Week 18

Project Management

Week 18 assignment is to Complete My final project and tracking my progress. Here i will be answering :

what tasks have been completed, and what tasks remain?

What has worked? what hasn’t?

What questions need to be resolved?

What will happen when?

What have you learned?

Project Management

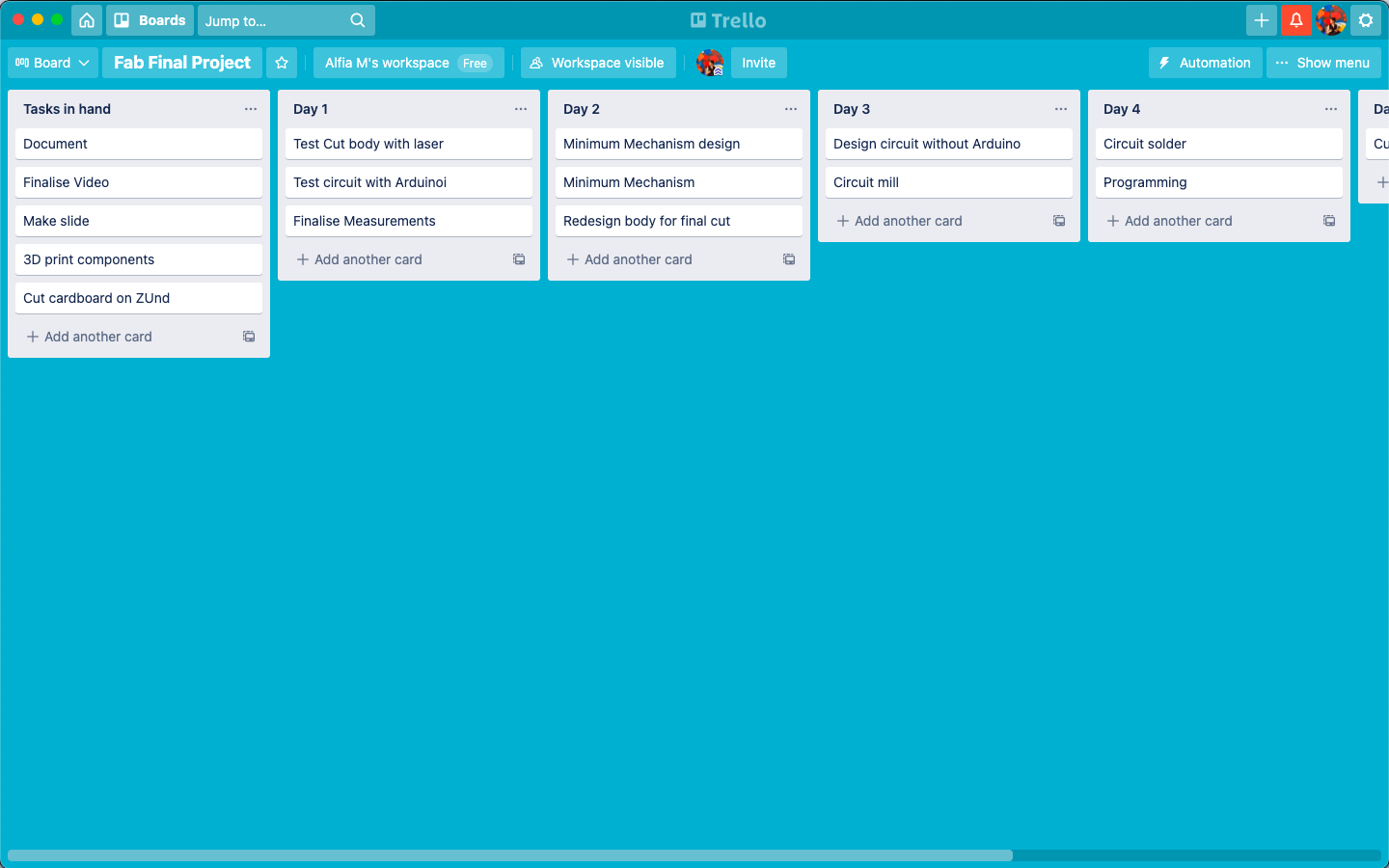

I had earlier decided to start with my final project works and do it with a schedule. I am using Trello to manage my project and tasks in hand.

Trello is a web-based, Kanban-style, list-making application and is a subsidiary of Atlassian. Originally created by Fog Creek Software in 2011, it was spun out to form the basis of a separate company in 2014 and later sold to Atlassian in January 2017. The company is based in New York City.

In trello I listed down each of my tasks and assigned a time deadline for each task. I moved the tasks to done, when i finished it. This helped me keep track of every task that I had to do.

What tasks have been completed, and what tasks remain?

So far, some of my tasks including design, electronics design, etc were completed. At this point, I was left with a bunch of other tasks including fabrication of the designed components using various methods, fabrication of electronics, assembling of parts, documentation, testing, etc.

I planned my tasks for the days ahead and charted my work for every day. I decided to start doing test cuts for fabrication using laser, and finalize measurements for the lid cut. The next task for the same day was to test my circuit and code with arduino, before fabricating the board.

For the next day, I planned to test the minimum mechanical design and redesign the body to cut of necessary. The next days were planned to fabricate the circuit and finish the programming and do the documentation, etc.

What has worked? What hasn’t?

So far, I encountered two major issues with my design. The first was an issue with the opening hinge of the lid. The issue here was that the distance between each cut of the design of the lid was to be placed perfectly, as the lid would stay lower than the rim if the distance was too less, and wouldn't open easily of the distance was too far apart. I did a bunch of test cuts to fix this issue and then found the right distance. More about this has been explained in the final project documentation.

The next issue was with the circuit. The circuit was not managing the power at first and burnt my ultrasonic sensor at first. This was because the circuit got short and power for the motor was passing on to the ultrasonic sensor. I figured this out and planning to re-mill the circuit and solder it carefully to fix this problem.

What questions need to be resolved?

At this point, I have a few issues to be resolved. This include:

1. Figuring out what all i should add to the project as part of spiral Development.

2. How to fabricate hexagonal bin as the surface is not enough for gluing and we see if i can use acrylic bending.

3. Find a cost efficient manufacturing method for the future.

What will happen when?

I have charted out what would happen when with the help of trello for me to track things properly. I decided to start doing test cuts for fabrication using laser, and finalize measurements for the lid cut. The next task for the same day was to test my circuit and code with arduino, before fabricating the board.

For the next day, I planned to test the minimum mechanical design and redesign the body to cut of necessary. The next days were planned to fabricate the circuit and finish the programming and do the documentation, etc.

Once I finish that, I am planning to do the tests, and then make the working video of the project showing the working of the project.

What have you learned?

The whole process so far has been enlightening for me. I learned more than I was taught while i was facing problems with my project. Some of the key highlights of what I learned includes the following :

-How to manage a project including everything

-How to troubleshoot issues with circuits

-How to use different types of hinges and cuts for making lids

-Different types of adhesives and uses

-How to work with blynk

-How to test and charge batteries, and a lot more

Dissemination Plan

Market Opportunities

The product can be made available in offices, schools, colleges and any buildings. The current products in the market does not incorporate all the features together while there are other features like automatic garbage disposal bag changing etc. Considering small spaces like individual office cabins and classrooms, such facilities are not required. So with all the required features, the trashcan would also be a good design upgrade to rooms. Mass production will further reduce the cost of individual trashcan making smart facilities available for affordable prices.

Future plans for the project include

-Controlling trashcan using virtual assistants like Google Assistant, Alexa, etc

-Screen display of filled trashcans in the janitor's room

-Test product in public places and check practicality

Licensing My Project

I decided to license it under the creative commons as it seemed perfect for my work. This licenses indicates that others can share and adapt my final project as long as they give appropriate credit and indicate if changes were made. And when they shape or adapt my work they should distribute my contributions under the same license. In addition, they may not use the material of my final project for commercial purposes. You can also easily create license by going to Creative Commons.

The license for my final project is shown below.

HEX+ by Alfia M is licensed under Attribution-NonCommercial 4.0 International