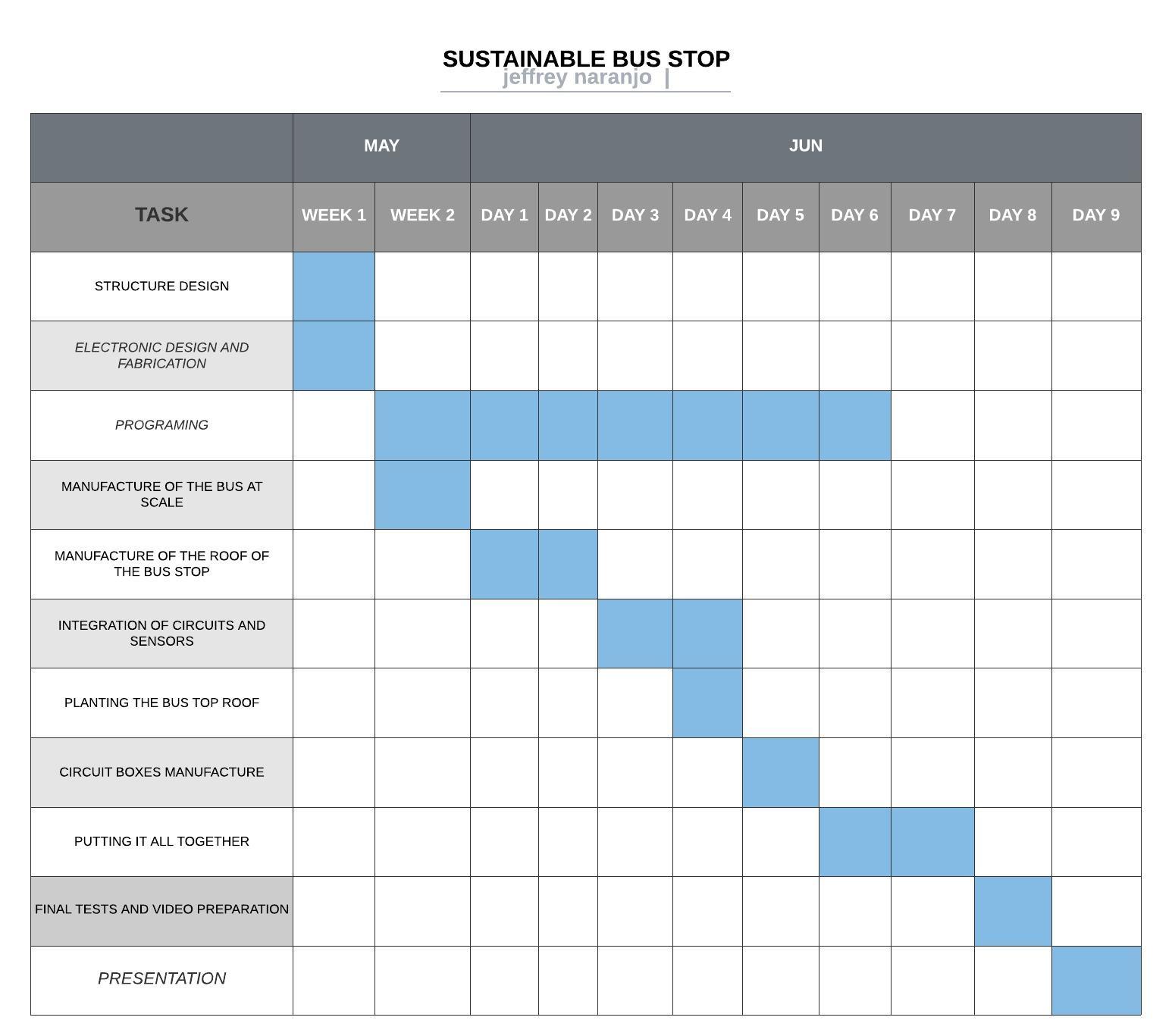

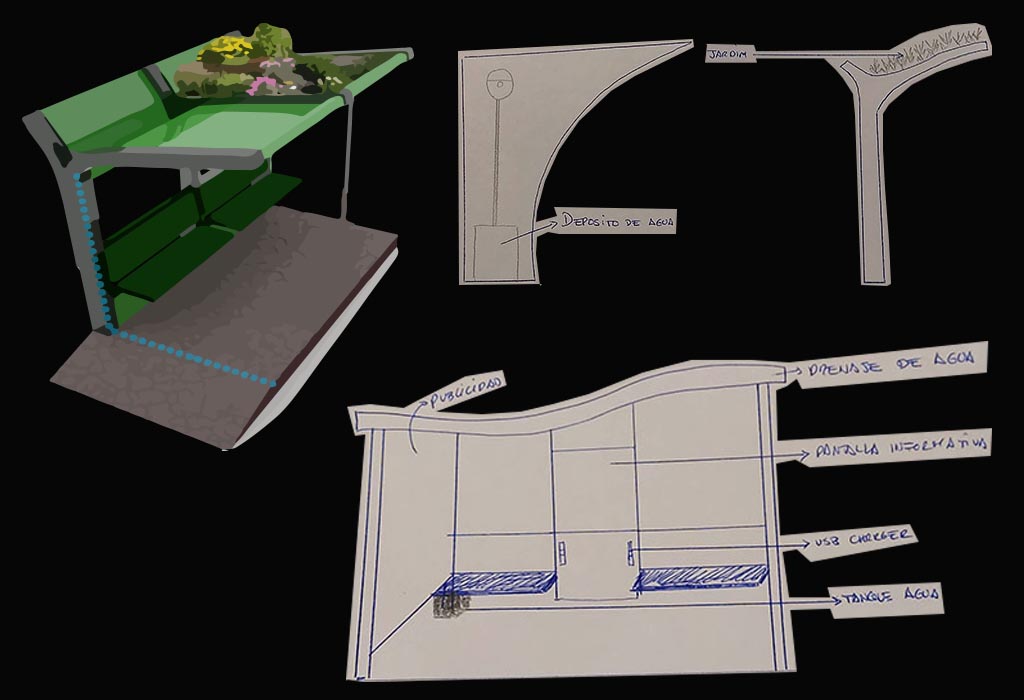

first diagrams and sketches:

fabrication of the structure:

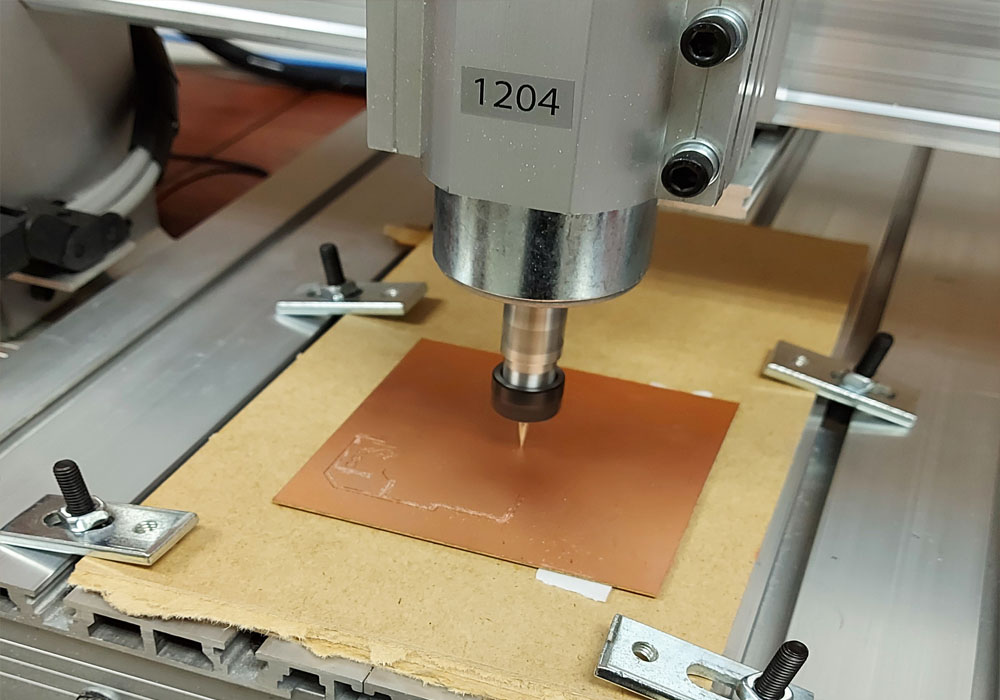

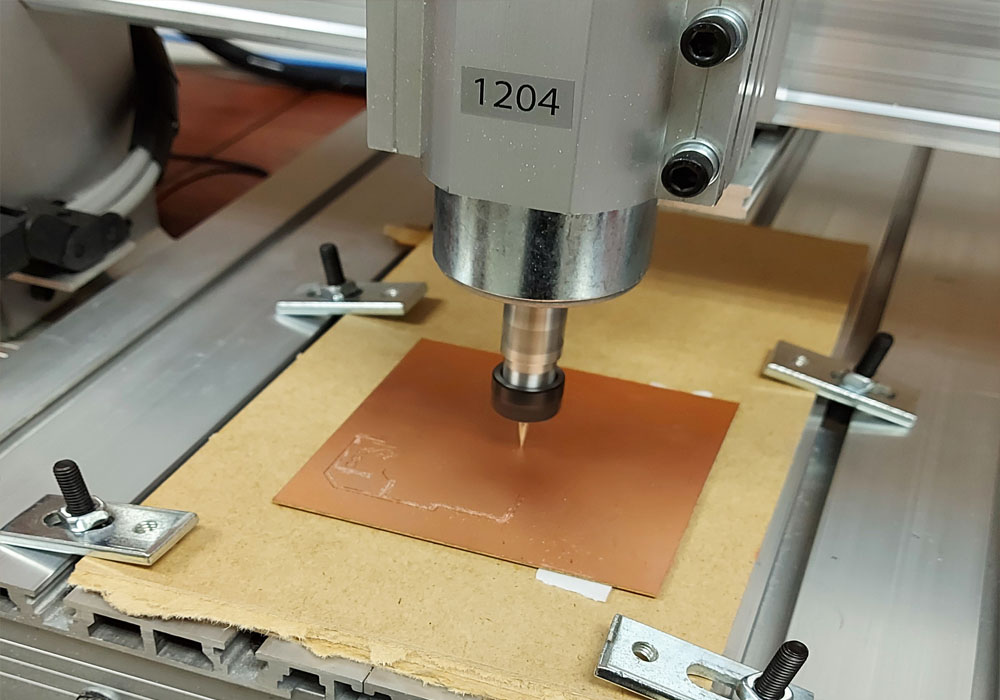

The most difficult part of the project was to understand on my own the operation of the CNC,

its calibration and sending of g files, so that it could do what it had to do, You can see the entire

design and construction process in the following link,

Computer controlled machining

Once I understood how the cnc works, the construction of the bus stop structure was very fast

Because I have limitations in my 60X90 cm cnc I made a design of the arms of the bus stop in two

sections that are assembled as a puzzle, thanks to the Computer-Controlled Cutting assignment, I was able to build an arm in two pieces.

In local suppliers I only found 12mm mdf, for this reason I joined two arms with white glue, one of the arms in its design has notches to

adapt the pergolas of the roof of the stop

Below we can see some videos of the manufacture of the arms of the sustainable bus stop

The files can be downloaded from the following link,

structure

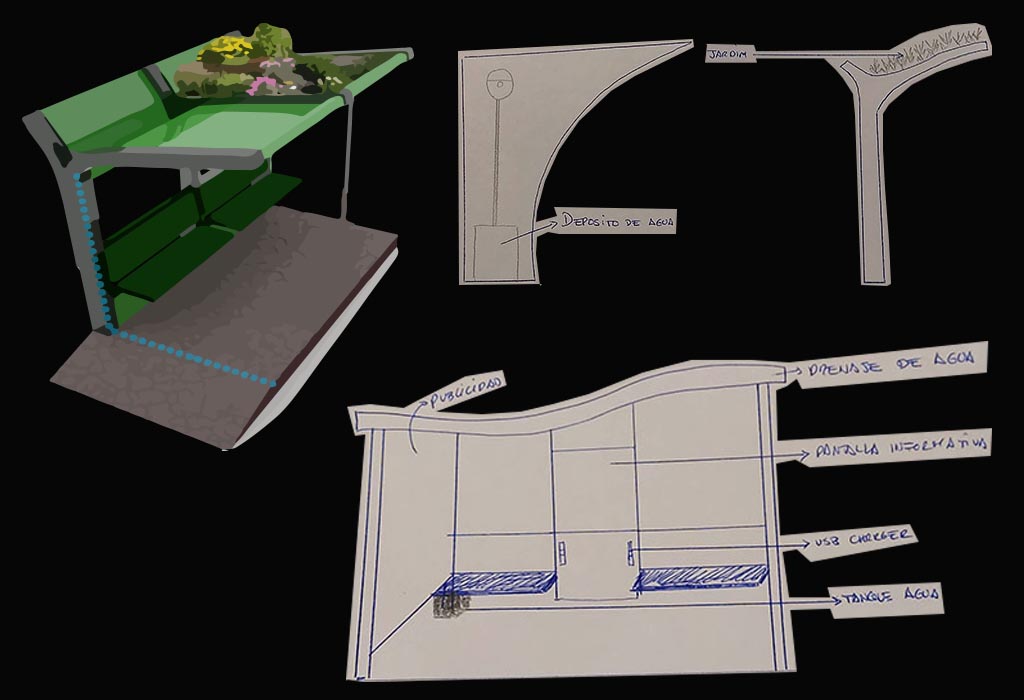

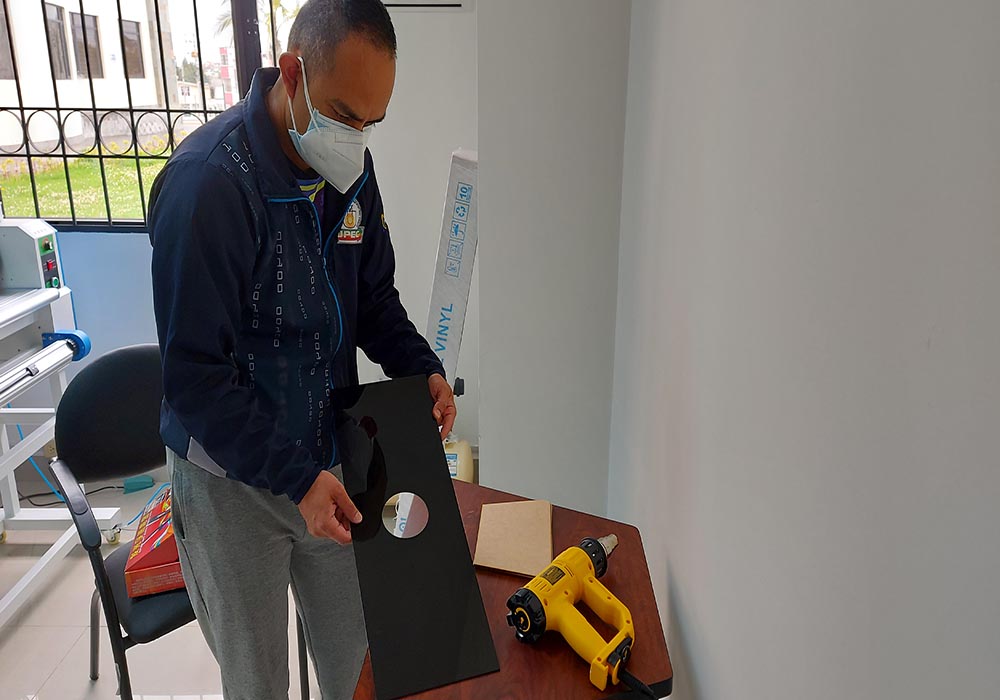

laser cut and acrylic fold:

It was a challenge to make the acrylic folds, the use of the heat gun involves some technique, especially

in very large areas such as the roof of the scale model of the bus stop, determining the right temperature, and even when to apply. hot.

to make the 3mm acrylic bends. I cut the shapes on the laser

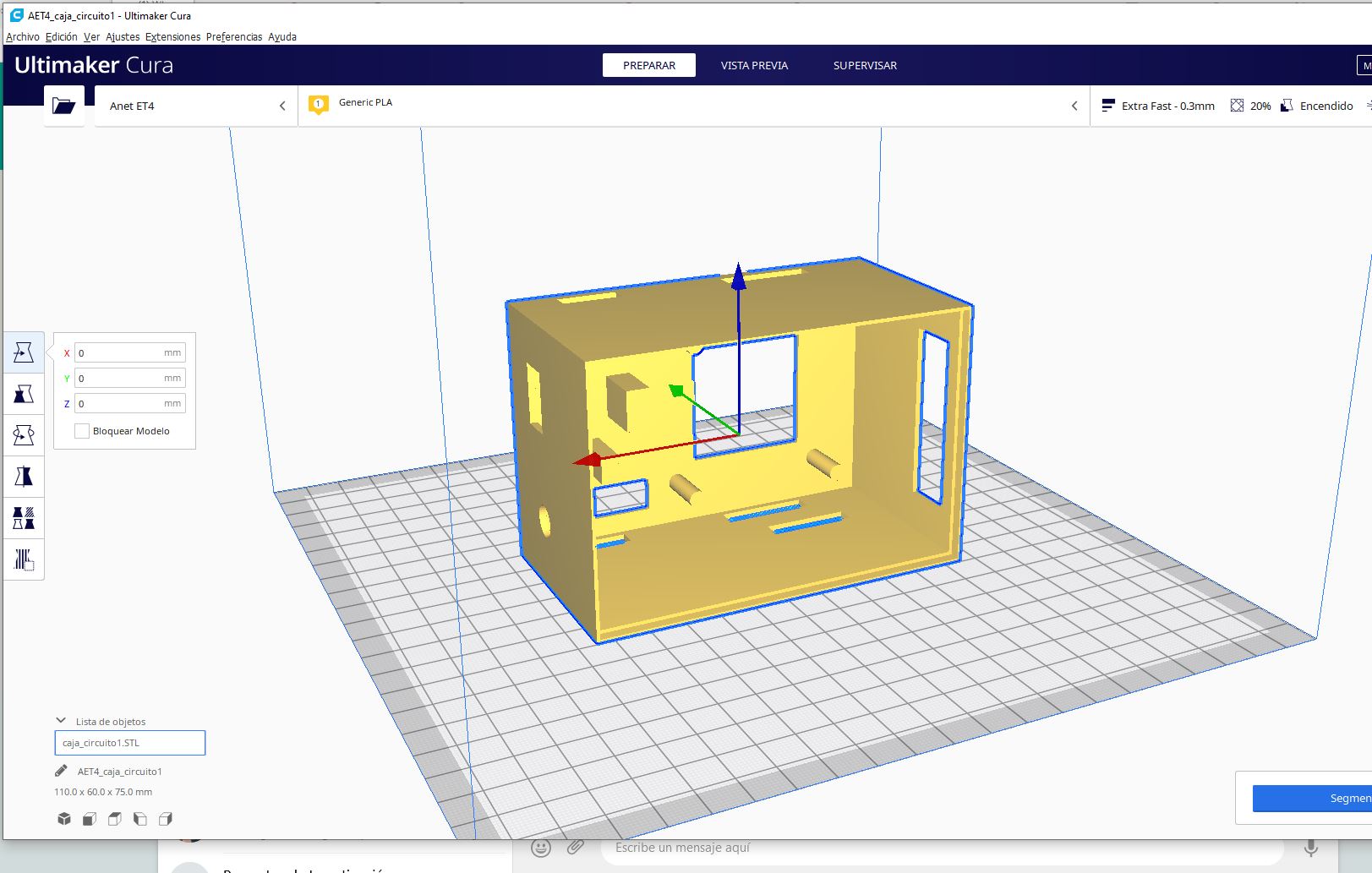

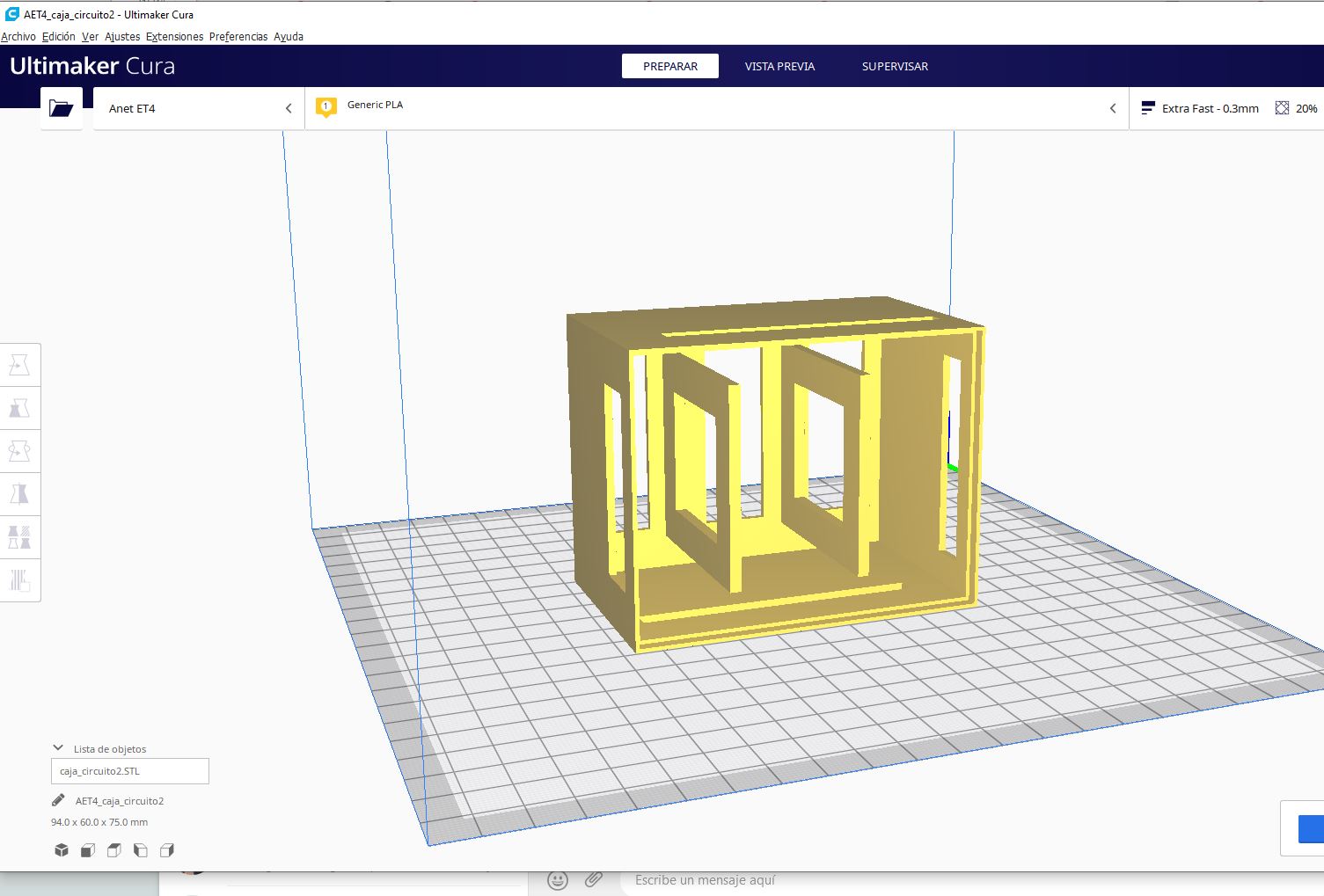

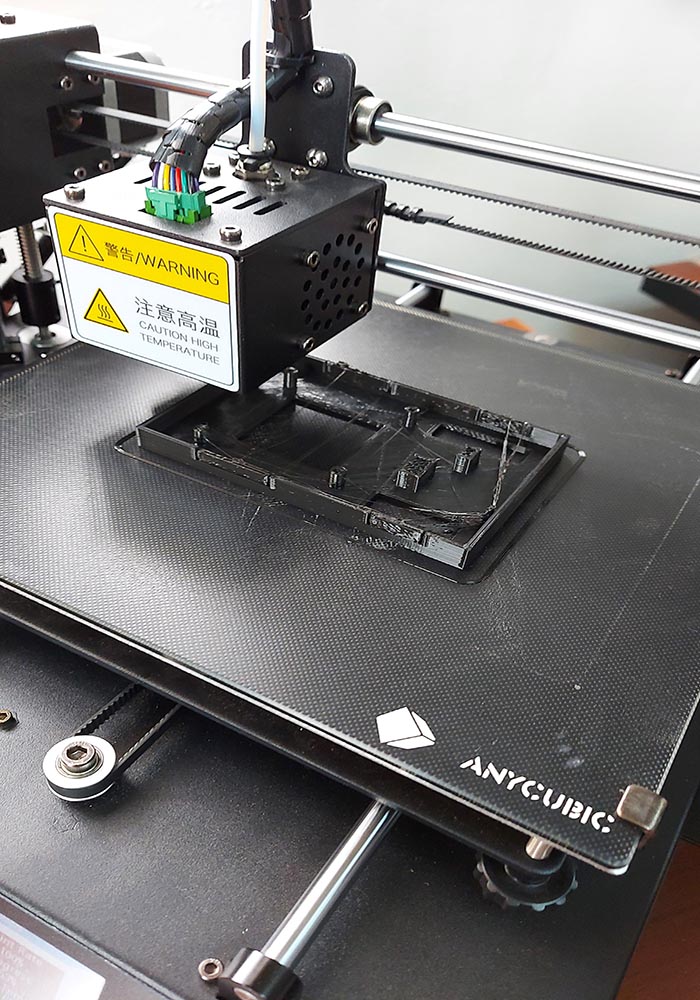

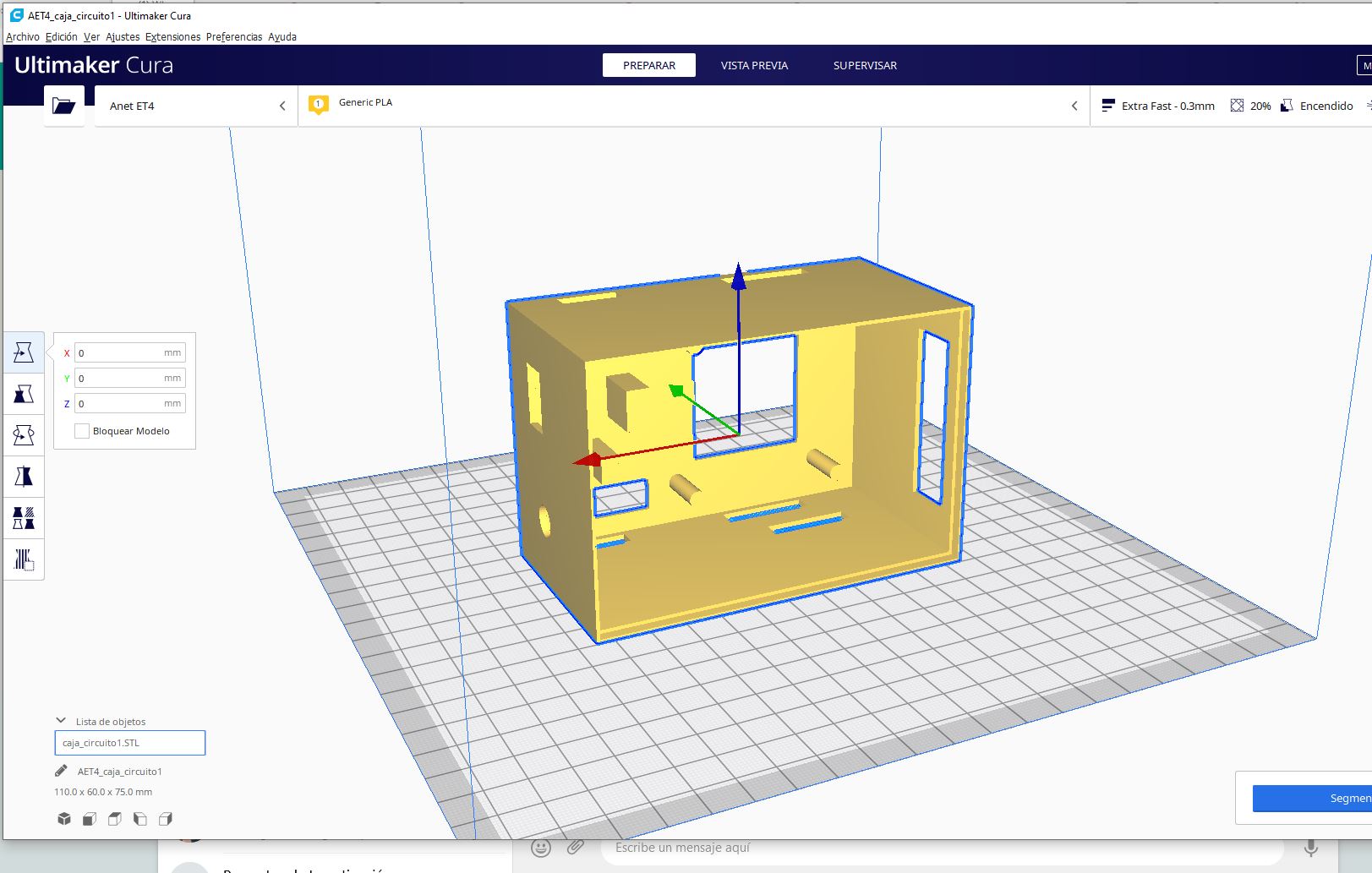

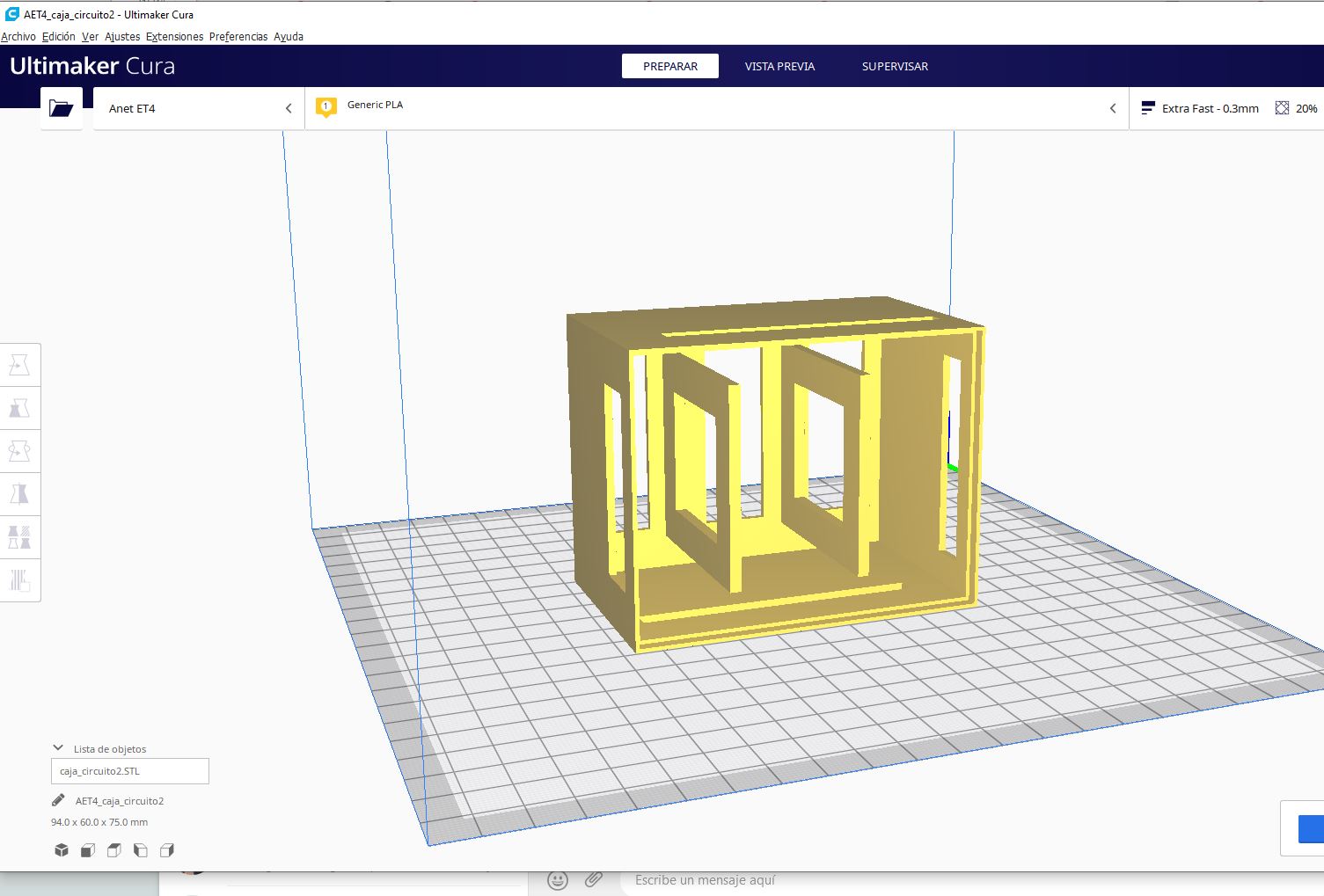

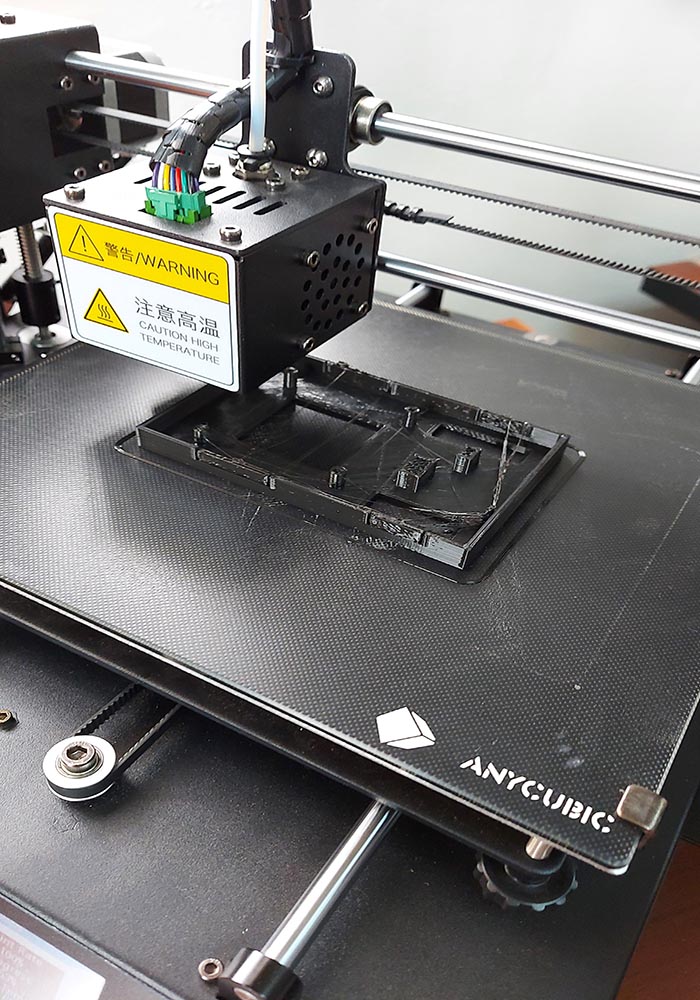

3d manufacturing:

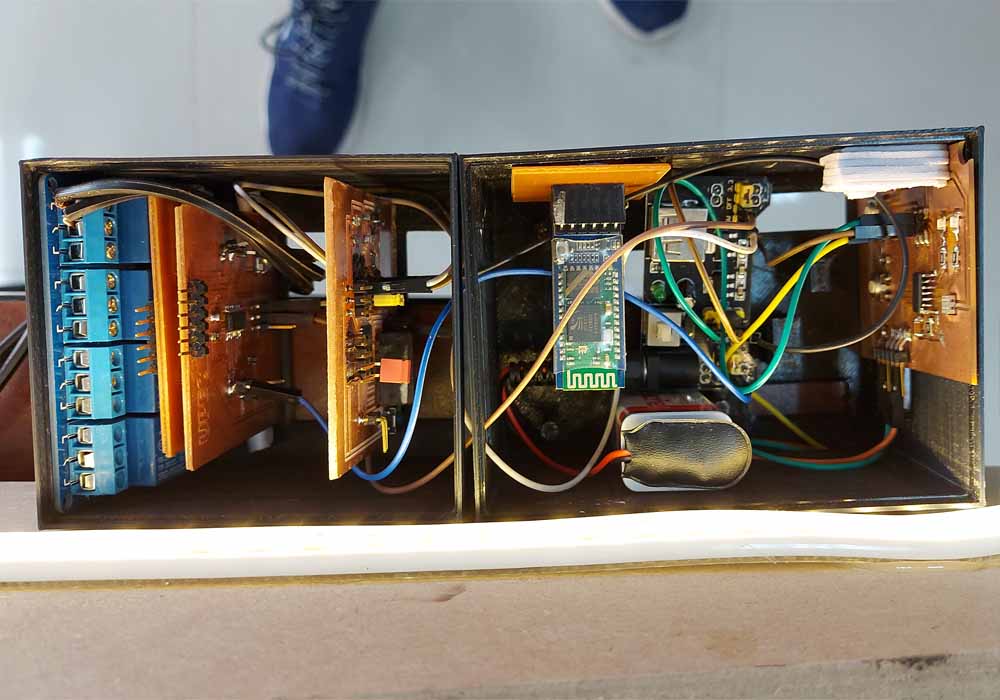

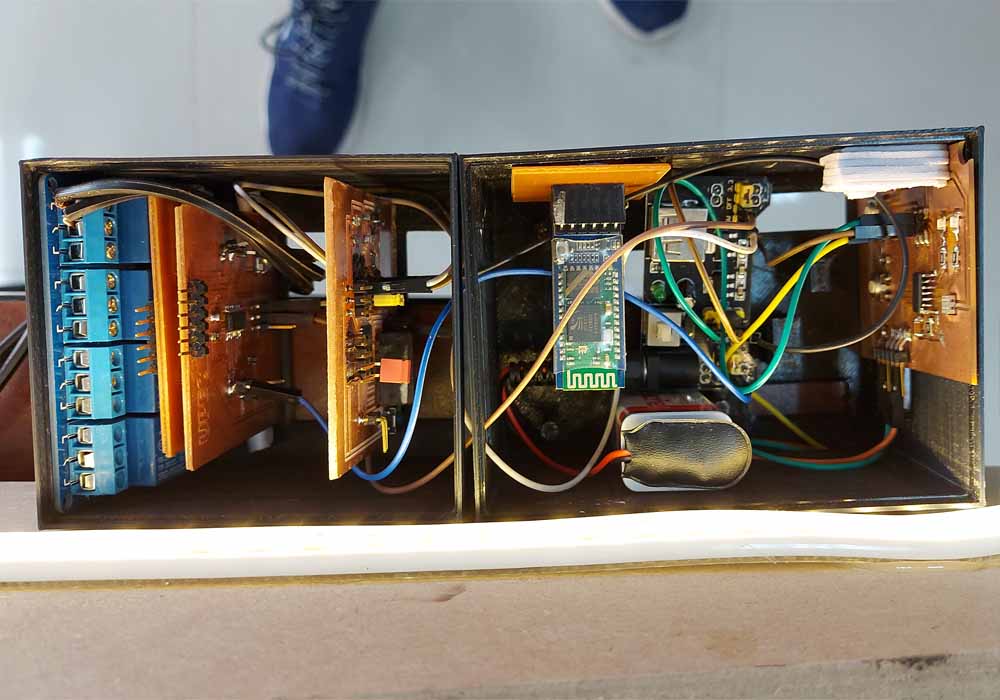

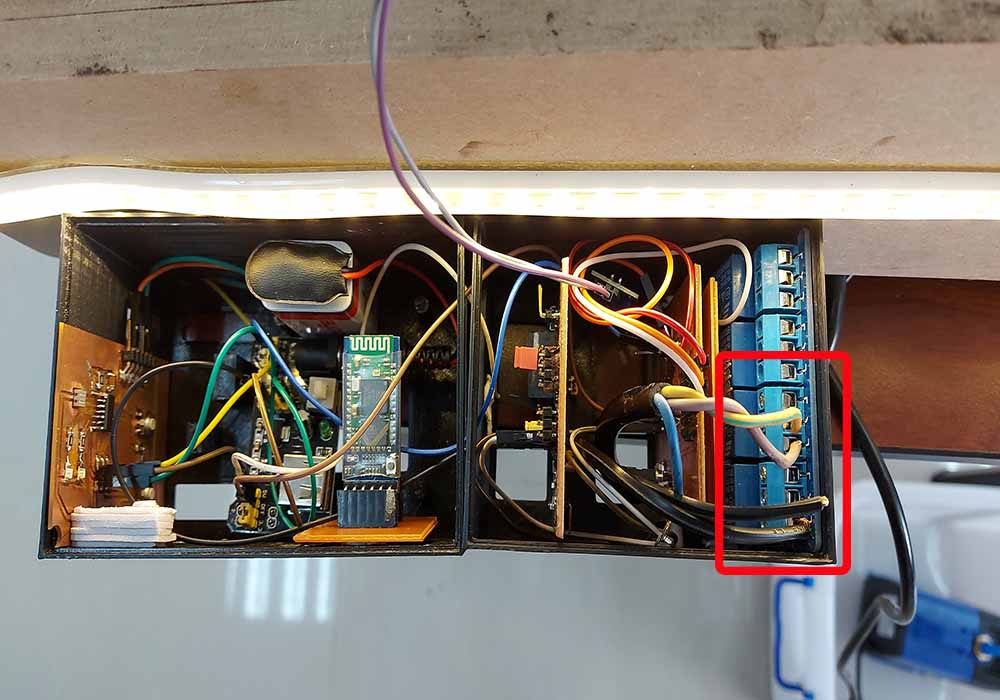

For the integration of the electronic circuits pcb, two boxes were designed to place the three palacas that are used

for the automatic control, both the movement sensor, water sensor, connection and bluetooth.

the covers of the electronic circuit pcb boxes were cut in 3mm black acrylic

|

|

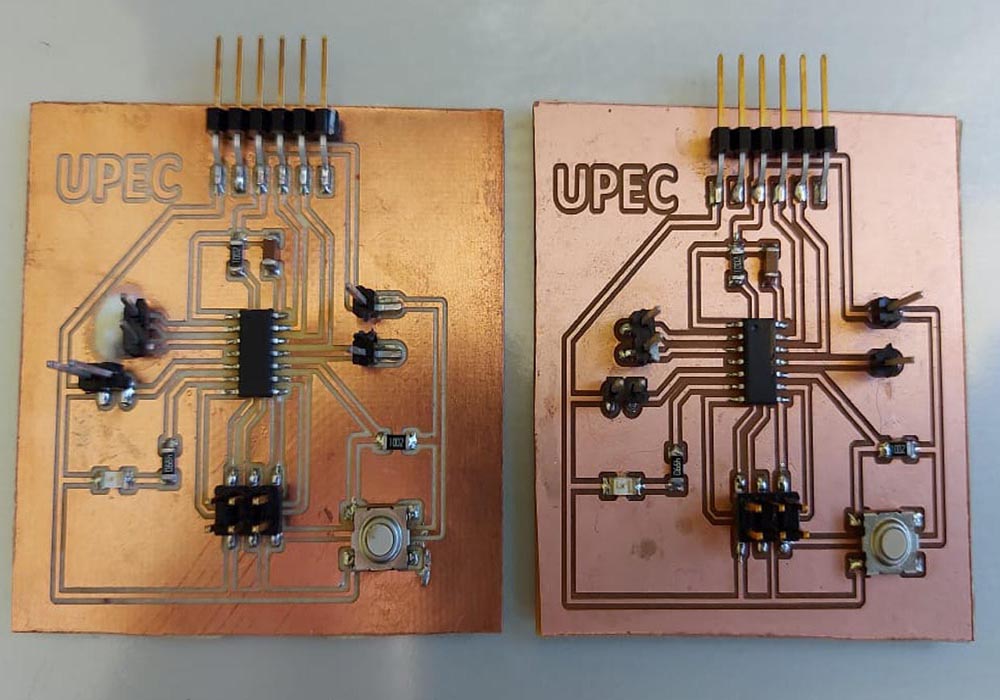

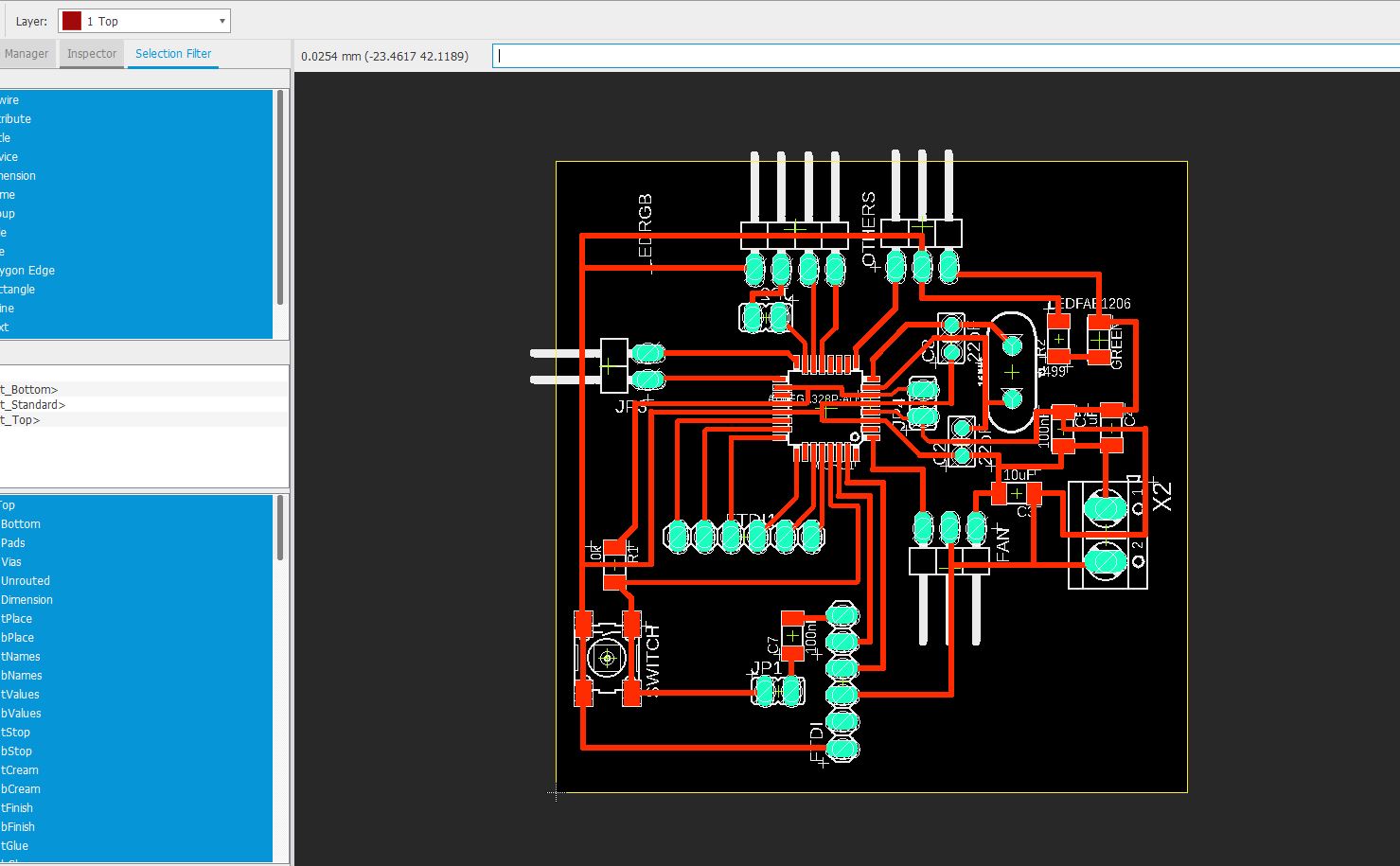

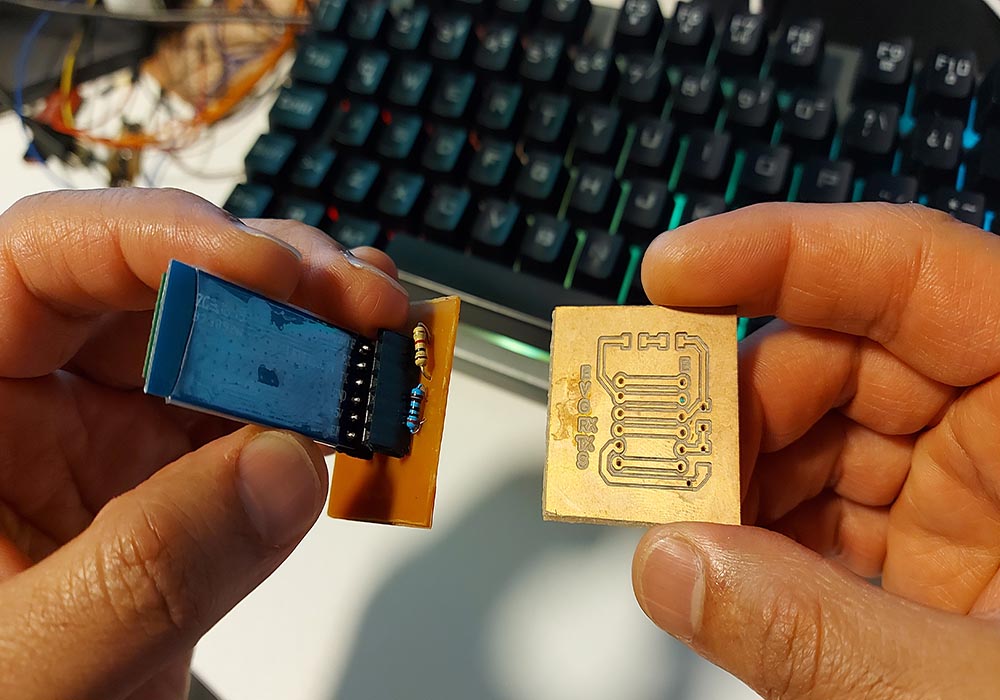

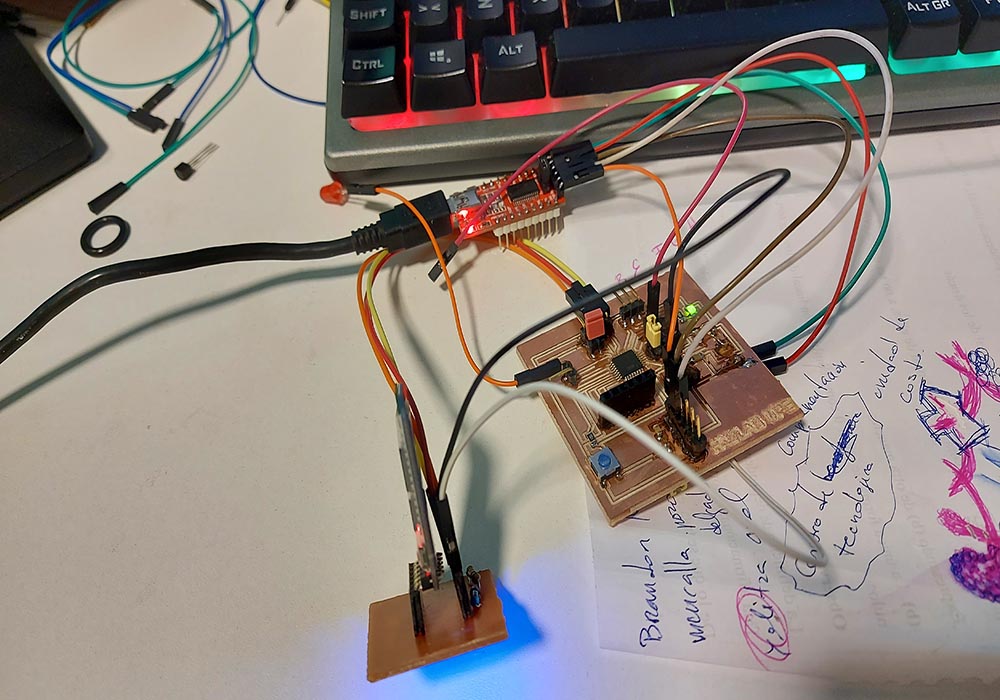

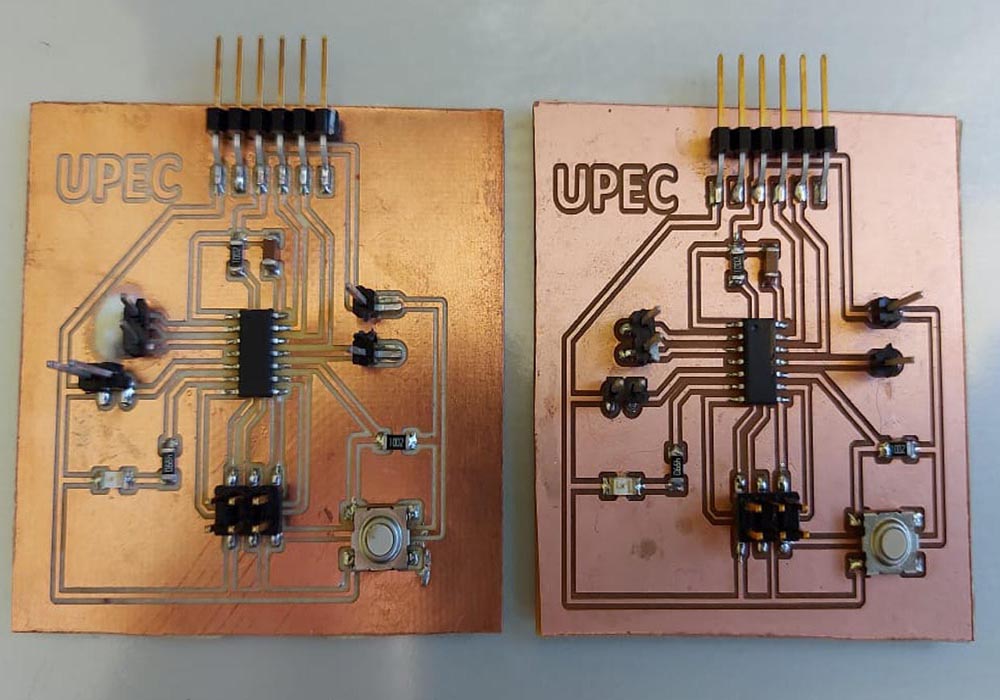

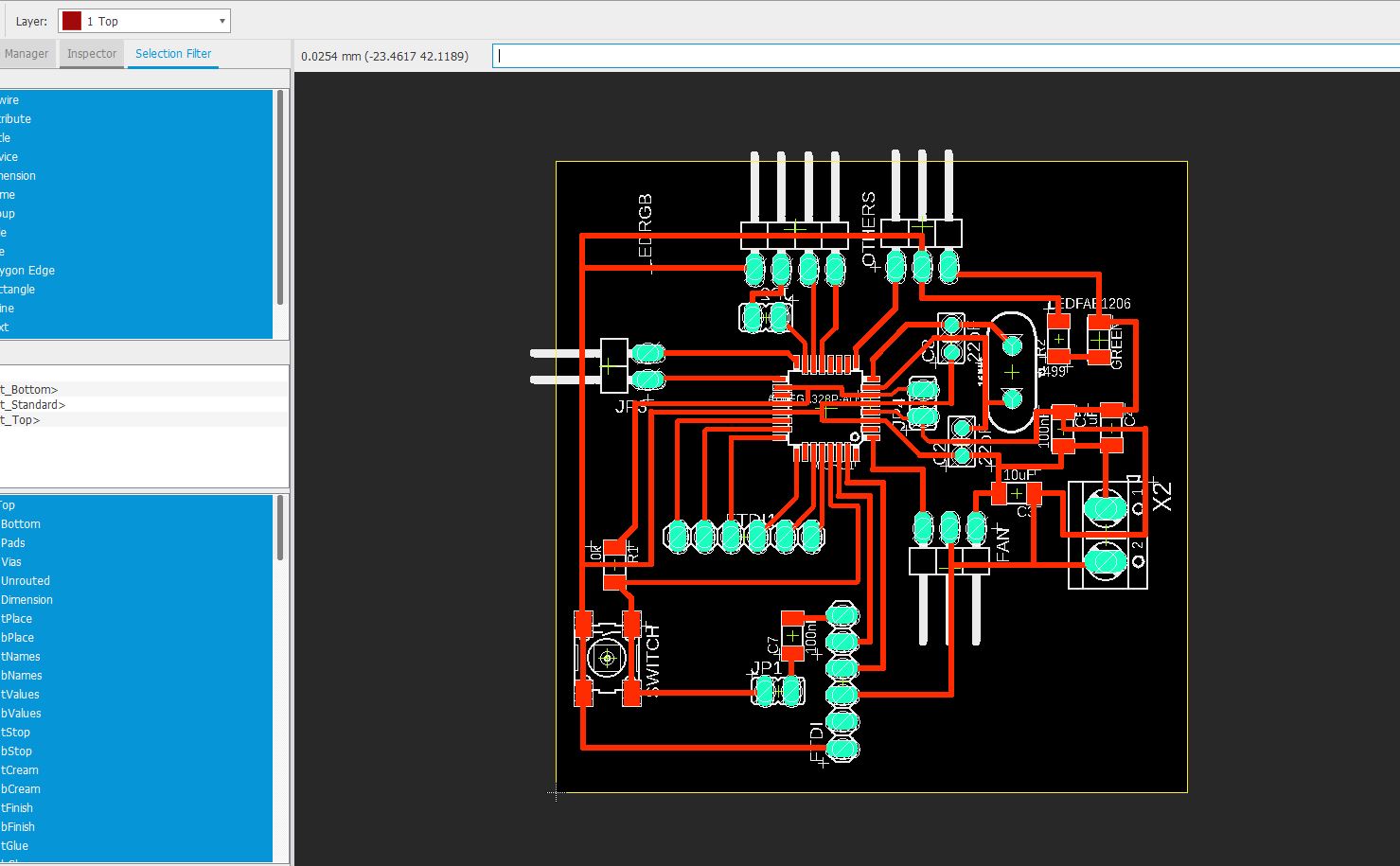

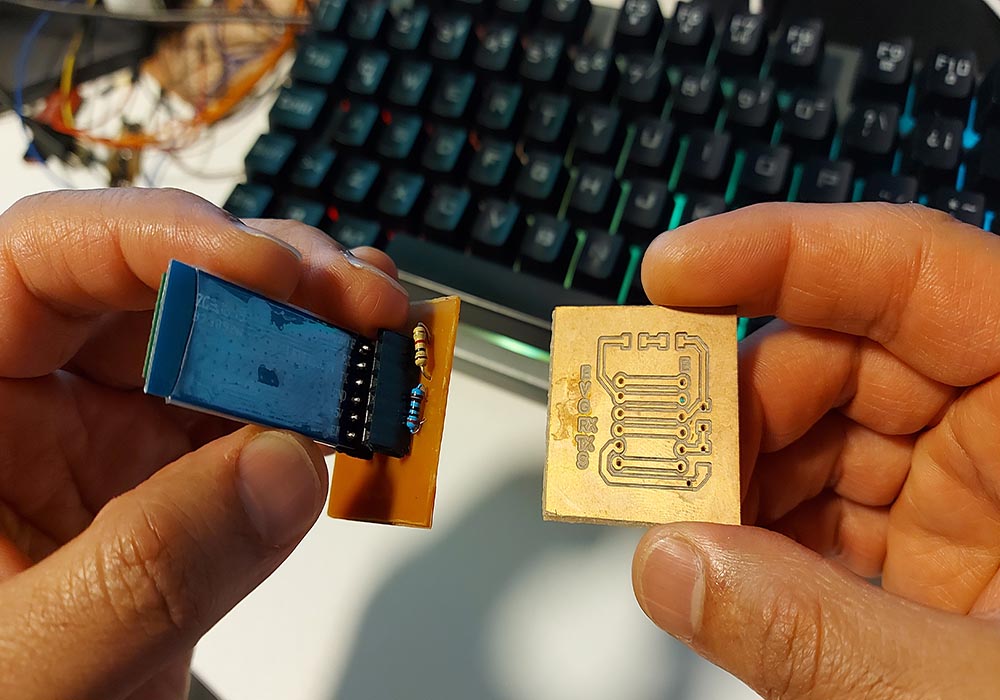

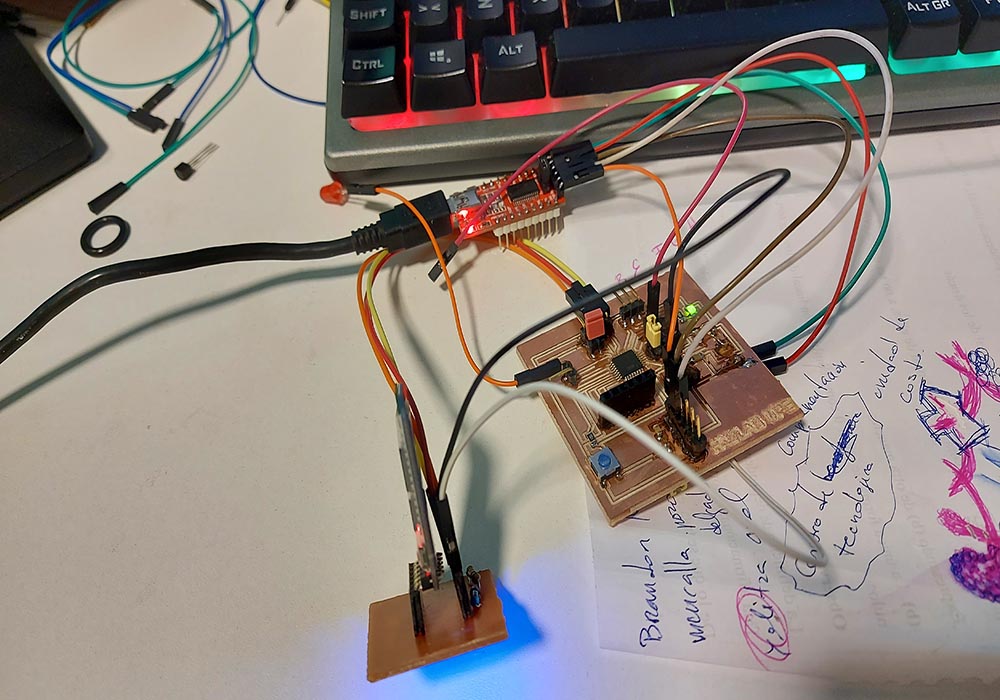

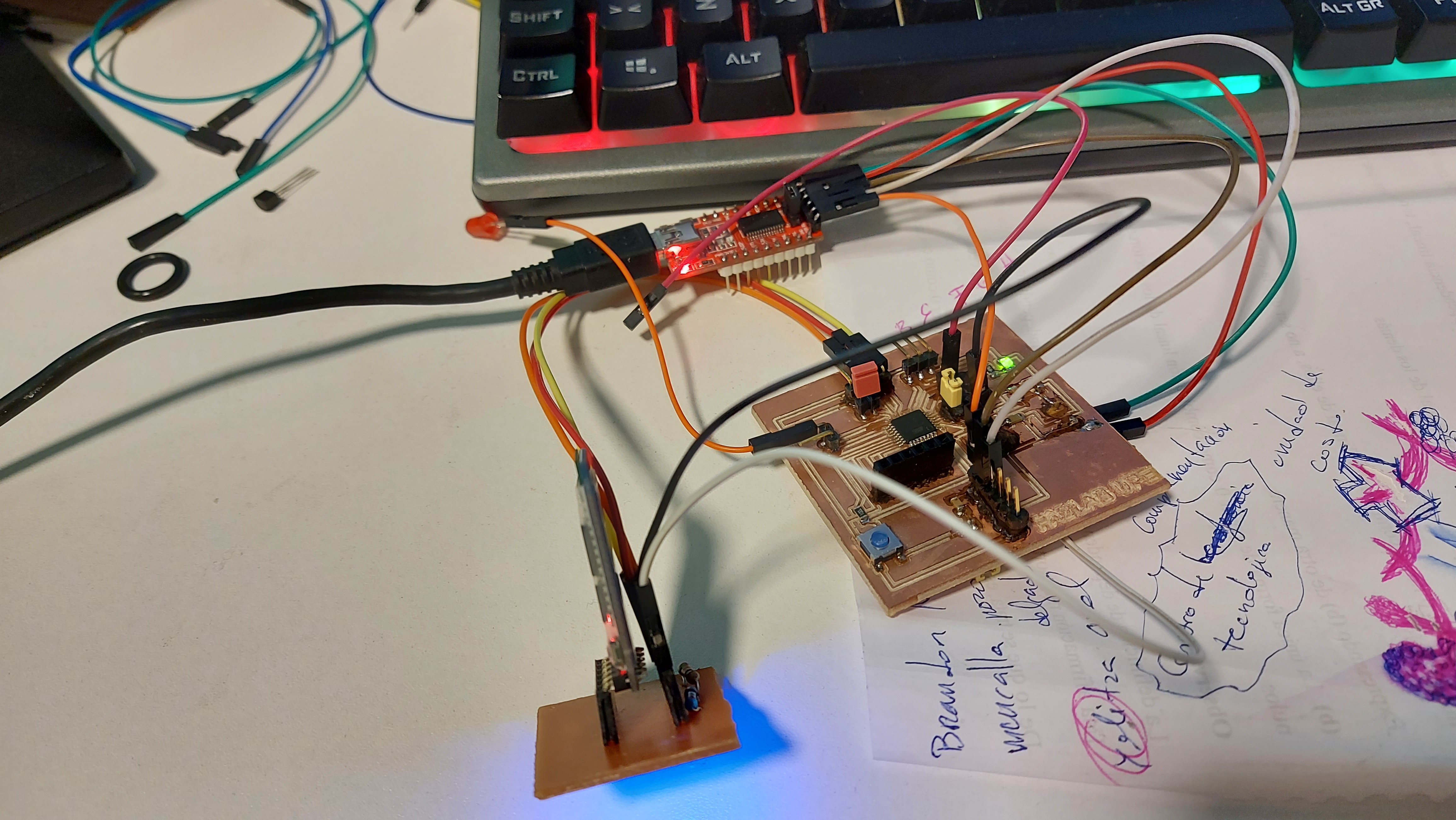

The electronic circuit boards pcb were developed throughout the course in the assignments of inputs,

outputs and networking, we can see their development in detail in the following links

Inputs

Output

Networking

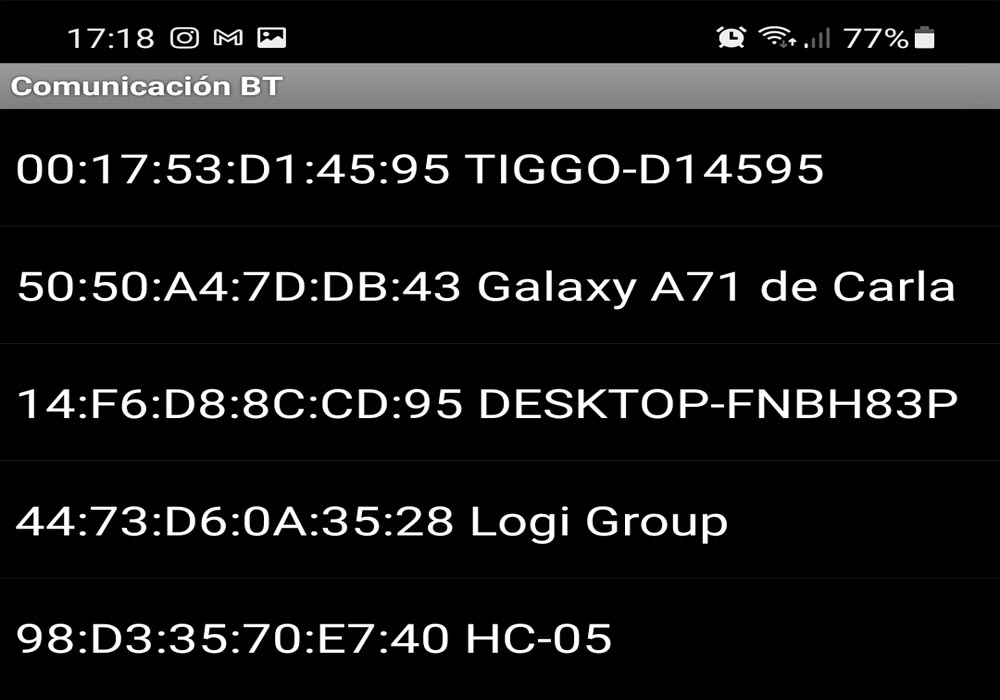

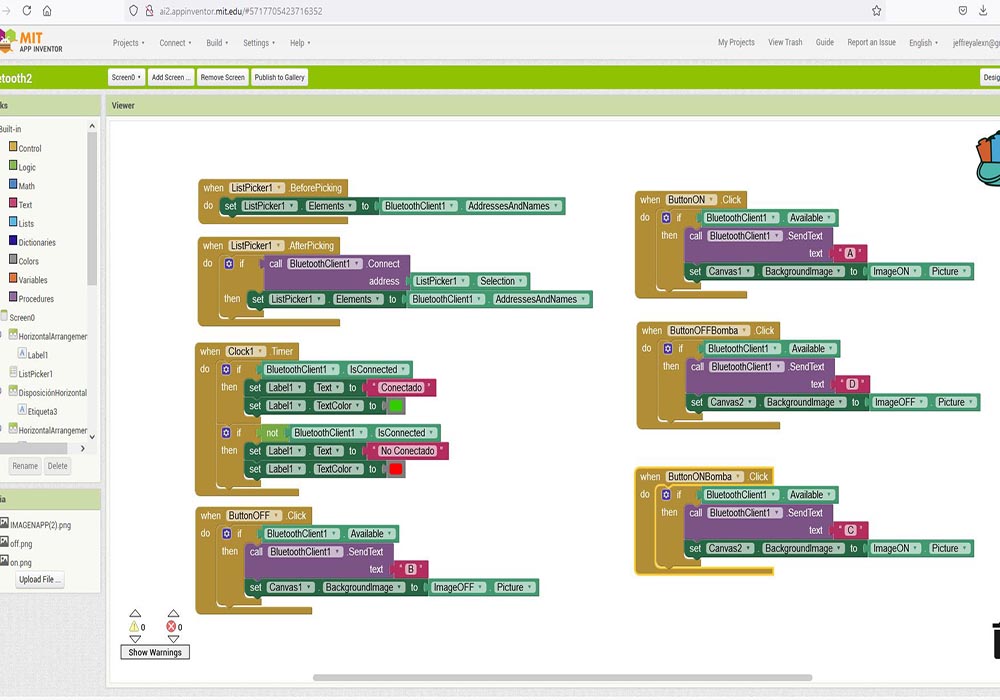

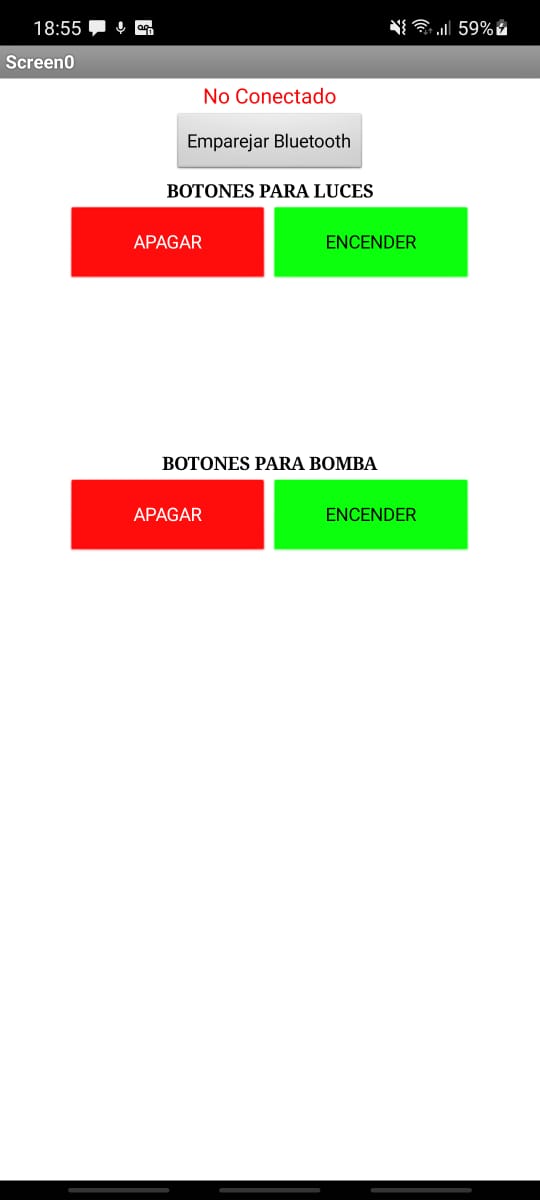

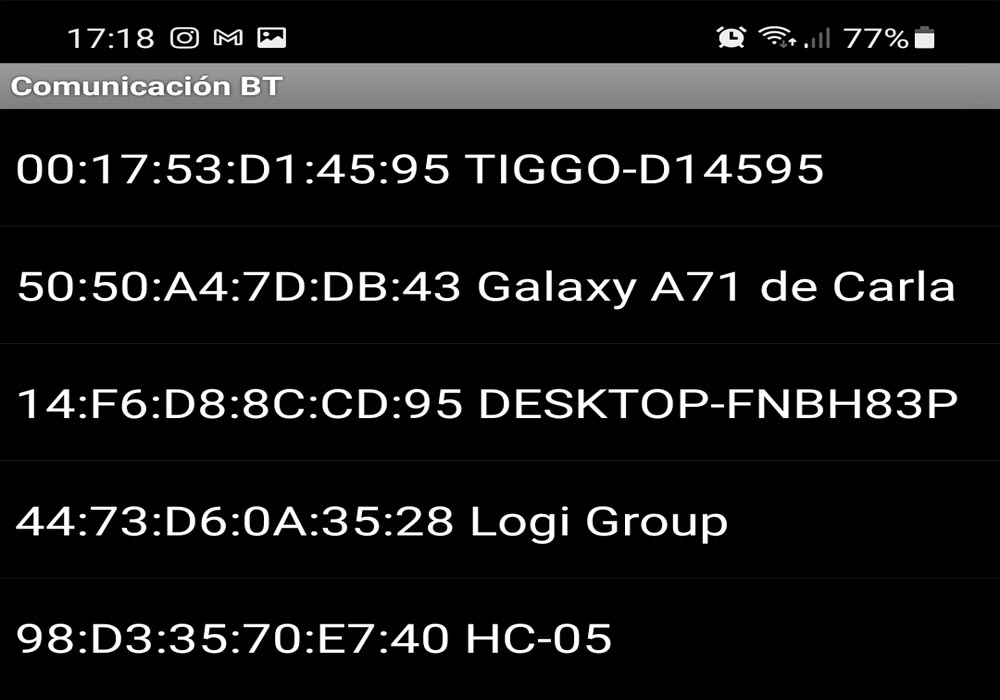

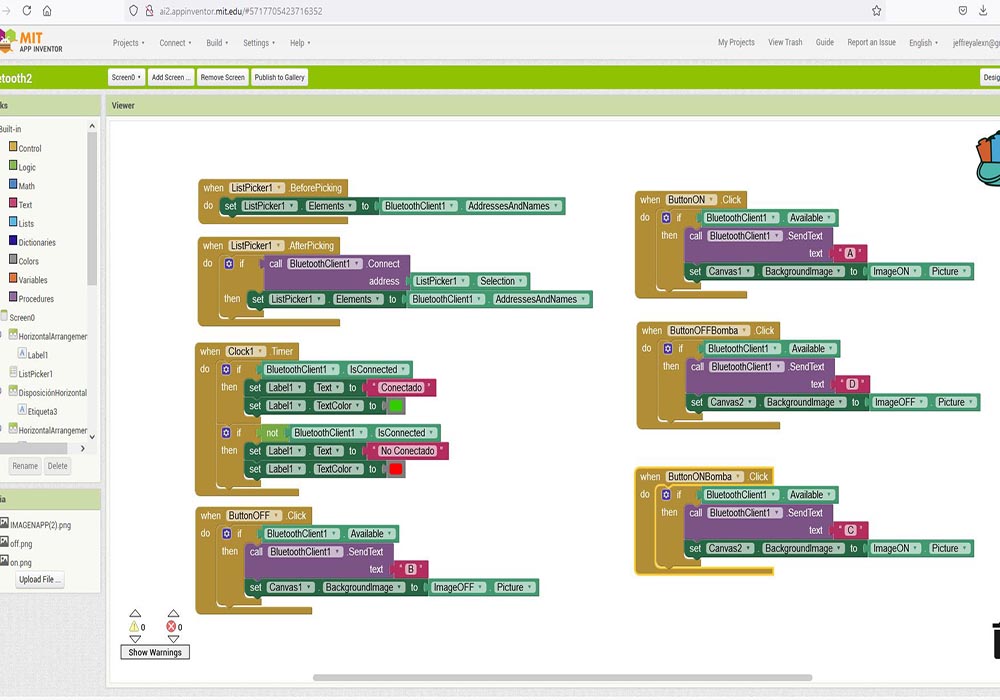

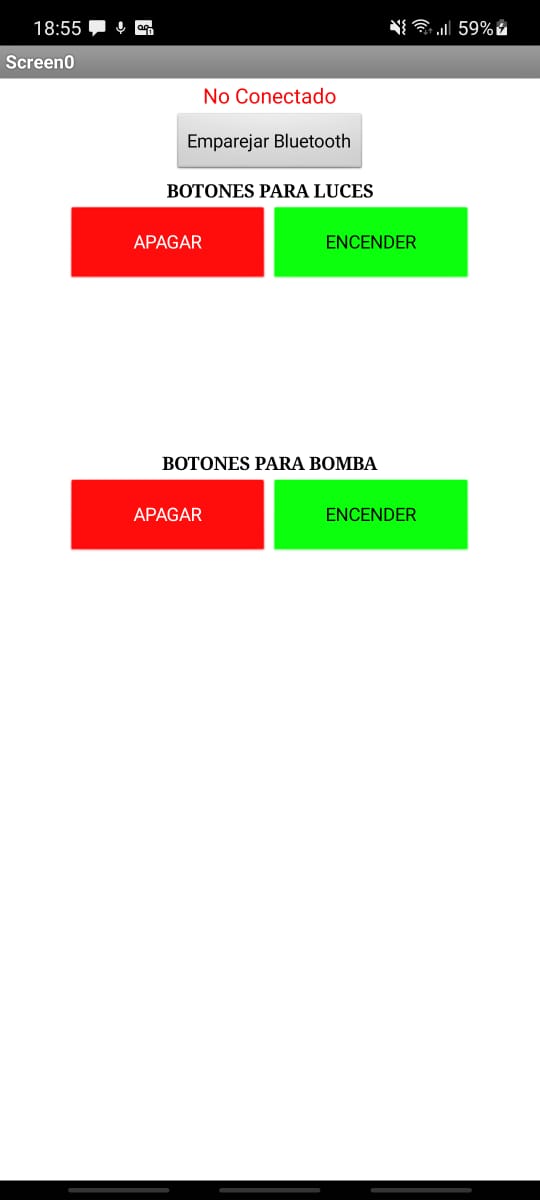

Development of the mobile application with the app inventor

For remote control of the bus stop, turn on the lights, activate the water pump if manual activation is required,

a mobile application was developed that connects to the bus stop via bluetooth. we can see its operation in the following link

Final Project

For the development of the mobile app, the inventor app was used, you can see more in detail in the Interface and Application

Programming assignment, the application consists of two screens, one welcome with the logo of the final project and another

that allows us to connect via bluetooth to the bus stop, where we can turn on the lights and the water pump

Networking

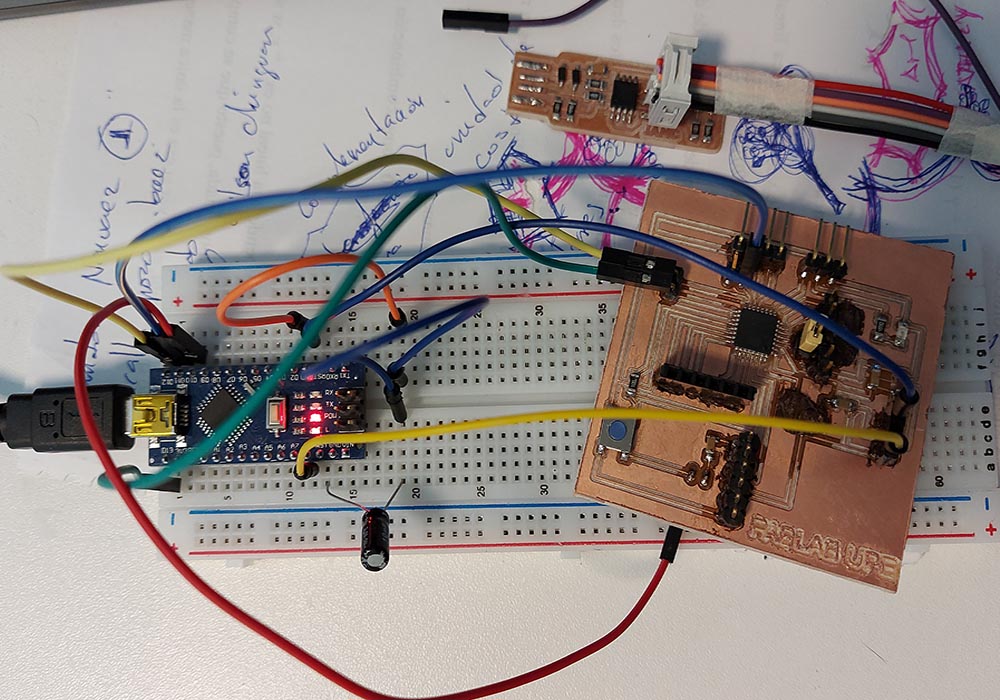

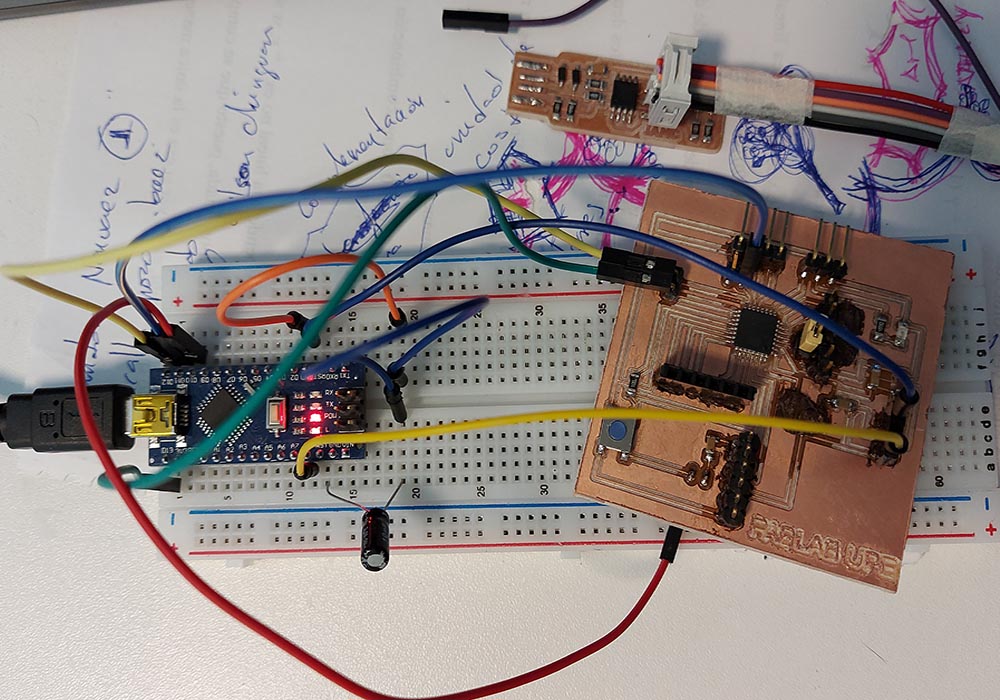

The communication between the app and the bus stop is carried out by means of a bluetooth module

that is controlled by the master board of the project with the Atmega 328p controller.

To see more in detail how to do this, I invite you to see the networking assignment in the following link

Networking

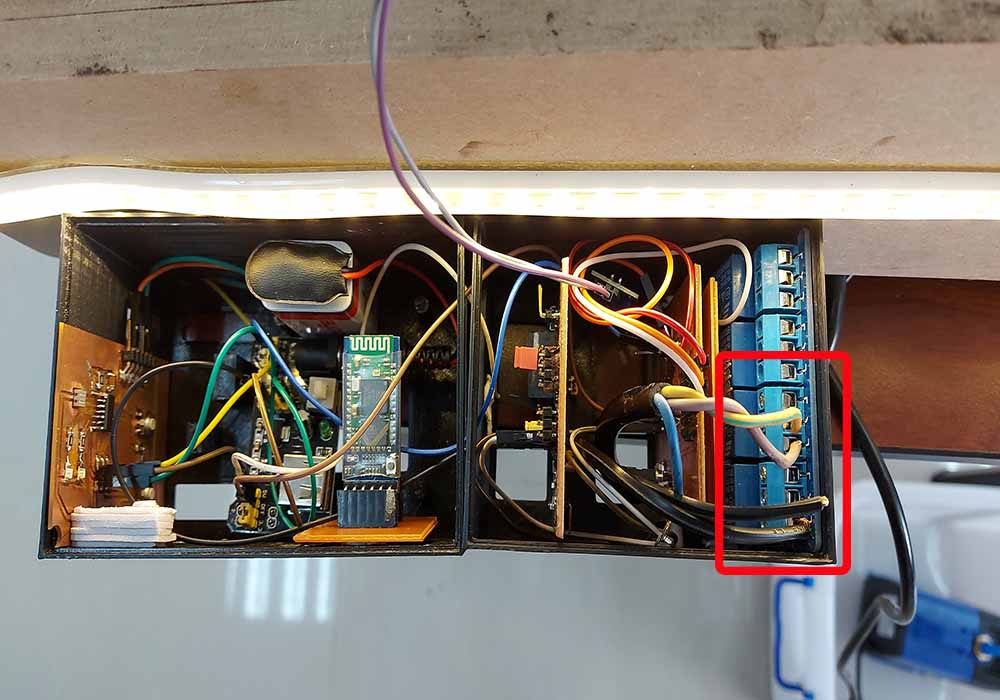

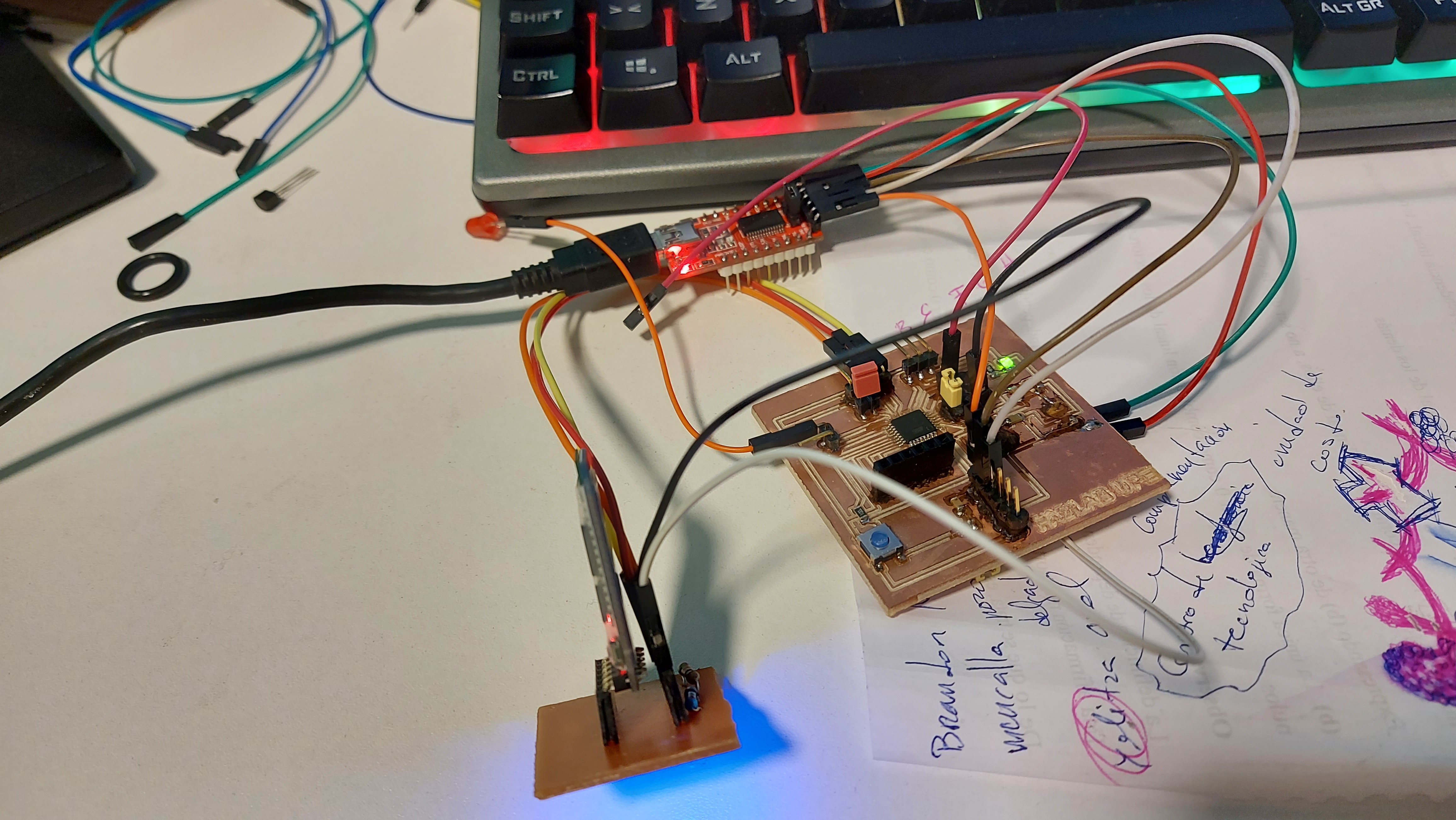

Integration of all electronic pcb boards, power supply, ftdi module, bluetooth module, relays.

Finally we integrate all the electronics inside the boxes manufactured in 3d printers

The files can be downloaded from the following link,

circuit integration boxes

planting the bus stop roof

Putting it all together

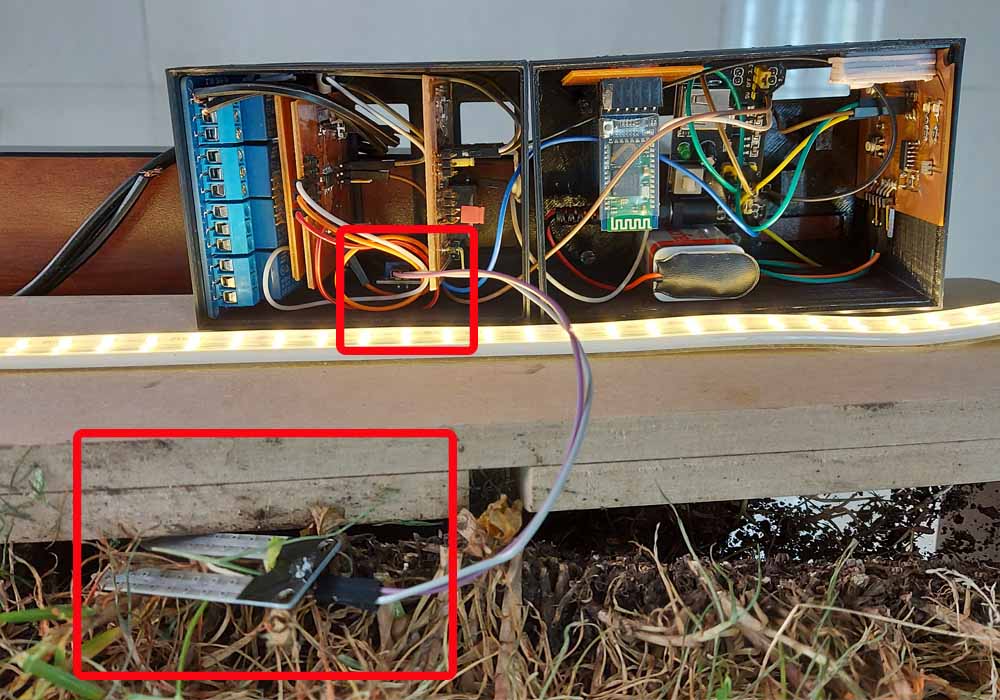

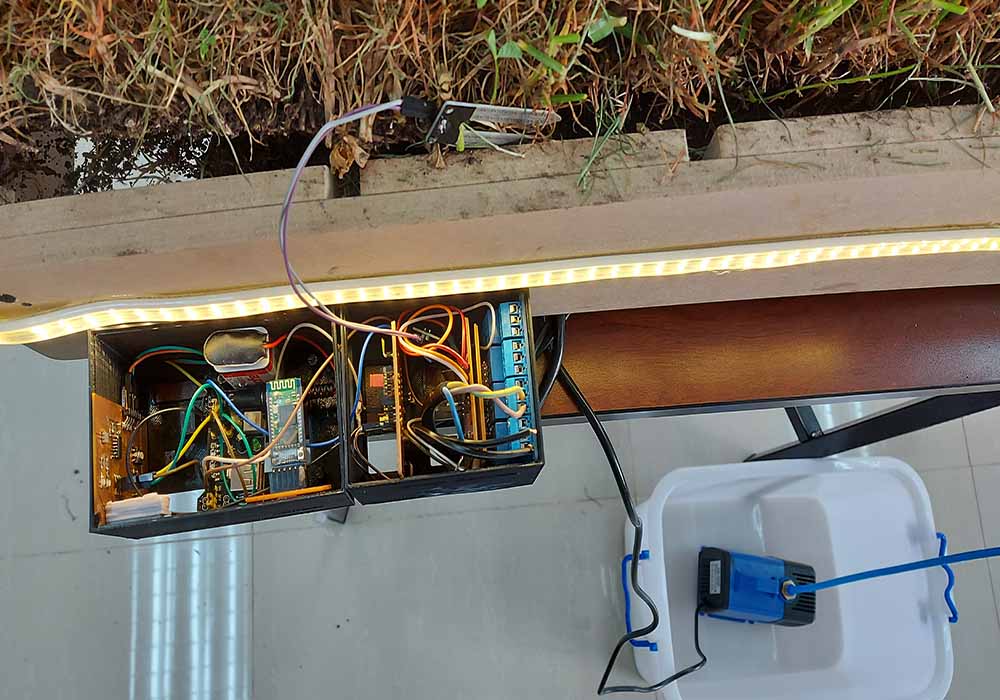

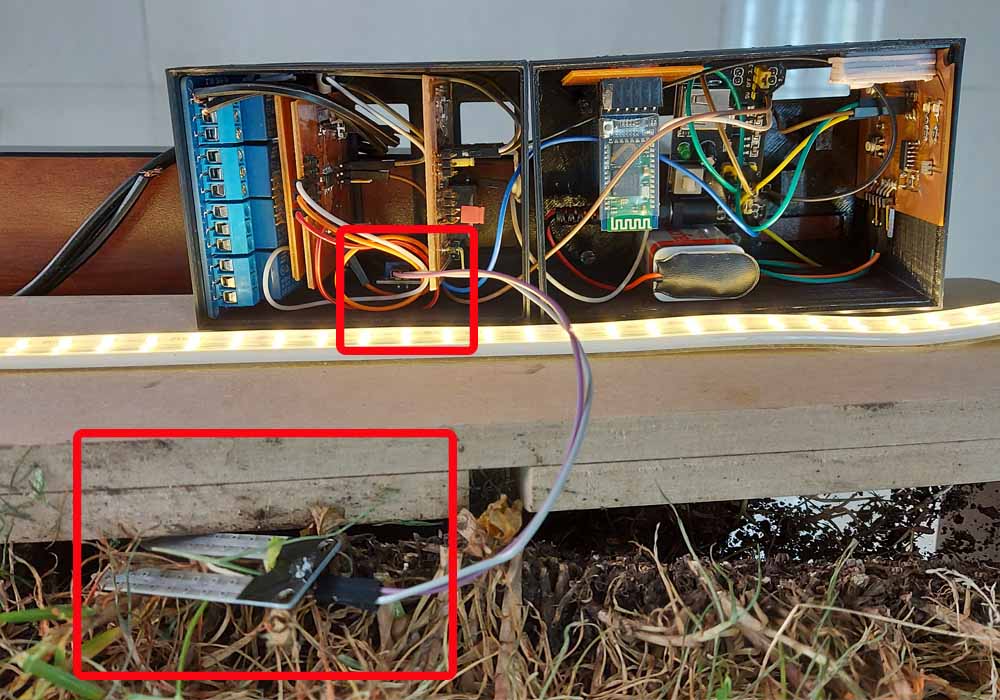

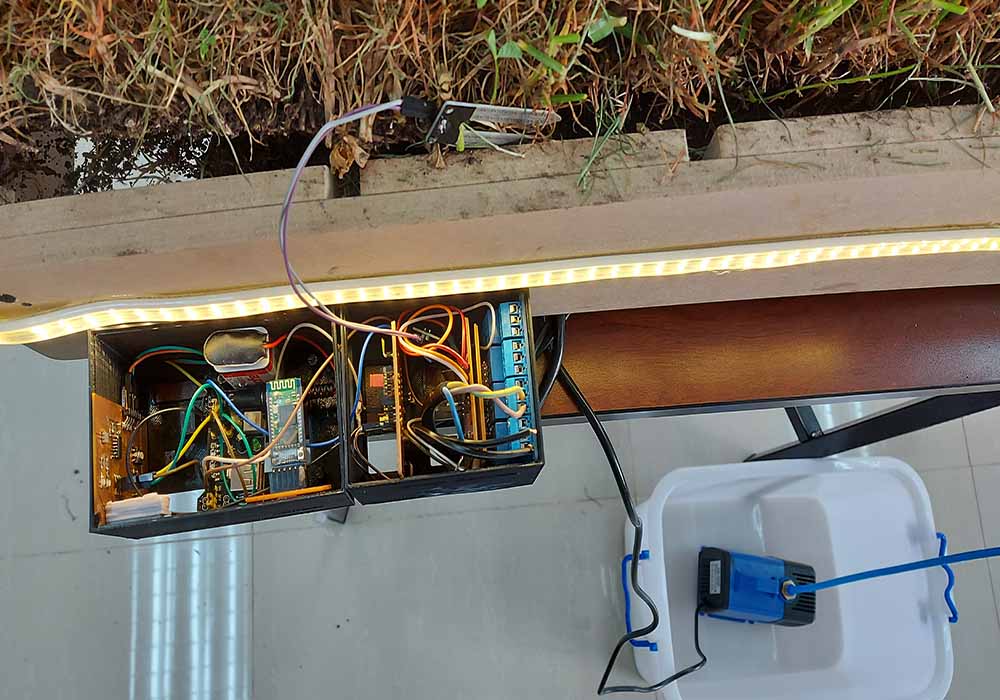

First of all, we place the motion sensor at the bottom of the bus stop to detect the movement of people.

The boxes for the integration of all the electronics will go to one side of the model, near the sensor and

the main light socket, to be able to connect everything when being close to each other.

Here we can see how everything is integrated into the boxes that were printed in 3D, here the relays

were integrated, and a 9-volt battery as a power source

Below we can see the connection of the humidity sensor and the wiring of the motion sensor

Below we can see the connection of the humidity sensor and the connection of the water pump, as well as the connection of the relays

We can see in more detail the handling of the pump in the week of Output Devices, how the water pump is programmed and controlled

Being a too large bus stop to assemble it in its entirety, it was decided to manufacture a model of the roof on a smaller scale,

which integrates all the electronics, sensors and others. But a complete model of the bus stop was also manufactured to be able

to see the whole project, the small model has a motion sensor and an Attiny44 controller along with the led strip, in general

the small model is not functional, only the part of the lighting of the lus led is done with a movement sensor

Roof structure of the bus stop download files

Final list of downloads of my final project

Roof structure of the bus stop download file

Boxes for the integration of pcb boards download file

Mobile application to control the bus stop remotely download file

slave pcb board download file

master pcb board download file

bluetooth pcb board download file

Motor module download file

PCB board programming

Bluetooth controller download file

App App file

Move sensor download file

Water pump control download file

Schematic design final project

what tasks have been completed, and what tasks remain?

Initially, the bus stop was thought of as a tourist point that has information about the city and that allows users to connect to

the internet and be powered by solar cells, depending on how the project was progressing, I had to give up these ideas for Lack of

materials, such as a touch screen and a solar panel, the city where I live is small and due to a pandemic it was difficult to

ask for it from another city.

The humidity and movement sensors were implemented to ensure that the shutdown is sustainable at night and does not consume

energy if no one uses it, and through the humidity sensors take care of the roof plants

You can also control these elements through an application that allows you to connect the bus stop to the cell phone via bluetooth

what's working? what's not?

The motion sensor, humidity, the connection via bluetooth, the control through the attiny 44 slave boards and the Atmega328p master

are working, make

the bus stop light independent so that it turns on by movement and through the app it was no longer achieved the relay burned out

what questions need to be resolved?

how to integrate motion and humidity sensors and mobile application?

How to manufacture the structural elements, so that they are resistant to the environment, in the laboratory?

What is the right size for the city?

what will happen when?

I will complete all the electrical connections, integration of the controllers in their respective boxes, placement of the sensors and water pump, all this

to be ready for the presentation of the final Project on June 9

what have you learned?

What have I learned? Well, a lot, the best for me, the manufacture of the electronic pcb boards, the programming of the

controllers, this will have a lot of possibilities in the manufacture of new machines, for example now I started a project

with a student for the manufacture of an incubator of chicken and quail eggs that is managed through a mobile app, and that

has a knowledge database, to increase the efficiency in the hatching of eggs and raise productivity, this will help the

local economy a lot, and I cannot forget the design tools. I use the cnc that will be very useful for the management of

the laboratory that I implement in the university